How to choose a room thermostat for a heating boiler

Wired or Wireless

Wired models are not limited in functionality, can be installed in any room (up to 20 meters from the boiler), are cheaper, but require a wired connection to the boiler.

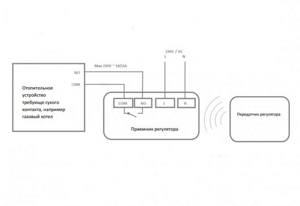

The wire itself is usually provided in the kit. Wireless thermostats consist of a control panel with an air temperature sensor (essentially a regular thermostat) and a receiver that receives a signal from the remote control and transmits it to the boiler in a wired manner. Accordingly, the receiver is installed in the boiler room, and there may be more than one thermostat, for example, in several rooms. The advantages of wireless communication are obvious: there is no need to run wires throughout the house.

From the thermostat to the receiver, the signal is transmitted over a standard household appliance channel with a frequency of 433 or 868 MHz and does not affect any other household appliances or any other electronic devices in the house. Most models transmit signals over distances of up to 20 or 30 meters, taking into account walls, ceilings or partitions. It is worth considering that batteries are required to power a wireless thermostat, usually 2 standard AA batteries.

Temperature setting accuracy

Mechanical and electromechanical thermostats are quite cheap, but have a high error in the context of home heating - from 2 to 4°C. In this case, the temperature adjustment step is usually 1°C.

Ability to set the hysteresis value

Hysteresis (lag, delay) in the context of a heating system and thermostat is the difference between the temperature at which the boiler turns on and off with a uniform flow of coolant. That is, if the temperature on the thermostat is set to 22°C, and the hysteresis is 1°C, then when the air temperature reaches 22°C, the boiler will turn off and start when the temperature drops by 1°C, that is, at 21°C.

In mechanical models, the hysteresis is usually 1 or 2°C and cannot be changed. In electronic models with the ability to adjust it, you can set the value to 0.5°C or even 0.1°C. Accordingly, the lower the hysteresis, the more stable the temperature in the house.

Availability of a programmer

An example of a programmable thermostat with a temperature graph displayed on the main screen.

The programmer is an opportunity to set a boiler operation pattern for a time period from 8 hours to 7 days. Of course, manually lowering the temperature before leaving for work, leaving or going to bed is quite troublesome. Using the programmer, you can create one or several operating templates once and, depending on the temperature and hysteresis settings, save up to 30% of fuel each subsequent month.

Availability of Wi-Fi or GSM module

Controllers with a Wi-Fi module can be connected to the home network and controlled using an application on a smartphone. A rather tangible advantage is the GSM module, with the help of which you can not only turn on the heating system in advance and heat the house even before arrival, but also control the operation of the system during a long departure: in case of any malfunctions, a corresponding notification will be sent to your phone.

Security systems

Protection against overheating or freezing of the heating system, protection against stopping the circulation pump, protection of the pump against souring in the summer (on once a day for 15 seconds) - all these functions seriously increase the safety of the heating system and are often found in medium and high-priced boilers segments. If such systems are not provided by the boiler automation, the issue can be resolved by choosing a thermostat with them.

Types of thermostats for gas boilers

Thermostats can be divided into three main types: mechanical, electronic and electronic wireless.

Wired models cost less, but require cable laying - it is better to install a thermostat on a gas boiler before or during renovation work in the house. Wireless models are more expensive, more functional, and more convenient.

The selection of a thermostat for connection to a gas heating system is carried out taking into account the following basic criteria:

- functionality;

- adjustment accuracy;

- thermostat cost;

- ease of use and installation.

According to functionality they are distinguished:

- simple thermostats - help maintain the desired temperature in the house;

- wireless thermostats - have a transmitter unit that is placed in another room for more precise temperature control;

- programmable - allow you to set a stable temperature regime separately for day and night, program the operation of the heating system by day of the week, which significantly reduces fuel consumption;

- with hydrostat function - help control the humidity level in the room, reducing or increasing it according to the settings.

- With an additional floor sensor - the model is used, among other things, to regulate the temperature of the coolant in the “warm floor” system.

- With an additional water heating sensor - the device is used both to regulate the temperature of hot water supply and to control the heating system.

Separately, it is necessary to say about programmers - thermostats that are more complex in terms of functionality, which are installed, among other things, to control climate systems in so-called smart homes.

There are models of Wi-Fi thermostats with voice control. Such room regulators support several foreign languages and can be controlled using a smartphone. During a power outage, the memory function is activated, which saves the programmer settings

Programmers control the operation of not only heating and water heating equipment, but also air conditioners, pumps, and other devices. Some of them help to program individual temperature conditions for each day of the week with the ability to set from 1 to 6 fixed operating points.

Homemade external thermostat for the boiler: instructions

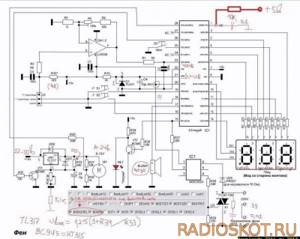

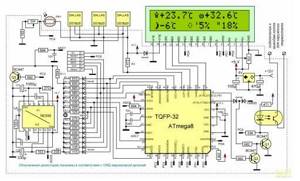

Below is a diagram of a homemade thermostat for a boiler, which is assembled using Atmega-8 and 566 series microcircuits, a liquid crystal display, a photocell and several temperature sensors. The Atmega-8 programmable microcircuit is responsible for compliance with the specified parameters of the thermostat settings.

Scheme of a homemade external thermostat for a boiler

Strictly speaking, this circuit turns the heating boiler on or off when the outside air temperature decreases (increases) (sensor U2), and also performs these actions when the temperature in the room changes (sensor U1). It is possible to adjust the operation of two timers, which allow you to adjust the time of these processes. A piece of circuitry with a photoresistor affects the process of turning on the boiler depending on the time of day.

Sensor U1 is located directly in the room, and sensor U2 is located on the street. It is connected to the boiler and installed next to it. If necessary, you can add an electrical part of the circuit that allows you to turn on and off high-power units:

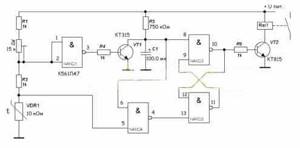

The electrical part of the circuit allows you to turn on and off high-power units

Another thermostat circuit with one control parameter based on the K561LA7 chip:

Thermostat circuit with one control parameter based on the K561LA7 microcircuit

The thermostat is assembled on the basis of the K651LA7 microcircuit and is simple and easy to adjust. Our thermostat is a special thermistor that significantly reduces resistance when heating. This resistor is connected to the electricity voltage divider network. This circuit also contains resistor R2, with which we can set the required temperature. Based on this scheme, you can make a thermostat for any boiler: Baxi, Ariston, Evp, Don.

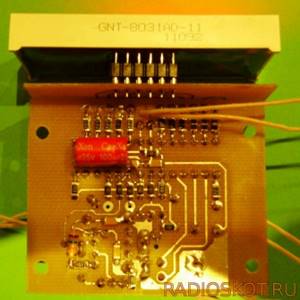

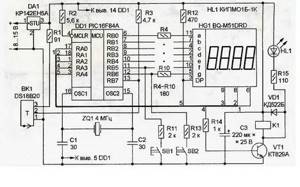

Another circuit for a microcontroller-based thermostat:

Circuit diagram for a thermostat based on a microcontroller

The device is assembled on the basis of a PIC16F84A microcontroller. The role of the sensor is performed by a digital thermometer DS18B20. A small relay controls the load. Microswitches set the temperature, which is displayed on the indicators. Before assembly, you will need to program the microcontroller. First, erase everything from the chip and then reprogram it, and then reassemble it and use it to your health. The device is not capricious and works fine.

The cost of parts is 300-400 rubles. A similar regulator model costs five times more.

A few final tips:

- although different thermostat options are suitable for most models, it is still desirable that the thermostat for the boiler and the boiler itself be made by the same manufacturer, this will greatly simplify the installation and operation process itself;

- before purchasing such equipment, you need to calculate the area of the room and the required temperature in order to avoid “downtime” of equipment and changes in wiring due to connecting devices of higher power;

- before installing the equipment, you need to take care of the thermal insulation of the room, otherwise high heat losses will be inevitable, and this is an additional cost item;

- if you are not sure that you need to purchase expensive equipment, then you can conduct a consumer experiment. Buy a cheaper mechanical thermostat, adjust it and see the result.

Advantages of using a thermostat in heating

Gas heating is a benefit in itself and significantly increases the quality of life. But simplifying the management of gas heating equipment is an equally pressing issue.

Setting up and controlling the operation of a gas boiler can be done in two ways - manually or using a thermostat, which will automatically ensure a stable temperature regime.

Manual adjustment helps set a certain temperature of the coolant in the system - when the temperature rises to the set values, the boiler turns off, when it decreases, it turns on. As a result, the temperature in the house is maintained at a certain level.

But as the temperature outside changes, the set mode turns out to be incorrect and you have to manually reprogram the heating device. Such manipulations are carried out throughout the heating season, and this is inconvenient.

A sharp increase in temperature outside the building and heating of the room by the sun's rays often require immediate shutdown of the heating system. The thermostat will shut down in a timely manner

In addition, manual adjustment means the gas boiler operates in a constant on-off mode, with a working cycle period of about 10 minutes. This does not have the best effect on the operating time of the boiler.

Even in a system with manual adjustment, regardless of the operation of the heating function, constant circulation of the coolant is ensured using pumping equipment, which means that excess electricity is consumed.

The use of a thermostat to control the operation of a gas boiler completely eliminates timing problems and also eliminates sudden temperature changes

Automatic control, unlike manual control, turns off the circulation pump. By reacting to the temperature of the air in the room, and not the coolant in the heating circuit, the thermostat for the heating boiler maintains a stable temperature in the room.

As a result, the microclimate in the house is significantly improved, the frequency of boiler switching on is reduced, which means its service life increases.

Energy savings when using an automatic thermostat reach 30%, but even the cheapest programmer provides savings of at least 15%

Using a thermostat provides other benefits:

- the device sets the optimal/economical temperature mode depending on the time of day;

- solves the problems of gas boiler clocking - frequent switching on and off;

- facilitates operation and increases the reliability of the heating system.

These are just some of the obvious advantages common to all types of thermostats. The advantages of individual models can be studied in more detail immediately before purchase.

How to connect a thermostat to a boiler, including an old one, without terminals...

An ordinary room thermostat brings great convenience to home heating. This is a small device, usually placed on the wall, in a key place where we want to measure the temperature and use its value to control home heating. For example, on the wall in the center of the house in the hallway, or in the kitchen on the outer wall, where it gets cold the fastest...

As soon as the air temperature at the location of the device has decreased to the set value, say, +21 degrees, the thermostat turns on the boiler... The boiler will turn off when the air heats up to the shutdown temperature, for example, +24 degrees.

But how does a thermostat manage to control the boiler?, and how to properly connect the thermostat to the boiler for this to happen?

- This issue seems especially problematic for many when using old boilers in which the connection of external control was not provided...

How does a room thermostat work?

Any room thermostat, mechanical or electronic, with radio transmission or wired, or programmable, which we call a room programmer, works very simply, on the principle of a one-button switch - “circuit open or connected” - “On / Off”.

A contact is connected in it when the temperature reaches the switching threshold, and the boiler control circuit becomes closed. When heating has occurred, the contact opens and the boiler stops.

What kind of thermostats are there?

- Mechanical, with mechanical adjustment by a rotating knob and a mechanism that responds to temperature. These are usually low-precision devices.

- Electronic, with more precise tuning and precise operation.

- With radio control. Sometimes cables are quite a nuisance in the interior. A temperature recorder-radio transmitter is mounted on the wall, and a receiver is located near the boiler, connected by wires like a thermostat.

- Programmable devices. With which you can set temperature changes during the day, which are very useful for saving money, since you can make it “cold” for several hours….

- Thermostat with control function via GSM or Wi-Fi connection - remote control of the boiler is possible.

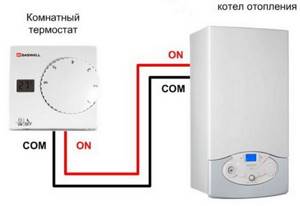

How a regular thermostat is connected to an automated boiler

Modern boilers are usually equipped with a terminal block with two terminals for connecting an external control device that operates on the “On-Off” principle. More often these terminals are designated as TA.

Initially, they are connected by a jumper, while the circuit between them is closed, the boiler always receives the “On” command. If the jumper is removed, the boiler will turn off.

- The jumper is removed and a pair of contacts from the thermostat is connected in its place, usually using a cable with a cross-section of copper cores of 0.5 - 0.75 mm square. according to the manufacturer's instructions.

In the thermostat itself, not everything is so clear; different manufacturers have terminals numbered as 1,2,3 or ABS. You need to connect a pair to those contacts that close when the device is triggered by temperature. If you can’t find this out from the instructions, all that remains is to call the closed contacts with an ohmmeter...

How to connect a thermostat to an old (brainless) boiler

Some models of gas, oil, electric...boilers do not have special terminal contacts for the external control unit. How to remotely control an old boiler?

It is likely that on the boiler itself there is a relay control knob for the coolant temperature. And you can find that this relay works on the same Closed/Open principle.

If you remove the terminal from this relay (control unit), i.e. open its power supply circuit, the boiler will turn off. He will perceive this as “the temperature is high - the circuit is open.”

It is clear that an external thermostat can be connected to the gap between the removed wire and this terminal. Tighten the knob on the boiler itself so that the “On” position is always on, and the external thermostat will break and connect this circuit, controlling the operation of the boiler as if the internal one was doing it...

- Using the same principle, turn on the thermostat in the power circuit of the control unit.

- Connect the magnetic starter coil to the break in the power supply circuit (not to be confused - not to the break in the power wires, but to the control circuit...).

- There is an open circuit of the water pressure sensor in the system, which also works on the “On/Off” principle. True, when the boiler is turned off by the thermostat, it will now report an error that the pressure in the system is below normal...

In general, connect it in series with any sensor that controls the boiler according to the connected-disconnected principle.

But you cannot enable, where a smooth change in resistance is recorded, the exchange of digital data packets, where you need to do a manual restart, for example, when a thermocouple is triggered...

As you can see, if you have the right desire to connect a thermostat, or programmer, to any boiler that is controlled by electrical circuits, sensors... - no problem...

What are thermostats for an electric boiler?

Why are they needed and how are they used?

Simple mechanical thermostat.

The temperature regulator is a wired or wireless control panel that is mounted on the wall in any convenient place.

There are both simple mechanical models, the functionality of which is smooth degree-by-degree temperature control (especially important for electric boilers with mediocre 3- or 6-step power control), and automatic programmable models with an information display, which allow you to configure more than 50 parameters of the boiler operation and program them change for the next day or even week.

In general, room thermostats for electric boilers perform the following functions:

- measurement, control and maintenance of a certain comfortable temperature of the working environment;

- transmitting signals to the electric boiler from any place in the house convenient for the owner;

- protection against overheating or freezing of the heating system;

- programming the operating mode for the next day or week;

- remote control from a phone if the thermostat has Wi-Fi or a GSM module;

- remote notification (including via smartphone) about malfunctions and emergency situations in the operation of the heating system.

Existing types

The settings specified on the thermostat take precedence over the settings of the electric boiler itself. The operating principle of the device depends on the type of temperature sensor used in it:

1. Mechanical thermostats

The simplest models, the operating principle of which is based on the operation of membrane and capillary temperature sensors. They use substances placed in a capsule that expand significantly at the slightest increase in temperature. When the expanding substance reaches the maximum temperature threshold, it puts pressure on the relay membrane, as a result of which the contacts open, and the thermostat sends a signal about a partial or complete reduction in the power of the electric boiler.

The main disadvantages of such thermostats are simple functionality, limited to turning a round rotator to set the desired temperature, and a high error - up to 3-4°C.

2. Electromechanical

They have a more complex design based on the use of special metal plates as a heat-sensitive element, which produce a micro-discharge when heated to a certain temperature. The micro-discharge activates an electromagnetic relay that controls a mechanical valve. In general, electromechanical thermostats have +- the same functionality, but a much smaller error; their cost is 20-40% higher.

3. Electronic

The most modern and multifunctional devices, equipped with electrical boards (automation), often with remote sensors: both internal and external (street). Capable of maintaining or changing the operating mode of an electric boiler without human intervention. Allows a minimum error of up to 0.5-0.7 degrees

We recommend paying attention to electronic thermostats due to their functionality and cost-effectiveness

What is a thermostat for a heating boiler?

This is what a modern electronic room thermostat looks like.

Why is it needed and how is it used

The main reason for choosing a room thermostat is savings, that is, a reduction in fuel consumption by up to 25-30%. This is achieved through the ability to program the boiler’s operation for a day or a week in advance. For example:

- You can reduce the temperature at night to 18-19°C - the most comfortable temperature for sleeping. Moreover, each reduced degree reduces fuel consumption by 2-5%.

- You can lower the temperature to 15-16°C for times when the owners are not at home, for example during working hours.

Also, savings are achieved even without a programming function: by controlling the operation of the boiler depending on the air temperature, and not the coolant temperature. This allows you to more accurately and stably, without the slightest jumps, maintain the set temperature, minimize the inertia of the heating system, and if you have a modulating burner, keep it on for as long as possible, but at minimum power - the most optimal mode of operation of the boiler both in terms of fuel consumption and conservation of the resource.

Everything, even the simplest mechanical room thermostats, come with an air temperature sensor by default. Many models also include a remote sensor for heated floors.

Of course, in addition to saving money, the thermostat also increases the operating comfort of the heating system. Depending on the functionality, using the thermostat you can organize weather-dependent control by connecting an external street sensor, control the boiler from a smartphone (via Wi-Fi) and receive notifications of operational failures via SMS (if there is a GSM module), simply fine-tune the operation boiler

Existing types

The settings specified on the thermostat always have priority for the boiler; its operating principle does not change (modulation of the burner flame is used, adjustment of the turbine rotation speed, etc.) despite the “dry contact” with the thermostat. The operating principle of a room thermostat depends on the type of temperature sensor it uses.

1. Mechanical thermostats

The simplest and most inexpensive models without any broad functionality. The principle of their operation is to use membrane sensors - heat-sensitive metals, liquids or gases, which are placed in a small sealed capsule. When heated, the substances expand and, upon reaching the set temperature, exert pressure on the relay membrane sufficient to close the contacts, after which the thermostat sends a signal to reduce the boiler power or turn it off completely.

Mechanical devices, as a rule, are limited only by a rotator for selecting temperature, have a noticeable error of up to 3-4°C, and only have a wired connection method.

2. Electromechanical

More accurate (but still not enough), more expensive, still limited in functionality thermostats.

The principle of operation is similar to the action of mechanical ones, but in this case, heat-sensitive metals are used, which, when heated, produce a micro-discharge or create resistance. Some models have a simple screen for displaying temperature and a smaller step for changing it - 0.5°C. However, this still poorly justifies their 30-40% higher price, given that there are more accurate and functional analogues.

3. Electronic

Modern, accurate, multifunctional and convenient thermostats. The kit often includes additional sensors for heated floors. The error of electronic models is no more than 0.5-0.7°C, most have the ability to be programmed, almost all devices are equipped with functions of protection against overheating and freezing, stopping the circulation pump and other safety systems.

The most expensive models have built-in Wi-Fi and GSM modules, save statistics, have a large number of automatic modes and a wireless connection to the boiler. Despite the highest cost, electronic room thermostats fully justify it and pay for themselves within a few months of proper use.

Tips for choosing

- If you are short on funds, then purchase a simple, wired, electronic thermostat. Such devices are more technologically advanced, have a better response, and the quality of their operation does not depend on contacts oxidizing in air, as in mechanical analogues.

- If you are concerned about saving energy resources, and at the same time your own funds, purchase a weekly programmer. This device will significantly reduce the temperature in the room, and, accordingly, the frequency of turning on the boiler installation during hours when all household members are at work.

- If you have already made repairs, and there is no desire to ditch the walls for laying cables, then purchase wireless air thermostats.

In principle, any room thermostat is suitable for any wall-mounted gas boiler. However, boiler manufacturers strongly recommend connecting air thermostats of only one brand. For example, according to the manufacturer, the room thermostat for the baxi gas boiler should only be of this brand. This is a marketing ploy to attract more customers!

Temperature hysteresis

Any regulator has tolerances for switching to temperature conditions laid down by the manufacturer. All that remains is to select the heating range.

If you set the room temperature to +20°C, and the hysteresis (lag) of the temperature sensor is 2 degrees, then automatic switching on will be at +18°C and switching off at +22°C. The room cools down gradually. When the temperature drops to the set hysteresis settings, indoor air heating is turned on.

The set temperature and the speed at which it is reached depend on many factors. Four of them are the main ones:

- coolant supply temperature;

- radiator material (cast iron, aluminum);

- concrete depth and pipe distance (for heated floors);

- heat loss - if the window is open or the room is poorly insulated, you will wait a long time for the desired temperature.

This is why hysteresis is so important. It evaluates the above aspects and gives a signal to turn on/off individually for each room. The specified allowances in the temperature mode allow you to correctly set the temperature for a comfortable feeling and avoid unnecessary energy costs.

What are they for?

Temperature is the main physical quantity, moreover, sufficient to monitor the operation and control of the boiler and the entire heating system in the house. It is enough to know how much the coolant is heated in order to automate the operation of the boiler to a minimum extent.

If you add a thermometer installed in the room, you can already talk about energy-efficient boiler control and greater comfort for residents.

The most important thing for the user is to choose the best option for a room thermostat so that it is convenient to regulate the temperature in the room. You have to choose from mechanical or electronic devices.

Electronic thermostats provide greater accuracy and convenience, but mechanical devices still find applications, mainly due to their low cost, simplicity and, most importantly, energy independence.

Types of thermostats

Manufacturers of heating equipment produce a large number of different models of devices for regulating room temperature. Depending on the type of heating boiler, regulators are divided according to their purpose:

- for solid fuel;

- gas;

- electrical.

According to the type of device control, they are classified as follows:

- mechanical;

- electromechanical;

- electronic.

An example of a mechanical regulator is an attribute of a solid fuel boiler for changing the parameters of the coolant. After manually turning the adjustment wheel, the opening and closing angle of the blower will change using the chain drive of the device.

Electromechanical regulators are often used on household heaters and convectors. Turning the control wheel gives a command to the electrical appliance to turn it on or off, depending on the air temperature. The same principle is used to operate different types of boilers.

Electronic regulators allow you to set the required on and off parameters with high accuracy, using buttons that correct the value of the set value. Modern thermostats are additionally equipped with weekly programmers, thanks to which they can set different heating modes during the day or at night, as well as when leaving home for the weekend or for a longer period.

REFERENCE! Electronic programmers can respond not only to changes in temperature, but also humidity.

The ease of use and configuration of electronic and electromechanical thermostats contributes to the increased demand for these devices. Mechanical ones require a more painstaking approach during installation and configuration, but the operating process is no different from electromechanical attributes.

According to the method of temperature measurement, thermostats for boilers are distinguished:

- by coolant;

- by air.

This difference indicates exactly what temperature we regulate by changing the parameters of the device. Modern models of heating equipment are equipped with built-in thermostats for coolant, and convectors for air.

What is it needed for?

Even modern gas boilers of domestic and foreign production, as a rule, have the simplest system for regulating the level of heating of the coolant. The user sets the temperature parameters using a mechanical or electronic regulator.

The sensor monitors the heating of the liquid in the heating system and sends signals to turn off or turn on the gas supply. The main feature of such a device is its lack of efficiency, which is explained by the lack of taking into account the air temperature inside the heated room.

Installation work on installing a remote-type room thermostat for a gas boiler will become relevant if it is necessary to ensure the most accurate temperature control. Installing a special sensor indoors can reduce fuel costs by about 16-20%.

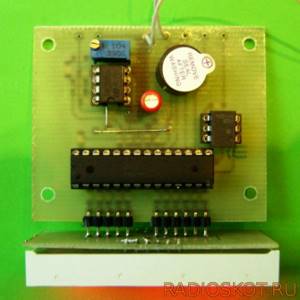

Thermostat circuit - second option

After some thought, I came to the conclusion that it is possible to connect here the same controller as on the soldering station, but with a little modification. During the operation of the soldering station, minor inconveniences were identified: the need to set the timers to 0, and sometimes an interference occurs that puts the station into SLEEP mode

. Considering that women do not need to remember the algorithm for switching the timer to mode 0 or 1, the circuit of the same station was repeated, but only the hair dryer channel. And minor improvements led to stable and “interference-free” operation of the thermostat in terms of control

When flashing AtMega8 firmware, you should pay attention to the new fuses. The following photo shows a K-type thermocouple, which is convenient to mount in the oven

I liked the work of the temperature controller on the breadboard and started final assembly on the printed circuit board.

I finished the assembly, the operation is also stable, the readings in comparison with the laboratory thermometer differ by about 1.5°C, which is basically excellent. When setting up, there is an output resistor on the printed circuit board; I have not yet found an SMD of this value in stock.

The LED models the heating elements of the oven. The only note: the need to create a reliable common ground, which in turn affects the final measurement result

The circuit requires a multi-turn tuning resistor, and secondly, pay attention to R16, it may also need to be selected, in my case it is 18 kOhm. So, here's what we have:

In the process of experimenting with the latest thermostat, more minor improvements appeared that qualitatively affected the final result, look at the photo with the inscription 543

– this means the sensor is disconnected or broken.

And finally we move from experiments to the finished design of the thermostat. I implemented the circuit into the electric stove and invited an authoritative commission to accept the work :) The only thing that my wife rejected were the small buttons on the convection control, general power supply and airflow, but this can be solved over time, but for now it looks like this.

The regulator maintains the set temperature with an accuracy of 2 degrees. This happens at the moment of heating, due to the inertia of the entire structure (the heating elements cool down, the internal frame is temperature equalized), in general, I really liked the scheme in the work, and therefore it is recommended for independent repetition. Author – GOVERNOR

.

Discuss the article THERMOREGULATOR DIAGRAM

Autonomous heating of a private house allows you to choose individual temperature conditions, which is very comfortable and economical for residents. In order not to set a different mode indoors every time the weather changes outside, you can use a thermostat or thermostat for heating, which can be installed on both radiators and the boiler.

Homemade external thermostat for boiler instructions

Below is a diagram of a homemade thermostat for a boiler, which is assembled using Atmega-8 and 566 series microcircuits, a liquid crystal display, a photocell and several temperature sensors. The Atmega-8 programmable microcircuit is responsible for compliance with the specified parameters of the thermostat settings.

Strictly speaking, this circuit turns the heating boiler on or off when the outside air temperature decreases (increases) (sensor U2), and also performs these actions when the temperature in the room changes (sensor U1). It is possible to adjust the operation of two timers, which allow you to adjust the time of these processes. A piece of circuitry with a photoresistor affects the process of turning on the boiler depending on the time of day.

Sensor U1 is located directly in the room, and sensor U2 is located on the street. It is connected to the boiler and installed next to it. If necessary, you can add an electrical part of the circuit that allows you to turn on and off high-power units:

The electrical part of the circuit allows you to turn on and off high-power units

Another thermostat circuit with one control parameter based on the K561LA7 chip:

The thermostat is assembled on the basis of the K651LA7 microcircuit and is simple and easy to adjust. Our thermostat is a special thermistor that significantly reduces resistance when heating. This resistor is connected to the electricity voltage divider network. This circuit also contains resistor R2, with which we can set the required temperature. Based on this scheme, you can make a thermostat for any boiler: Baxi, Ariston, Evp, Don.

Another circuit for a microcontroller-based thermostat:

The device is assembled on the basis of a PIC16F84A microcontroller. The role of the sensor is performed by a digital thermometer DS18B20. A small relay controls the load. Microswitches set the temperature, which is displayed on the indicators. Before assembly, you will need to program the microcontroller. First, erase everything from the chip and then reprogram it, and then reassemble it and use it to your health. The device is not capricious and works fine.

The cost of parts is 300-400 rubles. A similar regulator model costs five times more.

A few final tips:

- although different thermostat options are suitable for most models, it is still desirable that the thermostat for the boiler and the boiler itself be made by the same manufacturer, this will greatly simplify the installation and operation process itself;

- before purchasing such equipment, you need to calculate the area of the room and the required temperature in order to avoid “downtime” of equipment and changes in wiring due to connecting devices of higher power;

- before installing the equipment, you need to take care of the thermal insulation of the room, otherwise high heat losses will be inevitable, and this is an additional cost item;

- if you are not sure that you need to purchase expensive equipment, then you can conduct a consumer experiment. Buy a cheaper mechanical thermostat, adjust it and see the result.

Programmable room thermostat

A programmable electronic room thermostat allows you to select the desired and comfortable temperature at any time; it is easy to reconfigure and change the operating mode. The timer allows you to set a different heating pattern on weekdays and weekends. Some timers allow you to set different settings for each day of the week, which can be useful for people who work part-time or shift work. Many Terneo and KChM models are equipped with such thermostats.

Programmable room thermostat

A programmable room thermostat allows you to set individual heating standards for each day in accordance with your lifestyle and maintain the temperature of the house all the time, regardless of the presence or departure of the owners. Video: Connecting a room thermostat to a gas boiler

If the heating system is controlled by a boiler with a radiator, as a rule, only one programmable room thermostat is needed to control the entire house. Some patterns need to be adjusted in the spring and fall as the clocks move forward and backward or certain changes in climatic conditions occur. We also recommend changing the temperature settings when changing from day to night.

This climate controller has several options that expand its capabilities:

- “Party”, which stops heating for several hours, then resumes;

- “Override” allows you to temporarily change the programmed temperatures during one of the configured periods;

- “Holiday” increases the heating intensity or reduces it for a certain number of days.

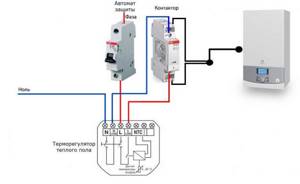

Connecting a heated floor thermostat to a gas boiler

Consumers often wonder whether it is possible to use a standard 220V thermostat for underfloor heating to work with a gas boiler?

What if you haven’t found a special thermostat with dry contacts, but you already have a model for heated floors in stock. Such a connection is possible.

However, for this you will need to “untie” the 220V voltage. In most underfloor heating thermostats, it comes to the power terminals and is then removed from the terminals going to the heating cable. And as mentioned above, when working with a gas boiler, “dry contacts” are used, through which low voltage pulses are transmitted.

If you directly connect the cable from the boiler control board here, you will cause a short circuit and damage your boiler.

For a safe connection, you will have to add an intermediate relay or an additional contactor with normally open contacts to the circuit.

From the thermostat terminals, instead of the underfloor heating cable, you supply 220V voltage to the relay coil (contactor), and through its normally open contacts (1-2 or 3-4), connect the wires to the gas boiler.

The principle of operation here is the same as discussed earlier. However, keep in mind the following feature.

Since this is a thermostat for heated floors, most likely it will work according to the scheme: air sensor + floor sensor. This means that it will require you to install and set a temperature limit using a floor sensor, which you will not have.

Therefore, in the settings you will have to unplug the floor sensor and leave only the air sensor in operation. How to do this, read in detail in the instructions for your model. There may be differences between different devices.

For example, with the Devi Touch, for this you have to break a special jumper on the back side.

In order to avoid all these difficulties and problems, it is better to initially choose the right thermostat model.

General principles for connecting a thermostat

The method and diagrams for connecting the thermostat to the heating equipment itself can be found in the technical data sheet of the gas boiler. Modern equipment, regardless of manufacturer, requires connection points for the thermostat. The connection is made using the terminals on the boiler or the thermostat cable included in the delivery package.

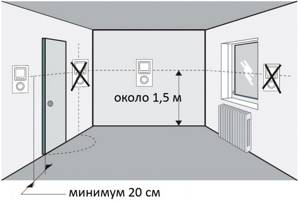

If you are using a wireless thermostat, place the measuring unit only in a residential area. This may be the coldest room or the room where the largest number of people often gathers, the children's room.

It is not advisable to install a thermostat unit in the kitchen, hall or boiler room, where the temperature regime is unstable.

The thermostat should not be exposed to sunlight, it should not be located in a draft, near heating devices and electrical equipment that emit a large amount of heat - thermal interference has a bad effect on the operation of the device

Connecting different types and models of thermostats may have their own characteristics; installation is carried out in accordance with the manufacturer's instructions, which are included with the device.

Recommendations include a comprehensive description of the regulator's operation, connection method and diagrams. Next, we will tell you how to properly connect a thermostat to a gas boiler and about the installation features of the most typical regulator models.

Connecting a mechanical thermostat

The mechanical type thermostat is distinguished by its reliability and simplicity of design, low cost, and long-term operation.

However, it supports only one temperature mode, which is set by changing the position of the handle on the temperature scale mark. Most thermostats operate in the temperature range from 10 to 30°C.

To connect a mechanical thermostat to an air conditioner, use the NC terminal; to gas or any other heating equipment, use the NO terminal

The mechanical thermostat has the simplest principle of operation and is activated through an opening and breaking circuit, which occurs using a bimetallic strip. The thermostat is connected to the boiler through the terminal box on the boiler control board.

When connecting the thermostat, pay attention to the markings - they are present on almost all models. If there are no markings, use a tester: pressing one probe to the middle terminal, check the side terminals with the second and identify a pair of open contacts

Installation of an electronic thermostat

The design of an electronic thermostat requires the presence of an electronic board that is responsible for controlling the device.

The control signal is potential - voltage is transmitted to the boiler input, which leads to the closing or opening of the contact. A voltage of 220 or 24 volts must be supplied to the thermostat.

Electronic thermostats allow for more complex settings of the heating system. When connecting an electronic thermostat, the power wire and neutral are connected to it. The device transmits voltage to the boiler input, which starts the operation of the equipment

An electronically controlled thermostat is used to organize the operation of complex climate systems. It will help in controlling not only an atmospheric or turbine gas boiler, but also a pump, air conditioner, and servo drive in the heating system.

How to connect a wireless thermostat?

The wireless thermostat consists of two blocks, one of which is installed in a living room and acts as a transmitter. The second unit is mounted near the heating boiler and connected to its valve or controller.

Data transmission from one block to another is carried out over a radio channel. To control the device, the control unit is equipped with an LCD display and a small keyboard. To connect the thermostat, set the sensor address and install the unit at a point with a stable signal.

Thermostat connection diagram for an open circuit - the equipment turns on at the moment the current appears. A similar circuit is used when connecting a mechanical thermostat

The main disadvantage of a wireless thermostat is that the remote unit is powered by batteries, which have a limited resource and therefore require frequent replacement. To ensure uninterrupted operation, the device is equipped with an alarm function that warns when the battery needs to be replaced.

Types of devices

The choice of a remote thermostat for a gas boiler is based on taking into account several characteristics, including the type of connection. Uninterrupted operation is ensured by contact of the remote module with the device that controls the operation of the gas boiler. From a constructive point of view, there are a couple of main options:

- cable models connected to a gas boiler via wires;

- wireless models with remote maintenance.

Mechanical

- durability;

- low cost;

- possibility of repair;

- resistance to voltage surges.

The main disadvantages of mechanics include not very precise adjustment and the likelihood of an error within 2-3 ° C, as well as the need to periodically adjust the indicators manually.

Electronic

In most cases, electronic thermostats for gas boilers are represented by a remote sensor with a display and a special control element responsible for the operation of the boiler. Currently, for this purpose, models with a timer are used that monitor the air temperature and change it according to the desired schedule, as well as electronic analogues. Main advantages of electronic devices:

- remote control;

- the smallest error;

- Possibility of installation in any room;

- adjusting the air temperature according to the schedule;

- the fastest possible response to temperature changes.

Almost instantaneous response to changes in indoor air temperature allows for significant savings in energy resources. The only disadvantages include the fairly high cost of such modern devices.

Programmable

The so-called “smart” equipment has decent functionality, which includes temperature control, hourly adjustment and programming according to the days of the week. Particularly popular are liquid crystal models, which have a very convenient and intuitive interface, as well as built-in Wi-Fi.

Important advantages of programmable models:

- the presence of a “day-night” function;

- significant energy savings;

- programming the mode for a long time;

- possibility of remote control of the entire system.

Gas heating boilers are equipped with devices with built-in SIM cards, which allows you to make adjustments using the most ordinary smartphone. The disadvantages of any programmable models include the rather high cost of these devices.

Wired and wireless

Wired thermostats typically have mechanical or electronic controls. Such devices are fixed only through a wired system designed to connect to gas heating equipment. The range of action, as a rule, does not exceed 45-50 meters. In recent years, programmable models of wired room thermostats have been increasingly installed.

Wireless devices include a working part for installation directly near the heating device, as well as a tracking element with a display. Sensors can be equipped with a touch screen display or push-button control. Operation is provided by a radio channel. The simplest models are capable of turning off or supplying gas. More complex devices also provide a special program for settings in order to make changes to the specified parameters.

Electronic thermostats for heating boilers

In order to fully automate the heating system, an electronic temperature controller is installed, which “takes over” all the processes occurring both in the boiler and in the environment.

As a rule, most of these devices consist of a remote sensor with a display that is installed in the room and a control element responsible for the operation of the boiler. The scope of application of these devices is quite wide: it can be either a room temperature regulator for a gas boiler or for equipment that runs on solid fuel or electricity.

Today the following models of electronic thermostats are available on the market:

- Devices with a timer, the task of which is not only to monitor the air temperature, but also its changes depending on the time of day. This function is especially suitable for those consumers who have no one at home on weekdays, so you can set the minimum temperature for heating the room, which will begin to rise by the time people return from work. This service allows you to save up to 50% of energy costs.

- If you need a thermostat for an electric boiler, then the best option would be an electronic analogue based on a bimetallic plate. It bends when the air temperature rises, cutting off the access of electricity to the heater. When the temperature drops below the programmed one, the plate will straighten and the current will again “run” to the electric boiler.

Advantages of an electronic thermostat for an electric boiler or other type of heaters:

- They are controlled remotely, which allows you to change settings without leaving the room and taking into account whether you are comfortable in it or not.

- The control panel can be installed in any living room, as long as it is not exposed to direct sunlight and there are no other heating or cooling devices nearby.

- Possibility of adjusting the air temperature taking into account the time of day.

- They react much faster to changes in the environment than their mechanical “brothers”, allowing an error of no more than 0.5 degrees.

- Significant energy savings due to rapid response to temperature decreases/increases and automatic reconfigurations.

Some consumers find that the disadvantage of electronic thermostats for boilers (solid fuel, gas or electric, it doesn’t matter) is their cost, but taking into account all the functions they have and the savings they create, this investment pays off within one heating season.

For those who want to not only set the necessary parameters for the temperature controller, but also monitor the operation of the boiler and the heating of the house from a distance, even more expensive and complex devices are suitable.

Why do you need a thermostat?

All types of heating equipment can operate in active heating mode using wood, gas or electricity, depending on the type of boiler. In addition to this mode, modern units switch to a passive state, in which the coolant continues to circulate in the system, but no longer heats up. Accordingly, the process of heating the required room slows down.

Switching from one state to another is done using a thermostat. It is this device that gives the command to the heating equipment to operate in active or passive mode.

Which thermostat is better to choose?

To make the right choice of a room regulator, we suggest considering the pros and cons of two types of household appliances. Disadvantages of mechanical models:

- low accuracy of maintained temperature;

- wired connection - the cable will have to be pulled from the boiler room to the desired room;

- lack of various convenient functions available in programmers.

There are also three obvious advantages of bimetallic thermostats:

- low price and availability;

- reliability in operation - in the simplest models there is nothing to break;

- ease of control of the boiler using one handle, which is important for older homeowners.

The negative aspects of electronic regulators are a higher price, a not always clear interface and the need to timely replace batteries. Cheap Chinese models encounter an additional problem - a breakdown in communication with the relay unit when installing the control panel behind 1-2 partitions.

An absolute plus of digital thermostats is comfortable operation. It is enough to set the weekly and daily operating program for the heat generator once; no further actions are required.

Wireless programmers need to change batteries on time.

We list a typical set of functions using the Baxi Magic Plus thermostat as an example:

- temperature control range – 5…35 °C;

- protection against freezing of the heating system, by default starts the boiler when the home cools down to +3 degrees;

- LCD display with backlight, control – push-button;

- shift of temperature sensor readings ±5 °C (read the explanation in the next section of the publication);

- 2 operating modes – economical and comfortable;

- hourly/daily/weekly programmer.

Knowing the features of electronic and mechanical regulators, it is not difficult to choose the appropriate model. Focusing on your budget, first of all consider reliable products from European, Japanese and Korean brands, there are also decent brands, but on average the quality of the products leaves much to be desired.