A diesel heater, as a rule, is not as small and lightweight as a gas heater, but it is more economically profitable. The gas is weightless, tourists put the equipment in a backpack and go on foot along with the heater. The hourly wage for pleasure is a little higher. Advantages of a diesel fuel heater: buy fuel at a gas station (it is prohibited to fill the gas cylinder), or a car with a diesel engine (SUV) will give you a liter or two of flammable liquid. Therefore, mass in the latter case is not a key factor. Diesel fuel, unlike gas, weighs a lot!

Where can it be used

Regardless of the type of fuel (diesel or gasoline), all catalytic heating devices have one important advantage - they can work for a very long time and are not controlled by humans. This means that such heat sources are fire and explosion-proof and can be used in everyday life.

Also, such stoves will find their use in garages, warehouses and workshops, in cabins and construction sites, and will heat a greenhouse, cottage or country house.

Mobile models are indispensable when camping - for heating tents and heating food. A gasoline portable heater is familiar to any traveler.

Common types

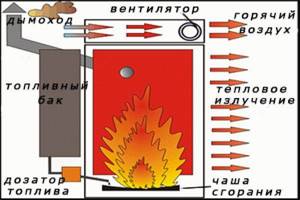

Forced air heating devices are widely used. Thermal energy in them is created due to the combustion of diesel fuel. This heat is used to heat the metal or ceramic element, and when the fan is turned on, warm air begins to circulate and warm up the room. They are best used in large rooms, without air flow and drafts. Such heaters are very effective and inexpensive.

Infrared diesel heaters. Infrared radiation is similar to solar radiation; it warms up objects and people first, and then the air. Infrared heaters using diesel fuel are also installed. An important advantage of this type of heating is the instant heating of objects located close to it. The devices are well suited for rooms with drafts.

Diesel infrared heat sources consume electricity very economically, and by connecting a generator, you can create your own autonomous heating.

Due to the fact that diesel fuel burns completely, such devices do not require smoke removal. They are often installed outdoors and in street cafes. The disadvantage of such heat sources is their inability to warm large rooms.

If we compare air and infrared types of devices, the first is significantly inferior to the second, since it dries out the air in the room quite strongly.

Diesel heating boilers operate on the same principle as turbocharged gas appliances. Their similarity is also in easy control using electronics in automatic mode.

Compact appliances – a kind of potbelly stove with a fan – are very popular on the market. They come in 2 types:

- with direct heating (without chimney);

- with indirect heating.

The operating principle of a potbelly stove with indirect heating is very simple. Liquid fuel enters the combustion chamber, where it is burned thanks to the air supplied by the fan. Passing the heat exchanger, warm air rushes into the room, heating it throughout the entire area. This heating device is very often used in garages. The design of heating devices allows you to: control the fuel consumed and regulate the temperature.

Basically, all modern diesel stoves have a flame control system, which means that if the device overheats, it will automatically turn off.

Operating principle of a gas heat gun

Using an electric motor, a fan is started, sucking cold air inside the gun. Fuel in the form of gas enters the burner through the reducer. Ignition occurs through a piezoelectric element (the safety of the unit is ensured by an automatic system with a temperature sensor that stops the gas supply if the flame goes out). The heated air flows passing through the gun are pushed out by a fan.

Some features of gas heat guns

- Possibility of quick connection and replacement of a gas cylinder

- Stable operation even in severe frost (in the worst case, you need to shake the cylinder)

- The efficiency of the device is close to 100%

It is important to remember that when the unit is operating, oxygen in the room is burned, so when heating the room there should be no people in the room, and after the unit has finished operating, ventilation is necessary

Types of autonomous diesel fuel heaters

To begin with, we list all the types of heating devices that use liquid fuel and are most often used by users:

- mini-ovens “Solyarogaz” with a power of 1.8-5 kW from the Russian brand Savo and their analogues;

- various diesel fuel heaters with forced air supply, also known as heat guns;

- a simple direct combustion stove for a garage is one of the most popular home-made designs;

- stove - dropper.

Diesel industrial air heater

Note. The first 2 types of diesel fuel heaters are produced in factories and can be purchased ready-made. The remaining two heaters function equally well on diesel fuel and waste oil, but they must be made independently.

Now we will consider the heating units separately and identify all the positive and negative aspects of their operation.

Review of the miracle diesel stove from Savo

Where such a catchy name came from is unknown. Most likely, it was invented by marketers promoting this product on the market. In fact, the miracle stove, powered by diesel fuel and kerosene, is a modernized descendant of kerosene gas, which was used during Soviet times for cooking. The operating principle is as follows:

- After opening the control valve, the fuel from the tank independently flows into the bowl, where the ends of two fabric wicks are immersed.

- Then the law of capillary rise of liquid operates, due to which the wicks wound on the burner are thoroughly saturated with diesel fuel.

- 2-3 minutes after impregnation, the burner is ignited with matches or a lighter. The operating mode is reached within 10 minutes.

- To turn off the diesel burner, you must close the fuel valve. The heating stove will completely go out in 6-10 minutes, when the diesel fuel that has soaked the wicks burns out.

The design and principle of operation of the miracle furnace burner

For reference. According to the operating instructions for this diesel fuel stove, the fuel supply valve must be closed during heating to prevent an open flame. When the top of the burner glows red and glows red, the valve opens again by 2-3 turns.

Heating devices "Solyarogaz" (Ukrainian equivalent - "Motor Sich") can boast the following real advantages:

- Acceptable price. Mini-stove PO-1.8 (power 1.8 kW) retail costs about 37 USD. e., and the price of a 5-kilowatt heater is 95 USD. e.

- Mobility due to small dimensions and low weight. The weight of the same 1.8 kW diesel-kerosene heating stove is 5.6 kg.

- Economical. If you believe the passport, then miracle diesel stoves with a heat output of 1.8-2.5 kW consume about 200 ml of diesel fuel in 1 hour. Judging by the reviews, real fuel consumption is practically no different from the rated one.

- Again, judging by user reviews (read in the next section), the stove does an excellent job of heating small rooms, even poorly insulated ones.

- The product is intended not only for heating, but also for cooking (a steel mesh is installed above the burner).

Let's move on to a few fly in the ointment. The first is inertia, which manifests itself during ignition, shutdown and adjustment of combustion intensity. As noted above, warming up and extinguishing the burner takes 6-10 minutes, and a change in the flame is observed 20-35 seconds after turning the tap, so you need to get used to the stove.

Aeroheat diesel fuel heaters

Despite the overseas name, the Aeroheat company seems to be Russian. Products go through the technological cycle on Japanese Amada equipment. In the Land of the Rising Sun, the concern is considered a leader in the production of machine tools. For 70 years, Amada has been providing humanity with various tools for metal processing.

For hunters, fishermen and summer residents with a personal car, Aeroheat offers to purchase a diesel fuel heater with a power of 2.6 kW. The consumption of the HS S2600 boxer is 0.25 liters of diesel fuel per hour. This is not too different from the performance of the Solarogas equipment; the heater weighs 4.5 kg. Here we get a gain in mass and a loss in unit price per hour. Available in a range of colors to suit taste and colour.

The diesel fuel heater HS S2600 boxer works like Solar Gas: you bring a burning match, the fire lights up, and lower the divider with the mesh into place. The fuel tank is located at the rear. Heating occurs in a 90 degree sector. The fire is surrounded by a metal mesh. Heat will be radiated throughout the working sector along with convective heating directed upward. The protective grille on the portal is flat on top, so you can cook food. The dimensions of the device are 0.35x0.29x0.27 m with an average retail price of 3,700 rubles.

The disadvantage of Solarogas heaters is the inconvenient wire handle, like a bucket. It is easy to get burned if you try to transport the device during operation. The boxer has a slot on the top of the sides of the case. All other things being equal, transportation will be safer. But you cannot grab hold of a bucket with your only hand, even if there is no fire. It turns out that these are the advantages and disadvantages of the boxer diesel heater.

Otherwise, the equipment gives the impression of equal opportunity.

Types of heaters

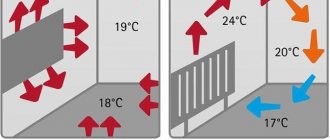

Depending on the principle of operation, there are two completely different types of devices. All such units can be divided into devices of direct and indirect action.

In the first case, the design is simplified as much as possible. There are no additional filters or air vents. This leads to the fact that waste combustion products enter directly into the room. Such units are prohibited from being used in residential areas. Such devices can only be used in industrial areas or for temporary work at low temperatures.

In the second case, the design provides a chimney, which additionally cleans the air from combustion products. In addition, such units have an additional filtration system. Such autonomous heaters can be used in closed residential areas.

TOP 3 best diesel heaters Ballu

- Ballu BHDP-20

- Ballu Biemmedue EC 85

- Ballu BHDP-100

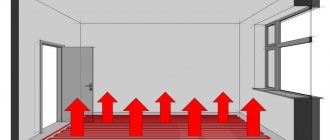

Diesel infrared heater

Such devices are most often used when it is necessary to quickly obtain heat where there are drafts. The principle of its operation is similar to exposure to direct sunlight. An infrared heat boiler does not heat the air, but the objects around it. When objects heat up, they release the resulting heat into the air and it also gradually warms up.

Heaters of this type are installed on open terraces, winter verandas of cafes and restaurants. Infrared heaters differ from a conventional diesel heater in the presence of a heat emitter and a heat reflector. Diesel infrared stoves do not require a smoke exhaust system. They are very effective and economical.

Their only drawback is the inability to quickly warm up a large room. But you can get heat quickly, literally within a few seconds after turning on the device.

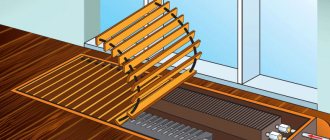

Air heat gun

This type of diesel heater is used when it is necessary to provide heating for a large area. Large volumes are quickly warmed up due to the powerful flow of warm air pumped by the fan.

The body of the heat gun is made of durable metal. This helps provide reliable protection against mechanical damage. The thermal energy obtained from the combustion of diesel fuel is used to heat a ceramic or metal element, which is blown by a stream of air.

The heat in the room will remain as long as the device is operating. If you turn off the heat gun, the air in the room will begin to cool quickly. This unit is very effective for large rooms, isolated from drafts and additional air flow.

Such diesel heaters are perfect for a summer residence, but they cannot be called completely energy independent. They still require electricity to operate. It is used to operate a security system: controllers for temperature, flame level and fuel consumption. When used correctly, the devices are completely safe. In case of overheating, the device automatically turns off.

Kerosene heater

These devices are indispensable in extreme conditions. They are capable of operating only on kerosene and do not require an additional source of electricity. This is an excellent option in cases where there is no electricity in the house or there is no gas pipeline.

The kerosene heater is also very popular among tourists. It is convenient to take it with you on a hike: to the mountains or fishing. With its help you can not only heat the tent, but also prepare tea or fish soup.

The design of the device is very similar to that of a conventional kerosene lamp. Only instead of protective glass, a burner shell and a safety grill are installed on top. The burner flame heats up the shell and begins to release heat into the room. Since as a result of work, not only liquid kerosene is burned, but also its vapor, the efficiency of such a device reaches 99%. This means that not a single drop of coolant will be wasted.

"Solyarogaz" and other miracle stoves

This option is similar to the previous one in terms of operation. The only difference is that in addition to kerosene, the device can also operate on regular diesel fuel. It's significantly cheaper.

"Solyarogas" also has the disadvantage of increased weight and size. Such a device without refueling weighs about 4 kg, and with a full tank of diesel fuel the weight can reach 7 – 7.5 kg. Agree, carrying such a stove in a backpack is not very convenient. Therefore, “Solyarogaz” is more suitable for those who travel in a car.

DIY heater

Of course, a diesel stove for residential premises, garages, greenhouses and other small objects can be purchased in a store. Their prices are reasonable. But you can make an equally high-quality model yourself.

There are several types of stoves using kerosene, diesel fuel or waste oil, that is, liquid fuel. Each has its own advantages and disadvantages.

A do-it-yourself liquid fuel stove will not be much different in quality from one bought in a store.

From two tanks

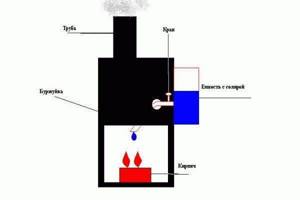

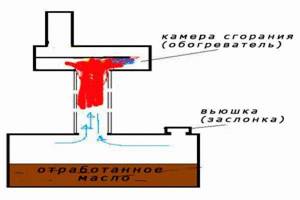

This version of the oven consists of two parts of a round or rectangular shape. The lower one, made in the form of a container on legs, is filled with used oil or diesel fuel. Here the liquid fuel, evaporating, goes through the stage of primary combustion. The lower container is connected to the upper one using a perforated pipe, in which secondary combustion occurs. Many holes are made in the pipe itself, which supply secondary air.

The lid on the lower container has two holes: for pouring fuel and with a damper that helps regulate the intensity of combustion. The combustion itself is carried out due to the natural supply of air, that is, draft.

Such a stove has high efficiency and heats the room well, but has a number of disadvantages.

Firstly, when even a small amount of water gets into a flammable liquid, unpleasant loud emissions begin to occur, often with flames or sparks from the burning oil, which can cause a fire.

Secondly, both during ignition and during operation, this model emits an unpleasant odor. This can become a serious problem when using the stove in a residential area.

Such a modification does not require the use of special materials and can be made from available raw materials. This explains its enormous popularity.

More information about the cylinder stove:

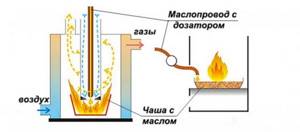

Dropper model

Although this version of the stove is technically more complex for homemade production, it is safer and more effective. Previously, it was used in the field. The stove can be called an army stove, since it was often the military or geologists who made such devices.

The operation of a greenhouse stove using diesel fuel or other liquid fuel is based on the method of drip feeding into the combustion chamber. To implement such a project, you can use an old gas cylinder or large diameter pipe. At the bottom there is a small container, like a bowl, where diesel fuel will burn.

A perforated pipe is installed from above to the bowl itself, through which air enters. Due to this, the furnace is especially economical, since not only fuel vapors are burned, but also pyrolysis gases.

A tube through which fuel is supplied is installed inside the air supply pipe. And the fuel tank itself is located at a distance from the main structure, which makes the installation safer. The fuel dosing is interesting. Here an ordinary dropper finds its application, and the supply is regulated by a dispenser from it.

Such a furnace can operate not only on diesel fuel, but also on mining

It would be useful to make two additional holes, one of which serves as an inspection window, and the second is intended for cleaning the unit from the inside. They will also act as an explosion valve if necessary.

In order to increase the performance of such a heater, you can add an adjustable fan to pump air. This will provide not only better combustion, increased temperature and efficiency, but also the possibility of more accurate temperature control.

The resulting homemade stove model can run on both diesel fuel and waste oil.

Heating device from a gas cylinder

To assemble such a diesel stove you will need:

- seamless balloon with a wall thickness of up to 1.5 cm;

- fuel capacity 8-15 l;

- smoke exhaust pipe 4 m long and with a cross-section of 10 cm;

- copper tubes for burner assembly;

- steel corners 20 cm;

- welding machine and grinder.

Diesel fuel will flow into the combustion chamber by gravity without forced air injection. The size of the outer contour of the stove must correspond to the height of the flame so that the device does not heat up to too high temperatures. The walls of the device should not be too thick so that the hot vapors generated reach a certain temperature. An empty gas cylinder must be divided into 2 parts - the upper one will serve as the lid, and the lower one will serve as the combustion chamber.

On the side of the bottom of the cylinder you need to weld the legs from the corners. On the opposite side, moving 10-15 cm from the edge, you need to cut a hole for the chimney using welding. A pipe with a cross-section of 10 cm and a length of 4 m is suitable for this. It should be welded exactly at an angle of 90° to the body. It is necessary to cut a hole in the chimney to regulate air access and cover it with a plate.

Stepping back 10 cm from the welding site, cut a small hole of 2-3 mm. Next, retreating 5 mm each time, you need to make 9 more of the same holes - the last one will be located 50 cm from the welding site. In addition, another hole is made in the pipe for a pipe with a cross-section of 5-8 cm and a length of 2-4 m. It is welded parallel to the floor. A hole with a cross section of 5-8 cm is cut in the top of the cylinder to supply fuel.

Diesel stove for the garage

The drip stove is suitable for basements, small rooms, country houses, garages, greenhouses where there is no heating or electricity.

Building a stove with your own hands is a fairly accessible and inexpensive activity. How to make a diesel-powered drip stove yourself will be discussed in our article.

Distinctive features

A stove assembled by yourself has a number of advantages:

- it saves fuel;

- if desired, you can design a stove of any size, which will be the most suitable option for a given room;

- easy to transport;

- ease of use;

- The oven dripper can be used for cooking. To do this, when constructing a stove, the pipe is placed on the side.

Diagram of a diesel-powered dropper stove. This is a very economical design. Complete combustion of compounds occurs in the furnace chamber

When making a drip stove with your own hands, you need to follow fire safety precautions:

- the device must be located in a draft-free room;

- flammable objects should be absent near the stove; it is advisable to have free space next to it (about half a meter);

- Do not use water to extinguish or cool the stove.

Materials needed to build the furnace:

The main tools that will be useful for the job are a welding machine, a drill and a clamp.

A popular do-it-yourself device is a drip stove made from a gas cylinder

How the device works

In the lower tank, the fuel boils after five minutes of operation. The oil vapor enters the next compartment, which is called the burner. There, for better combustion, the steam is enriched with oxygen.

The principle of drip feeding of waste into a bowl (click on the picture to enlarge)

Then, combustion products enter the upper compartment, and from there into the chimney. The highest temperature is in the upper module of the drip furnace.

Self-production

To do this, you will need a tank with a volume of at least 2 liters. There will be no smoke or soot during stove operation. During the process of igniting the stove, it will, so this process is recommended to be carried out outdoors.

Diesel from the fuel tank enters the wick cup. Using the dispenser, you can regulate the amount of incoming fuel. In the combustion cup, the fuel is heated until a gaseous mixture is formed, which then enters the combustion chamber. The spiral, which is located at the top of the chamber, is heated to a temperature of 800 °C. The smoke escapes through the chimney.

You can make your own apparatus weighing six kilograms. Diesel fuel is a fuel with a fairly high density, so its consumption is minimal. Overall, this stove is an efficient and easily transportable design.

Waste oil dripper stove

One type of cheap fuel is used oil. The stove can heat up to 800-900 °C. At the outlet the temperature will be 90 °C.

Pour a portion of oil and add 50-100 g of ignition agent (special fluid, heating oil, kerosene or diesel fuel). This is necessary to quickly ignite the stove. Wait until the combustion process stabilizes. Then you can pour in the next portion.

If there is any spilled oil, it must be removed immediately. Combustion occurs inside the pipe. This is a safe process. Fuel consumption is from 0.5 to 1.5 liters per hour. When the stove lights up, you can heat the water.

Waste oil dripper stove

Recommended for use: diesel oil, fuel oil, waste oil, heating oil. Do not use gasoline, acetone or other solvents. Avoid getting water into the fuel.

Special literature contains a large number of detailed instructions on how to make a drip stove with your own hands. Each of these designs is unique and has its own advantages and disadvantages. You can also use a store-bought version of the stove, but modify it at your own discretion.

Drip type oven

This design is suitable for small spaces, such as tents, and is quick and easy to assemble.

The build method is:

- Select a box of the appropriate size, for example 30x30x45 cm for a room of 3 m2.

- For the stove cabin, take a fire extinguisher body or a large 200 liter tank if a large heater is needed.

- For fuel, use a 2 liter medical burner. A thin copper tube 1 m long, bent at 90°, is attached to its rubber hose.

- The flexible hose is folded in half and a clamp is attached to the bend to secure the stove parts. The screw is mounted in such a way as to ensure a drip supply of fuel.

- A wick made of rags or old cotton briquettes soaked in diesel fuel is placed inside the body.

- Secure the door.

- In the center of the case or closer to the door, you need to drill a hole for the cross-section of the copper tube.

- At the end, the wick is set on fire, combustion is ensured by slowly dripping diesel fuel onto it.

Stove made from a pipe and pipe

A hole is cut out in the upper part of the structure to which the door is attached. With its help, the air supply and, accordingly, the fuel combustion force are controlled. The heat exchanger in this case is the pipe and the upper part of the structure, which can heat up to 800 ℃. A pipe is welded to the top of the pipe, on which an exhaust pipe made of galvanized steel is installed. Making it removable will make the pipe easier to clean in the future.

The lower cover for the upper element of the furnace is made of sheet metal 6 mm thick. To do this, cut out a circle with a cross-section of 35.2 cm. In this circle, not far from the edge, cut a hole with a diameter of 10 cm, into which a pipe 13 cm long will be mounted. There should be an indent of 11 cm from the center of the circle to the middle of the hole. You need to cut it out of the same metal rectangle 7x33 cm, which will serve as a partition. It needs to be welded closer to the hole for the pipe.

After this, they begin to manufacture the burner. In its lower part there are 48 holes with a cross section of 9 mm, located in 6 rows of 8 pieces. The space between the rows is 6 cm. The pipe is inserted into the firebox cover, made of sheet metal 4 mm thick. In this case, welding work is not required - you just need to adjust the connection to tightness with a file and a grinder.

You also need to make a hole in the fuel tank for the exhaust pipe, 16 cm long. Its upper and lower parts are tightly connected, but not welded. An O-ring with a cross-section of 35.4 cm is placed on top.

Finally, the fuel tank is welded to the burner. A small valve is made at the fuel filling hole. At the bottom, corner legs are welded to the tank.

Pros and cons of diesel heaters

Like any device, a heater that runs on diesel fuel also has its pros and cons.

Advantages:

- Compact size;

- Autonomy;

- Cost-effective – from a financial point of view, purchasing diesel fuel is much cheaper than purchasing electricity;

- Mobility – you can take it with you or move it to the most convenient place;

- Large range of heaters.

In addition to all of the above, modern models have additional functionality, are as economical as possible, and can be controlled remotely.

Flaws:

- High cost of the unit;

- High noise level during operation;

- Combustion products that can be released when heating a room.

The design of a diesel heater and its operating principle

The operating principle of a diesel heater is very similar to an electric one, but the difference is that the former runs on diesel fuel, while the latter requires electricity. The diesel fuel heaters package includes:

- The combustion chamber;

- Spark plug;

- Motor and fan impeller;

- Pump;

- Filters for air purification at the inlet and outlet;

- Fuel tank;

- Controller;

- Pipes through which air flows;

- Flame stabilizers;

- Fuel nozzle.

Diesel fuel is poured into the tank, from where it enters the combustion chamber.

Next, the fan will fan the air to ignite the fuel. Filters clean the air from various particles and combustion products of liquid fuel, and controllers regulate the air temperature. See also -

How to choose an inverter heater for home and street

Why are diesel heaters better than others?

Among the main advantages are the following:

- Efficiency is about 90%;

- Economical fuel consumption;

- Fast and high-quality heating of large rooms;

- Wheels that help you quickly move the device from place to place;

- A variety of types of diesel heaters and their capacities;

- Economical electricity consumption;

- Combustion and safety control occurs automatically;

- Fuel tank - allows the heater to operate for a long time without refueling.

Criteria for choosing a diesel heater

Undoubtedly, every person, before purchasing any unit, adheres to certain criteria that he gives preference to. When choosing a heater, the criteria may be the following:

- Air exchange. This indicator is very important for heat guns. The higher this value, the stronger the heat flows accelerate, and, consequently, the room heats up in a short period of time;

- Fuel consumption. It must be taken into account that 1 liter of fuel should produce approximately 10 kW of power;

- Direct and indirect action. For the first type of heaters, additional ventilation is required, because... combustion products enter directly into the room. For this reason, they are not practical for use in small and confined spaces. Indirect-acting units are equipped with filters; unlike the first type, they are not as economical;

- Possibility of changing modes. It is very convenient if you can change its power while the heater is operating. It is also economical, because some devices, with minimal heating, can operate without refueling for two weeks

- Timer. With its help, you can set the time during which the heating will be intense, after which the heater will turn off;

- Noise. When a diesel heater is operating, there will be noise in any case. This is a fundamental indicator and must be taken into account. Note that a figure of 45 dB can be considered suitable;

- Availability of wheels. Large heaters have wheels to make them easier to move

Features of diesel heaters for home and garden

Diesel fuel heat gun.

Today, diesel heaters are purchased for homes and cottages, industrial and warehouse premises, for heating garages and temporary buildings, during construction and repair work, when it is frosty outside. That is why this device can be called universal.

On the modern heating equipment market you can find the following options for diesel heaters:

- direct action;

- indirect action.

In addition, a diesel fuel heater for a summer house or home can have very different power, which determines the area it heats.

Design and principle of operation of heating elements using diesel fuel

. The equipment externally consists of an oblong metal case, which is placed on a movable platform (moves on wheels).

Structural elements of the device:

- fuel combustion chamber;

- candles;

- fan;

- engine;

- pump;

- filter system for fuel purification;

- air purification filters;

- container (tank) with fuel;

- flame controller;

- thermostat.

A diesel fuel heater for the country house and home operates according to the following principle. Liquid fuel is loaded into the fuel tank. The pump begins to pump it into the combustion chamber, where the spark plugs are present. The latter are powered from the mains. At the “Start” command, the spark plugs produce a spark and the fuel ignites. Through a system of pipes and filters, purified air is supplied to the chamber, which is needed to maintain the combustion reaction.

The operating principle of direct and indirect-acting units.

Direct acting equipment

. In this case, the combustion products of diesel fuel are not discharged outside the room, but are distributed throughout the room along with the heated air. This is the main drawback of the device. That is why it is not used for heating residential buildings and agricultural buildings. However, the equipment is simply irreplaceable when carrying out construction and repair work, in production workshops, as it can heat a large area in a relatively short period of time.

Indirect action devices

. They are used to heat residential premises, since the combustion products of liquid fuel are discharged outside the room. In this case, the smoke that is generated from the combustion of diesel fuel enters a special heat exchanger, from where it is supplied to the chimney. The latter is connected to the ventilation shaft. As a result, only thermal energy remains in the room.

IR heater using diesel fuel.

Modern diesel heaters for cottages and homes are equipped with a filter system for cleaning the energy carrier, which significantly extends the service life of the equipment. In addition, there is a large tank that allows the device to operate for up to 16 hours without refueling and in full, autonomous mode. The advantages of indirect action technology include the presence of controllers that protect equipment from overheating. There is also a fuel controller that works like an indicator.

Conventional diesel heaters for cottages and homes look like a heat gun. This device consists of a metal body, combustion chamber and fan. During operation of the device, the fan distributes heat in the room in the desired direction. Disadvantage: after turning off the heater, the room temperature drops sharply.

Heaters for summer cottages using liquid fuel with infrared radiation do not have this drawback. In this case, the energy from the combustion of the coolant is converted not into ordinary heat, but into infrared radiation, which warms up not the air in the room, but the surrounding objects. Even after the heater is turned off, the set temperature in the room remains for a long period of time.

This video will help you understand how the equipment works:

The best manufacturers

Today, you can choose a heater that runs on diesel fuel from a large assortment on the market. Moreover, you can choose according to various indicators: price, manufacturer, power, etc. But we advise you to purchase a unit from one of the brands presented below. Note that the rating was compiled taking into account customer reviews and tests.

- Kerona;

- Hintek;

- Ballu;

- Master;

- Biemmedue

All represented manufacturers supply the market with diesel heaters that combine such concepts as price and quality.

Classification of species

There is only one type of ultraviolet heater, which is familiar to almost every person. This is a blue lamp that is used to treat diseases such as runny nose or ear problems.

The equipment is used not only as heating for the room, but also for drying shoes.

You can also find more specific models of ultraviolet lamps - medical ones.

According to the functionality of the equipment, ultraviolet lamps are divided into several groups:

- Open type. The lamps are inserted into the housing and have a low power, and with the help of them the premises are disinfected. An important nuance - before use, it is necessary that all people, animals and plants are in a safe area.

- Closed type. Powerful light bulbs are installed in a special insulated chamber, with the help of which the disinfection process occurs.

- Special appointment. These lamps are low power and are used for a variety of physical therapy needs that can even be used at home.

Also, ultraviolet heaters are classified into several types according to the method of execution:

- Stationary samples.

- Tripod version.

- Compact and portable.

Self-assembly

Diesel units are very popular because they run on diesel fuel and waste fuel. In addition, creating them on your own is quite simple.

Any type of metal is prepared for the creative process. The fuel is definitely diesel fuel: the stove works well with it and creates high-quality heating. True, the work gives off a nasty smell; you can’t install this in every dacha. Therefore, it is better not to use this model in residential premises.

Often the creation of a diesel stove is due to its subsequent appearance in the garage. There are versions of garage stoves with direct and indirect heating. The former do not have a chimney and are very inconvenient for the intended purposes. The latter have a fuel tank and a combustion section that operate in a simple way: the liquid passes through the reservoir nozzle and ends up in the combustion section. There it is burned thanks to the air sent by the fan. Air flows in transit through the heat exchanger follow from the nozzle into the room. A similar diesel model may have the following composition:

- adjustment screw,

- frame,

- burner,

- removable tank,

- lattice,

- removable block,

- reflector.

In addition to the removable tank, a valve is included in the stove, and a wick is included with the replaceable unit.

Specifics of diesel equipment

Modern diesel modifications have flame control technology. It turns off the device when it overheats. As already noted, these stoves can heat small rooms. The same garage stoves are also extremely useful for heating emergency rooms. It is diesel ones that can be taken outdoors. They are especially needed when it rains during a hike and there is no possibility of making a fire.

General information about diesel heat guns

At first glance, the design of such a heater may seem overly complex and impractical. While the same convectors and radiators are almost invisible wall panels, diesel heaters include several working components, including a combustion chamber, a fuel tank, a fan and several communication channels. The multicomponent structure is determined by the operating principle, the effectiveness of which justifies the design flaws.

During operation, fuel is burned to produce heat. A fan is used to disperse the generated heated air flows - it must be directed to the target area. Actually, this principle of operation determined the second name of the unit - heat gun. An important advantage of the equipment is its independence from energy sources. As a rule, an autonomous diesel heater does not require power from the mains, since its function is provided by energy from the combustion chamber. However, there are also combined models in which the operation of the fan is separately supported by electricity.

Single-circuit

A single-circuit diesel boiler is focused on performing one function - heating the room. The liquid in the coolant is heated, after which it is supplied to the system circuit. A circulation pump can be used for this. If the system is properly organized, a water heater can be installed into it to provide the home with hot water.

Single-circuit diesel boiler

Dual-circuit

This equipment is used for heating and providing hot water. Two types can be distinguished, taking into account the method of water heating:

- Continuous heating of the coolant thanks to the use of a heat exchanger. An effective flow-through solution for a small family.

- There is an additional boiler, which allows you to heat a large volume of liquid at once. Can be used on an industrial scale.

Diesel fuel consumption depends on several factors:

- climatic conditions;

- ceiling height;

- thermal insulation efficiency;

- heated area.

As experts confirm, installing a condensing diesel stove allows you to save on fuel. Condensation of water vapor can help increase efficiency to a record 108%.

Fuel storage

Diesel heating requires the organization of a tank to store fuel and supply it to the equipment. The location for its placement is determined for reasons of fire safety. Convenient access must also be provided to refill the tank.

Note: According to established standards, a fuel container of no more than 0.8 m3 can be placed in the boiler room. This volume will not be enough, so a fuel storage facility is required. According to the standards, the volume of such a container should not exceed 20 thousand liters.

To organize a place for fuel storage, you can dig a pit, the bottom of which is covered with a cement-sand cushion. This is a layer of about 20 cm. This distance should remain between the walls of the container and the walls of the pit. The pit is filled with a cement-sand mixture. Compaction must be done every 20 cm, water must be added.

Fuel storage and diesel boiler

You should not save on capacity for heating equipment. If you make it yourself, cracks may occur, which will result in fuel leakage, which means high costs. Therefore, it is recommended to use certified containers.

You can use not one diesel tank, but several, connecting them with a special harness. Nowadays, tanks made of polyethylene lined with steel sheet are very popular. You can also use a reinforced fiberglass container.

If the diesel boiler is located below the tank level, then a gravity fuel supply system can be used. If the level is the same or the container is slightly higher than the burner of a diesel stove, the burner pump is able to independently suck in diesel. If the difference in levels is more than 5 meters, additional help is needed.

Fuel storage heating systems using a diesel boiler

If there is a fairly large distance between the container and the boiler, the fuel line runs outside, it should be buried 1.5 meters into the ground. This is necessary to prevent freezing.

Service

A diesel stove produces a lot of ash and soot. If you allow a layer of at least 2 mm, you can get increased fuel consumption by 10%. Therefore, there is a need for periodic cleaning.

And special attention in diesel heating devices is paid to the burner. When servicing, you should clean the divider and nozzles from carbon deposits. The frequency of such servicing of the heating device is determined by the quality of the fuel: the worse it is, the more often. The best option is once every 6 months.

Diesel boiler in action

You should not clean a diesel stove with your own hands, as this can lead to damage to the heating equipment. Trying on your own can be dangerous to your health.

Timely and qualified service of diesel heating equipment is a guarantee of its long-lasting and trouble-free operation.