General operating principle of infrared heaters

Any heating device (heater, heated floor, radiator, convector) warms the room in two ways - using infrared radiation and convection. Depending on the type, their ratio is different:

| Device | Radiation | Convection |

| Radiator | 15-30% | 70-85% |

| Fan heater | 0-10% | 90-100% |

| Warm floor (plinth) | 0-5% | 95-100% |

| Infrared heater | 70-95% | 5-30% |

Infrared light is emitted by any surface. The hotter it is, the more intense the IR radiation. When it hits any object, it heats it up. It begins to give off heat, warming the air in the room. The degree of heating depends on the power of the heater and the distance to it.

An infrared heater emits infrared rays in all directions. They pass through the air without heating it. When thermal radiation hits any surface, it gives off thermal energy. Then it becomes a source of heat.

With convection, the heater heats the air. It spreads throughout the room and gives off its heat to the objects in it. Heating efficiency depends on air flow, room volume and appliance power.

How to use

Since the combustion of gas burns oxygen and releases carbon dioxide, the heated room must be ventilated if there is no natural ventilation. If the concentration of carbon dioxide in the air exceeds 1.5%, the CO2 sensor will work, automatically turning off the gas supply.

In case of continuous operation of the device, it is necessary to periodically ventilate the heated room.

The temperature regulator will allow you to control the intensity of heating. For example, after a long absence, you can quickly warm up the room by setting the heating mode to maximum, and then switch it to minimum.

Wavelength affects everything

Infrared heaters emit in the range with a wavelength of 0.75-2000 microns and a frequency of 0.15-400 THz. They are divided into three types:

- Short-wave (wavelength 0.75-2.5 microns, frequency 120-400 THz);

- Medium wave (wavelength 2.5-50 microns, frequency 6-120 THz);

- Long-wave (wavelength 50-2000 microns, frequency 0.15-6 THz).

The shorter the wavelength, the more thermal energy the heater produces with the same radiation area. But the temperature of the radiating element is higher.

Short-wave and medium-wave heaters are usually equipped with an open-type heating element. It emits orange light in the visible range. This leads to a loss of effective power (up to 10%).

Long-wave heating elements do not emit visible light. They are usually used in closed-type panel heaters. They have a lower operating temperature and the percentage of thermal energy released due to convection is lower than that of short- and medium-wavelength ones.

The effect of IR radiation depending on the wavelength is described in the section “ Infrared radiation and human health ”.

Bottom line

Infrared gas burners are the best option for heating large rooms. Due to the fact that they do not heat the air, their efficiency is significantly higher than that of their electric counterparts.

Such devices are widely used not only for heating residential premises, but also for heating verandas, gazebos, and open areas in cafes and restaurants. Due to their ease of use and high efficiency, these devices quickly gained popularity in the heating market.

Rate this articleAdd a comment Cancel reply

Name *

Email *

Website

Comment By clicking on the “Submit Comment” button, I accept the privacy policy.

Save my name, email, and website in this browser for the next time I comment.

Popular articlesTypes of welding We understand the drawings of welding seams according to GOST If you say that is your favorite word, you are unlikely to 086.2k.Types of welding

How to learn to cook with an inverter from scratch? In a private house, country house or garage quite often 054.8k. Types of welding

All about cold welding: properties, application, instructions What is cold welding Cold welding - in a broad way 0202You may also like Features of a welding transformer It’s hard for a modern person to imagine creating 03k.

Main types and categories of filler wires for semi-automatic welding Welding wire is the most important consumable material05.4k.

Features and advantages of the CNC metal plasma cutting machine is used as a high-tech method to process 01.4k. Types and use of centralizers in the process of pipe welding A prerequisite for pipe-laying0924 Diagram and features of the welding inverter The diagram and diagram are significantly different from each other.05.3k.

What are the markings of welding electrodes and what is their purpose? Working with manual electric arc welding machines03.1k. Types and principle of operation of welding generators A welding generator is an indispensable device that allows0319

How to make a semi-automatic welding machine? Anyone can make it with their own hands08.6k.

Types of heaters

All infrared heaters are divided according to their energy source into:

- Electrical;

- Gas;

- Diesel;

- Another type of fuel.

Electricity

Electrical IR devices can be divided according to the method of producing thermal radiation and design into:

- Panel;

- Film;

- With open heating element;

- Micathermic;

- Combined;

- Halogen.

Panel heaters produce long-wave radiation. Their surface heats up to +50, less often up to +70 degrees. The heating efficiency depends on the radiation area. Such heating devices are used in residential buildings, apartments, offices, and small premises.

Film IR devices are used in electric floor heating systems. The operating temperature does not exceed +40 °C. Supplied in roll form.

Heaters with open heating elements operate in the short-wave and long-wave ranges. They are the cheapest options. With minimal dimensions they provide powerful heating (operating temperature +600 degrees and above). Such infrared heaters have a large number of pros and cons.

Micathermic devices are no different in efficiency from their analogues. They use mica as the emitting plate. Operating surface temperature up to +60 °C. About 20% of thermal energy is released due to convection, 80% - by radiation. You can read more about them in the article Micathermic heater: principle of operation, pros and cons, real reviews and efficiency.

Combined systems - a mixture of a convector and a panel infrared heater. They have 1-3 low-power fans installed, which circulate air along the radiating element. Depending on the model, the share of convection is 20-50%.

Gas

Gas infrared heating devices are divided according to the design of the radiating element:

- Tubular;

- With flat element;

- Vertical compact.

Tubular infrared gas heaters heat up to no more than +250 degrees. The combustion of the gas-air mixture occurs in a tubular element. The device emits in the long-wave range.

Gas IR devices with a flat element are used to heat small areas or rooms. The gas burns in (or near) the perforated ceramic tiles. They emit in the long-wave range, less often in the mid-wave range.

Vertical (compact) IR heaters are a special case for heating open spaces. The gas is burned in a small ceramic chamber that emits infrared rays. They operate in the long-wave or medium-wave range.

Diesel

Diesel IR heaters come in three types:

- Direct heating;

- Indirect heating;

- Tubular.

Direct infrared diesel heaters emit exhaust gases through a radiant grille (disc). The radiation range depends on the model and power of the device, and the degree of heating of the emitter. Used in rooms with good ventilation or outdoors.

Diesel infrared indirect heaters emit exhaust gases through the exhaust pipe and chimney. They have lower efficiency than models with direct heating. The emission range depends on the degree of heating of the emitting disk or grating. Used indoors.

In diesel IR devices with heating elements, combustion of a mixture of diesel fuel and air occurs in a sealed pipe. emit in the long-wave, sometimes mid-wave range. They are used for heating premises of any purpose, area and height.

Other

Any type of fuel can be used as an energy source to heat the radiating element. It all depends on the installation model and resource availability. Most often this is:

- Kerosene;

- Eco-diesel;

- Used engine and transmission oil;

- Paraffin.

Which model is better to choose

To decide which device is right for you, you should carefully study its characteristics, capabilities and control system. It all depends on the area of the heated room, operating conditions and the goals you are going to achieve. For example, where exactly will the device be placed, will it have to be dragged to another room or installed permanently?

There are wall, ceiling and baseboard infrared heaters.

The most convenient solution, especially for owners of small apartments, will be the ceiling option for placing the heater. It does not require much space and is mounted directly into a suspended ceiling or attached to a regular ceiling using brackets.

The heater can also be installed on the floor. Floor-standing electrical appliances are less efficient than ceiling-mounted ones, because the radiation flow will not be directed directly, and heating will be more difficult.

The carbon heating element is a tube made of quartz. Inside it is a vacuum space with a carbon spiral. When a heater with a carbon tube operates, a characteristic reddish glow appears, which is not very pleasant to the eyes. The ceramic element is of lower quality, but does not glow during operation. And halogen can even have a negative effect on the human body due to the emitted waves being too short.

Installation options

Based on the type of installation, IR heaters are divided into four types:

- Ceiling (suspended);

- Wall-mounted;

- Floor-standing (mobile);

- Skirting.

Each type of heater can be installed in a certain way. This depends on the features of the device and the models produced. Here is a table showing the available installation options for different types of infrared heaters:

| Type of IR heater | Ceiling | Wall mounted | Floor-standing | Skirting |

| Electrical | ||||

| Panel | + | + | — | + |

| Film | + | + | + | — |

| With open heating element | + | + | + | — |

| Micathermic | — | + | + | + |

| Combined | — | + | + | — |

| Gas | ||||

| Tubular | + | + | — | — |

| With flat element | + | + | + | — |

| Vertical compact | + | — | + | — |

| Diesel | ||||

| Direct heating | — | — | + | — |

| Indirect heating | + | — | + | — |

| With tubular emitter | + | + | + | — |

Selection options

Typically, heating equipment is selected according to thermal power. But gas infrared heaters do not have such a wide range of power - from 2 kW to 4.5 kW. However, 4 kilowatt models are recommended for heating an area of 60 square meters. Few people need more powerful installations. So for ordinary rooms - about 20 square meters in area - they usually take 2.3-2.7 kW heaters. And they heat up the air in 20-30 minutes. Depends on the starting temperature and insulation.

What else may be useful:

- Multi-section burner. Most often it has three sections, that is, three operating modes.

- Oxygen monitoring device. Since oxygen is consumed during combustion, and its lack has a negative impact on well-being, oxygen control is a useful thing. Especially if you plan to use the gas infrared heater for a long time or at night.

If there are combustion problems, replace the gearbox with an adjustable one. With its help you can achieve stable operation

All these “bells and whistles” cannot be called superfluous. They are found in those devices that are more often called “gas infrared mobile fireplaces.” Most simple and cheap devices do not have them. All control functions remain with the users.

Advantages and disadvantages

Infrared heaters are not a panacea for the cold. They have positive and negative sides.

Pros of IR heaters

#1 Direct heating

Infrared heaters heat the objects they are aimed at. They do not use air as a heat carrier.

No. 2 Fast heating

The equipment reaches operating temperature very quickly. For options with heating elements this happens in a few seconds, for gas and diesel ones – up to 1-2 minutes.

No. 3 No convection

Due to the fact that the air is heated indirectly, from heated objects, there is no convection. Accordingly, the temperature is distributed evenly throughout the room. Heat loss through the walls and ceiling is minimized.

No. 4 Local heating

In larger rooms, infrared heaters can be used to heat specific areas. Other heating devices are ineffective for these purposes.

No. 5 Working in open spaces

It is possible to efficiently heat open areas. Primary heat loss is minimal, since heating occurs due to direct radiation and not from warm air.

No. 6 Silence

If the IR heater is working properly, it operates almost silently. The exception is high-power installations running on gas, diesel or other fuel.

#7 Easy to install and run

To bring the device into working condition, it is enough to connect an energy source (electricity, gas) or pour fuel into the tank. After this, the infrared heater is ready for use.

No. 8 High service life

In IR heaters, the number of moving parts and mechanisms is minimal (unlike air conditioners, heat pumps, and other heating systems). Simplicity reduces the risk of breakage and reduces overall wear and tear.

#9 Environmental friendliness

Electric infrared heaters do not emit harmful substances into the atmosphere. Models powered by gas or diesel fuel are no less environmentally friendly than cars. But they have less harmful emissions.

Cons of infrared heaters

#1 Quick cooling

Unlike other heating systems, IR devices cool down almost instantly. Therefore, you have to constantly monitor the presence of voltage in the network or fuel in the tank.

No. 2 Uneven heating

Infrared thermal radiation heats only the side of the object that it hits. The temperature difference can be significant.

No. 3 Electricity consumption

Unlike air conditioners and heat pumps, the COP (efficiency factor) of electric infrared devices is 95-99%. From 1 kW of electricity they cannot produce more than 0.99 kW of heat. Air conditioners and heat pumps can produce 4 kW of thermal energy or more from 1 kW of power consumed.

No. 4 Dangerous for humans

Failure to comply with the rules for using infrared heaters can lead to illness and disorders. The high temperature of the heating elements, if handled carelessly, can cause injury.

#5 Bright light

Electric infrared heaters with an open heating element emit light in the visible range. This can lead to sleep disturbances.

No. 6 Water ingress

When water gets on hot heating elements, they are destroyed. This may result in short circuit, fire, etc.

No. 7 Fire hazard

Heated radiating elements may cause a fire. Protective grilles cannot always protect them from the ingress of foreign flammable objects.

#8 Reduced effectiveness at a distance

Heating efficiency decreases depending on the distance to the object. The comfort zone is quite narrow and amounts to 1-4 meters depending on the type and power of the heater.

Advantages and disadvantages

The advantages of a ceramic heater include:

- Fast heating.

- Compared to heating boilers, fuel savings reach 50%.

- Installation of heaters is possible at a height exceeding 60 m.

- Possibility of changing the direction of heat flow.

- Autonomy, independence from electricity.

- Compact, easy to transport.

- Easy installation.

Among the shortcomings, users noted:

- High cost.

- The need for equipment cleaning and annual maintenance.

Operating principle of gas infrared heaters

In this section we will analyze the design and operating principle of gas infrared heaters of various types.

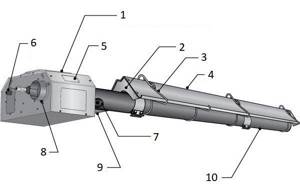

How does a tubular infrared heater work?

- Burner control unit;

- Reflector plugs;

- Radiating tube brackets;

- Polished aluminum reflectors;

- Maintenance hatch;

- Power connector or cord;

- Glass window for viewing the burner;

- Air intake;

- Ignition unit;

- Tubular emitter.

A tubular gas IR heater works as follows. A mixture of gas (natural or propane) with air enters the tube. It is ignited by the ignition unit, which causes the tube (tubular emitter) to heat up. The heated emitter begins to emit infrared radiation.

Radiation directed upward is reflected by an aluminum reflector. The rest is freely distributed throughout the heated area. Some of the thermal energy warms the air through convection.

Depending on the settings, the gas supply speed or the ignition frequency is adjusted. This affects the temperature of the tube and the length of the emitted waves. The efficiency of heating depends on it.

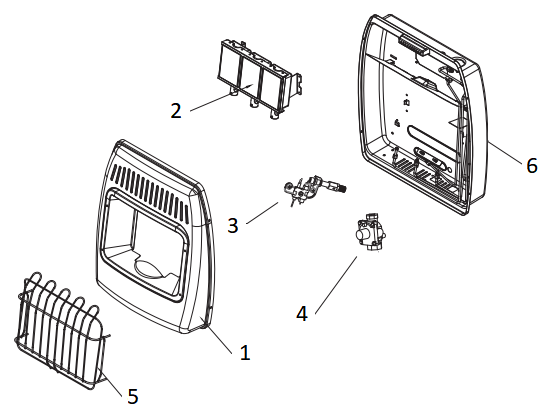

Operating principle and design of an IR heater with a plate

- Front panel assembly;

- Burner assembly;

- Oxygen sensor assembly;

- Manual gas valve;

- Front grille;

- Rear panel assembled.

The basis of such heating devices is a ceramic or stone plate (or stove). It is located in the burner assembly, or immediately above it, and is the source of IR rays.

The gas-air mixture enters the burner and ignites. Passing through the channels in the stove, it warms it up, and combustion products exit into the room. Thus, part of the thermal energy is transferred by infrared radiation by convection, and a smaller part by convection.

An oxygen sensor is needed to regulate the gas supply rate. In case of its failure, it is possible to manually shut off the gas line.

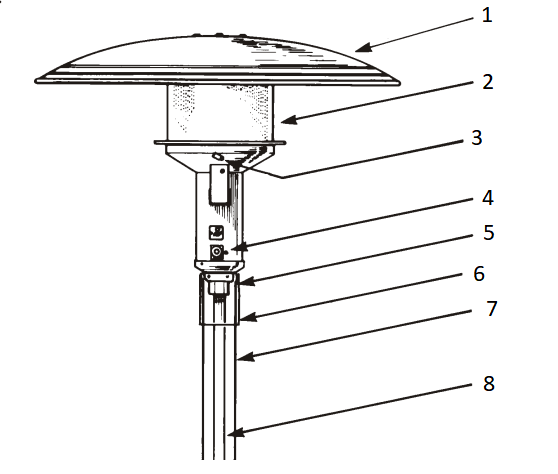

Vertical (compact) infrared gas heater

- Reflector;

- Radiating element;

- Air access hole;

- Manual gas valve;

- Adapter for connecting the pipeline to the burner assembly;

- Burner assembly fastening coupling;

- base pipe;

- Gas pipeline.

In such gas infrared devices, the burner is located in the radiating element under the reflector (reflector). It is a chamber made of metal or ceramics in which the gas-air mixture burns. Air is taken from the environment.

There is a small distance between the element and the reflector. Combustion products escape through the gap. The radiating element can be monolithic or in the form of a lattice. In the latter case, the device releases up to 40% of the thermal energy through convection.

Such IR devices can be installed in the form of poles, or in a suspended manner. In the second option, it is necessary to arrange an appropriate gas supply.

Types of industrial gas IR emitters

Light emitters

These heating systems are considered high-temperature and highly efficient, since the most suitable ceiling height in the installation premises should not be lower than 4 m. When calculating the power of the device, the following ratio is used: 1 kW of equipment power = 20 m3 of room.

The annular air intake draws in ambient air due to the hot air and combustion products escaping from the burner nozzle.

This heated mixture is directed to the pressure balance chamber, and then transported to the combustion chamber through through holes. To eliminate combustion products, supply and exhaust ventilation or artificial exhaust are most often used.

Similar devices are used in forges, foundries and high-tech machine shops. It is also allowed to install devices in dusty rooms and rooms with high air humidity. Often such heaters are installed in camp pavilions, tennis courts, etc.

Expert opinion Mikhail Yurievich Afanasyev Leading engineer of a company engaged in the production of energy-saving heating equipment.

IMPORTANT: An additional frame for the gas infrared light radiation heater system is not required, since they do not exert significant loads on the supporting structures.

Dark emitters

These devices received this name due to the method of low-temperature combustion of a gas mixture. If in light systems temperatures up to 1000 °C were reached, then in dark ones they did not exceed 450 °C. Moreover, combustion occurs in a closed system with heating of the screen tube.

That, in turn, emits waves of the infrared spectrum in a range invisible to humans. Therefore, the heating element never turns red, yellow or white, as is observed in light types of heaters.

The device design includes the following components:

- gas outlet;

- emitting screen tube;

- reflector;

- gas stove.

Today you can find models with U-shaped or linear tubes. In the first case, due to the decomposition of the warm and cold luminescence spectra opposite each other, uniform heating of the space is achieved.

In linear systems, the temperature will be higher than the end that is adjacent to the burner nozzle, so the radiation will slightly change temperature and intensity in certain areas. Such installations are used in rooms with a ceiling height of at least 3 m.

Expert opinion Mikhail Yurievich Afanasyev Leading engineer of a company engaged in the production of energy-saving heating equipment.

SAFETY MEASURES: The distance from the dark gas IR heater to explosive and flammable materials should not be less than 1.5 m.

This type of heater cannot be used in workshops and industrial warehouses with the processing and storage of flammable materials, offices and residential premises. Due to their larger size, installation complexity and significant fuel consumption, such systems are installed:

- in workshops where it was not possible to install light burners for some reason;

- in rooms where high temperature maintenance is not required;

- in narrow passages and corridors;

- in poorly ventilated large buildings located isolated from the heating system.

How does an electric IR heater work?

The basic operating principle of an infrared electric heater is generally simple. But different types have fundamental differences.

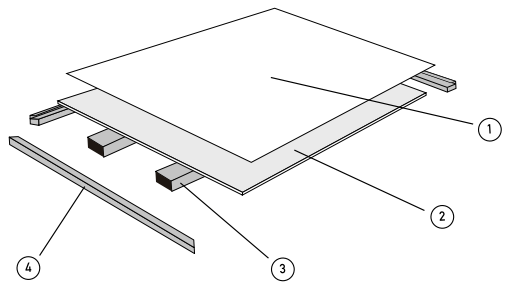

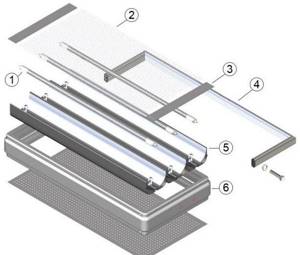

Operating principle of panel infrared heater

- Decorative coating;

- A heating element;

- Bracket;

- Side pad.

The heating elements of such heaters are made of ceramics or natural stone. They are a plate in which a spiral of nichrome or a metal with similar characteristics is laid. The stove emits infrared rays, a small part of the thermal energy is released due to convection.

Decorative coating is not always present. It can be made of different materials, stylized as an interior element or a painting. The efficiency of heating depends on the level of its thermal conductivity.

Some models have a reflector behind the heating element. It reduces the level of convection and increases the efficiency of infrared heating by 5-30%.

Film infrared heaters

Film IR heaters are used for laying under the coating. Most often, they are used to install warm floors, less often - warm walls. They can only be classified as infrared heating devices only conditionally, based on their operating principle. Read more about them in the article Types of warm electric floors.

Combined IR devices

This type of heaters is a hybrid of panel IR devices and electric convectors. The back of the heating element is blown by small fans, which ensures efficient heat transfer.

Due to forced airflow, the IR radiation/convection ratio changes in favor of the latter. A combined infrared heater warms up the air in the room faster than a regular one.

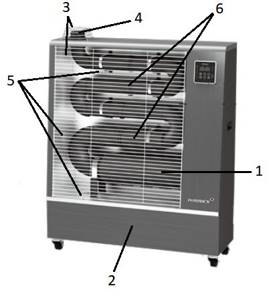

Operating principle and design of a micathermic IR heater

- Top air outlet;

- Protective grille;

- Micathermic heating elements;

- Digital LED display;

- Control Panel;

- Housing for storing the power cord.

Micathermic infrared heaters are analogues of panel heaters. The difference is that the heat-releasing surface is made of mica. The spiral can be located either inside the mica panel or between two separate sheets.

In the second case, one- and two-component materials are often used on the inside of mica slabs. They provide good absorption of the energy released by the filament.

Micathermic heaters are usually floor-mounted and emit infrared radiation in two directions. There are models in the form of hinged panels and cylindrical shapes. Such heaters are light in weight. emit up to 80% of thermal energy in the form of infrared rays, the rest is due to convection.

Infrared heaters with open heating elements

- heating element (incandescent filament, heating tube);

- Protective grille;

- Support part;

- Mounting bracket;

- Reflector;

- Device body.

The filament (spiral) in the heating element directly emits in the infrared range. Some of the IR rays go directly into the heated room, and some - due to reflection from the reflector. At the same time, the amount of heat given off due to convection is minimal.

There are two types of heating elements - ceramic and glass. In the first, a ceramic tube is first heated, which subsequently releases heat. In glass heating elements, infrared radiation comes directly from the filament.

Heaters with ceramic elements need some time to reach the specified power. But during operation, such heating elements do not glow as brightly as glass ones. Their radiation wavelength is longer.

Varieties

There are several types of mobile gas heaters for summer cottages.

Infrared

It works on the principle of converting the heat released during fuel combustion into infrared radiation.

The metal housing houses the burner, valve, combustion regulator and heated panel. She is that same emitter. The panel can be made of metal pipe, mesh, perforated sheet, ceramics, etc. When heated to 700-900 degrees, the panel emits infrared waves. They give off thermal energy not to the air, but to surrounding objects. They gradually warm the air. An infrared gas heater works on this principle.

This option of direct heating, when combustion products are vented inside and not outside, is optimal for short-term use in well-ventilated areas.

If it is possible to install an indirect heating heater, it is better to buy it.

Infrared gas heater for a summer residence with a cylinder.

Ceramic

According to the method of heat transfer, a gas ceramic heater is of the infrared type. The main element of the heater is a ceramic insert or panel. It serves to convert combustion energy into thermal radiation.

If it is possible to connect to a portable cylinder, the device will work autonomously. This is convenient, especially for owners of country houses located where there is no infrastructure yet, or where it is turned off during the winter months.

To turn on the heater without automatic ignition, you need to bring the flame from a match or lighter to the top of the ceramic panel. It is strictly forbidden to light a flame near the nozzle.

Ceramic gas heater for a summer house with a cylinder.

Catalytic

One of the safest heating devices is a catalytic gas heater. The main difference from other types of similar devices is the flameless combustion of fuel and the release of heat during the oxidation reaction. Since a gas heat source operates without fire, combustion products are not released into the room air.

The main element is a catalytic or catalytic plate made of fiberglass, with the addition of platinum. When fuel hits its surface, an oxidation reaction begins, during which thermal energy is released.

The consumer heats the house, but does not receive the negative side effects that occur during normal combustion, such as burning of air oxygen and saturation with carbon dioxide. In this regard, a catalytic gas heater is much safer and more environmentally friendly. These are the main advantages of such a device, judging by user reviews. It also has disadvantages, the main one of which can be considered cost. The catalytic plate reaches its end after 2500 hours of operation. Replacing it costs almost the same as buying a new heating source.

It is more advisable to replace an exhausted unit with a new one rather than buy a plate for it.

Catalytic gas heater for a summer residence with a cylinder.

Portable

Portable gas heaters for heating are useful in camping conditions, in buildings not equipped with any type of heating. At the back of the device there is a small gas cylinder with a volume of 200 ml to 3 liters. The fuel consumption of such a heater is 100-200 g/hour, the power is no more than 1.5 kW/h. The portable heat source operates as infrared. With the help of piezo ignition, a flame appears in the burner, which heats the ceramic plate. The radiation from it provides the necessary heat.

Relatively inexpensive, cheap, lightweight, convenient, designed for heating small, up to 15 m2, rooms, garages, tents.

Portable gas heater for a summer residence with a cylinder.

Design and operation of a diesel infrared heater

In this section you will learn how different types of infrared diesel heaters work. The information also applies to other liquid fuel infrared heating devices. The differences in design are insignificant.

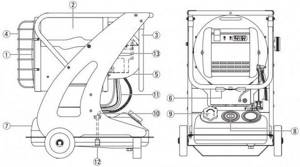

Working principle of diesel direct heating IR heater

- Radiating element (disk);

- casing;

- Pen;

- Protective grille;

- Burner cover;

- Air intake fan;

- Fuel tank;

- Fuel level indicator;

- Gas tank cap;

- Suction pipe;

- Return line;

- Filter element;

- The combustion chamber;

In diesel IR heaters, the fuel element is made in the form of a perforated disk made of ceramic or metal. It is located after the combustion chamber, or is part of it.

When diesel fuel burns, high-temperature exhaust gases are generated. They pass through the holes of the IR emitter and heat it. the radiating element begins to emit thermal energy in the infrared range, predominantly mid-wave.

Heating of areas and premises is carried out due to thermal radiant energy and the heat of exhaust gases. It is advisable to use such heating devices in open spaces, in large rooms with ventilation.

How does an indirect heating IR heater work on a diesel engine?

Indirectly heated infrared diesel heaters do not emit exhaust gases into the heated room. To remove them, an exhaust hole is provided, to which the chimney is mounted.

The radiating element is the wall of the combustion chamber. It is made of ceramic or metal and has no perforations or holes. The element is heated by the temperature generated by the combustion of a mixture of diesel fuel and air. When heated, it emits thermal infrared radiation.

Indirectly heated diesel infrared heaters are less economical than direct ones. Some of the heat leaves along with the exhaust gases. Such devices can be used in any room. The radiation range depends on the heating temperature of the radiating element and the heater model.

Tubular diesel IR heaters

- The combustion chamber;

- Fuel tank;

- Protective grilles;

- Exhaust port;

- Reflectors (reflectors);

- Exhaust pipe.

The main element of a tubular diesel infrared heater is the combustion chamber. The mixture of diesel fuel and air is not burned. In this case, a maximum temperature is released. the walls of the chamber heat up and emit thermal infrared radiation.

From the chamber, fuel combustion products pass through the exhaust pipe. it is less heated and does not emit as much IR light as the combustion chamber. Heat transfer also occurs due to convection. Subsequently, the exhaust gases are discharged through the chimney.

Such heating devices are produced in two versions:

- Models that run exclusively on diesel fuel;

- Universal models that run on diesel fuel, kerosene, and oil.

Dark emitters

The combustion process of a gas-air mixture in a low-intensity IR device occurs in a closed system in which a metal pipe serves as the radiating element. It works on the same principle as the light emitter, but at reduced temperatures of about 350-450 degrees. During operation, flue gases heat up the screen tube, which begins to emit infrared rays.

The gas IR heater received its name “dark” due to the fact that its radiant tube never becomes red hot.

The design of the device includes:

- gas burner;

- reflector;

- screen emitting tube;

- gas outlet

Manufacturer Pakole ZENIT

Screen tubes are available in linear and U-shaped. In the latter case, infrared radiation is distributed more evenly in space due to the location of the hot and cold segments in the structure opposite each other. When choosing a model with a linear screen tube, keep in mind that at its end the temperature will always be lower than at the burner side.

Dark gas infrared heaters are installed in rooms whose height is three meters or more. When installing heating devices in warehouses with high racks, it should be taken into account that flammable materials and explosive objects are not allowed to be placed at a distance of one and a half meters from the radiator.

It is prohibited to use dark emitters:

- in residential premises and offices;

- in workshops where the work process involves flammable substances.

Dark gas heaters are heavier and larger than light ones, so the costs associated with their installation will be more expensive. They do not take up useful space, as they are suspended from the ceiling. And they are used for both general and zone heating.

It is most beneficial to use dark emitters:

- in isolated large buildings with minimal air exchange;

- in narrow passages;

- in rooms with reduced heat requirements;

- in workshops with relatively low ceilings (3 meters), where the use of light-colored models of gas emitters is not allowed.

It should be noted that with high humidity conditions in the room, it is necessary to choose a device made of stainless steel.

Infrared radiation and human health

There are many speculations about the benefits and harms of infrared heaters for human health. Basically, manufacturers and sellers openly deceive potential buyers . We will talk about the real impact on human health without bias.

Therapeutic effect

Manufacturers of infrared heaters made of natural stone claim their healing and even therapeutic properties. Not a single reliable study has confirmed this. Experts do not deny the benefits of thermal effects on humans in certain cases. But only on the recommendation of a doctor for specific diseases.

Long wave heaters

It is believed that exposure to long-wave infrared heaters is beneficial for humans. The main argument is that the wavelength and frequency of such devices coincide with those emitted by the human body. In practice, this means that long-wave infrared heaters do not harm human health .

Skin cancer

The effects of medium-wave and short-wave IR heating devices have not been sufficiently studied. It is believed that such radiation can destroy the DNA of skin cells. Because of this, mutations can occur that lead to the development of malignant epithelioma (skin cancer). But this has not been confirmed by scientific research .

Colds

The use of infrared heating devices threatens colds - this is a proven fact. And the problem is not the equipment, but the inability to use it correctly . People turn on the IR heater at high power and stay under it for a long time.

The body warms up and the cold is not felt so clearly. If, after a long stay under direct thermal radiation, a person goes into a cold room, he will not feel a sharp temperature change . And the cooling of the body will take its course. In such a situation, the risk of catching a cold or catching an infection increases significantly.

Regular ailments

They occur if a person stays under a ceiling-mounted infrared heater for a long time. Because of this, the upper part of the body warms up much more than the lower part. To warm up the legs, the heart begins to pump blood through the vessels faster.

The heart cannot pump blood to each part of the body separately. Therefore, blood circulation in the brain also increases. When this happens for a long time, you will begin to feel tired, drowsy, unable to concentrate, and a decline in mental abilities .

Sleep disorders

If you sleep with an IR heater on and an open heating element, this will negatively affect the quality of your sleep. The emitting element glows quite brightly, and the presence of a light source impairs the production of melatonin, the sleep hormone. As a result, you will get worse sleep.