In recent years, seam roofs have become widespread both in private housing construction and in the construction of apartment buildings and industrial facilities. When the individual metal sheets that form the roof are joined with a seam seam, a reliable and leak-resistant coating is created. Fastening of roofing panels to the sheathing is carried out using clamps; This technology eliminates the need to make through holes in the coating, which also contributes to its water resistance. But even double seams rolled up using special equipment require additional sealing with sealant.

Why are roofing sealants needed?

Sealants can be used both as a building material and as a repair agent for roof maintenance.

Using this material you can carry out the following roofing work:

- Seal seams between individual roofing elements. Most often, this is needed on roofs with a small slope angle.

- Seal joints in areas where the roofing material comes into contact with other coverings.

- Eliminate cracks in the area of chimney ducts, drainpipes, ventilation shafts, communications and other elements that cause a violation of the integrity of the roofing covering.

- Treat skates located on a slope.

- Prevent cold bridges.

- Carry out quick sealing of leaks.

The most popular are six types of roofing sealants

Sheet metal adhesive Colozinc Soudal

This adhesive sealant is ideal for gutters, trapezoidal sheets and roofing sheets, including varnished, galvanized and raw sheets, as well as ceramic tiles for metal, wood, concrete and brick.

We can use it to repair downspouts and gutters and to seal joints in roofing work. It guarantees excellent adhesion, can be painted, does not react with foam, does not discolor materials and is resistant to extreme temperatures and solar radiation.

Sealing tapes

An inexpensive and effective means of roof protection. This material withstands low temperatures and exposure to the sun. It is very easy to install, and just as easy and quick to remove if replacement is necessary. The bitumen layer created in this way is characterized by good thickness and tightness. It is very resistant to mechanical stress and has good durability.

The tape is often used as a repair patch on bitumen roofing. With its help, it is convenient to insulate junctions, seal vapor barrier material, and repair seam metal roofs and drainage systems. The use of sealing tape is especially suitable for those new to roofing work. It is used to waterproof seams and joining areas. In application, the tape is very similar to regular tape.

Cost of sealing roof joints and seams (price per 1 m2)

The question of cost is one of the most frequently asked by our clients, since everyone wants to get maximum sealing services at an affordable price. It is worth saying right away that the client will be able to hear the final figure only after drawing up an estimate, because, despite the presence of a price list with basic prices, the amount is influenced by the location of the object, its technical condition, and many other factors. As a rule, the cost is determined after inspecting the roof and carrying out a series of calculations of material consumption, for example, sealing corrugated sheets on the roof will be slightly lower than similar work on waterproofing the joints of bitumen shingles.

| Type of work | Unit measured | price, rub. |

| Primary sealing | p.m. | from 120 |

| Secondary sealing without opening the seam | p.m. | from 200 |

| Secondary sealing with opening of the seam | p.m. | from 300 |

| Other types of sealing | p.m. | price negotiable |

Bitumen sealant

Metal roofs made of corrugated sheets, metal tiles, etc. are most often sealed using bitumen sealant. The material can also be used on tiled and roofing felt roofs. Bitumen sealant for roofing is quite toxic and not very resistant to high temperatures (read: “Types of roofing bitumen sealants, rules of use, methods of application”).

As for the strengths of this rather elastic sealant, it is first of all worth highlighting its high strength and moisture-resistant characteristics. Bitumen sealants can be laid not only on dry, but also on wet substrates, with the possibility of subsequent painting to match the overall coating.

Repair and sealing of seam roofing.

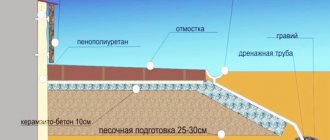

The purpose of any type of roof is to provide high-quality protection for the building from adverse weather conditions, and if roof leaks occur during snow melting and heavy rains, then it is necessary to waterproof the roof joints. In winter, the ice and snow on the roof melt from the heat that comes from the attic, and the top layer of snow presses water into poorly made roof seams. For any type of roof, in winter it is necessary to regularly clean the roof from snow, ice and icicles.

To eliminate leaks in a seam roof, you need to repair the roof seams. By bending the seams or covering them with strips of soft roofing and organizing a system for draining water from the roof, leaks can be eliminated, but not for long, because when the temperature changes, the strips crack and the seams separate again.

Rubber and silicone

For the sale of silicone mixtures, both standard packaging for pistols and buckets can be used, which makes it possible to apply the substance with modern spray guns and construction rollers. Roofing silicone is one of the most popular materials of this type.

The fact is that this universal material is not afraid of significant fluctuations in air temperature and direct sunlight. Once applied, silicone roofing sealant hardens quickly. It is used for both temporary and permanent purposes. Silicone-type compounds can be acetic or neutral. The latter option is not as durable as the first, but does not emit toxic substances and is practically odorless.

Acrylic

This type of sealant is very similar to the previous one, at a lower cost. In addition, to apply it, the surface to be treated must be thoroughly dried. The advantages of the material include the complete absence of solvents and odor during use.

If you want to achieve maximum invisibility of the treated area, this will be quite easy, thanks to the significant color range of acrylic sealant. When using this material for roofing work, one should take into account its low waterproofing characteristics. This is explained by the presence of aqueous dispersion in the acrylic composition. To solve this problem, it is recommended to use joint tape in parallel with acrylic sealant.

Polyurethane

Polyurethane sealant is based on polymerized resins, the production of which will require special conditions. The result is a viscous and fluid substance that can be easily processed on any surface.

This type of sealant is quite toxic and the most expensive: the cost of purchasing it is fully compensated by the high performance characteristics of the material. In this case, sealing can be carried out in fairly severe frosts; The substance is easy to apply and hardens quickly. The resulting surface effectively serves for a long time, withstanding mechanical stress, moisture and corrosion. Any substrate is suitable for applying polyurethane sealant.

Two-component

The two-component mixture is based on silicone rubber, the ingredients of which are adhesive paste and a special hardener. The shelf life of this sealant until the moment of application is quite significant, however, after mixing the individual components, the sealant must be applied within a certain time, otherwise the polymerization process will begin.

The two-component composition is quite convenient to apply, and this can be done at temperatures from -25 to +40 degrees. As for the temperature stability after the substance hardens, it ranges from -70 to +70 degrees. Rubber roofing sealant adheres well to metal, concrete, plastic, brick surfaces, and the resulting seam after sealing is characterized by strength and smoothness.

What will you get by collaborating with us?

The answer to the question of how to seal a roof made of corrugated sheets or any other material can be easily found on the Internet. But it is almost impossible to translate this into reality without a base of knowledge and experience. Considering that the durability of the building and the comfort of staying in it will depend on the quality of the work performed, the sealing process must be approached very carefully.

By trusting us, you will receive 100% high-quality roof waterproofing for many years. After all, we guarantee our clients:

- use of professional equipment and materials from trusted suppliers;

- involving only experienced employees in the process;

- quality control

Mastic

Along with the above sealants, the roof can also be treated with mastic. To produce this viscous plastic mass, you will need to mix binders and fine fillers such as carbon black, talc, graphite, etc.

The material also contains special additives. By dosing different components when mixing, you can give the substance the required characteristics. Waterproofing is mainly carried out with bitumen mastic, however, if we are talking about the installation of roll materials, a more expensive polymer version can also be used.

Metal roofing

It is best to seal a metal roof with a material that has the following properties:

- Elasticity.

- Resistant to precipitation.

- Good adhesion to metal surfaces.

- Ability to withstand vibration well.

Having carefully studied the question of which sealant to choose for corrugated sheets, you can come to the conclusion that polyurethane and bitumen-rubber type substances are most suitable in this case. The metal surface, before applying them, must be thoroughly cleaned, dried and degreased.

In case of urgent repairs, a metal roof sealant is selected that can be applied to a wet base. Corrugated sheeting and metal tiles have similar characteristics, so the process of sealing them is identical. In addition, roofing sealants for corrugated sheets can be successfully used on other types of metal roofs.

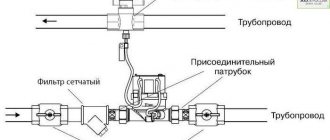

In order for the sealing of a corrugated roof to be reliable and durable, the following procedures should be carried out:

- Carefully check all joints before applying sealant. If necessary, clean and dry them.

- To apply sealant to a corrugated roof, an even layer of 2-3 mm is used. In this case, polyurethane tape will not be superfluous.

- The work must be carried out in dry, warm weather, since sealant for roofing with corrugated sheets does not react well to humidity.

Regarding the application of sealant to metal roofing, the following recommendations will be required:

- Gaps up to 5 mm are sealed with silicone sealant. For this purpose, a composition is selected that tolerates sunlight well.

- All roofing joints need to be treated, both longitudinal and transverse. It is also important not to forget to seal the ventilation duct, antenna outlet and chimney.

Roofing screw plus a piece of plywood

A good way that does not require the purchase of additional materials. The technology is simple. A self-tapping screw screwed in by mistake is unscrewed. A piece of plywood or board (preferably at least 5x5 cm, at least 8 mm thick) is placed under the hole and the self-tapping screw is screwed in again. At the same time, it will already enter the base and press against the metal. The rubber washer will ensure a tight seal at the connection point. Considering that the self-tapping screw will be the same color as the metal tile, an installation error will be almost invisible.

Soft roof

Global sealing of soft roofs is mainly carried out using mastic.

In other situations, the following sealants are used for membrane roofing:

- Flat roofs are sealed with liquid rubber.

- It is convenient to carry out fragmentary repairs with one-component liquid rubber.

- Seams and joints can be sealed with sealing tape or roof joint sealant.

- Even wet substrates can be treated with sealing mastic. This material is characterized by strong adhesion to basic building materials.

Which manufacturers to focus on

The cost of roofing sealants is determined taking into account what properties the material has, who produces it, and in what region it is sold. In addition, wholesale purchases will be cheaper than individual purchases.

The most popular manufacturers of materials for roof sealing are:

- Soudal.

- Makroflex.

- Tytan.

- LIQUID NAILS.

Before purchasing roofing sealant, carefully study its packaging. It is important to understand what setting speed this material has and how it reacts to high humidity. A separate list usually indicates the compatibility of the sealant with certain roofing materials.

It is also very important whether it can be painted after drying, and what is the level of resistance to climatic influences. The correct selection of material and its proper application will guarantee the creation of high-quality protection for the roof. Most of these jobs will not require any special experience. However, if in doubt, it is better to hire experienced roofers: they will tell you which roofing sealant to use for a given situation.

Work technology

| Careful adherence to the technology for performing waterproofing work guarantees reliable sealing of the roof covering and 100% elimination of leaks for a long time. |

Stages of implementation:

- Inspection of the work site, preliminary determination of the scope of repairs, selection of materials and tools.

- Preparing the roof surface - the coating must be cleaned of dirt, dust, old sealant, and materials made of galvanized steel or other metal must be degreased using a solvent.

- If there are pockets of corrosion, the metal must be cleaned.

- Laying sealing tape in joints and seams. To improve the connection with the metal surface, it is worth pressing the edges of the tape with a roller.

- In dangerous places where there is an increased likelihood of moisture getting under the coating, it is necessary to reinforce with fiberglass.

- Coating the gaps with mastic is done using a special gun or brush.

| When sealing a roof junction, strict adherence to the application conditions and temperature conditions specified by the manufacturer of the waterproofing material is necessary. The vast majority of materials are not applied to a wet surface. |

Carrying out work to seal the roof seams would be a good option if the roof covering itself is in satisfactory condition. When metal roofing sheets require repairs, sealing is a temporary solution to the problem of leaks.

Sealing of roof junctions with walls and technological shafts

It is impossible to achieve a perfect fit of the roof covering to the walls, ventilation shafts, and roof windows. To eliminate cracks, it is necessary to seal the joints.

| Small gaps are eliminated using sealing gaskets and tapes. Then it is coated with waterproof mastics and sealants. |

If the sealing area is quite large, then it is necessary to install a waterproofing apron. This is true for areas adjacent to the walls of a building, around chimneys. At the joints of the roof window openings, a multi-layer insulating seam is made.