Supply ventilation with air heating includes the following elements: one or more heating fans or a radiator (heating element) with high heat transfer. An air filter that serves as a barrier to large dust particles. Some models use humidifiers and ultraviolet bacterial filters. Together, such a ventilation system provides good air exchange, heating, cleaning and humidification of the supply air. This is especially important in winter. Therefore, heated ventilation is the best option for all types of residential buildings.

What is supply ventilation with air heating

Complete set of compact heated ventilation for an apartment

Ventilation with a heat exchanger provides a continuous supply of heated fresh air flow. This creates a good microclimate. Ventilation providing heating of incoming air masses includes: central supply and exhaust equipment with a recuperator, which provides heating of air coming from the street. This occurs due to the temperature of the exhaust air being removed. The recuperator, passing air, does not mix it with the exhaust air masses. That is, air enters and exits through individual channels, the walls of which are located end-to-end.

Heating of the supply ventilation can be carried out using recirculation (air conditioners, heaters). Warm “exhaust air” is mixed with supply air, which is heated to the desired temperature and then supplied to the room.

How to use a fan heater

The main purpose of a fan heater is to heat air masses. For more intense circulation of flows, the fan forces air into the air. This makes this device universal.

Options for operating the fan heater:

- This device can be used as the main source of heat supply to a room that does not have central heating.

- The fan heater can complement the main heating system.

- For heating construction sites and workers on them.

- For quickly heating air in a small room.

- The fan heater can be used as a regular fan: in winter for heating, in summer for cooling the air.

- For ventilation and heating of enclosed spaces.

Design Features

Essential elements

- Air intake grille. It has both a decorative purpose and serves as a barrier to dust and other particles contained in wind masses.

- Valve. When ventilation is turned off, the valve blocks the passage for fresh air, creating an insurmountable barrier. In winter, it can block a lot of air flow. You can automate its operation using an electric drive.

- Filters clean wind masses. They need to be changed every six months.

- Water, electric heater, which performs the function of heating the air.

- For small buildings it is advisable to use an electric heater. In large rooms it is better to use a water heater.

Additional items

- Diffusers - help distribute air.

- Fans.

- Silencer.

- Recuperator.

Connecting a water heater

Air flow using a water heater can be performed in two versions, right and left. It depends on where the mixing unit and the automation unit are located. When the air supply unit is considered from the air valve side, then:

- Left-hand execution means that the automatic unit and mixing unit are located on the left side;

- Right-hand execution means that the automatic unit and mixing unit are located on the right side.

In each version, the connecting pipes are located on the air intake side, where the air valve is installed. Depending on the version, there are the following features:

- In the right-hand versions, the supply tube is located at the bottom, and the “return” tube is located at the top;

- In left executions everything is different. The supply is at the top and the outflow is at the bottom.

Because in air supply installations using water heaters, a mixing unit is required, the latter must contain a 2 or 3 way valve. You need to select a valve based on the parameters of the heat supply system. For individual circuits of autonomous heating systems, which can be a gas boiler, a three-way valve is required. If the air handling unit is connected to a central heating system, then a two-way valve is required. To summarize, the choice of valve depends on:

- System type;

- Temperatures of supply and return water;

- Pressure drop between the supply and return pipes if the system is central;

- Is there a separate pump on the ventilation supply circuit if the system is autonomous?

When installing a circuit with a water heater, installation in a position where the input and output pipes are located vertically is prohibited. Also, installation should not be carried out if the air intake is located at the top. This is due to the fact that snow can get into the inflow of the installation and melt there, which threatens water penetration into the automation. In order for the temperature controllers to work correctly, it is necessary to place the temperature sensor inside the air duct exhaust so that the area is even in length at least 50 cm from the inlet installation.

You should also know that:

- It is prohibited to install an air supply unit 100 – 3500 m3/h if the motor axis is vertical;

- It is prohibited to install air supply units where they may be exposed to moisture or chemically active substances;

- It is prohibited to use the air handling unit where there is direct influence of precipitation on the installation;

- It is prohibited to block access for servicing installations;

- To install the air handling unit in a heated room and avoid condensation on the supply air duct, it is necessary to use only a thermally insulated air duct.

There is nothing particularly complicated in installing air heaters; you just need to follow the rules and observe safety precautions. Sometimes it is better to entrust this matter to professionals and be sure that all work is completed taking into account all requirements.

Heating of influent masses using recirculation

Ventilation with heating due to recirculation, speaking in general terms, works according to the following principle:

- air enters the house through the influx of the ventilation system;

- after a certain period of time, it enters the exhaust system, where part of the incoming air masses is removed outside the house;

- the remaining air enters the mixing chamber.

In the mixing compartment, fresh air is mixed with “exhaust” air, thus heating cold wind masses (if the system in the control settings is set to air heating mode, and not vice versa). Next, the air flow is directed to the heater or air conditioner, then through the ventilation ducts into the house.

Important! Recirculation reduces the load on the air handling system (air conditioning). In order for the air in the room to remain clean during recirculation, the following conditions must be adhered to: the influent masses must be at least 10%, and the air entering the room may contain no more than 30% of harmful substances.

Ventilation options

In cottages and private houses there are several main options for ventilation.

Natural - from the bathroom, kitchen and necessarily the boiler room (this room requires a constant supply of fresh air to maintain the combustion process and remove air with carbon monoxide).

Forced exhaust ventilation - from the bathroom, kitchen and natural from the boiler room. In this case, a fan is installed in each bathroom or bathroom, which is turned on along with the light, either with a separate button, or through a time delay relay to turn off some time after the light is turned off.

Forced supply and exhaust system - if you need a complete ventilation system for residential premises so that the house always has a comfortable internal climate, then you need to use a forced supply and exhaust system. Here it is more appropriate to use a system with heat recovery, i.e. heating the incoming air due to the exhaust air. This will save energy, since the volume of supply air for the whole house is assumed to be quite large and the power for the heater will be equal to almost the entire allocated power for the house.

But with the ventilation of restaurants and cafes, everything is somewhat more complicated.

Even a small cafe or restaurant is a rather complex facility in terms of ventilation from the point of view of standards and is under special attention of inspection authorities (SES, Rospotrebnadzor, etc.). Depending on the functions, any establishment must be divided into several zones: kitchen, bathrooms, hall with visitors, utility rooms

The kitchen must be equipped with an autonomous exhaust system above the stoves in addition to the general supply and exhaust system

The supply and exhaust system of the hall with visitors ensures continuous air exchange, and it is important not to forget that the amount of supplied air must exceed the amount of air removed; this will create a so-called “air pressure” that will not allow odors from the kitchen to penetrate into the hall. In the smoking area (due to the anti-tobacco law, this is now only relevant for establishments where you can smoke hookahs) the opposite is true - there should be a slight vacuum so that tobacco smoke disappears more actively. In the smoking area (due to the anti-tobacco law, this is now only relevant for establishments where you can smoke hookahs) the opposite is true - there should be a slight vacuum so that tobacco smoke disappears more actively

In the smoking area (due to the anti-tobacco law, this is now only relevant for establishments where you can smoke hookahs) the opposite is true - there should be a slight vacuum so that tobacco smoke disappears more actively.

Utility rooms and pantries have their own system, preferably automated (for example, if food is stored, it is convenient to set the necessary parameters - temperature and humidity).

Supply and exhaust ventilation in cafes and restaurants

Systems with recuperator

The supply air can also be heated using a recuperator. These devices are divided into two types:

- Rotary recuperators operate using electricity. A rotor element is mounted inside the cylindrical housing, which continuously rotates between the supply and exhaust air valves. The size of this type of recuperator is quite large. Efficiency reaches 87%.

- Plate recuperators consist of plates that are joined together. Fresh air and “exhaust air” pass through separate channels towards each other. They do not mix, the cold supply air is heated by the warm exhaust wind flow. Such recuperators are compact.

Principle of operation

Heated ventilation is simple.

Air masses coming from the street go through several stages of processing:

- First they enter the air intake equipped with a grille. It traps large debris and prevents insects and contaminants from entering the system.

- Air is supplied into the channel and enters the internal housing of the device. Here it goes through several stages of purification. A filter system is installed inside to remove various small contaminants and dust. To prevent the wall from freezing, the air duct is made of insulated plastic pipe. Sound insulation is also used, which makes the device operate quietly.

- Then the air masses are fed into the heater. Here they are heated to a predetermined temperature. Its level is constant and maintained automatically.

- Warm air passes to the finest filters, where fine dust, allergens, odors, etc. are removed from it.

- Purified heated air masses are supplied to a fan, which directs them into the room.

- To control the air supply, a remote control or a unit mounted on the wall is used. The device is installed quickly, within an hour.

Automated air heating in supply ventilation

Options for constructing round and rectangular ventilation shafts - the system is automated

- The operation of the equipment is controlled using a control panel (CP). The user presets the mode for regulating the supply air flow and temperature.

- Using a timer, the heated ventilation system automatically turns on and off.

- Equipment that provides heating can be connected to an exhaust fan.

- Heaters are equipped with a thermostat that prevents fire.

- A pressure gauge is installed in the ventilation system to monitor pressure differences.

- A shut-off valve is installed on the supply ventilation pipe; it is designed to block the entry of incoming wind masses.

Attention! Automatically controlled supply ventilation in a heated private house is expensive to maintain. Installation and maintenance are carried out only by specialized companies. Although it is very convenient to use.

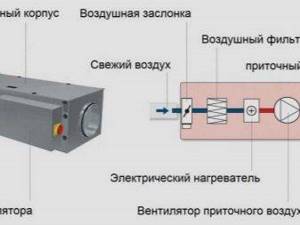

Integration of the heater into the ventilation system

It is possible to properly install the necessary heating in the inlet at the stage of installation of the entire ventilation system, since disassembling a ready-made complex to integrate a separate unit is a rather labor-intensive process. But to install a water heater, this procedure is practically impossible, since this unit must be connected to the heating system of the apartment.

To install an electric heater into a ready-made and functioning ventilation system, it is necessary to disassemble the latter up to and including the unit with the fan.

The figure shows a schematic design of a supply ventilation system suitable for an apartment with heating of street air using an electric heater

The heater is installed in front of the fan immediately after the filters.

This location is due to the fact that in winter the lubricant of bearings in radial fans tends to thicken, which can cause jamming of parts and overheating of the winding. The heating element neutralizes the effects of cold and prevents damage to such an important unit.

Supply ventilation with water-heated air

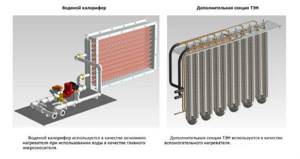

The air is heated to the required temperature by a water heater. It is presented in the form of a radiator with tubes containing coolant. The pipeline has fins that increase the area of contact with the circulated air.

The principle of operation of the system is as follows: the coolant heats the tubes to the desired temperature, they transfer heat to the fins, which in turn heats the air. Thus, heat exchange takes place.

Supply ventilation with water heated air is much more profitable than heating using electricity. On the other hand, there is water inside the water heater, so there is a risk of it freezing with minimal radiator operation.

The power of such a device is adjusted using electrical and plumbing components.

- Area with controller and temperature sensors. Servomotor that controls the valve.

- The mixer is responsible for heating the water in the heating equipment to the required temperature.

The electrical component will control the plumbing unit. It is enough to set the required air heating temperature, and the system will execute this program.

Where to place the supply vent?

The supply vent should be placed on the wall opposite to the wall with the hood.

The following places are suitable for placing the supply channel:

- under the window;

- in the wall next to the window;

- in the window frame.

Modern plastic windows, in most cases, are initially equipped with a supply ventilation valve with a filter and damper. This configuration makes the operation of the valve adjustable and as convenient as possible.

A hole for air flow can be made in the wall. But if in the region where you live the temperature in winter goes far beyond zero, icy air will flow into the room through such a channel. Because of this, condensation or even frost will begin to appear on the wall.

To solve this problem, ventilation systems are equipped with special air heaters.

Ventilation in the apartment

The most optimal place to place a supply vent is the space under the window sill. During the operation of such ventilation, no significant problems or inconveniences arise. At the entrance to the room, the air will be sufficiently heated by the heat of the heating radiator, which eliminates the need to install additional heaters.

Ventilation valves can have different shapes. There are no specific recommendations for choosing a form. Choose the valve that is most convenient for you to install and use.

Ventilation kit

- Sledgehammer.

- Spanners.

- Locksmith's hammer.

- Hammer.

- Screwdriver.

- Ratchet wrench.

- Clamps.

The installation kit can be expanded or reduced depending on the method you choose for arranging the supply ventilation. At this point you must find your way on your own.

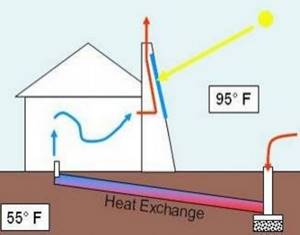

Another solution

In conclusion, we can offer another option for heating the supply air, which is used less often in practice - a solar collector. It runs on the sun.

The solar collector, where the air is heated, is usually large. After all, it must ensure heating of the required amount of air, even with minimal operation. Collectors of this type are more profitable than water ones; they do not freeze.

Conclusions and useful video on the topic

As an example of the implementation of a home “supply”, although of dubious quality, we offer the video below:

The idea of a heated “air supply” for a city apartment (private house) has a right to exist. Moreover, the possibility of implementing such an idea cannot be ruled out, provided there is a deliberate, rational approach.

It is worth emphasizing: when arranging this kind of system in an apartment or in a house, it would be reasonable to calculate how effective the air exchange will be as a result. You should also take into account the “drying” factor of the air passed through the heater. Thus, the high-quality implementation of an idea is a complex, ambiguous issue that clearly cannot be resolved on the fly.

Do you still have questions about arranging the heating of the “inlet”? Or would you like to share your own experience in assembling and installing supply ventilation? Ask your questions to our experts, share your experience, take part in the discussion of the issue - you can leave your comments in the feedback block located below.

Kinds

Heaters for supply ventilation are classified according to the type of heat source and can be water, steam and electric.

Water models

They are used in all types of ventilation systems and can be of two- or three-row design. The devices are installed in ventilation systems of rooms whose area exceeds 150 square meters. This type of heater is absolutely fireproof and least energy-consuming, due to the possibility of using water from the heating system as a coolant.

The principle of operation of water heaters is as follows: street air is taken in through air intake grilles and supplied through an air duct to coarse filters. There, the air masses are cleaned of dust, insects and small mechanical debris, and enter the heater. A copper heat exchanger is installed in the heater body, consisting of links arranged in a checkerboard pattern and equipped with aluminum plates. The plates significantly increase the heat transfer of the copper coil, which significantly increases the efficiency of the device. The coolant flowing through the coil can be water, antifreeze or a water-glycol solution.

Cold air flows passing through the heat exchanger take heat from metal surfaces and transfer it into the room. The use of water heaters makes it possible to heat air flows up to 100 degrees, which provides ample opportunities for their use in sports facilities, shopping centers, underground parking lots, warehouses and greenhouses.

Along with obvious advantages, water models have a number of disadvantages. The disadvantages of the devices include the risk of water freezing in pipes when temperatures drop sharply, and the inability to use heating in the summer when the heating system is not functioning.

Steam models

They are installed at industrial enterprises where it is possible to produce large amounts of steam for technical needs. Such air heaters are not used in domestic supply ventilation systems. Steam acts as a heat carrier for these installations, which explains the instant heating of passing flows and the high efficiency of steam heaters.

To prevent this from happening, all heat exchangers undergo a leak test during the production process. Tests are carried out using jets of cold air supplied under a pressure of 30 bar. The heat exchanger is placed in a tank with warm water.

Electric models

They are the simplest option for heaters and are installed in ventilation systems serving small spaces. Unlike water and steam heaters, an electric heater does not require the installation of additional communications. To connect them, it is enough to have a 220 V outlet nearby. The principle of operation of electric heaters is no different from the principle of operation of other heaters and consists in heating air masses passing through heating elements.

Even with a slight decrease in this indicator, the electric heating element overheats and breaks down. More expensive models are equipped with bimetallic thermal switches that turn off the element in case of obvious overheating.

The advantages of electric heaters are simple installation, no need for piping, and independence from the heating season. The disadvantages include high energy consumption and the inappropriateness of installation in powerful ventilation systems serving large spaces.

Kinds

By what criteria can air heaters be classified?

Heat source

It can be used as:

- Electricity.

- Heat generated by an individual heating boiler, boiler room or thermal power plant and delivered to the heater by a coolant.

Let's look at both schemes in a little more detail.

An electric heater for supply ventilation is, as a rule, several tubular electric heaters (TEHs) with fins pressed onto them to increase the heat transfer area. The electrical power of such devices can reach hundreds of kilowatts.

With a power of 3.5 kW or more, they are connected not to an outlet, but directly to the panel with a separate cable; With a power of 7 kW or more, a power supply of 380 volts is strongly recommended.

The photo shows a domestic ECO electric heater.

What are the advantages of an electric heater for ventilation compared to a water heater?

- Easy to install. Agree that it is much easier to connect a cable to a heating device than to organize the circulation of coolant in it.

- No problems with thermal insulation of the liner. Losses in the power cable due to its own electrical resistance are two orders of magnitude less than heat losses in a pipeline with any coolant.

- Simple air temperature setting. To ensure that the supply air temperature is constant, it is enough to install a simple control circuit with a temperature sensor in the heater power supply circuit. For comparison, a water heater system will force you to solve the problems of coordinating the air temperature, coolant and boiler power.

Does the power supply have any disadvantages?

- The price of an electric device is slightly higher than a water one. For example, a 45-kilowatt electric heater can be bought for 10-11 thousand rubles; a water heater of the same power will cost only 6-7 thousand.

- More importantly, when using direct heating with electricity, operating costs are prohibitive. To heat the coolant, which transfers heat to the water heating system, the combustion heat of gas, coal or pellets is used; This heat per kilowatt is much cheaper than electricity.

| Thermal energy source | Cost of a kilowatt-hour of heat, rubles |

| Main gas | 0,7 |

| Coal | 1,4 |

| Pellets | 1,8 |

| Electricity | 3,6 |

Water heaters for supply ventilation are, in general, ordinary heat exchangers with developed fins.

Water heater.

Water or other coolant circulating through them transfers heat to the air passing through the fins.

The advantages and disadvantages of the scheme mirror the features of the competing solution:

- The cost of the heater is minimal.

- Operating costs are determined by the type of fuel used and the quality of insulation of the coolant distribution.

- Air temperature control is relatively complex and requires a flexible circulation and/or boiler control system.

Materials

For electric heaters, aluminum or steel fins on standard heating elements are usually used; A heating scheme with an open tungsten spiral is somewhat less common.

Heating element with steel fins.

Water heaters are characterized by three design options.

- Steel pipes with steel fins ensure maximum low cost construction.

- Steel pipes with aluminum fins, due to the higher thermal conductivity of aluminum, guarantee slightly greater heat transfer.

- Finally, bimetallic heat exchangers made of copper pipe with aluminum fins provide maximum heat transfer at the cost of slightly lower resistance to hydraulic pressure.

Non-standard execution

A couple of solutions deserve special mention.

- Supply units are a heater with a pre-installed fan for air supply.

Supply ventilation unit.

- In addition, the industry produces products with heat recuperators. Part of the thermal energy is taken from the air flow in the exhaust ventilation.

Where can I buy

Do you want to buy an electric duct heater or water heater for your home, office or cottage? Are you unsure about your choice? We will be happy to advise you, select the right model, if necessary, we will make a ventilation project and, of course, we will carry out high-quality installation of this equipment in Moscow and the region on time! Our company sells duct heaters and water heaters not only in Moscow and the region, but throughout Russia.

Call - multi-channel tel.,

send applications by mail