The principle of operation of the pellet device

As a rule, a standard pellet-type burner is sold by manufacturers already equipped with additional devices:

- screw device for fuel supply;

- controller for automatic regulation of the functioning process;

- bunker box for fuel;

- lambda probe that measures the residual amount of oxygen and automatically regulates combustion.

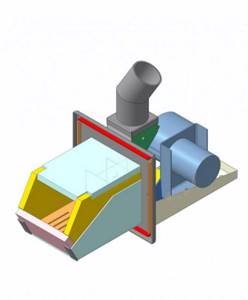

Construction of a pellet boiler

In the area from the burner to the auger, a plastic corrugation is sometimes installed, which allows, when a reverse draft is formed, to prevent the spread of fire.

The main elements of a pellet burner also include:

- an air supply fan located at the bottom of the device or behind the burner and controlled by a special controller;

- thermoelectric heating element involved in automatic ignition of pellets.

The fuel supply is carried out through an electrically driven auger, and is also checked by a controller with temperature sensors and indicators that reflect the operation of the pellet burner.

The control scheme for the temperature regime of the coolant in the heating system is very simple.

When certain temperature values are reached, the burner is switched by the controller to the “standby” mode with prolonged smoldering of the fuel. After the coolant cools to the required level, the sensor sends a signal to turn on the burner fan, which causes the pellets to ignite and transfer the equipment to standard operating mode. A heating element can be used for ignition.

The performance of a pellet burner depends on the rate of fuel supply to the firebox and its quantity, therefore only proper adjustment of these parameters helps ensure optimal operating efficiency of the equipment.

Installing a gas burner in a solid fuel boiler

To make a kind of modification, as I call this process, it is necessary to purchase equipment and components, and then, in accordance with the instructions, install the auger, hopper and lambda probe into the chimney pipe.

It is equally important to connect the electronics correctly; if there is a fan, it should also be securely fastened and tested before use.

Some boilers are not designed for installation of exhaust burners or other types, so before starting work and directly purchasing one of the models, you should make sure that installation is possible.

To carry out manipulations of this nature, there must often be space in the housing for additional installation; manufacturers specify this point in the passport for a solid fuel boiler, so I advise you to pay attention to this and take care of the documents until the equipment requires replacement.

Making a pellet burner

Pellet installations are often ignored by buyers because of their high cost compared to gas and electric equipment, and the problem is solved by making the device at home.

General diagram for making a pellet burner yourself

The combustion chamber can be constructed from a square or round pipe. It is better to give preference to heat-resistant steel that can withstand elevated temperatures; the wall thickness should be at least 4 mm.

The home-made installation is fastened to the boiler using a flange plate made of heat-resistant steel with a thickness of 3 mm.

A container for supplying fuel to the combustion chamber can be purchased or made by yourself. The best option is to immediately make an installation in which fuel will be supplied automatically. To do this, place an auger in the purchased pipe of the required diameter. The rotation of the device will be carried out by a bearing, gearbox and motor operating at low speeds.

Additionally, the store can purchase a fan that will pump air. The fan is mounted on a plate, which is made depending on the size and door design of the boiler used in your home.

It is also important to take care of adjusting the amount of incoming fuel and the volume of air pumped by the fan, otherwise the homemade device will work unstably. In home devices, the air supply force and the number of pellets are adjusted manually

This method is inconvenient because it requires constant supervision of the burner.

For automation, an electrical incandescent element and a photosensor are purchased. The first device ignites the flame if the pellets go out and also regulates the switching on of the device. The photo sensor monitors the appearance of the flame: if the flame is stable, the sensor transmits a signal to the glow element to stop ignition.

To automate the system, a filling sensor is also purchased. It will notify the electronics of the device about the degree of filling of the combustion chamber with pellets.

Pellet burners are modern equipment for boilers, which can improve the environmental friendliness of the process and reduce fuel costs. At the same time, the equipment in the store itself is expensive. For basic household needs, it is better to give preference to homemade devices, the operation of which can be automated if necessary.

Advantages and disadvantages

The equipment has a number of advantages:

- Pellets are a safe fuel compared to gas and electricity;

- Allows you to significantly reduce space heating costs compared to using electric boilers. At the same time, pellet installations are more expensive than gas equipment, but do not forget that it is not always possible to supply gas and purchase gas cylinders;

- Homemade installations guarantee high efficiency - 95%. Some store installations are over 97%;

- They are used not only for heating the room, but also for producing hot water;

- There are no rules for transporting and storing fuel. When near a person, pellets do not cause allergic reactions, and there are no toxic fumes when burning;

- Fuel is available for purchase. Equipment owners complained about the lack of fuel and the need to prepare a supply of pellets from the winter when the devices appeared; now there is no need to store a large volume of pellets at home; if necessary, they can be bought everywhere;

- The price of pellets is on average at the same level, unlike gas and electricity, the tariffs for which periodically experience seasonal fluctuations;

- Installation of the device does not require special skills, and there is no need to coordinate the installation with authorized bodies;

- After combustion of pellets, natural mineral ash is formed, which does not require special rules for disposal.

Along with the advantages of such equipment, there are also a number of disadvantages:

- High cost of ready-made store equipment. Despite the popularization of devices in recent years and some reduction in prices, pellet boilers are still more expensive than gas or electric equipment of similar power;

- The equipment requires constant maintenance (especially outdated models). The user will have to clean the ash pan and heat exchanger from accumulated ash once a week. In modern models, cleaning is provided at an automatic level;

- In the absence of automatic fuel supply, the user has to load pellets into the bunker manually;

- It is necessary to ensure minimum humidity conditions in the rooms in which pellets will be stored awaiting use;

- Imported equipment is practically not designed for the conditions of the harsh domestic winter, as a result of which breakdowns and malfunctions often occur;

- In remote areas, fuel for the winter still has to be stored due to the instability of supplies.

Operating principle, design

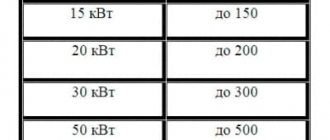

Pellets are granulated, compressed products from the forest industry. Pellet devices are one of the types of solid fuel boilers. Depending on the power of the model, the area that the boiler can serve is determined.

There are three types of boilers:

- Powered only by pellets.

- Having alternative backup fuels: firewood and briquettes (provide additional work for several hours).

- A combined boiler with several combustion chambers, the same performance of the boiler on several types of fuel.

The pellet boiler is made of stainless thick-walled steel. The pellet boiler structure includes:

- boiler with burner;

- conveyor feeding granules into the chamber;

- a bunker where fuel is stored.

The operating principle of the equipment is consistent. Initially, pellets are poured into a bunker, from there they are poured into the furnace using a screw conveyor, where they burn. The gases released during combustion undergo several combustion stages (two or three) in different chambers, which ensures the complete exhaustion of the granules' lifespan. Heating appliances using pellets have a very high efficiency rate - up to 98%.

The heat exchanger, which is made of steel or cast iron, is equipped with an automatic electronic control system. The temperature of the coolant is regulated by supplying a certain amount of fuel for combustion. Program the supply of pellets with clear settings. You can pre-set the function of switching the combustion mode from one type of fuel to another. If the main type runs out, the device automatically ignites firewood prepared in a separate firebox or runs on coal.

Pellet heating boilers for home use are very easy to maintain. The main point is the level of granules in the hopper. One load can last for several days (2-14), it all depends on the volume of the bunker. It is necessary to regularly clean the ash pan from ash.

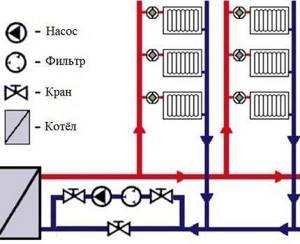

Possible options for fluid movement

There are many schemes. But all methods can be divided into two main groups depending on the principle of movement of the coolant through the pipes. Therefore, a specific scheme is selected depending on whether natural or forced pumping is used in the system.

Features of natural circulation

The simplest and most inexpensive solution is piping the boiler, where the coolant will move through the pipes using the laws of physics. Even a beginner can implement such a scheme, and it will take a minimum of time.

The peculiarity of a heating system with natural circulation is the absence of a pump. In this case, the movement of liquid in the pipeline occurs due to the ability of a colder medium to push out a hotter and less dense one.

When organizing a heating system without a pump, the radiators should be located higher than the boiler. At the same time, the number of bends and turns of pipes must be minimized (+)

The advantages of this solution include:

- low installation cost;

- low cost of service;

- ease of installation;

- the ability to quickly restore system operation if a breakdown is detected.

But the scheme with natural fluid movement also has its drawbacks. First of all, it can only be used with a single-circuit system. In addition, such a solution will be effective only in small houses.

Forced circulation option

The greatest demand is for heating systems that use a circulation pump. And this is not at all surprising, because such a scheme is convenient, versatile and practical. It can be used in houses and buildings of absolutely any size.

But even despite the unique advantages, schemes with forced coolant circulation have some significant disadvantages:

- high cost of installation - the average cost of a pump is about 150-160 dollars;

- complexity of implementation - the circuit consists of a large number of elements, which significantly complicates its implementation;

- the need for balancing - all components of the home heating system must be precisely aligned with each other;

- dependence on the availability of electricity - the heating pump will only work if current is supplied to it.

When organizing a heating system for a building with two or more circuits, it is recommended to use the option with forced movement of the coolant.

The heating system with forced liquid pumping operates thanks to a circulation pump. Therefore, it is better to give preference to reliable devices from trusted manufacturers

However, in this case, the fundamental performance factor is the power of the heating boiler. Please note that if it is not enough, the equipment will not be able to heat a sufficient amount of coolant.

Design and principle of operation of a pellet burner

The functions of the pellet burner device are to create conditions in the combustion space for uniform and complete combustion of pellets, to create the required percentage of the fuel-air mixture and a stable flame combustion mode, to generate and transfer thermal energy to the water coolant circulating along the internal section of the boiler heating surfaces.

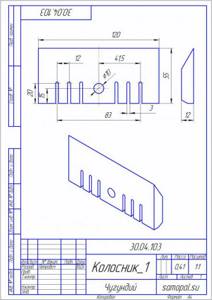

Basic components to make a pellet burner yourself:

- combustion chamber for burning fuel, made of heat-resistant pipes of rectangular or round cross-section;

- pellet burner grate;

- fuel bunker for loading pellets;

- screw-type fuel conveyor for moving pellets;

- a blower fan for pellet burners, which supplies oxygen to the combustion zone.

The operation process of household and industrial pellet burners can be fully automated. When installing a large fuel bunker, autonomous operation of the equipment without the presence of an operator for more than 7 days is allowed.

For such boilers, universal devices are selected, for example, the Pelltechpv 20b pellet burner with a price of 96,083 rubles, which can be installed not only in a pellet boiler, but also in a diesel and any solid fuel unit.

Pellet burners for boilers have a simple operating principle; it consists of several stages:

- When you turn on the boiler start button, the blower fan is turned on and at the same time the screw conveyor, which supplies pellets from the hopper to the combustion chamber.

- The control controller gives a signal to the electric heating element to ignite the pellets.

- When the temperature of the heating water in the heating circuit reaches the set value, the temperature sensor sends an electrical signal to the electronic control unit to transfer the boiler to the hot standby state.

- When the temperature in the heating circuit drops below the set level, the temperature sensor transmits a signal to the control unit to start the boiler, first the fan is turned on, then the screw conveyor with fuel and the ignition device.

Gravity burners

The gravity pellet burner has the simplest method of operation. It is non-volatile and can work even without electrical energy. The movement of pellets in it is carried out directly from the bunker in bulk, directly into the pyrolysis chamber.

The air supply and removal of exhaust flue gases occurs due to natural draft in the smoke duct of the boiler unit, created by the chimney.

Adjustment of the combustion mode and air supply is carried out manually using an air damper on the burner device and a damper on the chimney.

This mode provides low efficiency and practically cannot be automated, so it is practically not used in modern pellet boiler devices.

Kinds

flare

Such burners for solid fuel boilers are typical mainly for Russian products. The fire rushes to the side plane. The pellets are supplied via a horizontal auger or using a vacuum tube. Draft into the boiler must be provided by force. The air pressure created by the fan is fully consistent with the needs of heating equipment; depending on the vortices that form, combustion occurs more or less stably.

Flare burners provide excellent process efficiency. You can put almost any fuel inside. In addition to pellets of various types, it is possible to use even ordinary dry wood chips that are suitable in size. The device uses the supercharging effect. Smooth adjustment is ensured by a direct connection between the fan and the automatic control system.

Principle of operation

All pellet installations that can be purchased in the store are equipped with additional components:

- Auger – supplies fuel from the bunker to the combustion chamber;

- Controllers for automating the work process;

- Bunker – the place where the fuel is located before being supplied to the combustion chamber;

- A lambda probe is a special sensor that monitors the oxygen content in smoke chambers and independently controls the fuel combustion process depending on conditions.

The pellet burner must be protected with a plastic corrugated pipe. It acts as a fuse when reverse draft occurs. If the fire begins to move towards the bunker, the pipe burns out, preventing the flame from spreading.

Additionally, a fan is used, which enhances the combustion of pellets by pumping air, as well as a thermoelectric heater, which allows the fuel to be ignited without human intervention.

In automated devices, pellets are fed into the combustion chamber automatically; a person is only required to monitor the amount of fuel in the bunker. The need to supply fuel to the combustion chamber is determined using temperature sensors (they can monitor the air temperature in the room, the water temperature, or any other environmental indicators depending on the operating mode of the equipment).

The required temperature of the coolant is set by the user, all further increases and decreases are controlled using automated equipment. As soon as the temperature reaches the set level, the burner begins to operate in standby mode (the pellets do not go out, they begin to smolder). If the temperature, on the contrary, drops, the controller activates the built-in fan. Under the influence of air, the pellets flare up and the burner goes into operating mode. If during downtime the pellets go out for any reason, the heating element is activated, which re-ignites.

Kinds

flare

Such burners for solid fuel boilers are typical mainly for Russian products. The fire rushes to the side plane. The pellets are supplied via a horizontal auger or using a vacuum tube. Draft into the boiler must be provided by force. The air pressure created by the fan is fully consistent with the needs of heating equipment; depending on the vortices that form, combustion occurs more or less stably.

Flare burners provide excellent process efficiency. You can put almost any fuel inside. In addition to pellets of various types, it is possible to use even ordinary dry wood chips that are suitable in size. The device uses the supercharging effect. Smooth adjustment is ensured by a direct connection between the fan and the automatic control system.

Forced fuel systems

It is the method of fuel supply that determines the fire safety of a boiler with a pellet burner. In general, pellets can be fed into the burner by force or by gravity, when they themselves pour out of the hopper. The safest method is forced. However, this is exactly the case when you have to pay for safety and convenience: forced-feed burners are the ones that cost from $3000.

Pellet boilers with forced fuel supply and burners for them

Forced pellets to the boiler from the bunker can be pneumatic lift (item 1 in the figure and auger (item 2 and see below). What they have in common is that there is an ascending branch in the fuel supply path. If the fire comes out of the burner, then it to get into the bunker, you will need to go down, which is unlikely. Pneumatic supply completely eliminates combustion leakage into the bunker, since there is no solid mass of pellets in the fuel line, and the air blows towards the possible path of fire, so boilers with pneumatic supply can be powered from open bunker, which is loaded once a month. However, in both cases, a cup burner is needed (volumetric, see below) with a screw feed of pellets from the feeder, positions 3 and 4; it is technically complex, and its cost is at least 1/ 3 of the entire boiler power system.

Auger feed systems use 2 separate mechanical units (left and center in the figure): a pick-up auger lifts the pellet from the hopper. The fuel then falls into the feeder (receiving hopper) of the burner, where another auger pushes the fuel into the combustion zone. Oddly enough, combustion leakage into the bunker is not completely ruled out, because In the ascending branch of the fuel line, the pellets lie in a solid mass, so the descending section of the fuel pipeline is made of fusible (but not flammable!) or heat-shrinkable material. If the feeder catches fire, it will melt or break off and interrupt the path of the fire. The system with free fall of pellets into the feeder (on the right) is used less frequently due to lower fire safety, but it can be used to power gravity burners, see below.

A serious drawback of systems with forced supply of pellets is their energy dependence: you need to turn 2 electric motors. But then it makes sense to use the burner with forced pressurization, this increases the efficiency of the boiler by 3-7 percentage points, and connect the control automation, see below. In cold countries that heat themselves with imported fuel or their own waste, savings on heating for the season in this case can amount to an amount that pays for the cost of a burner with a boiler.

Burners in forced-feed systems use volumetric screws, i.e. The pellets in them are also forcibly squeezed into the pyrolysis chamber, and the pyrolysis gases are burned in the boiler furnace. Burners with a flame bowl (item 1 in the figure) are gradually falling out of use: if the automation fails (see below), the fuel in the bowl cokes, which means an extraordinary cleaning or repair of the boiler, and the penetration of fire into the feeder is not such a rare occurrence in models from the best manufacturers. When using standard fuel (recommended by the manufacturer), you need to clean the burner with the bowl from any remaining ash once a week.

Methods for supplying fuel from the feeder to the pellet burner

Burners with secondary air supply to the afterburner (item 2) or with a retort that forms primary and secondary flows directly in the bowl (item 3) are free from most of these disadvantages. A burner with an afterburner almost never cokes, but it still needs to be cleaned manually once a week, while a burner with a retort needs cleaning monthly, and only then based on the results of an inspection.

About automation

Burners of systems with forced supply of pellets are not examples for beginners to repeat, not only because of the complex mechanics. All its advantages, incl. safety, they show only under the control of a microprocessor operating from a whole set of sensors:

- In the chimney - it gives not only the presence, but also the amount of draft.

- In the firebox – shows the flame temperature.

- In a heating system, it gives the return temperature.

- In the burner, in the combustion zone - shows the presence and level of fuel.

- Same thing in the feeder.

- Same thing in the bunker.

The microprocessor, guided by data from the sensors, regulates the supply of both fuel and air according to a program specified by the user from the remote control, for example. “Winter”, “Spring/Autumn”, “Lower level of comfort”, “House is empty”, etc. It is the simultaneous coordinated regulation of air and fuel supply that ensures the highest possible efficiency of the boiler using any available pellets; this is a serious advantage of systems with forced supply.

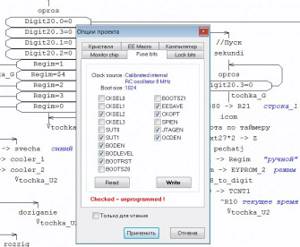

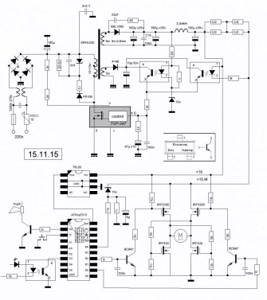

Burner control controller.

The Petropeleta controller (CP) is assembled on an Atmega-16 processor. The liquid crystal module MT-20S4M produced by the Russian company MELT was used as an indicator. You can use any other similar LCD indicator, but the format must be 20 characters 4 lines.

The controller is powered by a separate 12 volt 1 ampere adapter. Control is carried out by four buttons. Burner power control

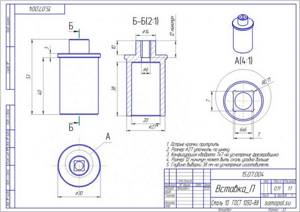

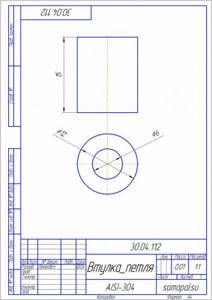

Pellet feeding, continued.

The pellets are supplied by a screw mechanism. I bought the auger at . We had to drive 250 km, but it was worth it. The auger, a spiral, is made of carbon steel, actually a spring. With an outer diameter of 44.3 mm, it slides well in a sanitary sewer pipe with a diameter of 50 mm. They sell pieces no smaller than 1 meter, the actual length of a piece is 1.1 meters, i.e. with reserve.

On one side, the screw is put on Insert_P and fixed by TIG welding at one point. On the other hand, the auger is not fixed and rotates freely in a plumbing plastic pipe, which is inserted into a 57x3.5 seamless metal pipe.

Feeder electronics.

The power supply unit is designed rather heavily, but there is no need to make the gearbox protection even more complex and more expensive mechanically. The power supply “produces” a voltage of 15 Volts at a current of up to 6 Amperes. When the current exceeds, the power supply goes into current mode and the voltage gradually drops. Short, no problem. But there will be no short term, because... when the voltage drops below 9 volts, a logical zero will appear at pinB.4 of the processor. The processor will give a short “reverse” to the engine. After this, it will restore direct rotation. And so 5 times. If after five attempts the gearbox is not unlocked, the power supply will sound a beep. A speaker with a generator is used for sound. The 2313 processor performs PWM modulation for smooth engine starting and reverse. The operating current of the motor increases to a maximum of approximately 0.5 seconds. To debug the mechanism, and simply for different situations, you can turn on the feed using the button provided for this.

Here are the files for the power supply. HEX-08 dated 01/05/2016 BP3 board wiring

Using pellets

In areas where there is no centralized gas supply, pellets are the most effective and relatively inexpensive fuel. When 1 kg of pellets is burned, thermal energy is released, which is equal to what will be produced after burning half a liter of diesel fuel. The total output power is 5 kW/h. To heat a one-story house in an area where winters are not too severe, it will take approximately 50 kg of pellets per day. The advantage is that they can be filled once every few days, depending on the boiler model. Pellets are placed in a special hopper, from which they are automatically fed into the burner. You will have to service your homemade pellet burner twice a week.

One of the disadvantages of using pellets and pellet burners is the possibility of backdraft. In this case, fire may break out into the bunker. The consequences of such a process will not be the most pleasant, because it will be a good fire. The second nuance that requires special attention in relation to a pellet burner is the amount and intensity of air supply. Pellets are quite light, so an excessive flow can simply blow them off the device, and they will remain unburnt. With less air supply, the pellets also do not burn completely, which leads to the need to clean the burner. For the entire pellet combustion process to be correct, it must have a certain sequence.

To ignite, you must use a special lighter, which is a ceramic rod. It does not affect the pellets with direct fire, but heats up to a temperature of over a thousand degrees. This approach is necessary so that when igniting pellets, the flame does not go into the fuel bunker. The next step is to supply the required amount of air, which is necessary to ensure that the combustion flame is even and stable. Next comes the exit to operating mode. This occurs due to the larger amount of air supplied to the pellet burner. The important factor here is fire without smoke. The stop occurs due to the complete cessation of air supply to the pellet burner.

This is interesting: Laying heated floors under tiles - system installation technology

How to choose?

From the very beginning, it is worth considering that when choosing pellet burners for a stove or boiler, retort models will have to be considered last.

Their efficiency, even for the best samples, does not exceed 76%. If just one node fails, the system completely loses its functionality. Only when replacing the problematic unit will it start again. The rating of the best samples confidently includes Pelltech PV 20-180. This system uses a standard Euroflange, which allows the device to be installed in pressurized budget boilers or boilers designed for biofuel. Heat-resistant steel is usually used to produce the firebox and grate.

In more advanced models, the combustion chamber is formed from ceramic stones. The tubular design of the firebox and the addition of a screw allows for more efficient combustion. Any Pelltech modification is designed for 7-9 levels of work intensity. Power can be assigned manually or in modulation mode.

Also worth noting:

- presence of pellet level sensors;

- automatic ignition;

- display on the control panel;

- pneumatic or mechanical cleaning circuit;

- storing a “message log” in the automatic device’s memory.

The OXI Ceramik+50 pellet burner is definitely worth mentioning. This device is equipped with movable grate bars with self-cleaning and is installed in any solid fuel boilers. A modulation system is provided. The monoblock design has repeatedly proven itself in practice under the most difficult conditions. The important features of this model are:

- damping function;

- automatic backdraft protection system;

- input for connecting a room thermostat;

- Possibility of connecting heating pumps, smoke exhausters, pumps and thermal sensors of hot water boilers;

- Suitable for boilers up to 70 kW.

The manufacturer indicates that installation should be carried out in the boiler door

It is equally important to note that this model should only be installed by certified personnel. The delivery set includes:

- corrugated pipeline;

- auger 1.5 or 2 m long;

- 2 kOhm temperature sensor (1 for boiler, 1 for feeder);

- technical certificate;

- installation and application manual;

- warranty card.

When choosing systems with a flare burner, it is necessary to take into account the difference between models that go into stop mode after heating the boiler, and those that are designed for modulation, that is, maintaining a given temperature level. Retort systems are mainly suitable for cases where automatic ignition is not very important. In passive mode, they do not go out completely, but begin to smolder.

You should definitely pay attention to the screws. The stability of the entire system depends on the quality of these screw spirals.

Retort burner units are usually equipped with axial screws. They can handle pellets of any length and any sawdust concentration. Axleless types of augers, typical for flare burners, are much more reliable; they create significantly less load on the drive gearboxes.

The pellets in some retort boilers are fed by two augers; other models use a valve. If designers have chosen a single-screw feed, the hopper must be sealed to eliminate the risk of fire. The auger must also be protected from the penetration of foreign objects. Flare structures rarely provide such protection.

Gravity type devices

Gravity-type burners may not depend on electricity. The fuel enters directly into the pyrolysis chamber; pressurization can be provided thanks to the chimney draft. You can put the burner into operation manually, using one damper and a draft regulator in the chimney. But this type of device requires serious maintenance.

Non-volatile manually controlled products are only homemade. Only gravity-driven semi-automatic designs are available for sale, where fuel is supplied by means of a “self-dumper”.

To prevent fire from entering the bunker, you need to install a gateway based on elements that expand when heated, or use a double-grate design. It is movable and periodically moves back, picking up some of the pellets and transferring them to the combustion zone, while at the same time the ash is pushed into the ash pit. But there is a risk that the gap between the grates can quickly become clogged with ash. If the grate gets stuck in the rear position, fire may enter the hopper.

The diagram of a gravity-independent energy-independent burner is as follows:

- Sawdust is poured directly into the pyrolysis chamber in the form of a perforated steel basket. It is removable; a new one needs to be made for each pellet size.

- Tertiary air, which is sucked through special holes, prevents fire from entering the bunker.

- Pyrolysis of sawdust in the basket is carried out using primary air.

- In its secondary form, it enters the chamber together with gases, where combustion takes place.

- A torch of gases comes out of it.

Some factory-type burners can also be manufactured according to this design. But, unlike homemade products, they will still depend on electricity, since they have built-in automation.

Automation methods

The ratio of fuel and air supply to the combustion chamber must be adjusted, otherwise the operation of the heating equipment will be unstable or constantly occur at high power.

The easiest way to change the speed of the fan and screw motor is to install a simple regulator. But in this case, there will be an added need for regular supervision and adjustment of the equipment, taking into account the ambient temperature and coolant. Setting up a heating system with your own hands consists of selecting, in different operating modes, such a ratio of air and fuel supply, during which the flame will be stable and even. This can only be achieved by automating the operation of the boiler.

First you need to purchase an electronic control unit. If the boiler is already equipped with this device, then you need to carefully study the possibilities of its use. Typically, controllers from leading manufacturers have free control contacts where electric auger and fan motors can be connected. In this case, taking into account the sensor readings, the controller will begin to increase or decrease the fuel supply and regulate the fan speed.

In terms of ignition and flame control, the burner can also be automated. It is necessary to purchase a photosensor, as well as an electronic filament element. The latter turns on at the very beginning, igniting the pellets, and the photosensor, when a persistent flame appears, will notify the controller, which will turn off the incandescent element.

A filling sensor is installed on the pipe; its main task is to send a signal to the electronic control panel if the auger is filled with pellets in order to complete the fuel supply. All these automation methods make it possible to burn fuel efficiently and create comfort during heating boiler maintenance. But there are also certain disadvantages:

- The cost of manufacturing the burner increases significantly.

- The electronic unit of the heating boiler included in the kit is usually not suitable for simultaneous operation with devices for controlling and igniting the burner; in this case, it is necessary to purchase a new one.

- The burner cannot be connected to any controller.

How to make a pellet burner with your own hands

In addition to firewood and coal, there are other types of solid fuels available to many homeowners. These are wood pellets, sawdust, seed husks, grain processing waste. Due to their granular structure, burning such fuel in the classical way is inconvenient and ineffective.

You can get more heat and automate the process by installing a special burner device on the boiler. The latter are commercially available, but they are adapted to work on pellets.

To burn husks and small sawdust, you will need an additional device; one solution is a homemade pellet burner.

DIY pellet burner

The structure of the product and the purpose of its elements

The task of any burner device is to create a powerful, even flame to heat the water jacket of the boiler, the intensity of which can be adjusted.

In this regard, the pellet burner design serves the same purpose and consists of a small combustion chamber in the form of a wind tunnel into which fuel is supplied and air is pumped.

A screw conveyor is used to feed granules or husks, and fuel enters it from a loading hopper. The volume of the latter determines the duration of the installation. Air is forced into the combustion zone from a fan - supercharger.

Screw conveyor

The combustion chamber can be either rectangular or circular in cross-section. The latter is more common because it is easier to manufacture.

If we look at the design drawings of a pellet burner, then a flat tray for burning fuel must be installed in a round chamber, and it itself is attached to a flange plate, which is adjacent to the frontal plane of the boiler from the outside.

The outer part of the device consists of a screw conveyor with an upper inlet through which fuel from the bunker enters. The second element is a fan installed under the auger and supplying air to the lower part of the chamber.

Pellet burner mechanism

Bulk solid fuels after combustion produce very little waste in the form of fugitive ash, so the design of the pellet burner provides for its self-cleaning from the air flow supplied by the blower. As a result, all the ash accumulates in the ash pan, which needs to be cleaned no more than once a week.

Description of operating modes

The very principle of operation of a pellet burner is as follows: a portion of fuel enters the chamber, it is ignited and the minimum air supply is turned on. As the fuel burns and the chamber warms up, more air is forced in. As a result, a stable, even flame appears, heating the heat exchanger with water.

In factory burner devices, the process is fully automated, ignition is provided by an electric incandescent element, and its operation is controlled by a photosensor. The amount of air and pellets supplied to the chamber is regulated by an electronic unit, receiving signals from temperature and pressure sensors.

A diagram of a pellet burner will help you understand how the device works.

https://www.youtube.com/watch?v=pkvWhUl1Nws

Fuel in the form of wood pellets or seed husks can be supplied to the pellet burner auger in various ways:

- The traditional method is to supply pellets from a separate large hopper so that its capacity is enough for at least 7 days of operation of the boiler, which needs to be cleaned once a week. From the bunker, the fuel is moved to the burner device by an additional screw conveyor of the required length.

- A DIY gravity pellet burner can be equipped with a simpler fuel supply. In it, husks and granules are poured under their own weight into an auger from a hopper installed directly above the burner device, which delivers the required amount into the combustion chamber. Then the power reserve of the boiler will be from 1 to 3 days, depending on the intensity of work.

It is not difficult to select materials for making the device. Considering the temperature regime of the combustion chamber, it is better to take a pipe made of heat-resistant steel with a wall thickness of at least 4 mm. The flange plate, with which a homemade pellet burner is attached to the body of the boiler installation, can be made of ordinary quality steel with a thickness of 3 mm.

The feed conveyor can be purchased assembled, or you can make it yourself from an ordinary pipe by placing a screw in it. For rotation, a low-speed electric motor, gearbox and bearings are selected. The fan must be purchased and fixed to the plate, preparing a seat for it.

The plate itself must be made by studying the drawings of the pellet burner, and depending on the design of the boiler door.

Pellet burner parts

Petropelette.

Petropelette was developed for installation on the industrial Cooper boiler of the Novosibirsk OOOTeplodar. The burner is simply hung instead of the bottom door of the boiler on the hinges on the boiler. Therefore, switching from firewood to pellets takes no more than 3 minutes. Pellets are not firewood, they just don’t burn in air. They require pressurization to burn, and the conditions of pressurization depend on the specific boiler and other factors. Therefore, the Petropelette consists of the fryer itself, a pressurization system and an ignition system. There is also a combustion sensor on the burner.

Supercharging For supercharging, I used a fan from a VAZ-2110 stove or the like. Issue price 850 rub. In terms of performance, it is clearly “overkill”, so it has to be powered from 2.5 to 5 volts. At higher voltages, it simply blows the pellets out of the combustion chamber. Of course, over time I plan to use some kind of lower-capacity fan. Let me say right away that impeller type fans are not suitable. Only “squirrel wheel” systems or they are also called “snail”. Time passed and I found a more suitable fan. I bought it on AliExpert.

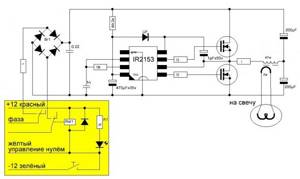

Ignition.

One of the ignition options is ignition with a HAIRDRYER. I advise those interested to try igniting with a soldering HAIRDRYER. When installed 450 deg. pellets light up in a minute. Having tried many options, I have so far settled on the so-called “candles from Zaporozhets”. This is a heating element similar to a spark plug, but there is a spiral inside.

At a voltage of 4 volts, it consumes a current of 10 Amps. An inverter had to be developed for this candle. I thought that this candle would not work for a long time, but now it’s winter 2014/2015 and today it’s autumn, no problem. I keep a spare one just in case. Delov, in the auto shop 120 rubles with delivery to Aleksandrov.

Part of the circuit in the yellow square is installed in the power panel, so in all modes except “Ignition” the burner is not under dangerous voltage. This is what a spark plug inverter really looks like.

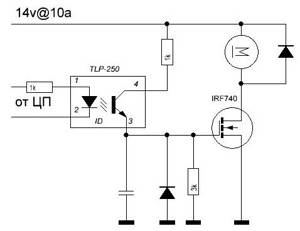

Pellet supply.

I made a temporary plywood bin to feed the pellets. Pellets are fed with a homemade auger. The pellet feeding auger is rotated by a window lift motor gearbox from some VAZ. The “supply” is powered by a separate 14 volt 10 ampere power supply. The electronics on the burner are also powered from the same power supply. The size of the portion and the pause between them is determined by the CPU. The feed motor key circuit does not contain any special features.

As an auger, I used a choke made from a copper bar from a welder that was lying around. I stretched it to a pitch size of 40 mm. All this worked, and is still working in a 50 mm plastic plumbing pipe. This auger worked for one winter, and then its motor went haywire. I had to use the remainder of the throttle. Now, since the design exceeded all my expectations, I ordered a proprietary auger. I'll show you as soon as I receive it.

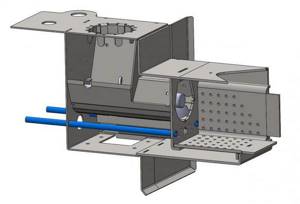

Burner.

I designed the burner “like an adult.” Three-D model, drawings, developments. Manufactured using CNC lasers and plasmas. Bending according to cutting. The model in the figure shows the principle of its operation. In order not to cut a hole for the burner in the bottom door of the boiler, I simply made another door. Now, when switching from one type of fuel to another, I just need to change the door and install (remove) the grate. The operation takes no more than 3 minutes.

Next are the drawings for those who want to tinker with a file and a grinder.

Pre-weld 2 20 mm long stainless steel pins into the main door into the holes provided for this. Then TIG weld two doors, the main one and the additional one, placing mineral wool or some other kind of wool between them. Of course, some kind of solid insulation would be much better. Weld hinges in place for hanging the burner on the boiler. M6 studs are also welded into the Flange part to fasten the “Mounting plate” part.

Next are the parts made of 0.8mm stainless steel.

The holes on the “Box” part are intended for installing the “Combustion” and “Overflow” sensors. Holes with a diameter of 0.5 mm are cores for subsequent welding of M3x6 bonnets. The combustion chamber is lined from the inside with grates made of heat-resistant cast iron. The material used was a panel for the stove without rings. The parts are cut out using CNC plasma. But enthusiasts can do this manually with a grinder.

H

Cast iron is quite acceptable to cut and drill. It is even very easy to drill with cobolt drills. And here is the new burner design. Everything has been rearranged for the new turbine.

Rating of pellet boilers

The table below shows models of leading manufacturers of pellet boilers.

We carefully studied them and prepared our independent rating. Summary table of pellet boiler models

| Model | Maximum power, kW | Fuel | Hopper capacity, kg | Burner type | price, rub. |

| 1. Stropuva P20 | 20 | pellets Ø6-8 mm | 90 | torch, manual ignition | 91340 |

| 2. Teplodar Kupper PRO 22 with APG25 | 22 | pellets Ø6-8 mm up to 50 mm long, firewood | 120 | flare, auto-ignition | 92400 |

| 3. Obshchemmash Valdai 22M2 | 22 | pellets Ø6-8 mm, firewood with humidity up to 35%, coal, briquettes | 160 | flare, auto-ignition | 136700 |

| 4. FACI 26 | 26 | pellets Ø6-8 mm, firewood | 210 | retort, manual ignition | 158000 |

| 5.TIS Pellet 25 | 30 | pellets Ø6-8 mm, firewood | 210 | flare, auto-ignition | 189500 |

| 6.ZOTA Pellet-25S | 25 | pellets Ø8 mm, length 15-35 mm, firewood with humidity up to 20% | 200 | retort, auto-ignition | 196000 |

| 7. Kiturami KRP-20A | 28 | pellets Ø6-8 mm, length no more than 35 mm | 110 | flare, auto-ignition | 225300 |

| 8. Buderus Logano S181 25 E | 27 | pellets Ø6-8 mm, coal | 150 | retort, auto-ignition | 227300 |

| 9. OPOP Biopel Line Kompakt 30/V9 | 31,5 | pellets Ø6-8 mm | 150 | retort, auto-ignition | 234900 |

| 10. Pellets Fuzzy Logic 25 | 25 | pellets Ø6-8 mm, firewood with humidity up to 20%, coal 5-25 mm, grain | 220 | retort, auto-ignition | 265 160 |

Stropuva P20 – from RUB 91,340.

The original development from the Lithuanian company Stropuva P20 combines simplicity, operational efficiency and low cost. The feature of the model is its design. There is no auger for supplying fuel; pellets are fed into the combustion chamber under the influence of gravity. There is no automatic ignition system. You will have to start the boiler using a gas burner. But this will only need to be done a few times per season.

The boiler is equipped with 4 temperature sensors, which provide fine tuning of the heating system and control the operation of the burner. Changing the power of the equipment is ensured by regulating the air supply by the fan. The maximum pellet consumption is 4 kg/h, which, with a 90 kg hopper, provides up to 22.5 hours of continuous operation at maximum power.

The design of the heat exchanger also deserves attention.

The water jacket is located in the walls of the cylinder, the rest of the space is occupied by a device with steel disc elements. They play the role of turbulators, reducing the speed of flue gases, increasing the time of their contact with the surface of the heat exchanger. In addition, they serve as a filter for solid combustion products and prevent the formation of blockages in the chimney. Cleaning the boiler comes down to removing the ash accumulated in the combustion chamber and cleaning the surface of the turbulators, which are easily removed when the top cover is opened. Main technical characteristics of Stropuva P20

| Characteristics | Values |

| Rated power, kW | 20 |

| Heated area, m² | 200 |

| Efficiency, % | 90 |

| Fuel | pellets Ø6-8 mm |

| Hopper capacity, kg | 90 |

| Fuel consumption, kg/h | 4 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | torch, manual ignition |

| Chimney diameter, mm | 160 |

| Dimensions, mm | 500x1000x1500 |

| Weight, kg | 92 |

| Homeland of the brand / Production | Lithuania/Russia |

| price, rub. | 158 000 |

Watch video review of Stropuva P20:

Teplodar Kupper PRO 22 with APG25 – from RUB 92,400.

The manufacturers of the Kupper PRO pellet boiler simply modified the popular model of their steel solid fuel unit: they installed an APG-25 automatic pellet burner on the Kupper PRO single-circuit boiler. The result was equipment with a power range of 4-22 kW. By default it runs on pellets, but if necessary you can switch to emergency fuel in the form of firewood. The basic configuration includes a 6 kW heating element, so another backup option is electric heating. APG is supplied as a set consisting of a fuel hopper with a feeding mechanism, a control panel, and the burner itself.

The peculiarity of the model is the location of the hopper directly on the boiler.

Thanks to this solution, space is saved, but ergonomics suffer - more effort is required to load pellets. The automation system controls the operation of the boiler from the very start of the system; you just need to set the heating parameters before starting the unit. With a filled hopper and continuous operation of the burner, the fuel will last for 13.3 hours. As for maintenance: the boiler needs to be cleaned at least once a month, the burner - at least once a week. Main technical characteristics of Teplodar Kupper PRO 22 with APG25

| Characteristics | Values |

| Rated power, kW | 22 |

| Heated area, m² | 220 |

| Efficiency, % | 95 |

| Fuel | pellets Ø6-8 mm up to 50 mm long, firewood |

| Hopper capacity, kg | 120 |

| Fuel consumption, kg/h | 9 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | flare, auto-ignition |

| Chimney diameter, mm | 150 |

| Dimensions, mm | 1775×740×1058 |

| Weight, kg | 165 |

| Homeland of the brand / Production | Russia, Russia |

| price, rub. | 92 400 |

Watch a video review of Teplodar Kupper PRO 22 with APG25:

Obshchemmash Valdai 22M2 – from 136,700 rubles.

Valdai 22M2 is a single-circuit steel boiler with a water-tube heat exchanger with a power of 22 kW and a control range of 4-22 kW. The main fuel is pellets of various qualities, including wood, flax pellets, sunflower husks, and peat. Firewood with a moisture content of up to 35% can be used as emergency fuel. In the latter case, you will have to install additional grates. The efficiency of pellets with low ash content reaches 90%; with wood, a maximum of 76% can be achieved.

The control unit can operate in several modes: maintaining the temperature of water or air entering the boiler in heated rooms, based on information from an external sensor; work according to schedule; work in conjunction with an electric heater; stop-start mode; emergency mode on wood. You can also control the heating system pump. The operation of the boiler can be controlled remotely via a smartphone or computer.

To ensure safe operation, overheating protection is provided: the temperature of the exhaust gases at the boiler outlet is recorded.

At maximum power of the boiler, the volume of the bunker will last more than 25.4 hours. The simple design of the unit minimizes the amount of deposits on the surface of the heat exchanger and makes it easy to clean. There is an automatic mechanism for mechanical cleaning of the burner. Main technical characteristics of Obshchemmash Valdai 22M2

| Characteristics | Values |

| Rated power, kW | 22 |

| Heated area, m² | 220 |

| Efficiency, % | 90 |

| Fuel | pellets Ø6-8 mm, firewood with humidity up to 35%, coal, briquettes |

| Hopper capacity, kg | 160 |

| Fuel consumption, kg/h | 6,3 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | flare, auto-ignition |

| Chimney diameter, mm | 150 |

| Dimensions, mm | 1173x516x854 |

| Weight, kg | 335 |

| Homeland of the brand / Production | Russia, Russia |

| price, rub. | 136 700 |

Watch the video review of Obshchemmash Valdai:

FACI 26 – from RUB 158,000.

FACI 26 is a boiler from an Italian-Russian joint venture with an original steel drum heat exchanger. The maximum power is 26 kW, it can run on both pellets and wood (backup fuel). The pellet supply system uses a twin-screw design that protects the hopper from backfire.

It is distinguished by a large water jacket that covers the entire combustion chamber. The drum heat exchanger is equipped with turbulators - plates with a developed geometry to increase the contact time of hot gases with the wall of the heat exchanger. It is important to consider that auto-ignition, a system for automatic ash removal and cleaning of the heat exchanger are additional options for which you need to pay extra. The fuel in the bunker with constant supply and operation at maximum power lasts for 35 hours.

Among the design features, one can also note the location of the bunker: only behind the boiler - as well as ease of maintenance.

It takes no more than 15 minutes to clean the entire boiler, because all components are freely accessible. Main technical characteristics of FACI 26

| Characteristics | Values |

| Rated power, kW | 26 |

| Heated area, m² | 260 |

| Efficiency, % | 92 |

| Fuel | pellets Ø6-8 mm, firewood |

| Hopper capacity, kg | 210 |

| Fuel consumption, kg/h | 6 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | retort, manual or auto-ignition |

| Chimney diameter, mm | 160 |

| Dimensions, mm | 500x1800x1205 |

| Weight, kg | 350 |

| Homeland of the brand / Production | Italy / Italy and Russia |

| price, rub. | 158 000 |

Watch video review of FACI 26:

TIS Pellet 25 – from RUB 189,500.

If questions about the quality of fuel pellets are paramount, then you should pay attention to the Belarusian TIS Pellet 25 unit. It operates in the range from 10 to 30 kW of power on wood, peat, flax pellets, and sunflower husk pellets. You can even burn cherry pits or grains unsuitable for food purposes. As an emergency option - ordinary firewood, coal and peat. In the latter case, we are talking about manual bookmarking.

The presence of weather-dependent automation allows you to fine-tune the operating mode based on the weather and fuel quality. Fully loading the hopper in maximum power mode guarantees up to 35 hours of continuous operation. By default, thermal sensors are installed to protect against ignition of the fuel supply and boiling of the coolant. The burner has an automatic ignition and a mechanical ash removal system.

As options, a room thermostat, a module for controlling the boiler depending on the temperature in different rooms, a control module for 2 mixing circuits and 2 pumps, and a remote control module via the Internet are connected.

Main technical characteristics of TIS Pellet 25

| Characteristics | Values |

| Rated power, kW | 30 |

| Heated area, m² | 270 |

| Efficiency, % | 93 |

| Fuel | pellets Ø6-8 mm, firewood |

| Hopper capacity, kg | 210 |

| Fuel consumption, kg/h | 6 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | flare, auto-ignition |

| Chimney diameter, mm | 159 |

| Dimensions, mm | 530x720x1260 |

| Weight, kg | 338 |

| Homeland of the brand / Production | Belarus / Belarus |

| price, rub. | 189 500 |

Watch the video review of TIS Pellet 25:

ZOTA Pellet-25S – from RUB 196,000.

The presented model of the steel single-circuit boiler ZOTA Pellet-25S is designed for harsh operating conditions: not always good fuel, operation at full capacity, power outages. According to the manufacturers, it can give a head start to imported analogues in terms of resistance to the harsh Russian reality. The power is adjusted automatically and can be set in the range from 13 to 25 kW. Automation provides control of the unit’s power and coolant temperature, and also provides the user with data for analysis on current fuel consumption.

The hopper volume of 332 liters is enough to load up to 200 kg of pellets.

This amount is enough for uninterrupted operation of the boiler in maximum mode for 31.7 hours. If necessary, you can use firewood and briquettes as fuel. For these purposes, additional grates are installed. It is possible to optionally install a heating element for heating using electricity. By default, a weather-related control program is provided. Among the system's features we can note the option of remote control using a cell phone. The bunker can be installed on both sides of the boiler, and if necessary, its volume can be increased by installing additional modules. Main technical characteristics of ZOTA Pellet-25S

| Characteristics | Values |

| Rated power, kW | 25 |

| Heated area, m² | 250 |

| Efficiency, % | 90 |

| Fuel | pellets Ø8 mm, length 15-35 mm, firewood with humidity up to 20% |

| Hopper capacity, kg | 200 |

| Fuel consumption, kg/h | 6,3 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | retort, auto-ignition |

| Chimney diameter, mm | 150 |

| Dimensions, mm | 1140x1660x1110 |

| Weight, kg | 395 |

| Homeland of the brand / Production | Russia, Russia |

| price, rub. | 196 000 |

Watch a video review of ZOTA Pellet, in this case – at 40 kW:

Kiturami KRP-20A – from RUB 225,300.

Steel double-circuit boiler Kiturami KRP-20A for heating buildings with an area of 60 to 280 m². It features an efficiency of up to 96%, as well as the installation of high-quality Korean automation. The use of turbulators and a large water jacket ensure effective heat removal. In this model, vibration cleaning of the heat exchanger and burner grate is automated, which greatly facilitates maintenance of the unit: when using light pellets, manual cleaning is only needed once every 2-4 weeks. The system is equipped with automatic ignition; the coolant circulates in the jacket forcibly, producing up to 9 liters of hot water per minute.

It is possible to fine-tune the automation. This includes entering the absence mode with minimal fuel consumption to maintain a temperature at which the heating system does not freeze. In this mode, the equipment can operate for up to two weeks. On average, fuel consumption per season for heating an area of 100 m² is 3.5-4 tons of pellets.

The boiler uses a bowl-shaped torch burner.

The ash accumulates in a large ash box, which is enough to store the ash after all the fuel in the bunker has been burned. The equipment is supplied fully equipped, including a boiler with a burner, a remote-type thermostat-controller, systems for cleaning the grate and protecting the auger from fuel overflow, and a fire damper. Main technical characteristics of Kiturami KRP-20A

| Characteristics | Values |

| Rated power, kW | 28 |

| Heated area, m² | 280 |

| Efficiency, % | 96 |

| Fuel | pellets Ø6-8 mm, length no more than 35 mm |

| Hopper capacity, kg | 110 |

| Fuel consumption, kg/h | 6 |

| Heat exchanger material | steel |

| Number of circuits | 2 |

| Burner type | flare, auto-ignition |

| Chimney diameter, mm | 125 |

| Dimensions, mm | 1060x920x1250 |

| Weight, kg | 278 |

| Homeland of the brand / Production | South Korea / South Korea |

| price, rub. | 225 300 |

Watch video review of Kiturami KRP-20A:

Buderus Logano S181 25 E – from RUB 227,300.

Single-circuit boiler Buderus Logano S181 25 E 27 kW with an efficiency of 88%, equipped with a steel tubular heat exchanger. Coal or pellets are used as fuel. The standard fuel tank volume of 240 liters at maximum power is enough for 50 hours of operation on high-calorie coal, and 25 hours on white pellets. The volume of the bunker can optionally be increased by 140 liters; it is enough to add one section - this takes no more than 15 minutes. The fuel container can be mounted either on the left or on the right. By default, the system is equipped with automation that regulates fuel consumption, fan and pump operation.

The control unit has an intuitive interface; the display shows all information on the operation of the boiler. If necessary, as options you can install a room thermostat, connect additional heating circuits, and a remote control unit via WiFi or GSM.

As for maintenance: once a day it is necessary to clean the ash drawer, once a week - to clean the heat exchanger, once a month - to completely clean the boiler.

Considering the availability of all nodes, even the last stage requires no more than 15 minutes. Main technical characteristics of Buderus Logano S181 25 E

| Characteristics | Values |

| Rated power, kW | 27 |

| Heated area, m² | 270 |

| Efficiency, % | 88 |

| Fuel | pellets Ø6-8 mm, coal |

| Hopper capacity, kg | 150 |

| Fuel consumption, kg/h | 6 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | retort, auto-ignition |

| Chimney diameter, mm | 150 |

| Dimensions, mm | 1155x1216x837 |

| Weight, kg | 274 |

| Homeland of the brand / Production | Germany/Germany |

| price, rub. | 227 300 |

Watch video review of Buderus Logano S181 E:

OPOP Biopel Line Kompakt 30/V9 – from RUB 234,900.

Despite the fact that this rating considers models with a power of up to 30 kW, we simply could not ignore the development of the Czech company OPOP. After all, this steel boiler can operate in the range from 8.5 to 31.5 kW, which means it is suitable for most homes. The efficiency of the unit reaches 92.2%; at maximum power, the hopper is enough for continuous operation for 34.7 hours. Such high efficiency is achieved thanks to the large jacket and the presence of turbulators in the heat exchanger to increase the efficiency of heat removal. An automatic cleaning system can also be optionally installed here.

If it is necessary to increase the volume of the bunker, the manufacturer suggests installing a separate 3-ton bunker. But the main feature reveals itself when installing the complete set.

In this case, human participation in servicing the boiler is minimized - you will only need to remove ash from the ash drawer. Also, if necessary, you can connect a room thermostat, a remote control and management system via the Internet. The hopper together with the burner can be installed on the left or right, and the ash pan door can also be hung. Main technical characteristics of OPOP Biopel Line Kompakt 30/V9

| Characteristics | Values |

| Rated power, kW | 31,5 |

| Heated area, m² | 315 |

| Efficiency, % | 92,2 |

| Fuel | pellets Ø6-8 mm |

| Hopper capacity, kg | 150 |

| Fuel consumption, kg/h | 7,2 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | retort, auto-ignition |

| Chimney diameter, mm | 150 |

| Dimensions, mm | 558x906x1078 |

| Weight, kg | 282 |

| Homeland of the brand / Production | Czech Republic / Czech Republic |

| price, rub. | 234 900 |

Watch the video review of OPOP Biopel Line Kompakt 30/V9:

Pellets Fuzzy Logic 25 – from RUB 265,160.

Steel single-circuit boiler Pellets Fuzzy Logic 25 with an efficiency of up to 92%, capable of working not only with pellets, but also with fine coal, grain and even firewood. In the latter case, we are talking about manual loading of fuel onto cast iron grate segments specially installed for these purposes. There are two operating modes: summer and weather. In the first case, the boiler serves to provide hot water for domestic purposes in the summer season (connected to the boiler), in the second, it works as part of the heating system. The boiler power can be changed in the range of 8-25 kW. Up to 220 kg of pellets can be loaded into the bunker. At maximum power this should last for 38 hours.

To optimize the amount of thrust, the design includes a lambda probe.

This helps save up to 20% fuel. There is a temperature sensor at the chimney outlet that will notify you when the temperature of the exhaust gases is exceeded and the boiler needs to be cleaned. Maintenance is quite simple, and when using pellets with low ash content, ash removal is necessary approximately once a month. It should be noted that the fuel tank can be installed on opposite sides of the boiler - this allows the unit to be adapted to any boiler room. Main technical characteristics of Pellets Fuzzy Logic 25

| Characteristics | Values |

| Rated power, kW | 25 |

| Heated area, m² | 250 |

| Efficiency, % | 92 |

| Fuel | pellets Ø6-8 mm, firewood with humidity up to 20%, coal 5-25 mm, grain |

| Hopper capacity, kg | 220 |

| Fuel consumption, kg/h | 5,8 |

| Heat exchanger material | steel |

| Number of circuits | 1 |

| Burner type | retort, auto-ignition |

| Chimney diameter, mm | 160 |

| Dimensions, mm | 1080x1150x1230 |

| Weight, kg | 430 |

| Homeland of the brand / Production | Poland / Poland |

| price, rub. | 265 160 |

Watch a video review of Pellets Fuzzy Logic 25:

Build process

The process of creating a boiler includes several stages. When manufacturing each element, it is worth taking into account the special operating conditions of the product being manufactured.

We cut a section from a thick-walled pipe with a diameter of 100 mm, the length of which will be equal to the height of the firebox. We weld a bolt to the bottom. From a steel sheet we cut out a circle with the same diameter as the pipe or larger. We drill a hole in the circle large enough to pass the bolt welded to the pipe. We connect the circle and the air duct pipe by tightening the nut onto the bolt.

As a result, we will get an air supply pipe, the lower part of which can be closed by a freely moving metal circle. During operation, this will allow you to regulate the intensity of firewood combustion and, consequently, the temperature in the room.

Using a grinder and a metal disc, we make vertical slits approximately 10 mm thick in the pipe. Through them, air will flow into the combustion chamber.

Housing (firebox)

The body will require a cylinder with a sealed bottom with a diameter of 400 mm and a length of 1000 mm. The dimensions may be different, depending on the available free space, but sufficient for laying firewood. You can use a ready-made barrel or weld the bottom to a thick-walled steel cylinder.

Sometimes heating boilers are made from gas cylinders for a longer service life.

Chimney

In the upper part of the body we form a hole for the removal of gases. Its diameter must be at least 100 mm. We weld a pipe to the hole through which the exhaust gases will be removed.

The length of the pipe is selected depending on design considerations.

Connecting the housing and the air supply device

We cut a hole in the bottom of the housing with a diameter equal to the diameter of the air supply pipe. We insert the pipe inside the body so that the air vent extends beyond the bottom.

We cut out a circle from a metal sheet 10 mm thick, the size of which is slightly smaller than the diameter of the body. We weld a handle made of reinforcement or steel wire to it.

This will greatly simplify the subsequent operation of the boiler.

Convection hood

We make a cylinder from sheet steel or cut a piece of pipe, the diameter of which is several centimeters larger than the outer diameter of the firebox (body). You can use a pipe with a diameter of 500 mm. We connect the convection casing and firebox together.

This can be done using metal jumpers welded to the inner surface of the casing and the outer surface of the firebox, if the gap is large enough. With a smaller gap, you can weld the casing to the firebox around the entire perimeter.

From a steel sheet we cut out a circle with the same diameter as the firebox or a little larger. We weld the handles to it using electrodes, wire or other available means.

Considering that the handles can become very hot during operation of the boiler, it is worth providing special protection made of material with low thermal conductivity.

Legs

To ensure long burning, we weld the legs to the bottom. Their height should be sufficient to raise the wood-burning boiler at least 25 cm above the floor level. To do this, you can use various rolled products (channels, angles).

Congratulations, you have made your own wood-burning boiler. You can start heating your home. To do this, just load the wood and light it by opening the lid and heat dissipation disk.

Despite the fact that science and technology have come far ahead, there is no denying that even today the use of devices such as wood boilers for heating a home is common.

Most models of modern wood-burning boilers today combine the following two elements: a traditional source of thermal energy - wood, as well as a steam heating system, which came into use relatively recently - 100-150 years ago.

For those who live in the city, such a persecution of ancient traditions in the form of wood-burning boilers may seem strange. However, this cannot be said about villages and villages. After all, there is no passing gas main here, electricity fluctuates, and paying bills will be expensive. It is in this case that wood boilers for heating a house will become the only salvation for people in the cold season.

The main types of homemade boilers

If you are going to make a long-burning boiler with your own hands, then you will definitely need the information from our review. In the following sections we will tell you how to make a heating unit of one design or another yourself, give several of the easiest schemes, and publish information about the most common long-burning boilers

Let's focus on the last question for now.

The time has come to consider the most current options for long-burning boilers, which we can assemble with our own hands at home. They will all eat wood. As for coal, it is more difficult to obtain, and it also leads to high temperature loads on heating units. In the following sections we will provide drawings of long-burning solid fuel boilers and provide explanatory information.

Long burning mine boiler

We can make the simplest mine boiler with our own hands. It is implemented according to a bottom combustion scheme. The basis of the unit is a capacious loading chamber, which is often called a shaft. Having a vertical design, it allows you to accommodate a large amount of firewood. As they burn, they fall down, and the combustion products are sent through the grate into the ash pan.

If we look at the diagram of a shaft furnace (boiler), we will find that the flame is raging not in the shaft at all, but in the adjacent chamber, from where the resulting heat enters the fire-tube heat exchanger. And the remaining thermal energy is sent to the chimney. The combustion here is long and is determined by the volume of the shaft - after loading a large amount of firewood here, you can safely go to bed.

Pyrolysis boiler

Let's see how a pyrolysis boiler works and how to make this unit with your own hands. The easiest way to explain the operating principle of this unit is to use the example of a potbelly stove. Here we see a volumetric combustion chamber that realizes long-lasting combustion. The resulting combustion products are sent to the afterburner chamber, into which secondary air is supplied. As a result, a large amount of heat is generated. All we have to do is retrofit the potbelly stove with a fire-tube heat exchanger.

There are dozens of drawings of long-burning wood-burning boilers built on the pyrolysis principle of operation. They differ in the location of combustion and afterburning chambers, the presence and absence of blower fans and automation, as well as methods for adjusting the intensity of the wood fuel combustion process. But in general, their operating principle is the same.

Boiler-furnaces Bubafonya

Bubafonya is a stove, and its modification is a water-heating wood-burning boiler with air supply from above, through a pressure piston. We have already written about such stoves more than once in our reviews, now it’s time to talk about units with a heating circuit. To implement the circuit, we can use three schemes:

- Installing a heat exchanger on a chimney is the easiest option;

- Build a continuous water jacket around the boiler body;

- Scald the body of the unit with the pipes through which the coolant will circulate.

Which scheme to choose is up to you. By the way, Bubafonya boilers, due to their spacious chambers, will help to realize long-term combustion lasting up to 24 hours or even more.

Long-burning boilers Bubafonya operate on wood and have an upper combustion scheme.

Boiler-furnaces Buleryan

Initially, Buleryans were (and are) convection-type ovens. They are equipped with powerful convectors, which allow you to warm up a large room in literally 20-25 minutes. Having originally appeared in Canada, these stoves reached Russia, which also boasts a harsh climate (true for some regions). Craftsmen turned stoves into boilers, having worked a little on the design of convectors - now not air, but coolant circulates through them. True, Buleryan boilers cannot boast of long-lasting combustion, since they do not have the largest combustion chambers. Some of them have the property of burning for up to 10-12 hours, some – a little longer. But you still can’t count on 24 hours. But they are characterized by high efficiency and the ability to quickly transfer heat to heating systems.