The principle of operation of a biofireplace

The biofireplace is made in the form of a simple system, functioning by burning a new type of liquid fuel mixture - bioethanol. Its energy qualities must be taken into account when creating bio-fireplaces with your own hands. The simplicity of the design and the availability of all materials will not require the performer to spend significant effort during its production. And the costs of purchasing materials will be insignificant. As a result, the master will receive an unusual piece of furniture. Which in turn will create warmth in the house from a real and living fire.

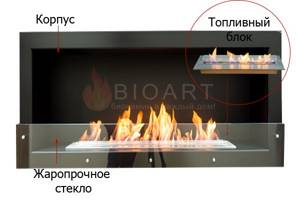

The device is made of simple 4 main blocks:

- The base is a frame structure for fixing working units;

- a safety screen made of refractory glass to protect the room from the possible spread of fire;

- consumable container for bioethanol fuel mixture;

- burner device for ignition and conducting the combustion process.

If necessary, a structural portal is installed near a self-made biofireplace. Which allows you to fit it into the interior as completely as possible. Due to their popularity, industry, both domestic and Western, has launched the production of biofireplaces. There are plenty of them in the retail chain today, but their cost is quite high. As a result, many users decided to make it themselves.

Which biofireplace is better?

Any piece of furniture is chosen according to its appearance, focusing on design.

Biofireplace, as one of the most original decorative elements, was also no exception.

In appearance, liquid fuel fireplaces may differ little from traditional stove structures. There are models with built-in fireboxes - portals, made in accordance with a certain decorative style.

These are corner or wall fireplaces, which in an elite finish can be equipped with fireboxes made of natural stone, granite, marble or wood. A number of models are produced in the form of stoves with a metal body, decorated with a variety of finishing elements.

Quite a lot of bio-fireplaces are made in a modern style.

These can be fireplaces of the most unexpected design and shape - models suspended from the ceiling, wall-mounted, floor-mounted, table-type fireplaces. The materials used are also the most modern - tempered glass, titanium, plastic, leather, aluminum, stainless steel, leather.

Today's market offers many options. In general, the minimalist style predominates - the simplest geometric shapes, devoid of any paraphernalia.

Depending on the type of design, interior fireplaces can be divided into stationary and mobile. The first type includes floor and wall models. The second includes various portable, often miniature, fireplaces, usually designed for installation on a shelf or table.

Some models of decorative fireplaces are designed for outdoor placement

In any case, when choosing a biofireplace, it is important to take into account its future location, especially when it comes to the classic model. Such devices, as a rule, become the “heart” of the interior, occupying a dominant position together with the TV

Among the technical capabilities of the selected biofireplace, it is worth paying attention to its power, determined by the design and volume of the heating unit.

The longer the block, the higher the extent of the combustion area and, accordingly, the flame comes out brighter and more intense. Very large fireplaces may have multiple heating units

You should also pay attention to the presence of an electronic fuel combustion control system. The most advanced models are equipped with an automatic bioethanol supply mechanism, a remote control, heating sensors, carbon dioxide level sensors and an automatic ignition system

It is also important to consider the type of fuel. There are fireplaces refilled with liquid and gel compositions

The design of the heating unit (burner) in this case is different. In general, gel fuel is more convenient to use - it cannot be spilled, and the flame instantly acquires a pleasant shade

There are fireplaces that are filled with liquid and gel compositions. The design of the heating unit (burner) in this case is different. In general, gel fuel is more convenient to use - it cannot be spilled, and the flame instantly acquires a pleasant shade.

However, such fuel produces smoke and is usually used in small fires.

Fire relaxes and envelops the room in an atmosphere of warmth and comfort. True, a slow and quiet fire is relaxing; it is unlikely that a burning house will cause a storm of solitude and tranquility for anyone. Fortunately, modern technology has made it possible to add a touch of relaxing live fire to every home.

This can be done using biofireplaces.

Their model range and design allows each buyer to choose a fireplace according to the interior direction of the room. True, not every ordinary buyer is satisfied with their high cost.

And if a person has a little knowledge of the construction industry, he can easily make a bio-fireplace with his own hands, using quite simple techniques and available materials. It is worth noting that there is nothing super complicated or impossible in the design of a biofireplace. It is enough to use any fireproof container, cover it with stones and select a flammable material with an alcohol-containing composition.

img src=»https://mainavi.ru/upload/iart/biokamin-svoimi-rukami/2.jpg» />

A bio-fireplace made for an apartment with your own hands will become not only a key element of the entire interior, but also a source of pride for the owner.

Important!

Bio-fireplaces are not recommended for use in bathrooms, as well as in rooms with an area of less than 16 sq.m. Under no circumstances should you use matches to light a fireplace; special lighters are available for this purpose.

Classification of biofireplaces

Depending on the installation location, biofireplaces are:

Floor bio fireplaces

Floor-standing biofireplaces are fireplaces that are installed on the floor surface near the walls or in the middle of the premises of private houses and apartments, photo 4. The materials from which they are made vary: natural stone, glass, ceramics, wood, steel. Basically, metal and glass are used to make bio-fireplaces, which give the fireplace a very sophisticated, beautiful look.

Photo 4. Floor fireplaces

Wall-mounted biofireplaces

Wall-mounted biofireplaces are fireplaces that are installed on the wall of a private house (apartment), photo 5.

Photo 5. Wall-mounted biofireplaces

Wall-mounted biofireplaces are produced with a size of no more than 1 m; upon individual order, the dimensions can be increased. The depth of wall-mounted biofireplaces is small (15...25 cm), so sometimes they can be placed in a wall niche.

Tabletop biofireplaces

Tabletop biofireplaces are portable fireplaces that can be placed anywhere on a desk or small table, photo 6. Tabletop biofireplaces are made in various geometric shapes, to suit any designer’s imagination. Most wall-mounted biofireplaces are made in the following shapes:

- rectangular;

- oval;

- bowls;

- cylinder.

The fuel unit is enclosed in a metal or stone casing, the maximum dimensions of which do not exceed 50x50x20 cm (width × thickness × height).

Almost all tabletop biofireplaces are protected on two or four sides by glass walls.

It should be noted that when choosing a tabletop bio-fireplace, there is a system of protection against tipping over and spilling fuel.

Photo 6. Tabletop biofireplaces

Outdoor biofireplaces

Outdoor bio-fireplaces are fireplaces that are installed in the yard, on a green roof, etc. (photo 7). Such fireplaces are large in size and weight.

Photo 7. Outdoor bio-fireplaces

Built-in bio fireplaces

Built-in biofireplaces are installed in niches or small wall openings, which are designed before the construction of the building begins or are manufactured locally, where this is permissible, photo 8.

The depth of the niche for built-in bio-fireplaces must be at least 20 cm. In this case, before installing the bio-fireplace, a protective box is built into the niche. It is allowed to install built-in bio-fireplaces in rooms with an area of at least 20...25 m2.

Photo 8. Built-in biofireplaces

Corner bio fireplace

A corner bio-fireplace is usually installed right in the corner, at the junction of two walls, photo 9. Such a fireplace is compact and takes up minimal space. Available for both floor and wall mounting.

Photo 9. Corner bio-fireplaces

Automatic bio fireplaces

An automatic bio-fireplace differs from previous models in the presence of automation, photo 10. The automation of bio-fireplaces allows you to maximize the safety of the device and ensure comfortable operation. The automation system may include the following:

- automatic ignition;

- remote control (RC);

- manipulator;

- LED control display, which displays information about the current operation and condition of the biofireplace. In case of breakdowns or other nuances of the bio-fireplace operation, the display shows the relevant information and recommendations for eliminating them.

- control Panel;

- electronic sensors for monitoring temperature, fuel quantity, humidity, carbon dioxide content in the air;

- electronic device tilt sensor;

- combustion intensity control system;

- fireplace cooling system, which includes a built-in fan and sensors that regulate its operation;

- child lock system;

- sound or light warning system;

- remote control using a Wi-Fi system, which allows you to control the operation of the biofireplace using a mobile phone or tablet.

Photo 10 Automatic biofireplaces

Automatic bio-fireplaces are more expensive than regular ones (approximately $10,000...$15,000). Automatic biofireplaces are presented on the market by such manufacturers as Decoflame (models Denver, Orlando, Denmark), Planika Fire Line Electronic (Poland), Bioteplo (Russia).

An automatic bio-fireplace can be integrated into the Smart Home system.

Types of biofireplaces by location and type of installation

Manufacturers of eco-fireplaces offer a large selection of equipment depending on the method of their installation. We can confidently say that the device can be installed in any room. Initially, biofireplaces were offered as an alternative to traditional fireplaces, but now they act as a separate type, allowing the owner to create a unique, original interior decor.

Popular types of eco fireplaces:

- desktop;

- wall;

- floor;

- built-in;

- suspension.

Fans of the classics prefer wall-mounted models and appliances built into niches. To enhance the similarity, a whole imitation system is created, including a false chimney, grilles, and accessories. Such equipment has a rectangular portal, decorated with stone, wood, ceramics and more.

As for adherents of a modern style with a touch of shocking, the space for imagination is unlimited. Such bio-fireplaces can look like a strip of fire (more than 1 meter in length), a candle, a torch, and have any shape. Popular solutions are corner and panoramic models, which is especially important when there is a lack of free space. An interesting solution is built-in fireplaces that are mounted in furniture or a wall niche.

Rice. 8. Options for installing an outdoor biofireplace

Rice. 8. Options for installing an outdoor biofireplace

Operating Parameters

To know which bio-fireplace to choose, you need to take into account its technical characteristics, and not just its appearance. The parameters demonstrate the advantages and disadvantages of the model for a specific room.

Important characteristics and their meaning.

- Hearth power. Indicates such features as heat transfer, flame height and flame saturation. The power of the structure can reach up to 7 kW, which, theoretically, is enough to heat a room with an area of 70 square meters. m. On the other hand, in the warm season, the operation of a powerful bio-fireplace can cause inconvenience due to the intense heat.

- Fuel consumption. Depends on the selected operating mode. On average, 500-700 ml of fuel is required for 1 hour of operation.

- Volume of the tank. Demonstrates combustion duration on one refill, and can reach 9 liters. When refueling, you should take into account the recommendations of the developers, namely, let the bioethanol burn out completely.

- Burner material and thickness. The optimal solution is stainless steel from 3 mm or ceramics. There are dual-circuit designs that collect excess fuel, returning it to the fuel block.

It is impossible to say which bio-fireplace is better without taking into account the room.

Please note that the biofireplace has high efficiency, but relatively low heat output (considering the size of the firebox). It is highly undesirable to use heating equipment - it is not rational from the point of view of fuel cost. There is another drawback that is worth considering - the need to ventilate the room due to the inevitable release of carbon dioxide during the combustion process. If we are talking about a small room and a powerful appliance, then it will not be enough to open the doors to other rooms, and you will need to open a window or window.

Rice. 5. Process of pouring bioethanol

Composition and features of biofuel

The “bio” part of the word “biofuel” explains that only natural, renewable raw materials are used to produce this substance. Therefore, it is completely environmentally friendly and biodegradable.

The main components used to produce such fuel are grasses and grains containing large amounts of starch and sugar. Thus, corn and cane are considered the best raw materials.

You can find various brands of biofuels on sale. Preference should be given to certified products, otherwise you may face serious troubles

They produce bioethanol, or a type of alcohol. It is a colorless liquid and has no odor. If necessary, it can replace gasoline, however, the cost of such a substitute is much higher. When burned, pure bioethanol decomposes into water in the form of vapor and carbon dioxide.

In this way, it is even possible to humidify the air in the room where the bio-fireplace is installed. The substance burns with the formation of a blue “gas” flame.

This is a purely aesthetic drawback that prevents you from still enjoying the sight of an open fire. A traditional fireplace produces a yellow-orange flame, which is a kind of standard. To eliminate this drawback, additives are introduced into biofuels that change the color of the flame.

Thus, the traditional composition of a flammable liquid is as follows:

- bioethanol – about 95%;

- methyl ethyl ketone, denaturing substance – about 1%;

- distilled water - about 4%.

In addition, crystalline bitrex is added to the fuel composition. This powder has an extremely bitter taste and is intended to prevent alcohol biofuels from being consumed as alcohol. Biofuel is produced in different brands, its composition may vary somewhat, but in general does not change. It is clear that the cost of such fuel is quite high.

It is not recommended to use homemade fuel for biofireplaces, but if you still decide to try, to make it you need to use only high-purity gasoline “Galosha”

Fuel consumption depends on the number of burners and the power of the biofireplace. On average, a 2-3 hour operation of a heating unit with a power of about 4 kW per hour consumes about a liter of flammable liquid. In general, operating a biofireplace turns out to be quite expensive, so home craftsmen are trying to find a cheaper alternative to fuel. There is such an option and it is viable.

To avoid trouble, you need to purchase only high-quality components for homemade fuel. We must not forget that the bio-fireplace does not have a smoke exhaust, and all combustion products immediately enter directly into the room.

If toxic substances are present in the fuel, and this is not uncommon for low-quality alcohol-containing compounds, they will end up in the room. This threatens with the most unpleasant consequences. We recommend that you familiarize yourself with the best biofuel brands.

Therefore, it is not recommended to make fuel for a biofireplace yourself. However, if you really want to experiment, this is the safest recipe. Take pure medical alcohol. It must be purchased at a pharmacy.

To color the flame, highly purified gasoline is added to it, which is used to refill lighters (“Galoshes”).

Filling the fuel tank must be done very carefully. If liquid is spilled, you must immediately wipe it with a dry cloth, otherwise an accidental fire may occur.

Liquids are measured and mixed. Alcohol should be present in a volume of 90 to 94% of the total amount of fuel, gasoline can account for 6 to 10%. The optimal proportion is determined empirically, but you should not go beyond the recommended values. Detailed instructions for the production and use of biofuel are given here.

It is important to remember that the resulting fuel cannot be stored, since the mixture of gasoline and alcohol will separate. It should be prepared before use and shaken well for better mixing.

Disadvantages of a biofireplace

Along with its advantages, this product has its own disadvantages, which are a tribute to convenience, safety and environmental friendliness.

Dependence on one type of fuel. The burner runs only on alcohol, while a regular fireplace can be lit with any solid flammable substance.

The relative high cost of fuel. A medium-sized heating unit (burner) consumes 0.3–0.4 liters per hour. The cost of 1 liter of fuel is on average 200–250 rubles*. Burning a fireplace for one hour will cost about 100 rubles.

We recommend: Izospan A: technical characteristics of wind protection and instructions for use, which side to lay the insulation

We are talking about factory fuel for biofireplaces.

Minimum room area. The room in which the fireplace is installed must be at least 25 square meters. m.

| Name | Dimensions, mm | Characteristics | price, rub. |

| Floor-standing | |||

| DirectCheminee Universal, France/Russia | 760x335x800 | 1 TB* 2.5 l, hearth walls included, classic look | 75 000 |

| DirectCheminee Universal Х2, France/Russia | 980x345x1100 | 2 TB 2.5 l, hearth walls included, classic look | 95 000 |

| Planika CALVADOS Cherry/Ivory, Poland | 860x870x365 | 1 TB 2.8 l, wooden portal, classic look | 120 000 |

| DirectCheminee Baroque Italiano, France/Russia | 1300x400x1100 | 1 TB 3 l, portal and tabletop made of cast marble, sophisticated look | 145 000 |

| BERLONI Turin, Italy | 1100x1100x320 | 2 TB 2.2 l, MDF portal and painted steel | 58 000 |

| Horus Freedom Wall, Italy | 950x400x870 | 1 TB 2.9 l, portal made of steel and glass | 160 000 |

| Horus Tetris, Italy | 1000x1000x450 | 1 TB, stainless and painted steel, tempered glass, independent location | 177 000 |

| Wall mounted | |||

| Planika Wallfire, Poland | 360x810x210 | thermostat, fan heater, stainless steel/glass, 2.5–3.7 kW | 191 000 |

| Horus ZEN, Italy | 1200x340x450 | steel/glass, 2.1–2.8 kW | 140 000 |

| Horus Closer inox Frame, Italy | 640x640x220 | steel/glass, 1.8–2.2 kW | 110 000 |

| DirectCheminee Premier, France/Russia | 800x250x500 | Any finishing option from any material, 1.8–2.6 kW | 42 000 |

| DirectCheminee Autofire 146 electronic, France/Russia | 1460x290x620 | Fully electronic control system, flow rate 1 l/hour, 6.2 kW | 300 000 |

| DirectCheminee Monumentale Huge for 5 fireboxes, France/Russia | 2000x300x790 | 5 TB, painted steel, 5.8 kW | 220 000 |

| Tabletop (small) | |||

| DirectCheminee Biocandle Reed 3, France/Russia | – | Interior element, stainless steel steel | 16 000 |

| DirectCheminee Biocandle “Classic” on a marble base (Modern collection), France/Russia | – | Interior element, stainless steel steel, marble | 9 000 |

| DirectCheminee Block box 2.5 l (Artificial stone), France/Russia | 440x340x105 | Stainless steel steel, artificial stone to choose from (200 types) | 28 000 |

| DirectCheminee Block box INOX 5 l, France/Russia | 550x510x350 | Stainless steel steel, surface finish - mirror, metal, wood | 50 000 |

| Planika Simple Commerce, Poland | height 420, diameter 380 | Glass flask - Italy, burner - 1.5 l (7 hours) | 48 500 |

| Planika Stone, Poland | height 410, diameter 450 | Glass flask - Italy, Scandinavian field stone at the base, burner - 0.6 l (up to 2 hours) | 82 000 |

| Planika VERANDA GF-07 Table, Poland | height 597, diameter 700 | Glass - Italy, wood legs - teak, burner 1 l (3.5 hours) | 95 000 |

* TB - fuel block.

Choosing fuel for biofireplaces

Making a biofireplace with your own hands is not difficult. After its manufacture, you will have to regularly buy biofuel. Other types of fuel are not suitable for it; only specialized mixtures with the “bio” prefix can be poured into the burner. This prefix was given to fuel due to the fact that it contains plant or animal components.

Different brands of biofuels can be produced from beets or potatoes, or from wood chips. Unlike other types of fuel, biological fuel does not emit toxic substances during combustion, which makes it safe for human health. In addition, when burned, biological fuel produces a beautiful and even flame, which cannot be achieved by other means.

Having made a bio-fireplace with your own hands, you need to adhere to the following principles in its operation:

- Choose fuel only from well-known manufacturers, whose quality is confirmed by appropriate certificates.

- Before adding fuel to the burner, you need to wait until it goes out completely and cools down.

- To light a bio-fireplace, use a special lighter with a long metal spout.

- Keep fuel containers away from hot surfaces and open flames.

If you purchase special fireproof decorative elements for fireplaces in the form of firewood, you can use biofuel to create the complete illusion of a real fireplace. This fuel does not produce soot or unpleasant odor; the only thing a biofireplace can produce is a small amount of steam. Some manufacturers add impurities to the fuel that color the flame different colors.

Do-it-yourself biofireplace video:

Advantages of a biofireplace

Biofireplace is a new product on the market that is rapidly gaining popularity. This is not only a tribute to fashion, but also a lot of beneficial advantages.

Convenience. The purity of combustion emissions allows the use of a biofireplace without a chimney. This decisive advantage makes it an exceptionally technological product - the fireplace can be placed in any location that meets the installation requirements. It does not require a separate foundation and heat-resistant floor lining. Approximately 50% of these products are made in a portable version, the rest are mounted on the floor, walls and even suspended from the ceiling.

Manufacturability. The alcohol burner hearth can be purchased separately, without a portal. It can then be installed into the firebox of an existing traditional fireplace. This will preserve the functions and appearance of the interior and eliminate the need to prepare solid fuel and the risk of smoke. Due to the simplicity and low cost of their design, full-fledged biofireplaces are available in a sufficient range of sizes. The portal can also be made to order from any material.

Safety. Factory-made fireplaces are supplied complete with protective panels and casings, so the biofireplace portal can be made of plasterboard or wood without fear of ignition from overheating. Ignition and combustion of fuel occurs without sparks or flame fluctuations (when using a special lighter). When burned, fuel breaks down into water vapor and CO2. The concentration of carbon dioxide is insignificant and does not affect air quality if there is standard ventilation of the premises.

Functionality. In a conventional fireplace, most of the heat is removed along with toxic waste gases through the chimney. In a biofireplace, the entire combustion temperature is transferred to the surrounding air. A medium-sized device is equivalent in power to a 3 kW electric heater.

Reliability, simplicity of the device. Basic models of alcohol fireplaces do not have mechanisms, moving parts, or wearable parts. When used correctly, these are “eternal” devices (service life is unlimited). “Biocombustion” does not form carbon deposits, which reduces maintenance of the fireplace to wiping along with other interior elements. More complex and expensive models have electronic control - from a panel, remote control or Wi-Fi from a tablet or phone. Like any electronic devices, they can fail, but not more often than others.

Originality and beauty. The new bio-fireplace can be matched to absolutely any design - from minimalist cold high-tech to luxurious baroque. The portal can be ordered in any workshop, from any material. Such an open fire in the middle of the room will become the emotional center of the entire house, intuitively reminiscent of distant ancestors relaxing at night around the fire. Always even and stable flames are a “living” piece of furniture that can be moved at your discretion.

Price. The price of the device itself, together with the portal, does not exceed the price of a fireplace of the same format with a traditional or electric layout.

Pros and cons of products

The main and obvious advantage of eco-fireplaces is that visually they can replace a real fireplace and create an atmosphere of comfort and coziness in an apartment or private house. Other advantages look like this:

- the design is simple and reliable, there is nothing to break in it, which means no repairs are required;

- due to the smokeless combustion of a small amount of fuel in the room, there is no need to install a chimney;

- hot coals do not fly out of the firebox and, in general, the device is considered fireproof, provided that the manufacturer’s instructions are followed;

- ease of maintenance.

Elite and expensive models of biofireplaces are equipped with electronic control units that allow you to control the operation and remaining fuel on the display, automatically ignite and extinguish the flame, and also control the device from a distance via a cell phone. They also have built-in safety systems - protection from children and pets, rollovers, and so on. But the prices of such products start from 3000 USD. e.

Now about the disadvantages of biofireplaces:

- The burner practically does not heat the room. The flame is natural, but too little heat is generated due to the slow burning of a small amount of fuel.

- Fuel supplied to order and sold in stores is quite expensive. The cheapest bioethanol in a liter container costs from 7 USD. e., and a branded one with the smell of coffee from the Kratki brand – 16 USD. e.

- No matter how little combustion products are released, supply and exhaust ventilation is required to remove them.

History of biofireplace

The first biofireplace was invented in 1977 in Italy. The inventor of the bio-fireplace was engineer Giuseppe Lucifora. It was he who proposed using alcohol as a combustible material for fireplaces. His invention began to gain popularity primarily due to the fact that such fireplaces did not need to be equipped with a chimney.

Biofireplaces are fueled with biofuel, most often liquid - bioethanol , although today there are also gel fireplaces with the prefix “bio”.

The combustion principle used in modern biofireplaces is the combustion of alcohol vapor . Bioethanol, as a flammable substance, does not burn in the absence of oxygen - combustion can only occur on its surface, which is a mixture of light hydrocarbons. Bioethanol vapors mix with air and ignite; If the access to oxygen is eliminated, the flame will go out.

Ethanol produces carbon dioxide and water during combustion, so its combustion is not accompanied by smoke, soot and an unpleasant odor.

“Live” fire without hoods and chimneys, without smoke and soot and without additional permits. What could be more convenient?

You can place a biofireplace both indoors (for example, an apartment, house, restaurant, office, study, etc.) and outdoors (on a terrace, veranda, etc.).

See real photos of biofireplaces indoors. By the way, installation does not require special preparation of the area, as well as permitting documents.

Let's understand the principle of operation

The biofireplace owes its existence to devices invented long ago - an ordinary alcohol burner and an oil lamp. The principle of operation is as follows: an element made of finely porous material - a wick - is immersed in a container with liquid fuel. Fuel, obeying the physical law of capillary rise of liquid, saturates it to the very top and evaporates through the open opening. If these vapors are ignited, we get an even, stable flame, as shown in the photo.

The heart of a biofireplace, made from modern materials, is a round or oblong fuel block. It includes the following basic elements (shown in the diagram below):

- a stainless steel container with a filling neck, equipped with an open opening on top - a burner;

- a damper or lid that blocks air access and is intended for extinguishing a fireplace;

- fireproof ceramic filler with many small pores;

- a side system that prevents fuel from splashing out;

- small portable structures are equipped with protection against ignition when tipping over.

Mechanical biofireplaces

Mechanical biofireplaces consist of:

- fuel block providing a living flame;

- housings;

- ignition system and lid, which allows you to extinguish the fire.

Design of a biofireplace of the hearth type

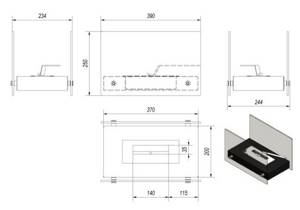

Fuel block (burner)

Only high-quality materials should be used for the biofireplace burner The best option is high-quality stainless steel. BIOART fuel blocks use high-quality heat-resistant stainless steel 5 mm thick. This material is least susceptible to oxidation and high temperatures. When heated, such steel will not deform.

All fuel blocks produced by BIOART are closed type; it is not the fuel itself that burns in them , but its vapor . This design allows you to turn the fuel block in any direction, but fuel will not spill out of it. The vapor combustion process significantly saves fuel consumption (about 1.5 times).

Advantages of BIOART biofireplaces

More information about the types of burners for bio-fireplaces can be found in our blog in the article “Types of burner designs for bio-fireplaces”.

Biofireplace body

The body of a biofireplace is its decorative part, which can be made from a variety of materials. Depending on the decorative purpose and the place where the fireplace will be placed, you can choose the following types of cases:

— panoramic housings that allow you to look at the fire from any of the 4 sides (for example, made of tempered glass or bio-fireplaces “glasses”). Biofireplaces with panoramic casings are more suitable for restaurants, pubs, bars, sofas, clubs;

- built-in - suitable for creating the illusion of a real wood-burning home fireplace. Installed in the wall. Built-in enclosures provide visibility only from the front.

Specially painted steel, metal, stones, marble, granite, veneer or fire-resistant glass can be used as decor and cladding for a biofireplace.

We recommend: Calculation of heating radiators, number of sections and battery power

What is a biofireplace

. A bio-fireplace, or eco-fireplace, is an improved version of wood-burning fireplaces . The first hints of it appeared in ancient times, when such installations consisted of a container with oil and a burning wick. Despite the development of science and technology, the principle of operation of modern biofireplaces remains the same. True, today they operate on a special liquid fuel, which is a mixture of ethanol with other substances. During combustion, it does not emit smoke or ash, but still burns oxygen. Because of this, it becomes necessary to periodically ventilate the rooms in which they are located. And perhaps this is their only significant drawback.

There are several types of biofireplaces, which are designed identically and consist of the same elements:

- Heating block - its function can be performed by a regular burner or a fuel tank with a valve that allows you to regulate the intensity of the flame. It is made from metal or stainless steel of sufficient thickness, which will protect the product from deformation under the influence of high temperature and extend its service life. The volume of the fuel tank ranges from 60 ml to 5 liters.

- Body - it depends on the design of the bio-fireplace and can take the shape of any geometric figure, or it can be stylized as a coffee table, shelf, or candelabra. It can be open or closed.

- Decorative elements - they are intended for decoration and are made of fire-resistant materials. Most often these are stones for burners of all sizes and colors, ceramic logs, tongs, pokers, forged grates and other surroundings of ordinary fireplaces.

Manufacturing nuances

When thinking about how to make a bio-fireplace yourself, the first thing that comes to mind is to find or draw a drawing or diagram of it. It will not be difficult to find such documents on the Internet or photocopy them in a store. As a last resort, you can draw drawings of a bio-fireplace with your own hands if you have the necessary skills.

A drawing of a biofireplace is necessary first of all in order to accurately verify the dimensions of the device. In this case, it is advisable to draw a diagram of each part of the system in order to understand how your bio-fireplace will be arranged inside, how the parts will be attached to the frame, and what elements will be required. A well-designed diagram of a biofireplace will subsequently greatly simplify your work on assembling the device, so when creating sketches, try to work out the details as much as possible.

Scheme of a small eco-fireplace

There are some nuances that need to be taken into account when developing such a device:

- The production of biofireplaces begins with the development of the design and general shape of the device. At the same time, do not forget about safety; you should decide how and where to install the protective screen. The glass protective screen should be placed at some distance from direct fire. It is believed that a distance of 15 centimeters will be sufficient. If the fire is closer, there is a chance that the glass will burst, even tempered glass.

- It is advisable to make the fuel tank for a biofireplace from metal with a thickness of 2-3 mm. Thinner steel sheets can simply burn out when exposed to temperature. For large fireplaces, it is best to buy a fuel block in a store; you should not neglect safety once again.

- You set the number of burners at your discretion, but experts recommend not placing large bio-fireplaces in small rooms. So for a room measuring 25-30 sq.m. You can install a couple of burners in the device, but no more.

Note that, if necessary, you can easily make a burner from a metal container of a suitable size yourself. Step-by-step instructions in this case will look like this:

- For open eco-fireplaces, the burner should be decorated; you can simply paint it the outside color of your choice. Of course, you can’t paint the inside, as the paint will certainly burn.

- A mesh is placed on top of the metal tank and secured. If the cells are too large, you can cut out several pieces. Note that the strength of the mesh is an important parameter, because we will place heavy decorative accessories on it.

- The bottom of the container is connected to the mesh with a wick. It’s okay if it shows a little; decorative elements will hide it later anyway.

When creating a tabletop fireplace with your own hands, you should experiment with the optimal size and type of burner that suits your decorative needs.

What it is

Wall mounted device

Before you start making such a product, you need to understand its purpose and operating principle. Biofireplace is an excellent alternative to real fireplaces. In this case, you get a live fire, eliminating the formation of ash and smoke. Such a device can be installed not only in a house, but also in an apartment. This is due to the fact that the fire safety requirements in a room of an ordinary high-rise building will be preserved; there is no need to make a chimney, since such a bio-fireplace does not produce smoke. The operating principle of the device is based on the combustion of biofuel. This biofuel is made from alcohol

As a result, the combustion process will not be accompanied by smoke, as well as the appearance of combustion products - soot, burning and ash. Note! Since oxygen is required for the combustion of biological fuel, the room with such a fireplace should be periodically and well ventilated. Thanks to this principle of operation, such devices can be installed not only in homes, but also in open areas. The design can be made in the following types:

wall. In this case, the mounting location is the wall. Such a device cannot be moved and is constantly located in one place;

floor;

Floor-standing device

Tabletop device

desktop.

Floor and tabletop bio fireplaces can change their location, which makes them more mobile and practical. In addition, this type of product may vary depending on how many fuel blocks (burners) it has:

- one burner. Such a number of fuel blocks is necessary for a device of small dimensions;

- several burners. Required to maintain fire in large products.

It is quite possible to make any type of the above options with your own hands. You just need to follow the instructions. The instructions for each type of biological fireplace will be almost identical, with the exception of small nuances.

What do you need to make your own bio-fireplace?

The biofireplace has a simple design, but a finished, high-quality design will cost a tidy sum. Therefore, making it yourself will be a great solution. The manufacturing process is not complicated if you have the basic materials and know the sequence of work.

So, the main elements for a do-it-yourself fireplace are:

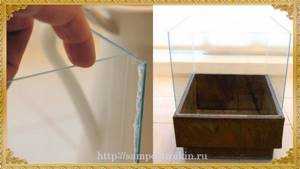

- Durable glass. Its dimensions depend on the size of the future fireplace. Choose heat-resistant, not thin glass.

- Burner made from a tin can or metal box.

- Wick cord.

- Silicone sealant for seams.

- Metal mesh with small holes.

- Special biofuel.

- Decorations made of stone, pebbles, etc.

Please also take into account the fact that when using the device, biofuel reserves must be constantly updated. There is no way to save money here, because only a special liquid will do, and other compositions are not safe in a residential area and can lead to poisoning.

Recommendations for making a burner yourself

- If your fireplace will be covered with glass for protection , then you need to look for a fireproof type option. It is also necessary to measure the distance from the glass to the open flame. It must be sufficient , otherwise the glass may crack.

- The burner must be made of stainless metal. This rule must be followed .

- Cover the burner with a mesh made of metal, then with stones or ceramic logs. This addition will help distribute heat evenly throughout the apartment.

- To light a fire, just leave the wick between the stones or logs. It needs to be soaked with fuel liquid. To make a wick, a regular shoe lace is suitable .

Step-by-step instructions for a DIY bio-fireplace

As can be seen from the previous paragraph, if you have step-by-step instructions for a biofireplace, it is very easy to make it yourself. After assembling the burner, the process is divided into the following stages:

The pieces of glass are fastened together with silicone sealant in accordance with the design idea. To dry completely, they need to be left for about 24 hours; a more precise time is indicated in the instructions for the sealant.

If desired, the base of the fireplace can be made from a rectangular metal box. Then it will hide the burner jar.

If the fuel was purchased in a tin can, you just need to place it inside the burner. If it was sold in a plastic container, you should take another tin can and pour it there. The size of the jar should be such that it is convenient to remove from the burner.

Place the pre-prepared wick into the fuel. Place a mesh over the burner and sprinkle pebbles on top of it.

To make a beautiful and simple bio-fireplace with your own hands, the step-by-step instructions above will provide you with all the necessary knowledge. The finished fireplace can be put into operation immediately, that is, the wick can be lit.

Simple tabletop biofireplace

Such fireplaces will serve as an ideal addition to any room design, and in the evening they will provide the opportunity to admire a live fire in all its glory. One of the main advantages of tabletop fireplaces is their simplicity. Let's take a closer look at how to make one of these bio-fireplaces.

To create such a fireplace with your own hands we will need:

- 4 glasses.

- A base box made of metal or other fire-resistant material.

- Glass cutter.

- Sealant for glass bonding.

- Steel mesh.

- Fireproof stones for decoration.

- Fuel container.

Step-by-step instructions for making a desktop biofireplace:

- We calculate the dimensions of the future structure. For one burner, the minimum distance between the glasses is 15 cm.

- We adjust the glass to the dimensions of the box. If they fit true to size, great. Otherwise, you need to cut off the excess with a glass cutter. The glass box after connection will be installed on the base.

- We connect the glass with sealant. To do this, apply sealant to the end of the glass and connect it at right angles to the other glass. It will take at least a day for the sealant to dry completely. To do this, stands are installed under each side.

- A glass box without a top or bottom is installed on a base. If the calculations were done correctly, then he should definitely be on the edge. To fasten the glass and the base, we again use sealant.

- We place a burner with biofuel in the center of the base and cover it with a steel mesh. It must be cut so that its edges lie on the edge of the base. It is recommended to lay the mesh in several layers so that it does not collapse under the weight of decorative stones.

- Place the stones in an even layer on the mesh. If you use natural stones collected with your own hands, they must be washed. In this case, when heated, they will not emit an unpleasant odor.

- If necessary, light the burner and check the result.

Important! This design is very easy to assemble, but has a number of disadvantages. First of all, it is impossible to replenish fuel without disassembling part of the fireplace

The second disadvantage is the lack of a combustion regulator. As a result, neither the flame intensity nor the fuel consumption can be changed.

Instructions for assembling a large bio-fireplace

If you need to make a large bio-fireplace, the most difficult part will be making the fuel tank. The easiest way is to purchase a ready-made element in a specialized store.

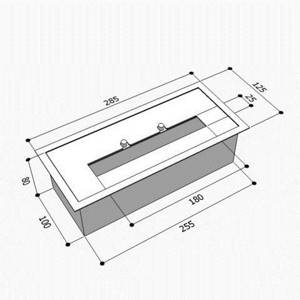

If you plan to make the tank yourself, you need to take a sheet of metal more than 3 mm thick. It must be stainless steel, otherwise during combustion there may be unwanted chemical reactions and even the appearance of toxic fumes.

Specialized stores sell fuel tanks for biofireplaces made of stainless steel. They are equipped with convenient fire extinguishing valves

The tank itself should consist of two compartments. The lower one is for filling fuel. Vapors of flammable liquid burn in the upper compartment. Between these compartments there should be a separating plate with holes, thanks to which vapors enter the combustion zone. The shape of the tank may be different, depending on the fireplace model.

The most popular option is a parallelepiped-shaped fuel tank with a narrow upper compartment.

It is easier to make a cylindrical tank. To do this, you can take an ordinary mug and cover it with a lid cut to size from a fine-mesh metal mesh. Fuel can be poured through the mesh, which is quite convenient.

There may be several such tank mugs in the design of a biofireplace. They can be arranged in several rows or in a circle. It is important not to forget to remove the handles from the mugs. This must be done carefully so that a hole does not form.

Having decided on the fuel tank, you can start making a bio-fireplace. Let's make a floor model with two glass screens. To work, you need to prepare fire-resistant glass for screens, a fuel tank in the shape of a parallelepiped, washers, bolts and silicone gaskets for glass, plastic or metal legs.

In addition, to make the base we will need thick plywood or plasterboard, screws and 40x30 mm wood blocks.

Let's start from the foundation. We mark a sheet of plywood and carefully cut out the side parts of the base box and the top panel from it. We will not make the lower part of the box.

Firstly, its presence will significantly make the structure heavier. Secondly, it will be much more convenient to secure glass sheets without it. We are preparing two pieces of wooden block onto which the plywood will be attached.

You can make a bio-fireplace with two glass screens yourself. The design of the base can be very different - in the form of a console, table, box

On a panel cut from plywood we mark the place where the fuel tank will be fixed. Cut out the required mounting hole for the tank. Now we assemble the frame and attach the top panel to it. We process the edges of the structure well.

If we used drywall rather than plywood, its edges must be treated with putty. We decorate the resulting base in any suitable way: paint, varnish, etc.

Preparing glass panels. First, cut out two parts of the desired size. In each of them you need to drill holes for decorative fasteners. This is quite difficult, because the slightest mistake can cause the glass to crack. If you have no experience in such work, it is better to entrust the process to an experienced craftsman with a set of special tools. Holes for fasteners are also drilled on the side walls of the base.

We recommend: How to clean chimneys in a stove using folk remedies: how to clean a chimney

Now we fix the glass screen to the base. To do this, we pass a bolt through the glass, do not forget to put on a silicone gasket so as not to damage the glass. We pass the bolt through the base, put on the washer and tighten the nut. This must be done extremely carefully, without applying excessive force, otherwise the glass may crack. In this way we install both glass screens.

During the assembly process, silicone gaskets must be used, otherwise the glass may not withstand the load and crack. It is wise to use a more durable option - tempered glass

You need to place legs on the bottom of the glass sheet. To do this, we put rubber gaskets into the parts and put them in place. We check the correct installation of the legs. The biofireplace should stand level and not wobble.

Using the prepared hole, we mount the fuel tank and securely fasten it. The structure is almost ready. All that remains is to decorate it with stones or ceramic logs, if necessary.

Business idea: bio fireplaces for sale

Any business starts with an idea. Then a business plan is drawn up and its practical implementation follows.

If you decide to start producing biofireplaces, you should start with such aspects as:

- Studying the legal requirements for equipment, as well as a thorough study of the manufacturing technology of devices of this kind.

- Study of consumer demand for this type of equipment, as well as analysis of the corresponding market segment.

This will help to find out in advance how much such equipment is in demand and how difficult it is to compete with existing manufacturers. In addition, an analysis of the most popular models will suggest the main direction of activity or an alternative path. - Availability of start-up capital to start production.

- Availability or need to purchase appropriate equipment, consumables, attract qualified personnel, etc.

- The need to coordinate the start of production activities with various regulatory authorities.

- The degree of preparedness and compliance of existing legal documents with the chosen area of activity.

For example, if you are already registered as an individual entrepreneur, then your declared field of activity should include the production of biofireplaces, etc. - Determine whether, under the current conditions, a franchise is needed to successfully start production.

The production of biofireplaces is a serious production, since these devices are associated with fire, so the main requirement for a biofireplace is its safety

In general, in order to decide whether it is worthwhile to engage in the production of biofireplaces, you should get advice on all issues of interest at the centers for assistance, support and business development.

As a rule, a number of government agencies have created departments whose functions are to provide assistance to small and medium-sized businesses.

Often, the basic necessary information can be obtained from local administrations, regional bodies of Gosstandart, chambers of commerce and industry, etc.

DIY bio-fireplace burner

The most important part of a self-built biofireplace is the burner for it. Having chosen a suitable metal container, you can begin manufacturing:

- If the fireplace structure is transparent, you can paint the container from the outside. You cannot paint the inside of it, as it will burn the first time you start the burner.

- A piece is cut out of a fine mesh to cover the top of the container. This mesh serves to distribute the flame evenly, as well as for laying decorative materials, between which the wick will be visible. You need to make sure that the mesh does not fall inside the container.

The size of the grid can be varied depending on the creative idea. It should be strong enough not to sag under the weight of the stones, and large enough to cover the entire area of the fireplace.

Thus, a burner for a bio-fireplace can be made with your own hands in a matter of minutes.

Types of biofireplace inserts

There are only two main types of fuel block. These are mechanical and automatic units. Automatic ones are equipped with a ventilation system, software, operate from an outlet and have an autostart function. Mechanical ones are a metal container into which you pour fuel and light it yourself.

“You can read more about automatic biofireplaces in

our article

»

Automatic fuel blocks have an isolation system that prevents fuel from spilling when the fireplace is tipped over, and the block itself is completely sealed. Mechanical blocks, in turn, can be either with or without filler.

Rules for the safe use of fireplaces

Despite the fact that biofireplaces are one of the safest fireplaces in the home , during their operation you need to follow simple rules .

- Models with an open combustion chamber must be installed at a considerable distance from combustible objects: textile interior elements, bookshelves, curtains.

- The surface on which the fireplace is installed must be level and stable, especially for models using liquid fuel.

- You should not leave the fireplace uncontrolled or trust children to light it.

- If the fireplace is not in use for a long time, drain the fuel from it. Bioethanol must be stored in a place that prevents overheating and contact with open fire.

- Fuel can only be added to a fireplace that is extinguished and has completely cooled down.

- Ignition is carried out with a special lighter for bio-fireplaces, which prevents burns.

- Bio-fireplaces can only be decorated using elements specially designed for this purpose: stones, imitation coals and logs made of heat-resistant ceramics.

- Built-in models must be installed in niches made of fire-resistant materials.

Burner decor

The following elements will help turn an unimpressive fuel block into a fireplace conducive to cozy conversation:

- Stones. Not all natural rocks are suitable, so it is better to purchase special stones in the store. Artificial ones are very popular - in various colors or even completely transparent.

- Ceramic imitation of logs.

All kinds of accessories designed for real fireplaces are used as decorative elements: tongs, poker, grate, etc.

How to choose?

In addition to design and execution, biofireplaces have a number of characteristics that need to be taken into account when choosing and purchasing. These include:

- power,

- control system;

- acceptable fuel type.

The power of the biofocus depends on the size and design of the fuel tank and burner . Bioethanol burns over the entire surface, so the larger the area of the fuel block, the more intense the flame, and therefore the greater the heat transfer and fuel consumption. Some models consist of several fuel blocks, which allows you to regulate the intensity of combustion.

The control system can be manual , it involves igniting the fire using a lighter, manually extinguishing it with a valve, and regular combustion control. Modern models of biofireplaces are fully automated , they feature remote control, auto-ignition, a system for monitoring fuel flow and combustion intensity, and also have built-in fuel and carbon dioxide sensors. Such models are much more expensive, but their safety and ease of use are higher.

The type of fuel determines the design of the fuel tank. Biofireplaces use special liquids or gel compositions ; each type of fuel has both pros and cons. The gel is more convenient when using small mobile models with an open chamber - it is not afraid of tipping over, does not spill, and is also odorless. The flame when the gel burns is indistinguishable from natural fire. Alcohol-based liquids are used primarily in large stationary models.

Types of models

Biofireplaces have two main design elements:

- Burner . This element has its advantages and disadvantages. The main advantage is considered to be the low price and the ability to install several elements in one structure. A disadvantage is that the flame is constantly open as there is no protective screen. The flame in this design is also not adjustable. Special devices are used to extinguish the wick of a biofireplace, but this almost always creates an unpleasant odor in the room. A homemade burner for a biofireplace is the best option for those who want to save money. This element is a small container filled with bioethanol.

- Fuel tank . This element has a big advantage - the absence of unpleasant odors. With the help of a damper, vapors do not enter the room and the flame can be extinguished at any time. This block has a sealed design, the combustion intensity is smoothly adjustable. But this one is a little overpriced. It is unlikely that you will be able to complete such a design yourself, even if you have the drawings.

How much do popular models cost?

If you study the list of popular models that are in constant demand, you get the following price picture as of April 2019:

| Model | Type | Average cost, rub. |

| BRADEX Prometheus | Desktop | 1699 |

| Kratki Delta 2 | Built-in | 10398 |

| Silver Smith Standard | Floor | 20900 |

| Zefire Elliot 1200 | Built-in | 29800 |

| Planika Automatic III 1190 | Built-in | 743660 |

| GlammFire Hypnosz | Wall | 593861 |

| Lux Fire Poster M | Desktop | 6812 |

| Berloni Turin | Wall-mounted | 35000 |

What does a biofireplace look like in the interior?

Below are photographic examples of the location of various bio-fireplaces in the interior.

The tabletop fireplace can be installed anywhere in the room

Wall-mounted fireplaces look best in small rooms with an elongated shape. They take up little space

If you want to use a bio-fireplace as a decorative element of the interior, place it on a long wall opposite the sofa and armchairs - from here you can comfortably watch its operation

A large fireplace at the end of the room or in the partition will help visually expand the area and make the room more spacious

Decorate the bio-fireplace as usual: with family photos, candlesticks, logs. You can hang a picture or TV above the fireplace

As you can see, an alcohol fireplace is an excellent solution for a city apartment, which does not require any drastic alterations from you. In conclusion, we offer you a short but useful video on the topic, and we expect useful information from you about your own experience with biofireplaces in the comments!

Watch this video on YouTube

general information

The biofireplace is a simple system, the basis of which is the combustion of liquid fuel, bioethanol. Biological fuel is nothing more than natural alcohol, so when burned, only steam and a small part of carbon dioxide are released. Pure alcohol burns with a blue flame, but a yellow fire should blaze in a fireplace, so bioethanol contains various additives that add realism to the fire.

The simple operating principle of the system allows you to make a bio-fireplace for your apartment with your own hands. At the same time, you will not have to make excessive efforts during the work process, and the cost of materials will be insignificant, but as a result you will receive an original piece of furniture that will bring the warmth of a real living fire into your home.

Let us note that it is important not only that a homemade bio-fireplace is easy to manufacture, but also that for its operation it does not require the installation of a chimney, an exhaust hood, or the installation of engineering systems and communications. All that is needed for the full operation of the system is regular ventilation of the room to supply fresh air saturated with oxygen. After all, as you probably know, oxygen is actively used in the combustion process of alcohol fuel.

Modest biological fireplace

Despite the fact that the operating principle and design of a biofireplace are always the same, there are a large number of different variations in the design of this device. Most often you can find the following varieties in stores:

- Floor-standing options can be installed along the wall or designed to be placed in the corner of the room. These systems can be large or small in size, allowing the bio-fireplace to be moved anywhere in the room.

- Hanging and built-in options have more modest dimensions. Such eco-fireplaces are hung on walls or mounted in special niches prepared in advance for these purposes. An interesting point is that such devices are fixed both in walls and in furniture, for example, in cabinets, on coffee tables.

- Tabletop options are a miniature version of a floor-mounted biofireplace. These decorative devices will fit perfectly on your table, shelf or nightstand. The easiest way to make a desktop biofireplace yourself is to fully evaluate how such devices work.

Tabletop variation on the biofireplace theme

Regardless of which biofireplace design is chosen, factory models usually provide the ability to adjust the height and pressure of the flame. If you make it yourself, this can be done by working with burners.

Adviсe

It is worth remembering that all safety requirements must be strictly observed:

- A fireplace is not a toy for children. When using it, you should make sure that there are no children near the fire.

- Storing biofuels near a fire source and in the public domain is prohibited.

- Do not add fuel while the fireplace is operating. It is worth waiting until the equipment cools down.

- Ignition is carried out only with the help of a special lighter.

The bio-fireplace serves as an excellent interior decor, and at the same time, it can also be improved. For example, place ceramic logs on the grill that imitate real firewood. This fire source can be used not only indoors, but also outdoors. For example, decorate a gazebo with a corner homemade eco-fireplace.

How to make a floor structure

The advantage of floor-mounted bio-fireplaces is their variety of shapes and sizes. They can resemble a geometric figure, a bowl or a cabinet, and remain stationary or mobile. But the heating block for them must be made of metal. The body itself can be made of stone, wood, plastic, ceramics or plasterboard. The main thing is to ensure that the fire does not affect flammable elements.

Required materials and tools

- heating unit;

- non-flammable drywall (1 sheet);

- metal profile with guides and rack elements (8 - 9 m);

- dowel-nails, screws for metal and with a countersunk head;

- heat-resistant tile adhesive, putty;

- metal scissors, screwdriver, knife for cutting drywall;

- insulating materials (2 sq.m);

- ceramic tile;

- grout (about 2 kg);

- building level, tape measure;

- wood or other material for the mantel;

- decor for decorating a finished bio-fireplace.

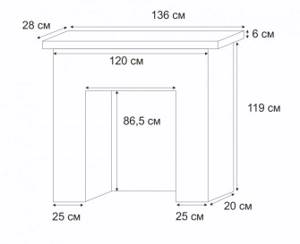

All calculations must be made taking into account the size of the space for the future bio-fireplace. One of the options is shown in the drawing.

Preparatory work

The drawing must be created taking into account fire safety

At this stage, you need to decide on the size and design of the biofireplace: large or small, wall-mounted, corner or located in the center of the room. After this, a drawing or sketch is created taking into account the fire safety of the object. When calculating its dimensions, you need to ensure that the distance from the hearth to the walls of the structure and the mantelpiece is at least 15 - 20 cm. After this, based on the drawing, markings are applied to the wall and floor.

Step-by-step manufacturing instructions

The process involves several stages: from fastening the profile to decorating the sheathed drywall

- Frame assembly. According to the finished markings, pre-prepared guide profiles are attached. Then rack elements are inserted into them, which are subsequently secured with self-tapping screws. Verticality is controlled using a plumb line.

- Fastening profiles to the wall using dowels and nails. In this case, the racks are additionally secured with jumpers.

- Laying insulating material into the walls of a structure. They can use compressed basalt wool.

- Plasterboard sheathing. To do this, you need to mark the sheets of drywall and cut off unnecessary elements using a special knife. The main thing is to make an incision on one side, breaking the material on the other. When covering the future structure, you need to screw in the screws at a distance of 10 - 15 cm from each other. Upon completion of this work, gypsum plaster should be applied.

- Bio fireplace finishing. To do this, the walls and bottom of the housing are covered with ceramic tiles, with the exception of the recess for installing the burner.

- Grouting joints. After it, the mantelpiece is installed, and the structure itself is decorated with prepared decorative elements - stucco molding, mosaics, facing bricks.

- Burner installation. You can purchase it or make it yourself from a metal glass in which the wick is lowered. In the latter case, you won’t be able to adjust the flame height, but you won’t have to pay for a factory design.

If you have time, desire and a welding machine, you should build a fuel block with a valve yourself. The principle of its operation is the same, only such a burner should consist of one or two chambers connected to each other by perforation. In this case, it will no longer be the fuel that burns, but its vapor, however, this will allow you to control the intensity of the flame.

The final stage may be the installation of a forged or fireplace grille made of heat-resistant glass, which will provide an additional level of safety for household members.

Due to the bulkiness of floor-mounted biofireplaces, they are often designed in the form of corner structures. The latter can be symmetrical or asymmetrical, when a column is installed instead of one of the back walls near the fireplace. Their installation is practically no different from the installation of standard floor biofireplaces, with the exception of the drawing.