A garage is a place that should be completely comfortable to use, which means it should have additional amenities. Moreover, this is required by the car, which must be in favorable conditions. Therefore, the idea of arranging additional communications and functions in the garage is born. One of the main options is a heated floor in the garage, which will take care of warming the air and save energy consumption. For example, when it is necessary to inspect and repair a car, there is a need for contact with the floors.

Do you need heated floors in the garage?

Whether it is necessary to fill the heated floor in the garage is an individual decision. Such a heating system is important not only for the user’s comfort, but also for his health. Prolonged stay in a cold room or on an icy floor can lead to illness and have serious consequences.

Having a heated floor in the garage saves time and money inevitably spent on warming up the car in winter. Regularly maintaining above-zero temperatures is useful not only for people, but also for equipment, tools, and materials stored indoors. If you can enter the garage from home, then you won’t have to waste time putting on warm clothes and shoes every time if you just need to pick up some item.

What material is best for thermal insulation?

Its choice depends on the characteristics, as well as on the structural features of the garage. The most common materials can be classified into one of two types:

- Foamed polymer materials. These include polystyrene foam, polypropylene foam and polyurethane foam. They can be purchased in blocks, slabs or panels. Such materials are among the most affordable (especially foam plastic), they are easy to install, and they are airtight. The features of such materials include the need to equip a ventilation system, this will avoid the accumulation of condensate;

- Materials based on mineral fibers. This type includes glass wool and mineral wool. Typically they are sold in rolls, mats or slabs.

Less common is the insulation of garage floors with expanded clay, roofing felt and other materials.

The criteria for choosing a material as insulation include health safety, fire resistance, level of load resistance, sound insulation, etc. When choosing insulation, these features should be taken into account. You can learn more about the topic of thermal insulation in the garage in the video.

Pros and cons of heated floors in the garage

Organizing a heated floor in a garage provides many advantages:

- creating optimal conditions for maintaining vehicles, storing tools and materials;

- user comfort regardless of the length of stay in the garage;

- the ability to install the system yourself;

- low energy costs in the presence of another heat source or high-quality insulation of the building.

The main disadvantage of underfloor heating is the cost of operating the system. If it can be connected to hot water supply, then there is no such problem.

Another possible drawback is the risk of the gate freezing. This happens due to the formation of condensation on them as a result of the temperature difference between inside and outside the garage. The situation is aggravated by melting and flowing snow from the car. The problem can be solved by organizing a slight slope towards the gate and drainage.

The remaining disadvantages are directly related to the installation of heated floors:

- materials costs;

- it may be necessary to dismantle the old coating;

- It is important to correctly calculate the thickness of the heated floor in the garage so that the surface warms up sufficiently, but does not sag under the weight of the car.

Comment! In warm weather, corrosion develops even more actively. To prevent this from happening, it is important to ensure good ventilation in the garage.

Types of heated floors

There are different ideas for heated floors in the garage. The most popular systems are water and electric types. There are a number of differences between them.

The water floor is a structure made of steel or metal-plastic pipes. The coolant is heated water moving through them. Its source can be a central heating system or an autonomous boiler - gas, electric, solid fuel.

A water floor ensures uniform heating, but in cold weather, a long shutdown can cause the entire system to fail.

You can install a water heated floor under the wooden floors in the garage or pour a concrete screed.

Electrical systems come in different types. The main difference is in the heating element:

- cable heated floor;

The cable system is based on a single-, double-core resistive or self-regulating cable - film (carbon).

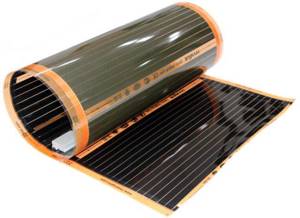

The basis of the film heated floor is a carbon infrared emitter

Infrared film is attractive due to its ease of installation. The main advantage of electric heated floors over water ones is the absence of the risk of leakage. The disadvantage is the risk of electric shock. This problem will be solved by reliable grounding and a residual current device (RCD).

Advantages and disadvantages

Portable heated floors have many advantages:

Mobility. Having one product, you can freely move it wherever you need it. You can use it in the living room during the day, and take it with you to the bedroom at night. It is also convenient to transport it in a car and take it to the country. You can use such systems under other decorative elements, for example, install a mobile heated floor under a carpet or hide it in a carpet. Thus, having this product, you don’t have to spend money on heated floors in all rooms at once.

No installation work. One of the basic operating principles of such systems is “turn on and heat up.” In this case, no repairs are required - just a trip to the store and the presence of an outlet in the right room.

- Efficiency. The efficiency of such a system is 90%. Floor heating is a very profitable type of room heating, because often the main cold in the room comes from the floor. It is also worth noting that with the help of the mobility of these systems, heat is delivered exactly where people are. You can add that the heat is located below, and does not immediately go to the ceiling.

- Durability. The resource declared by the manufacturers is 50 thousand hours of operation when twisting and moving from place to place. But this can only be observed with care.

- Temperature control. This system has the ability to regulate the heat output;

- Safety. High-quality products will not harm either people or pets;

- Low accident rate. There is nothing to leak from such a system onto the floor to ruin it. If all rules are followed, the risk of an accident is zero.

It is possible to highlight disadvantages both in general of such systems and in their various types:

- High price. Since this technology is still new and just conquering the market, its cost will be high.

- Increase in electricity bills. With the use of such systems, electricity consumption will increase.

- Furniture legs cannot be placed on mobile floors. They can cause a system crash and subsequent failure.

Use of floors with resistive film in dry rooms. Knowing that you have a mobile heated floor, you need to know exactly the type of film. Floors with resistive film should not be installed in the bathroom or kitchen. They are also prohibited from being used in rooms with humidity above 85%.

Decrease in heating intensity over time. Frequent power surges do not threaten to damage the system. But if there are surges, and they occur too often, it is necessary to either buy a voltage relay that will automatically disconnect the system from the voltage, or monitor these surges yourself. Otherwise, the floor heating process will be slowed down.

Technology for laying electric heated floors in a garage

It is better to install an electric heated floor in a garage under a screed. Wooden flooring is not recommended due to the material's flammability, low thermal conductivity and tendency to dry out.

Tools and materials

To install a heated floor, you need to select a heating element. This can be a resistive or self-regulating cable or a mat - a flexible sheet with a wire already fixed. The second option will cost more, but it is easier and more convenient to install.

In addition to the heating element, for a heated floor in the garage you will need:

- thermostat;

- temperature sensor;

- RCD;

- ground wire;

- fasteners;

- roulette;

- wire cutters;

- level;

- perforator;

- Screwdriver Set;

- stationery knife;

- cement-sand mixture and gravel or ready-made concrete mortar for screed;

- polyethylene film for waterproofing;

- thermal insulation material – polystyrene foam, extruded polystyrene foam, penoplex, Penofol;

- reinforcing mesh.

Preparatory work

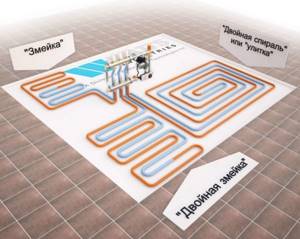

The arrangement of a heating system always begins with calculations. The layout of a heated floor in a garage can be in the form of a snake (simple, double or angular) or a spiral.

If you install an infrared heated floor in a garage, then it should cover up to 70% of the surface, and if there are other heating sources - up to 50%. The film is laid at a distance of 10 cm from the wall. It cannot be placed under heavy objects.

Be sure to calculate the power of the heated floor in advance so that the electrical network in the garage can cope with the load. Calculations depend on the selected heating element. For average calculations, you need to multiply the area of the room by 130 W.

Comment! If the heated floor area is more than 40 m², expansion joints are required. To fill them, synthetic polymer materials or special T-shaped profiles are used.

Before laying a heated floor, preparation of the base is required. It is necessary to clean the surface and level it. Small differences are acceptable, in other cases a thin filler screed is needed. It is important to wait for it to dry completely. If there is an inspection hole, before pouring the screed, it is better to build formwork around it.

To minimize heat loss, which leads to increased energy costs, you need to take care of insulating the entire garage

After preparing the surface for installation of a heated floor in the garage, you need to organize hydro- and thermal insulation. First, spread the film, releasing 10-15 cm onto the walls. Cover the perimeter of the room with damper tape.

The optimal layer of thermal insulation material is 10 cm. If you use polystyrene foam, you can take the thickness half as much. All that remains is to place the reinforcing mesh on top.

Installation instructions

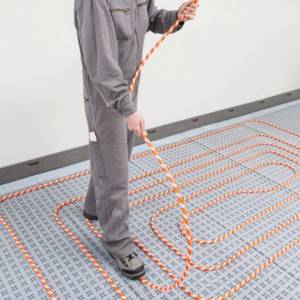

After preparing the surface and organizing hydro- and thermal insulation, you can begin laying the heating elements. The algorithm is simple:

- Make markings on the insulation.

- Lay the wire along the marks according to the selected diagram. Leave 30 cm between turns.

- Fix the cable to the reinforcing mesh with clips or using galvanized steel mounting tape with special teeth.

- Place the contours parallel, the maximum bend angle of the wire is 90°.

- Secure the mounting box and thermostat.

- Connect the power cable and grounding.

- Make a depression in the thermal insulation layer 0.5 m from the wall and place a corrugated tube with a temperature sensor inside it. Connect the wire to the thermostat.

- Check system functionality.

Comment! For installation, use a solid cable without twists. Their presence affects the quality of work and service life of the heated floor.

After laying the heating elements, all that remains is to pour the heated floor in the garage - you can make the solution yourself or order ready-made concrete. It is allowed to use screed as a finishing coating or lay tiles.

Methods for insulating a concrete base and their features

It is not difficult to insulate a concrete floor after studying the technology of performing the work and mastering the specifics of performing thermal insulation measures for various types of insulation. Let's look at these points in more detail.

Fiber insulation for concrete floors

Fiber heat insulator is used to insulate concrete floors between floors of a building.

Lay slabs or roll material according to the following algorithm:

- Waterproof the concrete surface with plastic film.

- Cut and lay insulation on the waterproofing.

- Seal the joint areas with special tape.

- Place foil insulation on the insulating layer.

When performing work, pay attention to the correct location of the metallized film, which should be laid with foil towards the room. Then the heated floor communications are assembled on the prepared surface or sheets of plywood are laid

Having studied the technology of performing the work, it is not difficult to carry out the floor insulation work yourself

Thermal insulation of concrete coating with polystyrene foam

The process of laying polystyrene foam sheets does not require special preparation. The thermal insulation material does not require waterproofing protection and is fixed with an adhesive composition directly to the concrete base.

Carry out work following the order of operations:

- Coat the concrete surface with a deep penetration antiseptic compound.

- Prepare the adhesive composition following the manufacturer's instructions.

- Apply a thin layer of adhesive to the boards and smooth it over the surface with a spatula.

- Place the heat insulator on the concrete surface and press evenly.

- Lay the remaining sheets according to the specified algorithm, ensuring that the joints are offset.

After laying the insulation, seal the joint areas with silicone, lay the mesh for reinforcement and pour the concrete screed.

We use expanded clay for thermal insulation: specifics of laying insulation

Expanded clay granules are used for thermal insulation of concrete foundations in private homes. When performing work, follow the specified sequence of actions:

- Waterproof the floor with polyethylene or mastic.

- Pour expanded clay onto the surface and level it.

- Lay the mesh for reinforcement.

- Prepare the screed solution in the required volume.

- Fill and level the surface of the screed.

After gaining strength, lay the finishing coating.

In private houses, expanded clay granules are used for thermal insulation of concrete foundations.

How best to insulate a concrete floor using spray compounds

Thermal insulation measures for applying sprayed insulation to a concrete floor are carried out only by professionals. After all, to carry out the work, you need special equipment that, under high pressure, supplies a layer of heat-insulating material to the surface of the concrete floor. As a result, a solid layer of insulation is formed. Distinctive features of the technology are the absence of the need to level the surface and seal joints.

Procedure for applying polystyrene foam:

- Clean the concrete surface and treat with primer.

- Secure the joists to the concrete floor using steel angles.

- Spray a layer of polystyrene foam.

When hardened, the material increases in volume, acquires a porous structure, penetrates deeply into cavities and seals microcracks.

How to use polymer thermal insulation

Polymer-based insulation is applied to the floor surface in an even layer. When performing work, follow the manufacturer's recommendations indicated on the packaging.

Follow the application procedure:

- Dust the concrete base.

- Treat the floor with a layer of primer.

- Apply polymer compound.

After the polymer insulation has dried, lay the finishing coating.

How to make a water heated floor in a garage yourself

It is appropriate to install a water floor in the garage when you can connect it to the heating system. In other cases, you need an autonomous boiler, and the cost of purchasing it may not be justified.

Materials and tools

For installation of water heated floors, metal-plastic pipes are usually used. The optimal cross-section is 16 mm. In addition to pipes, you will need:

- pump, power from 1.5 kW;

- thermostat;

- three-way valve;

- fitting;

- heat insulating tube;

- valves for supplying and draining coolant;

- supply hose;

- servo;

- two automatic air vents;

- perforator;

- wire cutters;

- level;

- stationery knife;

- fasteners;

- waterproofing;

- insulation;

- fittings;

- screed materials.

When preparing the subfloor for laying pipes, it must be taken into account that the differences should not exceed half of their diameter

Preparatory activities

If you make a warm water floor in a garage on the ground from scratch, then start with a rough screed. Before pouring it, it is important to prepare several layers:

- 10 cm sand cushion;

- 10 cm crushed stone;

- a layer of insulation, if you use polystyrene foam, then 10 cm is enough;

- waterproofing layer - usually using polyethylene film or roofing felt;

- fittings

All these layers are necessary to reduce heat loss. If there is already a concrete floor in the garage, then the surface should be cleaned and leveled. Hydro- and thermal insulation is done in the same way as preparing for the installation of an electric floor. Instead of plastic film, it is better to use roofing felt, treating the seams with bitumen mastic.

Installation stages

Pipes for a water floor in a garage can be laid in different ways:

- snake – parallel placement, use clamps or wire for fixation;

- spiral – better heating, installation is more difficult, the scheme is recommended for large areas.

The main stages of installing a water-heated floor in a garage under a screed:

- Make markings for laying pipes.

- Mount the sheathing on plastic supports. The distance to the insulation is 3-4 cm.

- Laying pipes according to markings. Fix with clamps or staples in increments of 30-40 cm, at turns 15 cm.

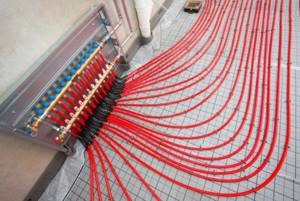

- Install the collector-mixing unit and connect it to the water supply source - a boiler or heating system.

- Connect the pipe of each circuit at both ends to the valves using fittings.

- Check the functionality and tightness of the system. Set the pressure twice as high as normal and observe for 24 hours.

- Fill the screed.

Make a distance of 10 cm between turns. Pipes can be placed less often in the center of the room than near gates and walls. At the end of the hose, attach a heat-insulating tube with a fitting to connect it to the manifold.

Regulation, supply of hot water and removal of waste coolant are provided by a collector-mixing unit. You can buy a ready-made structure or assemble it yourself. For the collector in the garage, you need to equip a special cabinet, its optimal size is 50x50x15 cm (WHH).

Comment! Turning on the system is allowed only after the concrete has completely dried. It's better to wait a month.

Antifreeze can be used as a coolant for a water floor, but the pump performance must be higher

Water or electric?

In most cases, you can only install an electric floor, because:

- Not all garage cooperatives have central heating;

- if there is a central heating system, it is not a fact that there will be batteries and taps in the garage: sometimes it is just 2 pipes along the wall (you can crash into them in the summer, when there is no coolant, but it is not a fact that they will be allowed to do this, but if you do it quietly , then if there is a leak you will be at fault);

- if there is a central heating system, but after your garage there are many other garages along the coolant path, you cannot have a heated floor: it will take in more heat, and the owners of subsequent garages may complain about cold radiators.

An option for those who have a central heating system, but their garage is far from the latest in the flow of coolant: you can make a water floor with a short circuit length.

And one more disadvantage of water TP in the garage: if the machine pushes the pipe to the point of cracking, there will be an accident. A hot water leak will form, which will freeze in your screed (and most likely destroy it). And this problem may not be noticed very soon - because not everyone is in the garage every day.

Now about electric transformer stations.

If you have normal wiring, this option is better because:

- this will not affect your neighbors in any way (while the water floor will “take away” some of the heat from the next garages);

- there is no risk of filling the screed with water if the machine pushes through the TP (even if the cable or infrared mat is damaged, you will simply lose heating, but the floor will remain intact).

There are also disadvantages:

- in some cooperatives, electricity operates in doses - for example, from 8.00 to 20.00 (although in this case it will not be possible to use other electric heaters outside of working hours, so this point is presented more for show);

- If the garage is poorly insulated, it has an individual meter, and you plan to heat yourself a lot, often, the electricity bill can be quite high.

As for the choice between electrical systems (rod or infrared mat), there is not much difference, you can take either one. Because we will not have the need and opportunity to measure every degree.

Therefore, our advice is this : electric transformer is in most cases better and safer. It’s worth installing a water garage only if your garage is on the edge or very close to the edge, you visit it often, and you’re not going to save every ruble (that is, make the screed thick enough and reinforced).

Safety precautions

When installing a heated floor, heating elements are hidden in the floor, which increases the level of safety. To maintain it, it is important to remember a number of factors:

- Level the base for the system.

- Carefully seal all joints.

- Correctly connect the system to the collector; if you lack personal experience, you should consult a specialist.

- Use certified materials.

- Electric underfloor heating cannot be tested by applying voltage. Control is carried out by measuring the resistance of the heating wire and checking with the manufacturer’s data.

Comment! When pouring a concrete base, it is important to make the slab thickness at least 10 cm. To increase strength, plasticizers and additives should be used.

Pipe laying

Water heated floor pipes are most often laid using the “snake” method with parallel distribution of turns over the entire area of the room. The pipes are secured with clamps or wire.

If the garage area is large, pipes are laid using the “spiral” method. In this case, the area is heated more evenly, although installation is considered more labor-intensive.

When laying pipes using any method, it is prohibited to bend the pipes at an angle of less than 90 degrees, so as not to damage the heating element. For the same reason, you should not step on pipes and damage them. If any section is damaged, the entire circulation circuit must be replaced.