Setting the gas pressure of navien boilers

To adjust the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm H2O scale

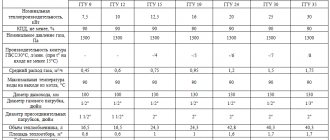

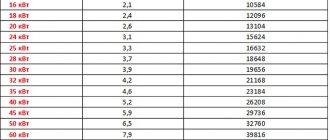

A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

2. Turn on the boiler

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

11. Turn on the boiler

12. Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

Source

03E - no burner flame.

Check

- Condition of shut-off valves.

The Navien error can be caused by user inattention - the valve blocks the pipe. - Shut-off valve lever position.

When it is triggered, the gas supply channel is blocked and the boiler stops; this can also happen in the absence of the owners.

If in fact there is a flame, the cause of the error is the ionization sensor: contamination of the electrode or its incorrect position, damage to the signal line, short circuit.

Presence of flame when the boiler is not working. False Navien error that occurs when there is a problem with the ionization sensor.

Boiler gas valve operating principle and settings

The gas valve is necessary to supply gas to the burner device of the unit. By adjusting the gas valve, you can regulate the amount of fuel supplied. This makes it possible to make the unit more economical or increase the power of the device. Thus, the user, depending on the situation, has the opportunity to adjust the performance of his unit.

How does a gas valve work?

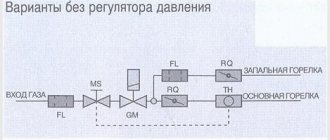

Most gas units have a SIT valve. It includes the following elements:

- gas pressure measuring port at the valve outlet;

- adjusting screw for minimum and adjusting nut for maximum fuel consumption;

- lid;

- inlet pressure measuring port.

The gas boiler valve consists of a shut-off and modulation coil. When a voltage of 220 V is applied to the shut-off valve, a minimum volume of gas is supplied to the burner in accordance with the factory settings. The voltage is then transferred to the modulation coil. The processor, depending on the operating mode (power), supplies voltage with different modulation frequencies, regulating the amount of gas passing per unit time.

To set the boiler gas valve to minimum power, you will need a differential pressure gauge, a wrench and a screwdriver. The setup process includes the following steps:

- Remove the protective cap covering the differential valve screws.

- Open the fitting to measure the gas pressure supplied to the burner - turn the locking screw 1.5-2 turns counterclockwise.

- Connect the pressure gauge hose to the inlet fitting.

- Turn on the heating mode and disconnect one wire of the modulation coil - this is necessary so that the valve supplies gas to the burner to a minimum, which will correspond to the minimum power of the unit.

- According to the pressure gauge readings, set the minimum gas pressure on the burner. To do this, rotate the internal screw located under the protective cap. At the same time, fix the outer nut.

The dynamic fuel pressure at the gas valve inlet ranges from 1.4 to 2.4 kPa. If measurements show that the pressure is outside the specified limits, it is necessary to call gas specialists.

In the factory power range, there is no need to manually reset the gas valve. This is required in order to transfer the unit to a power lower or higher than the values stated in the instructions. Often, valve adjustment is needed if the performance of the device does not correspond to the heated area of the house or apartment.

Setting the gas valve when the boiler is “clocked”

A problem such as “clocking” of a gas boiler can be solved by adjusting the gas valve. It usually occurs if the power of the unit significantly exceeds that required for a given area.

To prevent the device from “clocking” in heating mode, it is necessary to reduce the outlet pressure. This is done by turning the adjusting screw counterclockwise.

To stop “clocking” in DHW mode, reduce the maximum pressure. This can be solved by rotating the adjusting nut counterclockwise.

However, in more modern models, “clocking” is eliminated automatically. For example, setting the gas valve of the Buderus boiler is done by blocking the cycles:

- hold the button with the wrench for 5 seconds;

- select the duration of intervals from 0 to 15 minutes using the arrow buttons.

It is recommended that adjustments of this kind be carried out only by service center specialists, especially if the boiler is under warranty. Otherwise, if you damage the valve, the company will void the warranty and you will have to buy a new part.

Adviсe

Even the exceptional skill of South Korean manufacturers does not allow 100% to eliminate the occurrence of violations and problems during operation. Poor water heating is mostly due to the filling of the heating system with air pockets. The problem is solved by removing accumulated air or changing the automatic vent. It is also possible that the filter in the heating circuit is dirty.

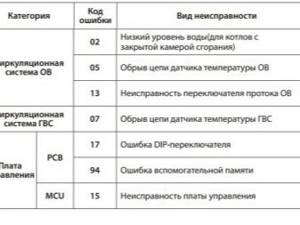

Error No. 2 means that the coolant concentration is below normal.

This situation can be corrected either by adding water or eliminating the leak. Code 3 indicates that gas is not supplied to the burner. It is necessary to check what position the valve is in, whether the fuel in the cylinder has run out, and whether there are any accidents on the line. Judging by the reviews of the owners, South Korean boilers are more compact than many other versions and are characterized by rapid achievement of the set temperature. But it is noted that there are no control elements on the boilers themselves and that occasionally turning on two hot taps on the water supply reveals insufficient heating power.

If the boiler is leaking, in many cases it is water leaking from a drain plug that is closed too loosely or is leaking for some reason. When the cause is more complex, you will have to remove the problematic unit, disassemble it and clean it. Unscrew the clamping nut and remove the air vent. Using a hexagon, unscrew the plug, then remove the rubber band (a needle or screwdriver with a thin tip will do). The piston and spring are removed, and when the float falls out, you need to wash it and then return it to its place (in the reverse order).

Warm home Setting the gas pressure of Navien boilers

Setting the gas pressure of Navien boilers

To adjust the gas pressure of Navien boilers (Ace, Deluxe, Prime, Atmo), you will need a differential digital pressure gauge with a mm h3O scale

A table with gas pressure values for various Navien boiler models is given at the end

1.With the boiler turned off, attach a pressure gauge to the gas pressure control fitting on the burner

2. Turn on the boiler

3. Set DIP switch 3 on the control board to the “ON” position, which will correspond to the minimum load.

4. Set the minimum gas pressure according to the table using the screw for setting the minimum pressure (Increase - counterclockwise, decrease - clockwise)

5. Set DIP switch 3 on the control board to the “OFF” position (Main state)

6.Set DIP switch 2 on the control board to the “ON” position, which corresponds to the maximum load

7. Set the maximum gas pressure in accordance with the table using the adjusting screw (Increase - counterclockwise, decrease - clockwise)

9. Disconnect the differential pressure gauge hose from the gas valve fitting

10. Set the DIP switch to the “OFF” position (Main state)

11. Turn on the boiler

12. Check the tightness of the gas valve (Fitting). If abnormal noises appear, you need to check the boiler for gas leaks.

The material was prepared by an employee of heating-mtsensk.rf - Warm Home.

Source

Design features of Navien gas boilers

Manufacturers of Navien produce devices of different capacities, floor-mounted, wall-mounted and with a hot water supply function. They can be connected both to a centralized line and to gas cylinders. The units have a modern appearance that allows them to fit into any home interior. Navien gas boilers are equipped with a safety group, which includes:

- modulating turbocharging;

- protection against coolant freezing;

- SMPS chip that protects against power surges;

- temperature sensor control panel, which allows you to adjust the operation of the unit to certain circumstances.

The most common model of Navien gas units is Deluxe, so let’s look at them in more detail.

07E/08E

Similarly for the Navien hot water system.

The error indicates there is no signal from the boiler fan.

The code is usually displayed when there is insufficient traction or its complete absence.

If an error appeared during the initial start-up of the Navien gas boiler, this may be caused by incorrect calculations of the chimney parameters or violation of the rules for its installation.

Check

The boiler error is related to the flow sensor: a fault or short circuit in the wires.

Blocked gas path. The probable cause of the error is the operation of the shut-off valve.

There are several malfunctions that cause the code to appear.

- Electronic board.

- Three-way boiler valve.

- Heating temperature sensor.

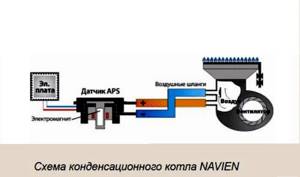

An error typical for Navien atmospheric models. Caused by a malfunction of the air sensor (APS) or lack of communication between it and the boiler board.

Other codes are also displayed on the Navien display.

But almost all such malfunctions are associated with the boiler’s electronic board. The only thing you can do yourself is to make sure that the contacts are tight and correct the connectors on the module. It cannot be repaired, especially at home.

Useful tips

- Before removing the casing of the Navien boiler and trying to solve the problem with it yourself, you should make sure that the warranty for the sample has expired (according to the mark in its passport). If it works, you need to call specialists from a service organization - you won’t have to pay for repairs.

- The risks of Navien errors can be minimized by proper arrangement of the heating system: power supply to the boiler via a UPS, high-quality water treatment, filters on the pipes of connected communications. Plus – professional installation of equipment.

- Navien boilers break down extremely rarely. If errors appear on the display, you should immediately check the corresponding sensors and connecting wires. In 85% of cases, the reason is precisely in them or in external factors (mismatch of parameters of house systems; for example, pressure in the main line).

The documentation for Navien heating installations contains scant information, including information on errors that appear. the user to contact an affiliated service center in case of problems with the operation of the equipment. This must be taken into account when calling a specialist. It is not a fact that this department has manuals for repairing Navien boilers.

The original article is posted on the website

fixbroken.ru

Setting up a Navien gas boiler

Next, we’ll look at how to set up a Navien Deluxe gas boiler with your own hands. Manipulations are carried out using a remote control with a built-in room temperature sensor.

Heating settings

To set the heating mode and set the coolant temperature, hold down the button with the image of a radiator until the same icon appears on the screen. If the “radiator” picture blinks, it means that the set coolant temperature is displayed on the screen. If the symbol does not flash, the actual water heating level is displayed.

Navien wall-mounted gas boilers - model range, pros and cons

How they work and what are the advantages of Navien Ace gas boilers

To set the desired temperature, use the “+” and “-” buttons with the “radiator” icon flashing. The possible range is from 40ºC to 80ºC. Once the temperature is set, it will be automatically saved. The “radiator” icon will blink for a few seconds, after which the actual temperature of the coolant will be displayed on the screen.

Heating with air temperature control

To set the desired air temperature in the room, you need to hold down the “radiator” button until the image “house with thermometer” appears on the screen. It means “Heating with room temperature control” mode.

When the “house with thermometer” symbol is flashing, the desired room temperature is displayed on the screen. When the icon is not flashing, the display shows the actual room temperature.

When the icon is flashing, using the “+” and “-” buttons, the desired level of heating in the room is set, adjustable in the range of 10-40ºC. The temperature is then automatically saved and the icon stops flashing.

Setting the hot water temperature

To set the hot water temperature, you need to hold down the “water tap” button until a similar flashing symbol appears in the right corner. You can then set the desired hot water temperature between 30ºC and 60ºC. The settings will be automatically saved and the “water tap” symbol will stop flashing.

Note! In the “Hot water priority” mode, the water heating temperature is regulated differently.

Now let’s look at how to configure the Navien Deluxe gas boiler in the “Hot water priority” mode. To activate it, hold down the “water tap” key until the “faucet and light” symbol appears on the screen. Now you can set the desired temperature using the “+” and “-” keys. While the DHW temperature is changing, the “water tap” icon should flash above the “tap and light” symbol.

Possible malfunctions and ways to eliminate them

Navien error codes:

- 01 – overheating (check if the pump is working and if the filter is clogged).

- 03 – no gas (check if the tap is open).

- 04 – false flame signal (check the serviceability of the gas valve, replace the electrodes or board).

- 05 – 06 – Short circuit on the temperature sensor or open circuit.

- 09 – problems with the fan.

- 10 – problems with smoke removal (check the operation of the fan, whether the chimney is clogged, whether the fan pipes are connected correctly, gusty wind could also be the cause).

- 013 – Short circuit on the OM flow sensor.

If the boiler does not give any errors, but works much worse, the reason may be a clogged filter or an airy system.

Navien boilers, like any other equipment, require good care and proper handling. Regular checks and service control will help avoid breakdowns.

Installation of an internal electrical network is an important stage in the arrangement of a new building. Electricity in a private house with your own hands - how to do the wiring correctly? Read the advice of professionals.

For recommendations on making a gas burner for a boiler with your own hands, read the link.

How to increase the time between starting and shutting down a gas boiler?

If there is a problem with frequent switching on and off (“clocking”) of a gas boiler, you can change the difference between starting and stopping the unit. This is possible using the Navien engineering menu:

- Turn off the remote control and press two buttons “+” and “-” at the same time.

- A number from 2 to 20 appears on the display. Usually 8 or 10.

- Use the “+” and “-” keys to increase the delta value between start and shutdown.

- After 5 seconds, the remote control goes out.

- The boiler is turned off and then turned on again.

Now the gas unit will operate in a new mode.

Source

Effective methods to reduce gas consumption

There are quite a lot of reasons that significantly affect the decrease in the efficiency of gas boilers, and, accordingly, the increase in fuel consumption. Therefore, the user should initially identify the one that negatively affects the performance of gas equipment. In order not to experiment, using the “trial and error” method to reduce power.

Moreover, often all that is needed to identify a problem that prevents the boiler from operating in optimal mode is to conduct a visual inspection of it. What can be done in a matter of minutes by both an employee of a gas service, a specialized company, and a person who has only a basic set of special knowledge.

And after identifying the problem, you should choose one of the suitable options for eliminating it. Which we will look at in detail below.

Method #1 - eliminating the causes of chemical underburning

Such important structural elements of any heating device, such as a heat exchanger and burner, are often covered with soot, caked dust and other types of contaminants.

As a result, there is a decrease in heat transfer efficiency. Therefore, in order to reach the set temperatures, the gas boiler has to operate for a longer time. Which leads to increased energy consumption.

While almost any user can handle adjusting the boiler settings, the rest of the work is not so simple. Actually, no one forbids you to do them yourself, but you should remember about quality and safety

The cause of clogging of the structural elements of a gas boiler is underburning of the “blue” fuel. This phenomenon occurs when insufficient air enters the combustion chamber of the heating device. The result is incomplete combustion of gas.

Troubleshooting occurs in several stages:

- Removing carbon deposits from the surfaces of the heat exchanger , gas burner and other elements of the boiler structure.

- Cleaning ventilation air ducts . Moreover, this is a mandatory procedure. Since it is the inefficiency of the ventilation system that often leads to the fact that insufficient air is supplied to the gas burner.

- Cleaning the channels of the smoke removal system . This procedure is necessary because ineffective removal of combustion products can lead to a lack of oxygen.

These manipulations can be performed by gas service specialists, specialized companies, as well as the boiler owner himself. But provided that he has sufficient knowledge and skills.

The photo shows soot in the chimney. The more it is, the less efficient any gas boiler becomes. Since a contaminated smoke removal system is always one of the most important reasons for such a phenomenon as chemical underburning and subsequent excessive energy consumption

If the boiler structural elements and air ducts are cleaned, but carbon deposits continue to form, and very quickly, then the problem of under-burning and inefficiency can be solved with the help of:

- performing commissioning works;

- arrangement of ventilation and smoke removal systems.

Since adjustment work is simpler and less expensive, you need to start with them. Why do you need to invite a gas specialist or a company that has the necessary license?

The arrangement of ventilation and smoke removal systems begins with calculations. They allow you to understand how much air is needed to eradicate such a phenomenon as under-burning with subsequent excess gas consumption.

To consistently supply the boiler with the required amount of air, it is better to use modern equipment (coaxial or sandwich air ducts).

Method #2 - eliminating the causes of mechanical underburning

This phenomenon occurs when part of the gas simply does not have time to burn due to excess oxygen, while the surfaces of the boiler remain clean.

That is, the situation is opposite to what happens with chemical underburning. And it is caused by the excessive performance of the smoke removal system, which leads to high draft. Which should be adjusted to eliminate the causes of incomplete combustion of “blue” fuel. Which, with a draft limiter, can be done in a matter of seconds.

If owners more or less successfully combat the problems created by dirty chimney ducts, then the same shortcomings of the air ducts of ventilation systems are often forgotten. But they need to be cleaned, and regularly, if you want to make your heating device efficient

If the specified device is not provided, then when using modern modular smoke removal systems, this deficiency can be easily corrected.

To solve problems with excessive draft, you can think about changing the type of smoke removal system, for example, to modern coaxial air ducts with the required diameter. This will be a practical solution - optimal dimensions and the absence of a limiter, which is a transverse partition, will make the air flow more stable. What will affect the quality of gas combustion?

In addition, the reasons for mechanical underburning, and, consequently, excessive gas consumption, can be:

- incorrect power setting;

- incorrect choice of gas boiler in terms of power.

In the first case, you can fix the problem by setting the heater manually. How to do this is described at the beginning of the article.

You should always remember that the boiler power settings are correct. Ignoring this warning may cause it to operate intermittently. And until the problem is solved, there is no need to mention economical gas consumption

Method #3 - cleaning the heat exchanger and coolant

A coating consisting of ferric iron, salt deposits and other foreign particles is deposited on the internal surfaces of the channels of the specified boiler structural element. Within a few months from the start of operation, this can lead to the fact that more thermal energy will have to be spent to heat the coolant to the required temperature. The production of which will require increased gas consumption.

Even when installing a gas boiler, care should be taken to carry out the commissioning work correctly. Since a poorly configured fuel valve, injector or electronics will not give the expected result. Moreover, from the first day of using the heating device, to eliminate this drawback, the internal cavities of the heat exchanger must be cleaned regularly.

What can be done in different ways:

- mechanical , that is, manual cleaning;

- chemical , for which special solutions are used;

- hydrodynamic , which is done using ordinary water (under pressure).

Mechanical cleaning of the heat exchanger is carried out using various brushes and scrapers. That is, with certain skills, you can perform this procedure yourself, although it is labor-intensive.

The chemical method involves connecting a special device called a booster to the dismantled heat exchanger. And it repeatedly flushes the internal channels with special liquids (acids). Which cope with even the most persistent plaque.

The hydrodynamic method is the least labor-intensive. Since all that is required when using it is to connect a special pump to the heating system. After that, clean water is pumped into its channels, the pressure of which gradually increases. Which leads to delamination and subsequent removal of plaque.

The photo shows a dirty heat exchanger with a layer of carbon deposits consisting of gas combustion products and fused dust. Since this is the normal state of the surface of any heat exchanger just a few months after use. And this should be remembered, because carbon deposits lead to a gradual decrease in heat transfer

The heat exchanger channels must be cleaned at least once every 2 years. It is possible to reduce the frequency of performing this procedure only by using filters that are used to clean the coolant from all kinds of dirt particles. This allows you to clean the heat exchanger 2 times less often, that is, once every 4 years.

To clean the coolant, you can use filters:

- rough cleaning;

- fine cleaning;

- magnetic.

All of the listed products can be used both together and separately. But the optimal combination of filters can be established only after laboratory analysis of the water that will be used as a coolant.

Method #4 - reducing overall heat loss

If a gas boiler consumes a disproportionate amount of gas, but there are no external signs of a problem and it is configured correctly, then we can assume that the problem is not in the unit itself. And the culprit is general heat loss , which will have to be eliminated. Otherwise, excess energy consumption cannot be avoided.

The arrows in the photo indicate the heat exchanger channels. As you can see, they are quite narrow, which is done to improve heat transfer. But this same feature leads to the channels quickly becoming clogged. What is the direct path to a significant increase in gas consumption?

The causes of general heat loss are:

- incorrect installation of radiators;

- suboptimal total thermal power of radiators;

- poor thermal insulation of doors and windows;

- lack of insulation of floors, roofs, walls of the building;

- insufficient thermal insulation of ventilation, smoke removal, etc. ducts.

You should know that the efficiency of any gas boiler directly depends on the correct operation of the radiators. And the worst news is that it will not be possible to reduce energy consumption by any manipulations with the heating boiler if the radiators are installed incorrectly.

Therefore, you need to move on to this issue as soon as it is determined that the boiler is working and correctly configured.

When checking the correct installation of radiators, you must make sure that:

- There are no distortions . This is an important point, since a radiator tilt of more than 1° begins to affect the efficiency of the heating system. And significant inaccuracies made during the installation of several products will lead to a significant loss of efficiency, by tens of percent;

- The batteries are located in places where heat loss is usually greatest (for example, near windows). And they are placed 12 cm from the floor, 2 cm from the wall and 10 cm from the window sill, which should cover the radiator by 2/3.

You should also pay attention to the absence of excessive bends in the places where the pipes through which the coolant flows turn, and to the correct installation of de-aeration valves.

Cleaning the heat exchanger channels with acids, although it requires a special device (booster), is less labor-intensive than the same procedure performed manually. Moreover, it is of higher quality. And most importantly, there is less chance of damaging the product structure

As already indicated, the total thermal power of the radiators and the gas boiler used should be approximately equal.

If you do not follow this rule, then at low total power the gas boiler will heat the coolant to a critical 75 °C. At which rapid wear of the resource of all structural elements of the heating system made of polymer plastics will begin. What threatens leaks.

In addition, at this temperature, dust particles burn en masse, which does not contribute to the comfort of living.

And the worst thing is that the difference in the performance of the equipment that is used as part of the heating system will lead to clocking (frequent switching on/off). In which a considerable part of the gas will simply fly out into the pipe without burning. The reason is that the electronics of all boilers are programmed so that gas is supplied first, and after a while a spark is produced.

The main reason for boiler inefficiency has traditionally been overall heat loss. That is, without eliminating heat loss, there can be no talk of any reduction in gas consumption

In addition, when turned on, the performance of gas boilers traditionally reaches peak values, which is designed to eliminate problems when igniting them. And this feature with frequent launches leads to even greater losses.

It should also be remembered that gas boilers cannot operate efficiently in a room equipped with windows, doors with slits, cracks and uninsulated walls, floors and ceilings. That is, the listed shortcomings should also be eliminated.

How to set up a Navien gas boiler - operating instructions

The high-tech Korean gas boiler Navien is a leader in the heating equipment market. Units with a wide range of power are produced for heat supply to houses with a main gas subscriber station. By design, they can operate on liquefied gas. The model range allows buyers to make a fine selection of equipment based on real technical conditions and financial capabilities. They have an impeccable minimalist design. The elegant appearance of the boiler fits into kitchens of any size and configuration.

Video on the topic

Each gas boiler is in many ways a unique development, despite its relatively unified structure. After all, every manufacturer tries to get ahead of its competitors and offer a more technically advanced solution. Navien Deluxe products were no exception.

Features of operation of Navien boilers

Navien - domestic double-circuit boilers with an open or closed combustion device are used for heating residential and public premises and heating water for domestic and technical purposes.

The boiler control is Russified and adapted to the real operating modes of Russian engineering systems.

The APS mechanism ensures a stable fuel combustion process with minimal consumption. The blower fan for supplying air and creating a working pressure of the gas-air mixture has different speed operating modes and allows the operator to control the rotation speed for complete combustion, preventing condensation.

Navien boiler equipment:

- Circulation pump;

- universal heat exchangers for the heating circuit and DHW system;

- security automation;

- expansion tank;

- selection of heating mode and timer to stop the unit;

- Navien boiler, installation and operating instructions.

The advantage of using a heating unit is that a burner with pre-mixing of the gas-air mixture has a modulation range of 30-100%.

Specifications

| Indicators, units | NAVIEN Ace-13A Atmo | NAVIEN Deluxe-16K | NAVIEN Deluxe-20K | NAVIEN NCN-25K |

| Heating area, m2 | 98.0 | 128.0 | 160.0 | 220.0 |

| Condensing type | No | No | No | Yes |

| Thermal power, kW | 13.0 | 16.0 | 20.0 | 25.0 t |

| Combustion chamber | open (chimney) | closed (turbo) | closed (turbo) | closed (turbo) |

| Electrical power consumption, for own needs, kW | 110.0 | 150.0 | 150.0 | 130.0 |

| Min. t in the heating circuit, °C | 42 | 42 | 42 | 30 |

| Max. t heating circuit, °C | 80 | 80 | 80 | 95 |

| Max. pressure in the DHW system, bar | 8.0 | 8.0 | 8.0 | 10.0 bar |

| Max. t DHW, °C | 65 | 65 | 65 | 65 |

| Capacity (Δt=25°C), l/min | 9.0 | 13.6 | 13.8 | 14.0 |

| Capacity (Δt=35°C), l/min | 5.5 | 8.6 | ||

| Summer operating mode | Yes | Yes | Yes | No |

| Hot start mode | Yes | Yes | Yes | No |

| Efficiency, % | 86.0 | 91.0 | 91.6 | 98.2 |

| Nominal gas pressure in front of the boiler, mbar | 18.0 | 18.0 | 18.0 | 18.0 |

| Max. hourly gas consumption, m³/hour | 1.33 | 1.72 | 2.15 | 2.51 |

| Expansion tank capacity, l | 6.5 | |||

| Chimney diameter, mm | 130.0 | 60/100 | 60/100 | 80/125 |

| Price as of 07/01/2019 | 32780 rub. | 35200 rub. | 37880 rub. | 69800 rub. |

NAVIEN Ace-16K Turbo

Gas wall-mounted 16 kW is a compact design of a gas boiler for autonomous heating and hot water supply in houses with an area of up to 98 m2 with a remote control unit. Net power is 16 kW, average efficiency is 86%, and the highest fuel consumption is up to 1.33 m3/hour. DHW capacity - up to 5.5 l/min at t=35C.

Operating instructions for Navien gas boilers

This document is a mandatory appendix to the technical documentation provided by the manufacturer when registering the device in the retail chain. Operation is carried out from the control panel, the model offers many modes of use.

"Navien" mounted boiler operating instructions, structure and description of functions:

- Power (POWER) - on / off;

- combustion (COMBUSTION) displays the combustion process;

- pump (PUMP) status of the network circuit circulation pump;

- hot water (HOT WATER) - water heating temperature;

- low level (LOW LEVEL) - emergency water level in the circuit;

- overheating (OVERHEAT) – unacceptably high water temperature;

- sensor (SENSOR) – sensor malfunction;

- reset (MISFIRE) mode on the panel to factory settings.

Installation features

Before purchasing a gas boiler you must:

- Prepare the installation site. Atmospheric apparatus requires a separate room, at least 2x2 m in size, with exhaust ventilation.

- The device must be powered from a stabilizer connected to a circuit breaker or outlet that has an emergency shutdown feature.

- The boiler body must be grounded, so you need to connect a grounding wire to the installation site.

- The wall where the device will hang, if it is flammable, must be sheathed with non-flammable material.

After purchasing a boiler, the difficult task of connecting it arises. The factory operating instructions recommend engaging an authorized service center specialist for this.

But if you have skills in working with pipes and taps, you can try hanging it on the wall and connecting the device yourself. The factory instructions describe this in detail.

But we must not forget that in any case, you will need to call a gas service specialist to conclude a service agreement and obtain a special permit to operate gas equipment.

Important! Unauthorized connection of gas to the boiler may result in penalties and even criminal prosecution.

Starting the boiler

After all installation work has been completed and pressure testing has been carried out, the first commissioning start-up of the boiler equipment is carried out. All work is carried out by service center workers with the preparation of appropriate documents, which in the future will preserve the manufacturer’s warranty obligations.

When starting the Navien boiler, the instructions must be followed impeccably. Sequence of work:

- The circuits are filled with water through the unit’s make-up unit, built into the structure, with a special tap at the bottom next to the tap water inlet.

- Monitor the pressure gauge; when the pressure rises to 2.0 atm, close the tap.

- Remove air pockets. At the first start, it is performed in manual mode, and at subsequent starts, through an automatic system. They start the process from the most distant battery, opening the Mayevsky tap, and alternately go through all the points of the heating circuit.

- After etching the air plug, the pressure in the circuit will drop, so re-filling will be required.

- Discharge the air mixture from the circulation pump.

- To turn on the unit, press the “Power” button.

- The electric ignition will work and the unit will start, after which it is necessary to adjust the temperature regime.

Settings

“Navien” is programmed for winter (heating and DHW) and summer (DHW) operating modes - with the “Snowflake” and “Sun” icons. The network temperature is adjusted on the LCD remote control when the “radiator” icon on it is lit. In some options, the “Heating Mode” is started, in others the knob is turned. A flashing LED records the set water temperature.

If the icon just lights up without pulsating, the actual temperature in the network is displayed. By selecting the icon, use “+” or “-” to increase or decrease the temperature. After a couple of seconds the LED will stop flashing and show the actual temperature. They regulate the heating temperature from 40.0 C to 80.0 C. If it is set incorrectly, an error code will be displayed.

Note! The DHW temperature is adjusted in the same way, only on the remote control there are pictograms with a tap, the range is from +30 to +60 C.

Tips and recommendations for operating the Navien boiler

The main advice from experts regarding the safe operation of the boiler:

- The room where the unit is located must have good ventilation.

- The unit must have a separate independent connection to the electrical network.

- The boiler must operate in a fully assembled and protective housing.

- The user is prohibited from independently repairing the gas equipment of the boiler.

- The boiler must undergo an annual inspection by representatives of Gorgaz.

- The boiler owner must periodically check the joints of the boiler and the gas pipeline for leaks with a soap solution.

Additional Information. If leaks occur, immediately turn off the gas valve, ventilate the room and call the emergency gas service.

Navien gas boilers have been used by Russian consumers for a long time. They have rightly earned the trust of customers. The lightweight layout with the widest range of modern water heating functions allows you to choose these models from a large list of offers on the heating equipment market.

Source

Cleaning the heating water filter

Filters collect all the impurities contained in the water.

They need to be cleaned periodically, for this:

- Drain the water (see previous paragraph).

- Wait until the equipment cools down completely.

- There is a filter located not far from the drain plug. To remove it, first remove the mounting bracket, then pull out the filter itself.

- It must be rinsed under pressure with clean water.

- Then reassemble in reverse order.