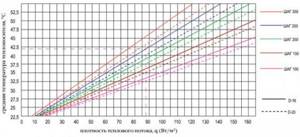

A mixing unit, or manifold, in a warm water floor system is needed to adjust the temperature of the coolant. The latter is heated by the boiler according to the parameters specified by the device program. Typically the supply temperature of the heating medium is 55 °C. This is enough for the heated floor to warm up to a temperature of 30 °C. This is the most comfortable value for the cold season.

Sometimes you can do without a mixing unit

If there is a collector, the high supply temperature does not matter - the mixer itself will lower it to the desired value by mixing in cold water. Accordingly, if a water floor without a collector is planned, then the coolant must arrive at a predetermined temperature, from which we can conclude that a separate boiler must be installed for a warm floor without a mixing unit.

Thus, for individual radiator heating you need a second boiler or a centralized communal radiator system. According to government regulations, the temperature of coolant supply to radiators is on average 70-80 °C, which is significantly higher than that required for heated floors.

The nuances of installing heated floors without a mixing unit

The main disadvantage of installing a system without a collector is the need to minimize coolant temperature losses along the path “coolant heater – pipeline” and in the system itself. You also need to maintain the required temperature on the floor area. Therefore, it is recommended to take into account the following requirements:

- Insulation of room walls;

- Laying thermal insulation on the floor;

- Availability of high-quality window systems;

- Laying the floor in close proximity to the heating element;

- The area of the room is no more than 20-25 m2.

The main and common mistake when installing such a system without a collector unit is trying to install it on too large an area.

Important! It is necessary to calculate the length of the circuit and its layout so that the return temperature of the coolant is not too low. Otherwise, a large amount of condensate will form on the boiler heat exchanger, which will lead to rapid breakdown of the device.

However, some craftsmen argue that in a situation where the “return” will be cold in any case, installing a condensing boiler can save the day. It has high efficiency and such a device is not afraid of low temperatures for heating.

Installation diagram of a heated floor without a mixing unit

How to choose a device

When independently choosing a comb for a heated floor, it is necessary to correctly determine the functional purpose of this unit, calculate the number of loops or inputs connected to the device, and also pay attention to the material of manufacture and the presence of automation, which makes operation convenient and as efficient as possible

Material of supply and return manifolds

Manifolds produced today can be made using traditional stainless steel, brass and high-strength plastic.

Stainless steel is an almost ideal, but rather expensive option. Brass components are cheaper, but less reliable, and are characterized by increased fragility.

Number of circuits on the collectors, permissible level of pressure and water flow

Heating collectors separating the flow of coolant are most often represented by two distribution combs. The first is where coolant flows in, and the second is where it is returned. The end part is equipped with a connection to the supply or return line, and directly along the body there are fittings for the loops (circuits) of the installed “warm floor” heating system.

Degree of product automation

The modern market of plumbing products is ready to present to domestic and foreign consumers technically advanced designs of combs connected to thermostats and a programmable controller, which allows adjustment of the temperature regime and coolant flow on the circuits according to changing needs.

Company manufacturer

The highest quality products are produced by European manufacturers, but their cost is very high, so the price of a modern and high-quality collector, as a rule, starts from $1000–1200. Purchasing affordable Chinese devices is often a risky endeavor, since such combs are usually not very durable. Nevertheless, there are a number of brands that have proven themselves well and are in demand by consumers.

Table: advantages and characteristics of various brands of collectors

| Name | Characteristics | Main advantages |

| Millennium | Manufacturer group made in China for efficient and safe use in the “warm floor” system. | The comb is characterized by an ideal balance between affordable price and functionality. |

| TIM | A collector group with Chinese-made flow meters for the installation of water-heated floors and use in collector-radiant heating distribution. | The comb is produced using European equipment, is of high quality, and is very reliable throughout its entire service life. Made by injection molding using high quality brass. |

| Oventrop Multidis | German distributor for an underfloor heating system with forced circulation. | The comb is made of stainless steel and is intended for underfloor heating with built-in rotameters and control inserts. |

| Stout | Italian manifold assembly, made of stainless steel, equipped with flow meters, which are manufactured under careful control. | High reliability is due to high-quality materials and optimal configuration of the unit in the version for installing heated floors. |

| Valtec | Italian nickel-plated brass manifold for distributing thermal fluid flows in a contour heated floor system. | At the outlets of the comb there is a control valve to control coolant flow with an average full resource of eight thousand cycles. |

Connection methods

You will need the following materials and devices:

- Pipeline;

- Pipeline components;

- Boiler;

- Three-way thermostatic valve;

- Pump assembly.

Some people try to use the simplest installation method - to embed the underfloor heating system directly into the central heating system. However, this approach threatens serious damage to the pipeline, because The temperature for radiators is much higher than that needed for the floor. Also, if such a “homemade device” is discovered by supervisory authorities, the owner of the apartment faces serious penalties and an order to completely dismantle the warm water floor.

Options for laying a pipeline without a collector : snail and snake. Moreover, both schemes must consist of a double pipeline: 2 parallel loops to the heated floor - supply and return.

- The advantage of the “snake” is that you can distribute heating zones. For example, go around furniture or plumbing fixtures.

- The advantage of the “snail” is more uniform heating of the entire area.

After laying the pipeline, it must be connected to the boiler. You must first calculate the pump power. The following formula is used:

G =Q X 0.86/Δt,

where G is the system capacity (l/h),

Q - system power (W),

0.86 — conversion factor in Kcal/h,

Δt—flow-return temperature difference (°C).

A pump is needed to ensure the speed of coolant movement through the pipes. Depending on the type of pump, it can be controlled either manually or automatically. The device is mounted on the supply pipeline. In a system without a mixing unit, the pump device is located under the boiler. The circuit between the pipeline with the pump and the boiler is closed by a three-way thermostatic valve.

In order for the heated floor to work stably without installing a mixing unit, you should choose a high-quality, powerful boiler. Electric or gas – it doesn’t really matter. The main thing is that the power of the device is designed specifically for the designed heated floor. Experts recommend choosing models with a pump.

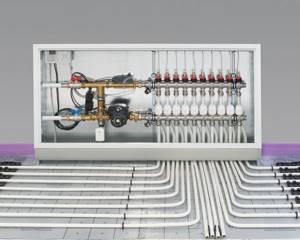

How does the comb assembly work?

When pipes are laid out in different rooms, their ends still come together in one place. A comb is connected to them. This is a distribution center. He has the following tasks:

- Reducing the temperature of the water coming from the boiler. The temperature for supply to the floor should be a maximum of 45 degrees, and the heat generator usually heats the coolant much hotter.

- Providing the required amount of heat for each room separately. The comb here functions as an energy distributor and is responsible for the flow rate on each circuit separately.

There are two collectors in the comb - return and supply. They are horizontal, connected to consumers - these are heating circuits. Coolant from the main line enters them from the ends.

What does a comb for a heated floor look like?

To regulate the volume of water entering the circuits, valves are installed on the manifold. They are equipped with a pressure rod. You can adjust manually or automatically. To control the volume of water, the outlets from the second collector are equipped with flasks that measure flow.

Another important detail is the circulation pump. Without it, nothing will work properly, because the pump regulates the water circulation.

Function of a two-way valve

The operating principle of a two-way comb is simplified when compared with a three-way mechanism. A two-way valve with a fixed remote temperature sensor is placed in front of the comb. The sensor is located together with the processing manifold.

The valve has 2 main modes - opening and closing. They determine the location of the stem. The rod is controlled by a thermal head.

The operating principle of the design is as follows: first, the two-way valve is in the open position, while hot liquid is supplied to the comb. It is mixed with cooled water from the check valve, only then it enters the manifold to enter the floor system. A remote sensor located at the outlet measures the temperature. When it is less than the required level, the two-way valve will open. After heating brings the water to the optimal temperature, the system closes and the coolant no longer comes from the main source.

As heat is transferred into the room, the water cools and its temperature becomes less than the established norm. The thermal head of the valve, receiving information from the sensor, raises the rod, opens the valve, then the hot water from the boiler is again mixed with the cooled water in the comb.

So, the two-way system is reliable, it minimizes the likelihood of breakdown and too hot water entering the system. This process is also controlled by a thermostat and the operating principle of the equipment.

It should be noted that the smoothness and accuracy of adjustment is worse in contrast to installing a three-way valve.

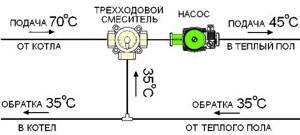

Operation of a comb with a three-way valve

When choosing a comb, you should study the structure of the three-way valve, its pros and cons. Unlike the two-way one, it is more optimized because the circuit has three inputs:

- 1 node – receives coolant from the boiler;

- Node 2 – receives water from the outgoing collector;

- Node 3 – line from the processing manifold.

Connecting this valve is not difficult, and the operating principle includes the following steps:

- At first the mixing line is closed, but the supply from the boiler is open. Heated water enters the comb.

- The sensor notifies that the temperature is exceeded. In this case, the lock in the valve shifts, at the same time the mixing unit opens, and the flow of coolant is closed.

- Now the temperature is normalized, and the locking structure does not change its location.

- When the water makes several cycles of movement, it cools down. The valve records this process and closes the mixing unit.

Operating principle

The operating principle of the three-way design is characterized by smoothness and the ability to more accurately regulate the temperature regime. Despite these advantages, the disadvantage is the lack of reliability of the system.

Installation of the thermostatic valve

The valve is installed on the pipe with the supply coolant, and a jumper is mounted to the return flow. The purpose of the three-way thermostatic valve is to regulate the temperature of the coolant supplied to the pump. In fact, it is a mixer with a heat-sensitive element located inside it.

The valve protects the system from overheating, and in the event of a breakdown and interruption of the return flow, it automatically shuts off the supply. The valve also eliminates the possibility of reverse flow of the supply flow. Thus, the valve partially takes on the role of a collector.

If the floor area is large and there are significant heat losses on the return side, it is recommended to install a valve at the cold inlet end. Thanks to this, excess condensation will not form in the heat exchanger.

How to delete history in Yandex on an Android phone

Almost every smartphone user who uses his gadget to access the Internet regularly looks for various information in search engines, both Google and Yandex. The lion's share of the Russian-speaking audience uses the domestic search engine Yandex, so we are talking specifically about it. At some point, it becomes necessary to clear the history in the search engine, and each person’s goals may be different: removing traces of activity, selling a smartphone and clearing data, deleting unnecessary files to save space.

Ways to clear Yandex history

You should understand the difference between search history and browsing history. These are two different chronologies that are recorded by Yandex as a result of all your actions. In this article we will tell you how to clear everything, including queries with artificial intelligence Alice.

Search history

Yandex remembers everything you request in the search engine, so it will display all your requests, especially the latest ones, in the search bar as an alternative. But this only happens if you are logged in to your Yandex account (most users are registered there). This is done in order to provide you with the most relevant and related tips in the future, so the history is recorded for each account by default. But it can be cleared in a few clicks, and on an Android mobile device this is done as follows:

- On your smartphone, go to the official Yandex website and in the top tab, click on “Login” to log in with your account;

- Once authorization has been completed, return to the main page of the search engine and click on the search line;

- The system will show you all the queries that you have entered recently. If you need to clear only specific ones, then click on the cross icon next to the phrase. By clearing some phrases, others will appear that you requested even earlier;

- If you need to completely clear the entire history of search phrases, then in the same list, find the item “Setting up query history” at the very bottom and click on it;

- You will be redirected to settings, where you need to uncheck the “Show query history” option, and then save your choice;

- Now all subsequent queries will not be saved by the search engine while you are using this account.