Advantages of combining electricity and coolant fluid

The main and main advantage that the new electric water underfloor heating scheme has is the absence of complex additional equipment.

Without a pumping and mixing unit, a manifold, safety valves and flow meters, it is difficult to imagine a full-fledged water heated floor in working condition. In the case of electric water floors, the situation is radically different. The system does not require the installation of a whole complex of servicing devices, devices and units. Other advantages of this system include the following aspects:

- the system evenly warms the floor surface to the specified temperature values;

- quick access of heating equipment to optimal operating parameters;

- automatic control;

- safe operation;

- extremely low power consumption;

- quick and easy installation.

There is a clear improvement in the well-known hot water floors. Thanks to new technologies, it was possible to eliminate a number of complex and expensive units and mechanisms from the system design. In addition, the combined system can be used to heat any residential premises. Of particular interest is the fact that the electric water heating circuit is equally effective when operating in different temperature conditions. Such heating can be installed for heating rooms of any size (as long as funds are available).

From an environmental and safety point of view, this scheme is practically safe. Automatic adjustment eliminates overheating of the heating elements. Accordingly, the set temperature will always be maintained in the heated room. When installing this heating option, you can use almost any floor covering.

Little can be said about the disadvantages of electric water heated floors. Compared to a water floor, heating costs will be slightly higher than usual. A one-time investment when purchasing equipment can also significantly affect your budget. However, overall, there are no serious disadvantages from such a heating system in practical terms.

Types of system. Device and principle of operation

Today on the heating equipment market in the underfloor heating segment, two models are presented:

- products of the Korean company Daewoo Enertec, warm water electric floors XL Pipe (XL Pipe);

- a product of the Korean company Caleo, capillary heated electric floor UNIMAT AQUA.

The latter option has domestic analogues, which are produced under license at Russian enterprises.

Both the first heating system and the second have some differences in the design and principle of operation of the heating elements, although everything else, both installation and principle of operation, are absolutely the same.

Warm electric water floors XL Pipe

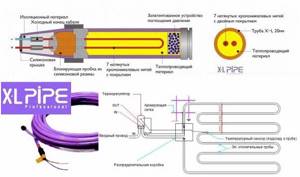

Let's consider what is special about the design of a heating system using electricity. For a first acquaintance, let's take the heating system, electric water heated floors XL Pipe (XL Pipe). What is new in this case is the structure of the heating element itself. The base of a polyethylene pipe (walls 20 mm thick) is laid with a heating cable along its entire length. The important thing is that this is not a simple cable, but woven nickel-chrome threads enclosed in a Teflon sheath. The rest of the internal space of the plastic pipe is filled with liquid coolant, which is in a static state. The pipe is a hermetically sealed single circuit.

Obviously, in this case you don't need either a pump or a manifold. The diagram clearly shows the internal structure of the heating circuit, the appearance of the plastic pipe and an approximate layout of the XL Pipe electric water floor.

The coolant in this case is antifreeze, so the system should correctly be called an electro-liquid heated floor. Using thermal energy from heating the electrical element, the coolant is evenly heated along the entire length of the heating circuit.

The operating principle of the underfloor heating system in this case is based on the interaction of the heating element with temperature control sensors. The thermostat is one of the main devices for any heating system, so in this case you cannot do without it.

Electric water heated floors operate according to the following principle:

- The first is getting involved in work. The power provides heating to the electrical cable, which in turn heats the coolant surrounding it.

- The second is the expansion of the heated coolant. Due to the fact that the volume of liquid is small and the power of the cable is large, heating occurs intensively.

- The third is an increase in the volume of heated liquid, thereby creating increased pressure inside the plastic pipe (nucleate boiling).

- Fourth – quick access of the heated floor to operating heating modes.

Here it is worth saying a little about the costs of operating an electrical element associated with heating the coolant. Energy consumption in this case is 14.4 -15 W per square meter. meter of underfloor heating, which is significantly lower than what is required when operating conventional electric floors. Due to the coolant fluid, even a switched-off heated floor cools down two or three times slower than a cable heating system.

Capillary warm electric floor

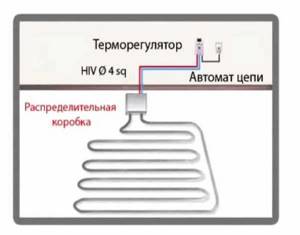

It is better to install such a heating system through connecting an RCD and equipping the entire complex with an automatic device.

This combined floor heating system is designed for heating small spaces. It is allowed to install the system in rooms whose area does not exceed 20 m2.

The advantages of the capillary heating system are as follows:

- wide functionality of the heating block;

- the presence of an antifreeze mode;

- automatic control of the heating temperature of the coolant depending on the indoor temperature;

- adjustment of the power of the heating device in the range of 0.1 - 2.4 kW.

- presence of a timer.

Heating of coolant in a closed circuit

An electric heated floor, built on the physically reliable principle of uniform heating of the coolant in the circuit, is presented on the market by the Daewoo Corporation. The XL Pipe brand product is a reliable and effective solution that can be used both as an additional and as the main source of heat in a house or apartment. The system is built on the following principle:

- there is no coolant circulation;

- the circuit is laid in a hermetically sealed tube;

- there is antifreeze inside the fuel element;

- heating is carried out by several nichrome conductors.

When the system is running, the following occurs:

- Applying voltage to the XL Pipe heating circuit causes heat to be generated;

- since the total amount of coolant is extremely small, there is no significant increase in volume;

- an increase in pressure is observed in the tube, which shifts the boiling point of the liquid upward and no processes of formation of gas bubbles occur.

The electric floor system is installed in the screed according to the general rules. In this case, simplified temperature control systems are used. The entire circuit is heated evenly, so it is enough to place the sensor in the main installation box where the heating system is connected to electricity.

This heating option has a key drawback. Repairs are carried out only by service engineers, since it is necessary to fill the structure with antifreeze and carefully eliminate breaks or other damage to the water-electric circuit. The positive features of a liquid heated floor include the easy location of the leak, as well as the need to break only a small section of the screed to access the circuit.

XL-Pipe diagram

What's Included in the XL Pipe System Kit

It is necessary to lay foil insulation under the water circuit

The entire system of electric water heated floors XL PIPE is offered to the consumer completely ready-made. Additionally, for installation you only need to purchase materials for thermal insulation, this can be technoplex, penoplex. You will also need to stock up on 3*4 mm thick reinforcing mesh, a distribution box and plastic clamps.

The XL PIPE underfloor heating system can be purchased in eight configurations. They vary in power and are capable of heating rooms of various sizes. The new product is completely autonomous. It is able to function without a radiator and boiler. The kit includes:

- pipe packed in a coil;

- instructions with warranty card.

You will need to purchase a thermostat separately.

Disadvantages of water heated floors

- The heat loss of the room where the heated floor is installed must be less than 100 W/m2.

Conclusion: with higher heat losses, you will have to either insulate the house or install combined heating (water heated floor plus radiators). - It is not always possible to install water heated floors in apartment buildings with single-pipe heating systems. Well, or at least you need to know how to make such a connection correctly and without any conflicts with neighbors or utility workers (this is discussed in detail in the article about installing a water-heated floor in an apartment).

- Large thickness of concrete screed over a warm floor. If such heating is on the second floor or higher, then the floor level will rise by ~10 cm. On the first floor or on the ground floor, the total is more - by 14-20 cm. In other words, when planning heating with water-heated floors in an old apartment (house), be prepared to other global works related to the reinstallation of doors. And one more thing: concrete screeds for heated floors will increase the load on floors and other structures... are you sure they will withstand it? What is your confidence based on? Think about it.

- Installation of a water heated floor and materials for it are more expensive than for radiator heating. True, these expenses are then paid off by saving energy resources, as I wrote about above.

There are several more disadvantages of heated floors that must be taken into account. I will list them.

- Any warm floor (not necessarily water) is not the best heating system for rooms where people are constantly present. Surprised? I'll explain why. Alas, almost everything in the world has a downside.

So, contrary to the same well-known saying (or proverb? - I can’t remember what the difference is), your feet do not always need to be kept warm. I mean, not all the time! Blood rushes to heated areas of the body, this is well known to everyone. And the legs, being warm all the time, do not rest, the veins do not rest... The result is a disease of the veins due to their constant expansion.

Conclusion: you need to stay in a room with heated floors for a limited time. That is, do such heating in the hallway, bathroom, in any passage corridor, in the bathhouse, in the dressing room... where you are rarely or for a short time.

I mentioned the lack of mixing of air layers in the advantages of heated floors. But this is also a minus, because it is impossible to provide normal natural ventilation. But with radiators, natural ventilation is possible.

Conclusion: when designing heated floors, design forced ventilation with all its “delights” (connection to the power grid, noise, additional expenses... this is a continuation of the topic of efficiency), otherwise the air in such a room will be stale.

Not every material can be used to cover a warm floor. Therefore, you need to know the following.

It is necessary to distinguish between two concepts that are similar in sound, but different in meaning: “comfortable floor” and “warm floor”. What is the difference?

What is the difference?

The comfortable floor has a temperature of 20…22 degrees and is only suitable for off-season use. But in real winter cold it will not cope with heating. And then you will need additional heating (radiator, air, or something else). Wood is quite suitable for covering a comfortable floor.

But in a warm floor, the coolant heats up to 55 degrees. And you can’t cover such a floor with wood! Wood will crack due to high temperatures. But if you don’t heat it, then, again, such a heating system won’t cope in cold weather.

And although there is a separate section about coverings for heated floors, I will say a few words here. As coverings for heated floors, you need to take only natural materials: carpet made from natural material, ceramic tiles, linoleum - also from something natural, and not from PVC, parquet and parquet boards, etc.). Non-natural materials contain various harmful substances that will evaporate when heated... however, they evaporate even without heating. Do you need it?

Well, I believe that now, knowing all the pros and cons of water heated floors, you will be able to make an informed choice, and not “because that’s it.” Next, we will consider the issue of energy saving when heating with water heated floors.

heating with water heated floor

Rod mats

The carbon mixture can not only be distributed on the film. To increase the heating surface, experts have developed heating systems with a rod element. The carbon mixture is formed into rods that are enclosed in a heat-resistant shell. The material is produced in rolls up to 25 m long. The rods are arranged in a stack.

Mats are recommended for heating rooms with the correct geometry. They are laid not only under laminate and parquet. This is a good option for heating rooms with tiled floors. The mats are laid in a screed or under tile adhesive. The layer thickness is 2 cm. To make heating more efficient, a substrate with a reflective surface is placed on the base of the floor.

Manufacturers warn that aluminum foil is not used as a screen.

Screed and tile adhesive further strengthen the mats on the base of the floor. High-power equipment is used to heat balconies, outbuildings, and verandas. Infrared heating is used to heat greenhouses and conservatories.

We recommend: Features of Fenix heated floors

The following brands of heated floors from Korea are distinguished:

- "CALEO";

- Felix Korea RHE;

- "UNIMAT".

Since the rod mats are installed in the screed, both hard and soft coverings can be used to cover the floor, which is an advantage of this heating system. Equipment from Korea is chosen for underfloor heating of rooms with high loads. If one of the rods breaks, the heating of the room does not stop. If necessary, you can change the rod to normalize the operation of the system.

Among the disadvantages is the installation of the highway. The rods must not be connected or overlapped. It is also impossible to cut out a curly outline from them. The carbon layer will be damaged. The system will stop functioning. Rod mats operate on 220 V electricity. This can be an additional financial burden.

How to assemble a collector with your own hands

It is impossible to directly connect a heated floor to the boiler with your own hands. For this you need a manifold with valves. It is installed in a cabinet, and the piping begins from there. The collector is provided with access to only one person who will service the system.

The range of collectors in stores is quite large, but it is often difficult to choose the right one for your heating system. In addition, a switchgear is needed on each floor of a private house, which leads to a significant increase in costs. A homemade manifold for heated floors is the right solution, allowing you to save a significant amount of money.

Connection

Since the heating system has a supply and return branch, the collector must consist of two combs connected to them. At the joints, branches are installed to drain water and remove air from the pipes.

The collector is assembled according to the number of connected loops. At each outlet, located at the top or bottom of the comb, taps are installed to ensure that individual circuits are turned off while the rest of the heating is running. It is recommended to make the distance between them 10-20 cm.

Manifold manufacturing

Before assembling a manifold for a heated floor, you need to understand the purpose of each element. It is recommended to make combs with your own hands from a square pipe. Round threaded pipes are welded to them for connection to the boiler and to the circuits. To do this, markings are first made, then holes are drilled, and then the pipes are attached. All joints are thoroughly scalded. A plug is made at one of the ends.

The scale is knocked off, the collector is cleaned and painted with oil compounds. In Fig. Below is a simple 3 loop manifold. The comb and coolant supply pipes from the boiler are painted red, and the return pipes, through which cooled water is supplied to heating, are blue.

DIY distribution manifold

Air vents are connected to the top of the combs, and plugs are installed at the bottom to discharge sludge. Each circuit can be closed with valves, which also serve to regulate temperature and pressure.

The distribution manifold is designed to control a small system that serves as additional heating. It will be much more complex if used for the main heating system in a large house. Assembling a manifold from polypropylene pipes is much simpler, but the simplest models are made this way.

DIY collector made of polypropylene pipes

Assembly of the collector unit

The underfloor heating manifold contains devices that ensure efficient operation of the system. Each circuit must have control valves. For a complex system, it is advisable to install automatic control valves.

Usually they operate in constant mode, the coolant flow changes only at the main supply inlet. For house areas up to 200 m², two-way valves are used. Their advantage is smooth adjustment. Valves often become clogged. Therefore, they are installed on detachable couplings (“American”) so that they can be removed for cleaning.

A more complex device is the three-way valve. It ensures mixing of forward and reverse water flows, maintaining the specified temperature at the outlet. Inside it there is a movable partition that regulates the flow of water from two inlet pipes. The device is used in all complex systems with automatic control of a large number of circuits. Its advantage is its significant throughput.

With the slightest turn of the tap, the temperature regime of the system changes. The adjustment can be manual or automatic. A three-way valve is often combined with a servo drive operating from an outdoor air temperature sensor. When the weather changes, the temperature in the rooms is maintained constant. As soon as cooling occurs, a signal from the weather sensor enters the control unit and the coolant temperature rises.

Capillary warm electric floor

Capillary water electric floors operate on a different principle. Their mechanics are based on high-speed pumping of a small amount of coolant through the heating circuit. The engineering solution looks like this:

- heating cable and other devices connected to the power grid inside the floor are missing;

- the heating circuit is laid from a tube of complex cross-section with a small clearance for the coolant passage;

- The system is powered from the central unit, where a miniature induction-diaphragm pump is located.

When the system is turned on, high-speed pumping of the coolant inside the circuit begins. The latter is assembled quite simply. Special tubes and sealing couplings are used. Since the speed of the coolant is high, heating equipment is not required to set records.

The specific characteristics of the main heater determine the criterion for choosing the coolant. The capillary floor uses only distilled water with stable electrical resistance and thermal expansion coefficient. It does not contain salts or foreign particles, which is important when circulating in a small-lumen circuit.

A central control unit with a power of 2-2.4 kW can cope with the task of heating a room with an area of up to 20 square meters. It does not require a separate connection line, but such equipment is still switched through its own circuit breaker and safety unit.

The capillary floor cannot be considered as a reliable main source of heat in the apartment. Although you can install a separate heating unit in each room, the overall energy output may not be sufficient. If residential premises lose a lot of heat, the volume of capillary tubes may not be enough to pump the required volume of coolant to ensure a comfortable air temperature.

Capillary heated floor

Table 3.4 - Fans

| Designation | Designation code |

| 3.4.01 | |

| 3.4.02 | |

| 3.4.03 | |

Radial with V-belt drive | 3.4.04 |

Radial with coupling connection | 3.4.05 |

Radial without casing, general designation | 3.4.06 |

Radial without casing, first version | 3.4.07 |

Radial without casing with V-belt drive | 3.4.08 |

| 3.4.09 | |

| 3.4.10 | |

| 3.4.11 | |

| 3.4.12 | |

| 3.4.13 | |

| 3.4.14 | |

| 3.4.15 | |

| 3.4.16 | |

| 3.4.17 | |

Roof axial with side discharge | 3.4.18 |

| 3.4.19 | |

| 3.4.20 | |

Roof radial with upward discharge | 3.4.21 |

| 3.4.22 | |

| 3.4.23 |

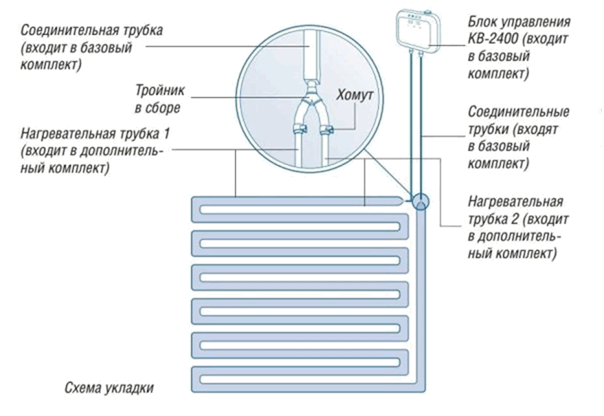

Features of the capillary heated floor Unimat Aqua

Liquid underfloor heating Unimat Aqua differs from XL Pipe in that the system does not consist of one thick pipe, but is equipped with many small diameter pipes. Hence the name of the system - capillary. It is connected to a device that has a power of 2.4 kW. In this way, the coolant is heated and heat is released. The whole system is closed. Installation of an additional heating unit is not required.

The coolant in the Unimat Aqua system is distilled water. It will require no more than 6 liters. The size of the heated area that one set can heat is approximately 20 square meters. How warm the room will be depends on the thermal insulation properties of the walls and ceilings. Warm floors very quickly create a comfortable indoor microclimate.

If necessary, several Unimat Aqua systems can be installed in one room. However, most often it is used to heat a small room. The service life of capillary heated floors is approximately 5 years.

Unimat Aqua comes in two types. Basic, which includes a control unit, an installation kit, and two pieces of pipe for connections. All this will be needed to form a small pipeline. The additional kit consists of a coil of small diameter tubes, which is enough to heat an area of 10 to 20 square meters. meters.

Results

Water-based electric heated floors are an interesting floor heating option in all aspects. XL Pipe (XL Pipe) seems more advantageous, but it also costs more, but it provides the possibility of using it as the main heating (it has enough power with good insulation). If you simply need a comfortable floor temperature in relatively small rooms, including those with high humidity, then the capillary heated floor UNIMAT AQUA looks more acceptable, although this is also your choice.

Simple power calculation for choosing a heated floor cable

The design capacity of a cable transformer substations depends, first of all, on the intensity of its operation and the method of use - as the main means of heating or as a system for increasing comfort. The installation of heated floors is not carried out over the entire area of the room, but when determining heating zones, the following factors must be taken into account:

- The cable is not installed under stationary furniture: sofas, cabinets, cabinets, etc. Firstly, it is a waste of materials and electricity. Secondly, the resulting local overheating negatively affects both interior items and the functioning of the heating elements themselves.

- Laying of heated floors is carried out in compliance with the parameters of the minimum cable indentations:

- from the baseboard – 5 cm;

- external wall - 20-30 cm (with good insulation it can be reduced to 5-10 cm);

- from the internal wall and stationary furniture - 10-15 cm;

- from the heating radiator – 20-25 cm.

Main heating system

Working conductors of TP must be located on at least 80% of the area of the room. In this case, the designed specific power should be 180-220 W/m2. If the room is not on the ground floor, the external walls are well insulated, and the windows have a multi-chamber profile and energy-saving double-glazed windows, the total power of the heating elements can be reduced to 150-180 W/m2.

The cable pitch of an electric heated floor is calculated using the following formula:

Шк=(100×S)/L, (1)

, where Shk is the cable placement pitch, in cm; S – quadrature of the heated area of the room, in m2; L — cable length, m.

In turn, the selection of cable length is carried out depending on the power of a particular brand. For example, if in a room of 10 m2 it is planned to install an electric heated floor as the main means of heating, then the total heater power should be 1600 W (we focus on the average standard indicators - 200 W/m2 and 80% of the total quadrature). We take the Nexans MILLICABLE FLEX cable with a linear power density of 10 W/m. Therefore, for working heating, 160 m of such electrical products are needed. Presenting the obtained data into formula 1, we obtain:

Shk=(100x8)160=5 cm.

This will be the step with which it is necessary to lay the cable in order to obtain a floor covering that can independently heat the room.

Cable heating

Cable sections can be used as a floor heater. Each section has a certain length and has a certain power. In cold rooms, sections with high power of 120 W are installed. For heating residential premises, sections with a power of 18-50 W are chosen.

The cable is laid in a screed or in tile adhesive. Porcelain stoneware and natural stone are used as cladding. Korean cable-type heated floors are installed in children's institutions and hospital wards. The system creates a favorable indoor microclimate.

For heating, a single-core or two-core cable is used. At the heart of a single-core cable there is 1 heating rod, a core. It is made of chrome or brass. On top of the rod there are several layers of insulating heat-resistant material. A single-core cable is connected to the thermostat at two ends.

A two-core cable consists of 2 heating cores and 1 drain rod: it is capable of collecting excess energy. This occurs when the cable is “locked”, the drain rod protects the section from overheating. Each rod is insulated with a fiberglass sheath. On top of the insulating layer there is a protective screen that blocks electromagnetic radiation.

We recommend: What types of mats are there for warm water floors?

When installing a section of a two-core cable, the wire is connected to the network at one end. The 2 cores that make up the wire are connected to each other and insulated. Lay sections in rooms with any geometry.

Among the heating systems, the most famous are the following brands:

- "CALEO";

- "Arnold Rak/Priotherm";

- "EASTEC";

- "EASYMAT".

The cable can be fixed on mats. They are easier to install over a large area or on a small cold section of the floor. Installation is not difficult. Select mats with a cable of a certain power depending on the location of the room: living room on the 1st floor, 2nd floor, balcony, bathroom, toilet.

EASTEC

There is concern that the cable section, when heated, creates an electromagnetic field that has a negative impact on human health. Experts reassure that the radiation from the section is negligible. Moreover, a two-core cable creates an electromagnetic field 50 times less than a single-core section.

Underfloor heating systems produced in Korea are of high quality and reliability. For production, innovative technologies are used that are constantly being improved. Korean heated floors have a service life of more than 50 years. Breakdowns only occur when the system is installed incorrectly.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- What are the characteristics of Rehau pipes for underfloor heating?

- How to install heated flooring under a shower stall?

- How does a comb for heated floors work?

- How to install a heated floor sensor?

- How to lay a warm floor under linoleum?

- How much does a heated floor consume?

Selection of heating system components

The main element of a heated floor is the cable, the choice of which determines the route of installation and the power of the system.

Resistive cable

Outwardly, it is indistinguishable from the usual one, but has completely different characteristics. If for the core of a conventional electrical cable, manufacturers choose a material with the lowest resistance in order to reduce energy losses to overcome it, then when manufacturing a heating cable, they do just the opposite. Most often, the cable core is made of nichrome, which has a very high resistance.

Heating resistance cable

The decisive factor in choosing a cable is the value of its linear power (specific heat release). For domestic use, this figure ranges from 15 to 21 W/m. When choosing a cable, remember that the distance between turns when laying should not be less than 5-6 cm - this is fraught with overheating, and more than 10-12 cm - otherwise temperature changes will be felt on the floor. Based on these values, the linear power of the cable should be selected. That is, with a distance between turns of 10 cm, per 1 m2 you will need 9 meters of cable. With a required system power density of 140 W/m2, the calculation will look like this:

140:9=15.6 W/m.

At the same time, when laying cable sections at a distance of 5 cm from each other, the calculation will look like this:

100 cm (1 m): 5 (distance between wire sections) = 20 m – required wire length.

140 W/m2: 20 = 7 W/m – required linear power of the cable.

Self-regulating cable

This is a two-core cable, both cores of which are made of low resistance material. The role of the heating element here is performed by a semiconductor polymer matrix. It is the properties of the semiconductor that allow such a matrix to perform the function of self-regulation.

Self-regulating cable for heated floors

The use of this cable eliminates the possibility of local overheating and allows its installation under coverings such as laminate and parquet boards. There is also no need to take into account the location of the furniture. So this cable is ideal for those who like to change their interior frequently. The only drawback of the self-regulating system is the rather high price.

Heating mats

Heating mats are essentially the same resistive cable, only laid out like a snake and attached to a polymer mesh.

Heating mats can greatly speed up the installation process

Thus, the installation of electric heated floors is greatly simplified, but its price increases. The cost of mats is on average 20-50% higher than the price of a cable of comparable quality.

Thermostat selection

The thermostat is no less important part of the underfloor heating system than the heating cable. Non-programmable thermostats must be turned on manually. The adjustment of such a device can be either stepwise or resistor (smooth).

Non-programmable and programmable thermostat

Programmable thermostats are much more complex devices that allow you to maintain a constant temperature in a room. Some are equipped with timers that turn the system on and off at specific times.

Choice of thermal insulation

To prevent heat from being wasted on heating the basement or ceilings, it is necessary to lay a layer of insulating material under the cable. There are two ways to do this, each of which has its opponents and supporters. The first method involves the use of extruded polystyrene foam with a thickness of about 30 mm. Opponents of this method argue that raising the floor so much does not make sense and advise using foil insulation. To which EPS supporters say that in the alkaline environment of the cement screed, the foil insulation will collapse in a few years, which will lead to additional heat loss.

For those who decide to install a heated floor themselves, but are afraid of mistakes in selecting the parts that match each other, there are ready-made kits that include a cable, a thermostat, a tube for installing a sensor under the floor surface and detailed installation instructions.

Date: September 25, 2021