In order to choose a boiler that runs on solid fuel, you need to pay attention to the power. This parameter shows how much heat a particular device can create when connected to a heating system. This directly determines whether, with the help of such equipment, it is possible to provide the house with heat in the required quantity or not.

For example, in a room where a pellet boiler with low power is installed, it will be cool at best. It is also not the best option to install a boiler with excess power, because it will constantly operate in an economical mode, and this will significantly reduce the efficiency indicator.

So, in order to calculate the power of a boiler for heating a private house, you need to follow certain rules.

Calculation of heating boiler power by area

For a rough estimate of the required performance of a heating unit, the area of the premises is sufficient.

In the simplest version for central Russia, it is believed that 1 kW of power can heat 10 m 2 of area. If you have a house with an area of 160 m2, the boiler power for heating it is 16 kW. These calculations are approximate, because neither ceiling height nor climate are taken into account. For this purpose, there are coefficients derived experimentally, with the help of which appropriate adjustments are made.

The specified norm is 1 kW per 10 m2, suitable for ceilings of 2.5-2.7 m. If you have higher ceilings in the room, you need to calculate the coefficients and recalculate. To do this, divide the height of your premises by the standard 2.7 m and obtain a correction factor.

Calculating the power of a heating boiler by area is the easiest way

For example, the ceiling height is 3.2 m. We calculate the coefficient: 3.2m/2.7m=1.18, round it up, we get 1.2. It turns out that to heat a room of 160 m 2 with a ceiling height of 3.2 m, a heating boiler with a capacity of 16 kW * 1.2 = 19.2 kW is required. They usually round up, so 20 kW.

To take into account climatic features, there are ready-made coefficients. For Russia they are:

- 1.5-2.0 for northern regions;

- 1.2-1.5 for Moscow region regions;

- 1.0-1.2 for the middle band;

- 0.7-0.9 for the southern regions.

If the house is located in the middle zone, just south of Moscow, a coefficient of 1.2 is used (20 kW * 1.2 = 24 kW), if in the south of Russia in the Krasnodar Territory, for example, the coefficient is 0.8, that is, less power is required (20 kW * 0 ,8=16kW).

Heating calculations and boiler selection are an important step. Find the power incorrectly and you can get the following result...

These are the main factors that need to be taken into account. But the values found are valid if the boiler operates only for heating. If you also need to heat water, you need to add 20-25% of the calculated figure. Then you need to add a “reserve” for peak winter temperatures. That's another 10%. In total we get:

- For heating a house and hot water in the middle zone 24 kW + 20% = 28.8 kW. Then the reserve for cold weather is 28.8 kW + 10% = 31.68 kW. We round up and get 32 kW. If we compare it with the original figure of 16 kW, the difference is twofold.

- House in Krasnodar region. We add power to heat hot water: 16 kW + 20% = 19.2 kW. Now the “reserve” for cold weather is 19.2+10%=21.12 kW. Round up: 22 kW. The difference is not so striking, but still quite significant.

From the examples it is clear that at least these values must be taken into account. But it is obvious that when calculating the boiler power for a house and an apartment, there should be a difference. You can go the same way and use coefficients for each factor. But there is an easier way that allows you to make corrections in one go.

When calculating a heating boiler for a home, a coefficient of 1.5 is used. It takes into account the presence of heat loss through the roof, floor, and foundation. Valid for an average (normal) degree of wall insulation - masonry with two bricks or building materials with similar characteristics.

For apartments, different coefficients apply. If there is a heated room on top (another apartment) the coefficient is 0.7, if there is a heated attic - 0.9, if there is an unheated attic - 1.0. You need to multiply the boiler power found using the method described above by one of these coefficients and get a fairly reliable value.

To demonstrate the progress of the calculations, we will calculate the power of a gas heating boiler for an apartment of 65 m2 with 3 m ceilings, which is located in central Russia.

- We determine the required power by area: 65m 2 /10m 2 = 6.5 kW.

- We make an adjustment for the region: 6.5 kW * 1.2 = 7.8 kW.

- The boiler will heat the water, so we add 25% (we like it hot) 7.8 kW * 1.25 = 9.75 kW.

- Add 10% for cold weather: 7.95 kW * 1.1 = 10.725 kW.

Now we round the result and get: 11KW.

This algorithm is valid for selecting heating boilers using any type of fuel. Calculating the power of an electric heating boiler will be no different from calculating a solid fuel, gas or liquid fuel boiler. The main thing is the productivity and efficiency of the boiler, and heat loss does not change depending on the type of boiler. The whole question is how to spend less energy. And this is the area of insulation.

The optimal choice of heating equipment - the nuances and subtleties of the issue

Having found out for yourself the necessary power parameters of the solid fuel boiler that will be in your home, you can begin to design and install the heating system. You should be aware that the declared data on the thermal load life of the equipment affects the cost of the unit. Low-power heating devices have limited technological capabilities and are designed mainly for heating small rooms. These can be country houses, saunas and country-type guest buildings.

If necessary, the question arises of how to increase the functionality and efficiency of a solid fuel device. In this case, there are reasonable technical and engineering solutions with which increasing the boiler’s performance will have a tangible effect.

Note: the efficiency of the device can be significantly increased by installing an additional heat exchanger in the chimney, which will receive heat from volatile combustion waste escaping into the atmosphere. An economizer (additional heat exchanger) will give an increase of 20-30% to the rated power of the boiler equipment.

It is not advisable to use high-power solid fuel boilers for autonomous heating of residential buildings. Such equipment is cumbersome and requires a special large area for installation. Considering the size and enormous power of industrial boiler equipment, one should remember the significant consumption of fuel resources.

Gas boiler power calculation

For typical heating schemes with ceiling heights up to 3 m, the volume of serviced space and microclimate are not taken into account. Here the result is obtained by multiplying 1 kW/10 sq.m (specific thermal power) by the total area of the house and a correction factor for a specific region (the value is taken from the tables). For example, near Moscow for 100 sq.m. 15 kW will be required.

In dual-circuit devices, water flows cyclically, heating and cooling. Here add 20% to the results already obtained. That is, using the example in the Moscow region, the result will be 18 kW.

To clarify the required parameter, it is necessary to take into account the heat dissipation coefficient. Information is also available in official tables. So, if all structures in a house consist of modern materials with thermal insulation, then the value can be in the range of 0.6-0.9, and for single brickwork from 2 to 2.9. That is, the power of the equipment for hot water supply will have to correspond to more than 10.8 or 36 kW.

The online calculator is programmed to take into account most of the nuances and provide results in a matter of minutes. It is enough to enter the following data: area, type of windows, degree of thermal insulation and number of external walls, negative thermometer readings, ceiling height.

Real power of a long-burning boiler

Many devices are designed for a specific type of fuel. If other types of fuel are burned in them, their efficiency will be lower.

The power calculation will be carried out on the basis of the Viessmann Vitoligno 100-S 60 pyrolysis boiler. Its features are as follows:

- Powered by wood.

- In 1 hour, from 6 to 15 kg of firewood burns in the loading chamber.

- Its rated power is 60 kW.

- The loading chamber volume is 294 liters.

- Efficiency is 87%

Let the owner plan to burn aspen wood in it. 1 kg of such firewood produces 2.82 kW/h. If a boiler burns 15 kg in 1 hour, then it emits 2.82*15*0.87 = 36.801 kW/h of heat (0.87 is efficiency). Such a device is not enough for heating a house with a 150 liter boiler, but it is quite enough for hot water supply with a 50 liter boiler. To get the figure 32.67 kW/h, you need to burn 13.31 kg of aspen firewood in 1 hour (32.67/(2.82*0.87) = 13.31). This is the case if you calculate the heat demand by volume.

You can calculate how long it will take to burn a full load of firewood . 1 liter of such firewood weighs 0.143 kg. The chamber holds 294 * 0.143 = 42 kg of firewood. This supply will last for more than 3 hours. This is not enough, so you need to choose a unit with twice the firebox or find another device, for example, a pellet one.

Some solid fuel heating appliances are designed for different types of fuel. For example, the Stropuva boiler. It can burn coal, wood and pellet fuel. Actual power output will vary with different fuels. The calculation of this indicator is done by hand, using the energy efficiency of each type of fuel. Then the best one is selected.

Correction for ceiling height

Private households have higher ceilings. If we are talking about 10-15 cm, then this does not play a special role. However, if the height of the room approaches 2.9 m, this must be taken into account when calculating the boiler power by area. For this they use the so-called. “correction factor” - the actual height is divided by the standard parameter of 2.6 m. The result of general calculations is multiplied by the resulting number. As an example, you can calculate the ceiling height correction for a building with a wall height of 3.2 m. Other parameters correspond to the first example.

Recalculation algorithm for choosing the power of a gas boiler for your home:

- Determination of the coefficient: 3.2 m / 2.6 m = 1.23.

- Correction of the initial result: 17 kW x 1.23 = 20.91 kW.

- Rounding upwards. This results in 21 kW required for heating.

As can be seen from the example, we are talking about a quite tangible difference. If you neglect it before choosing the power of a gas boiler, even in average winter cold the atmosphere in the house will be very uncomfortable. When severe frosts occur, drastic measures will have to be taken.

Calculation options for high-power solid fuel boilers

Currently, there is a fairly large selection of heating devices with which you can effectively organize an autonomous heating system. The desire of consumers to reduce dependence on centralized heat and energy services is understandable. Saving money spent on gas heating is a significant factor that residents of private houses pay attention to.

In addition, it is not always technologically possible to connect to a centralized gas supply. In such a situation, boiler technology that runs on solid fuel takes on the leading roles. A powerful solid fuel boiler is an excellent alternative to gas equipment. Manufacturers have managed not only to improve the manufacturability of heating equipment of this type, but also to achieve a significant increase in the efficiency of solid fuel units. The high power and high efficiency of a solid fuel boiler operating on various types of fossil and organic fuels make such devices in demand and popular.

An important aspect in order to choose the right heating device for your own needs is calculating the boiler power. Let's look in detail at how to do this and what you should pay attention to.

What to follow

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we will highlight several types of boilers.

Gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive and is available to a wide range of consumers. What types of gas heating boilers are there? They differ from each other depending on what type of burner is atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products escape through a special pipe using a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall-mounted gas boiler

As for the method of placing boilers, the choice of heating boiler involves the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to supply hot water, then you can install modern wall-mounted heating boilers. This way you won’t need to install a boiler to heat the water, and this will save money. Also, in the case of wall-mounted models, combustion products can be discharged directly onto the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall-mounted models is their dependence on electrical energy.

Electric boilers

Next, we will consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. These types of heating boilers are small in size, so they can be used in small houses, as well as in cottages with an area of 100 sq.m. All combustion products will be harmless from an environmental point of view. And installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and its prices are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as backup heating devices.

Solid fuel boilers

Now it’s time to consider what solid fuel heating boilers are available. Such boilers are considered the most ancient; such a system has been used for heating premises for a long time. And the reason for this is simple - fuel for such devices is available, its quality can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to operate in autonomous mode.

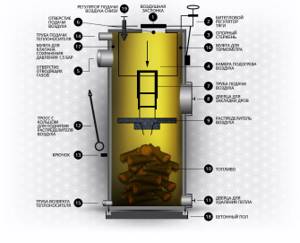

Gas generating solid fuel boiler

A modification of such boilers is gas generator devices. This boiler differs in that it is possible to control the combustion process, and the productivity is regulated within the range of 30-100 percent. When you are thinking about how to choose a heating boiler, you should know that the fuel that such boilers use is wood, and their humidity should not be less than 30%. Gas fired boilers depend on the supply of electrical energy. But they also have advantages over solid fuel ones. They have high efficiency, which is two times higher than solid fuel devices. And from the point of view of environmental pollution, they are environmentally friendly, since combustion products will not enter the chimney, but will serve to generate gas.

The rating of heating boilers shows that single-circuit gas generator boilers cannot be used for heating water. And if we consider automation, it is great. You can often find programmers on such devices - they regulate the temperature of the coolant and give signals if there is an emergency.

Gas generator boilers in a private home are an expensive pleasure. After all, the cost of a heating boiler is high.

Liquid fuel boilers

Now let's look at liquid fuel boilers. Such devices use diesel fuel as a working resource. To operate such boilers, you will need additional components - fuel containers and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this purpose, replaceable burners or special burners are used that can operate on two types of fuel.

Liquid fuel boiler

Why is it necessary to calculate power?

Based on the appearance and performance characteristics specified in the technical data sheet, you can get a superficial idea of the capabilities of the heating equipment. Power is the main parameter by which consumers select a unit.

Manufacturing companies offer many models of solid fuel boilers, which are designed for different operating conditions and differ significantly in cost. Therefore, in order not to overpay for such equipment, its optimal power for operation is first calculated.

What power reserve should be

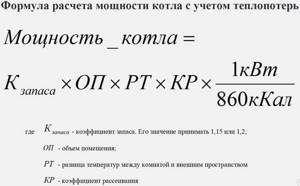

The power for selecting a heating source with an indirect heating boiler with simultaneous operation of heating and hot water supply is determined by the formula:

M k= (Mo+Mgvs)*Kz,

Where:

- Mk-combined power, kW;

- Mo - source power sufficient to provide the heating load of the house, kW;

- Mgvs - source power required to compensate for the load on hot water supply, kW;

- Кз - safety factor.

In the case of alternating operation of heating and hot water systems:

Mk= Mgvs *Kz Very important! When calculating the performance of heating and hot water equipment, it is necessary to take into account that the power of the BKN does not in any way exceed the same indicator in the boiler. For this reason, it must be selected with a heating capacity in kW so that it can cover the load of both heating and domestic hot water with a margin. The performance reserve is calculated depending on the design of the heating equipment

For single-circuit modifications, the margin is 20.0%; for dual-circuit - 20.0%+20.0%.

For the above examples, the heating output of the boiler will be equal.

When heating and hot water systems operate simultaneously:

Mo = 24 kW. Mgvs = 24 kW. Kz= 1.4.

Mk= (24+24)* 1.4= 67.2 kW.

When operating heating and hot water systems alternately:

Mk=24*1.4= 33.6 kW.

Thus, performing an initial calculation of the power of a gas thermal energy source is not a difficult process. It may be used for preliminary selection of boiler equipment. If the subscriber lacks an approximate calculation of the efficiency of gas boilers, and it is necessary that the heat loss of the building, the DHW load and the boiler performance be determined more accurately, he will need to contact qualified specialists to carry out a comprehensive home heating project with the development of a diagram and selection of equipment .

What are the advantages of a TT boiler?

What is the advantage of solid fuel boilers compared to their counterparts running on gas, electricity or liquid fuel? Let's look at their main advantages:

Autonomy

They do not depend on gas mains and power lines. Wherever your country house is located, you can always use a solid fuel boiler to heat it.

Fuel availability

Firewood and coal are traditional sources of fuel in Russia and the former CIS countries, due to their wide availability. In addition to affordability, wood or coal is significantly cheaper than gas or electricity.

Simplicity of design and connection

The simple design allows you to make even a homemade solid fuel pyrolysis boiler with your own hands and install it yourself, without much experience or significant expense.

Long service life

Modern boilers are made of cast iron or steel. With proper use and careful care, they will easily serve you for about 20-30 years.

As you can see, the TT boiler is ideal for heating your dacha or cottage. It has many advantages; it is not surprising that many owners of country property use a solid fuel boiler as the main source of heating.

Photo 1: Two-story country house

Which solid fuel boiler is best to choose for your country house? There are many modifications of TT boilers on the Russian market, which is not difficult to get confused. Let's look at their main types:

Traditional

They are characterized by simplicity of design and low cost compared to more complex modifications. The downside is that they have relatively low efficiency.

Pyrolysis

Their peculiarity is that gas is released from the fuel, which is burned separately from the solid part. This achieves a significantly higher efficiency due to significantly better fuel burnout. The disadvantage of such boilers is that they are 2 times more expensive than classic ones.

Long burning

Thanks to their design features, bookmarks have to be made much less often.

We have looked at the main modifications of solid fuel boilers, now let's look at what basic parameters should be used to choose one.

Return to contents

What is the power of a gas boiler

The performance of a boiler unit or its power is the most important indicator of the thermal process, on which the comfort of people in heated buildings directly depends.

The power of the boiler unit is the amount of thermal energy transferred to the heated water when the energy carrier is burned in the combustion device.

The indicator is measured in Gcal or MW. For household devices, the passport usually indicates the size in kW. In order to understand the physical meaning of this indicator, we can imagine the following relationships:

1 Gcal/hour is 40.0 m3 of coolant circulating for an hour and heated in the boiler at 25 C. Conversion ratio between the values:

1.0 Gcal = 1.16 MW. Calculation of the power of a gas boiler can be obtained using the formula:

Mo = (t1 - t2) * Rv/ 1000, Where:

Рв — flow rate of circulating water, m3/hour; t1 - t2 - difference T of water at the inlet/outlet of the boiler unit, C.

Heat loss can be very high

A sample calculation of the power indicator, which is carried out before choosing a boiler unit:

- T of the coolant on the supply line from the boiler is 60 C.

- The coolant temperature on the return line from the network to the boiler is 40 C.

- Network consumption is 1.0 m3/hour.

Mo= (60-40)*1/1000=0.02 Gcal. * 1.16 = 0.0232 MW = 23.2 kW,

with rounding Mo = 24 kW.

Many users, in order to save money, are wondering how to reduce the power of a gas boiler. From this example it is obvious that in order to do this it will be necessary to either reduce the temperature difference or the heating area.

The second value is constant, so you can work towards reducing the temperature difference. This can be done by installing a reliable thermal protection system for your home.

Boiler room organization

When planning a heating system for a country house, it is worth taking into account in advance the need to organize a boiler room in which a solid fuel boiler and other equipment necessary for the full functioning of the heating system will be located.

Depending on their location, boiler rooms are divided into:

built-in

They are located directly in the house itself, in one of its rooms.

external

Such boiler rooms are located in a separate extension, which is connected to the house by utilities.

Photo 4: TT boiler in the boiler room of a private house

The boiler room usually houses:

heating device

Actually, the water heating device itself, for example, the heating solid fuel boiler “Siberia” Hephaestus, which generates heat by burning solid fuel.

buffer capacity

This device accumulates heated coolant and releases it directly into the heating system.

distribution manifold

The collector includes a circulation pump that circulates the coolant through the heating system.

chimney

Responsible for removing volatile combustion products outside.

There are some rules that should be taken into account when planning a boiler room:

- The size of a boiler room operating on coal or wood must be at least 8 m2.

- Since a solid fuel boiler must be periodically loaded with fuel, the area of the boiler room must allow for storing an additional supply of coal or firewood.

- If you have a wooden house or the walls are made of highly flammable material, then they need to be sheathed with protective steel sheets 3mm thick and asbestos.

- The floor immediately in front of the firebox must be covered with steel sheets. This will protect the floor from burning coals when you light the boiler.

- The floor covering must be made of non-combustible materials.

- For every kilowatt of the boiler there should be 8 cm2 of window area.

- In a coal boiler room, all electrical appliances must be in a sealed housing.

- The cross-section of the chimney must correspond to the boiler performance.

- To increase gas tightness, it is necessary to cover the inside of the chimney with plaster, or insert an asbestos-cement pipe inside it.

- The boiler must be located on a special concrete foundation.

- The boiler must be installed at a distance of 10 cm from the nearest walls.

Watch a video on how to choose the right floor-standing TT boiler for your home:

In conclusion, I would like to note that using a solid fuel boiler is not always the best choice for a country house. In any case, when planning a heating system, it is worth considering it on a par with devices that use gas, electricity or diesel as fuel. After weighing all the options, you can finally decide which boiler to buy for your country house.

Solid fuel boilers are an excellent alternative to the widespread gas boilers. Modern and functional models of such boilers are successfully used for heating country cottage houses, city apartments (the prices for apartments in Kyiv are very low, so they are most often purchased), as well as administrative, production and industrial buildings. Correct calculation of the power of a solid fuel boiler will ensure the most comfortable temperature level and increase the efficiency of this heating equipment.

The concept of power usually means the maximum thermal load of a given product. And if this important parameter was chosen incorrectly, this can lead to a number of problems during operation. If this indicator does not reach the set value, the temperature in the heating system will be low, since the heating process will take too long and be of poor quality.

Power exceeding the maximum permissible is also extremely undesirable, since it forces the individual heating system to operate in the so-called pulse mode, which, in turn, provokes significant excess consumption of fuel used. Having figured out how to calculate the power of a solid fuel boiler, you can significantly reduce heating costs while maintaining a maximum level of comfort.

How to calculate how much heat is needed to heat water?

To calculate heat consumption in this case, you must independently add the heat consumption for hot water supply to the previous indicator. To calculate it, you can use the following formula:

Qв = с × m × Δt

- c

is the specific heat capacity of water, which is always equal to 4200 J/kg K, - m

– mass of water in kg - Δt

– difference in temperature of heated water and incoming water from the water supply.

For example, the average family consumes 150 liters of warm water. The coolant that heats the boiler has a temperature of 80 °C, and the temperature of the water coming from the water supply is 10 °C, then Δt = 80 - 10 = 70 °C.

Hence:

Qв = 4200 × 150 × 70 = 44,100,000 J or 12.25 kW/h

Then you need to do the following:

- Let's say you need to heat 150 liters of water at a time, which means the capacity of the indirect heat exchanger is 150 liters, therefore, 12.25 kW/h must be added to 28.58 kW/h. This is done because the Qzag indicator is less than 40.83, therefore, the room will be cooler than the expected 20 ° C.

- If the water is heated in batches, that is, the capacity of the indirect heat exchanger is 50 liters, the figure of 12.25 must be divided by 3 and then added independently to 28.58. After these calculations, Qzag is equal to 32.67 kW/h. The resulting indicator is the power of the boiler, which is necessary to heat the room.

How to calculate the power of a solid fuel boiler by displacement

Why do you need to calculate the power of a heating boiler based on its displacement? Everything is very simple, because if the volume of water in the heating system is an order of magnitude higher, then the boiler will not be able to cope with heating the rooms. All this will lead to a decrease in the comfort of living in the house, as well as to additional financial expenses.

To carry out all the necessary calculations, you will need to know how much water fits in 1 linear meter of pipe, in heating radiators, in the boiler itself, and in the expansion tank. An approximate calculation is made taking into account 10-15 liters of coolant per 1 kW of boiler power.

For example, if the power of the heating boiler is 4 kW, then in this case the displacement of the heating system will be 60 liters (4 kW * 15 liters). The boiler may not be able to cope with heating a larger amount of coolant in the system.

To make more accurate calculations, you need to sum up the volume of water in the pipes and heating radiators.

How much water is in an aluminum radiator

The volume of coolant in various heating radiators is as follows:

- 1 section of aluminum radiator holds 0.45 l;

- In 1 section of a bimetallic radiator - 0.25 l;

- 1 section of a new cast iron battery includes 1 liter of water;

- In 1 section of an old cast iron battery - 1.7 liters.

How much water is in 1 linear meter of pipe

Below, in this article from the construction magazine samastroyka.ru, the volume of water in 1 linear meter of pipe will be presented:

- ø15 (G ½") - 0.177 liters;

- ø20 (G ¾") - 0.310 liters;

- ø25 (G 1.0″) - 0.490 liters;

- ø32 (G 1¼") - 0.800 liters;

- ø15 (G 1½") - 1,250 liters;

- ø15 (G 2.0″) - 1.960 liters.

Thus, knowing how much water is in the radiators, pipes, in the heat exchanger of the boiler itself and the expansion tank, it will be possible to calculate the exact volume of the heating system. Knowing this value, you can more accurately calculate the required boiler power.

Also, this calculation will help in the case when you need to make a heat exchanger with your own hands. It is important to take into account not only the volume of the heating system, but also other, equally important indicators. For example, the depth of the combustion chamber - the larger it is, the more powerful the heating boiler will be.

Source

Determining the ideal ratio of power and economy

Several boilers included in one system

To follow the principles of economy, you need to take into account some more points when operating the boiler.

For the normal functioning of the boiler for many years, it is better if it operates at rated rather than peak power. But during the heating season, the need to maintain a high temperature in the house sometimes disappears. To get out of this situation, mixing valves are used.

Mixing valve

They are needed so that you can regulate the temperature of the coolant in the batteries. For this purpose, hydraulic systems with thermohydraulic distributors or four-way valves are used. If they are installed in a heating system, the temperature can be changed with a regulator, leaving the boiler power constant.

After such upgrades, even a small boiler will operate in optimal mode, sufficient for high-quality heating of all rooms. This solution is quite expensive, but it will help save on fuel consumption.

Another case is when the boiler has a power that is exceeded for a given room, and you don’t want to overpay for excess fuel, which should ensure its operation. To avoid these unpleasant expenses, you can install a buffer tank (battery tank), which is completely filled with water.

This addition will come in handy if solid fuel boilers are used for heating - the device will operate at full power, even if only short-term heat is required.

When the temperature outside rises and it is too early to turn off the boiler, the automatic valve begins to limit the flow of heated water into the radiators. He directs it to the heat exchanger of the buffer tank, and there it will heat the water that is already in the tank. The volume of the tank should be 10:1 in relation to the area of the house, for example, for 50 square meters of area you will need a tank with a volume of 500 liters.

Installing a storage tank provides significant energy savings

This water, having heated up, begins to function after the water in the circuit cools down - it begins to flow into the radiators, and the system will continue to heat the rooms for some time.

Heating boiler power - theory and real facts

A heating device operating on coal, wood or other organic fuel performs a certain job related to heating the coolant. The amount of work of boiler equipment is determined by the volume of heat load that a solid fuel boiler can withstand when burning a certain amount of fuel. The ratio of the amount of fuel consumed, the amount of thermal energy released at optimal operating modes of the equipment is the boiler power.

A heating unit that is incorrectly selected for power will not be able to provide the required boiler water temperature in the heating circuit. Low-power solid fuel devices will not allow the autonomous system to fully meet your needs in terms of heating your home and ensuring the operation of the hot water supply. There will be a need to increase the power of the autonomous device. A powerful device, on the contrary, will create problems during operation. It will be necessary to make design changes to the existing heating complex to reduce the thermal load of the solid fuel heating device. Why waste precious fuel if there is no need for so much heat.

For reference: if the boiler power exceeds the technological parameters of the heating system, the coolant in the circuit will disperse impulsively. Frequent switching on and off of the heating unit leads to excessive fuel consumption and a decrease in the operational capabilities of heating equipment in general.

*

From a theoretical point of view, calculating the optimal operating mode of boiler equipment is not difficult. It is generally accepted that 10 kW is enough to heat a living space of 10 m2. This indicator is taken taking into account the high thermal efficiency of the building and standard design features of the building (ceiling height, glazing area).

In theory, the calculation is made based on the following parameters:

- area of the heated room;

- specific power of heating equipment for heating is 10 kW. m, taking into account the climatic conditions of your region.

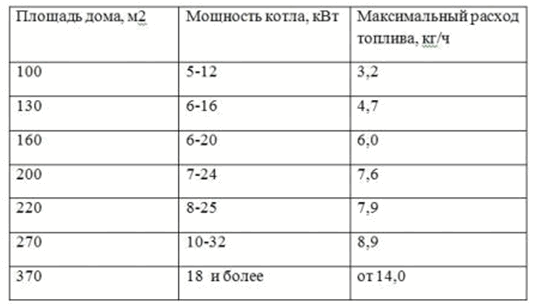

The table shows the average parameters of boiler equipment used by consumers in the Moscow region:

| Area of a residential building, other premises, m2 | Recommended unit power, kW |

| 60 — 200 | up to 25 |

| 200 — 300 | 25 — 35 |

| 300 — 600 | 35 — 60 |

| 600 — 1200 | 60 — 100 |

The thermal load parameters look optimal on paper, in theory, which is clearly not enough in relation to local conditions. The selected unit in reality should have redundant capabilities. In reality, you need to focus on equipment that can operate with a small power reserve.

Note: Excessive power of a solid fuel boiler will allow the entire heating system in the house to quickly reach optimal operating conditions. The additional resource should exceed the calculated data by 20-30%.

The actual load indicators of solid fuel units depend on a combination of various factors. The climatic conditions of the region in which you live may make adjustments when choosing a heating boiler. For the middle zone, the following power parameters of boiler equipment are considered optimal:

- one-room city apartment - boiler with an output load of 4.16-5 kW;

- for a two-room apartment - equipment rated at 5.85-6 kW;

- for a three-room apartment it will be enough to have a unit of 8.71-10 kW;

- a four-room apartment or a private residential house will require a boiler with parameters of 12-24 kW for heating.

Important! When it comes to installing solid fuel boiler equipment in private homes and suburban residential buildings, it is necessary to focus on devices with greater technological capabilities. To heat and provide hot water supply to a residential building with an area of 150 m2 or more, you will need to install a solid fuel boiler of 24 kW or more. It all depends on the intensity of the heating system and the volume of domestic needs for hot water.

It is always necessary to choose heating equipment individually, based on calculated data and your own needs.

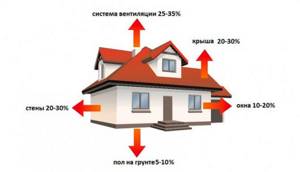

The influence of heat loss on the quality of heating

To ensure high-quality heating of the house, it is necessary that the heating system can completely replenish heat loss. It leaves buildings through the roof, floor, windows and walls. For this reason, before calculating the power of a boiler for heating a house, you should take into account the degree of thermal insulation of these housing elements.

Some property owners prefer to seriously deal with the issue of assessing heat loss and order the corresponding calculations from specialists. Then, based on the calculation results, they can select a boiler based on the area of the house, taking into account other parameters of the heating design.

When performing the appropriate calculations, you should take into account the materials from which the walls, floors, ceilings are built, their thickness and degree of thermal insulation. It also matters what kind of windows and doors are installed, whether the supply ventilation system is equipped and its performance. In a word, this process is not easy.

There is another way to find out heat loss. You can clearly see the amount of heat lost by a building or room by using a device such as a thermal imager. It is small in size and the actual loss of thermal energy is visible on its screen. At the same time, it is possible to find out in which areas the outflow is the largest and take measures to eliminate it.

People often wonder whether for an apartment or a private house, when calculating a solid fuel boiler or other type of heating unit, it is necessary to do this with a reserve. According to experts, the daily operation of such equipment at the limit of its capabilities has the most negative impact on its service life.

Therefore, you should purchase a device with a performance reserve, which should be 15–20% of the design power; it will be sufficient to ensure conditions for operation.

What factors need to be considered

The choice of a unit for a country house is influenced by external criteria, the characteristics of the building itself (wall thickness, building and finishing materials used, roofing, area, volume of heated rooms, etc.).

Condition of the premises

When calculating the power of a heating boiler, it is necessary to take into account the design features of the facility:

- building materials used to construct the building;

- ceiling height, wall thickness, room area;

- number and size of windows;

- parameters of entrance openings and doors;

- roof structure and material of manufacture;

- external and internal decoration of the house;

- use of insulating materials.

The glass area and thermal conductivity of the building must be taken into account.

Dependence on fuel type

Different types of materials can be used for solid fuel units. After burnout, the output power will vary (boiler efficiency):

- Coal: from 490 g you get 5.7 kW/h.

- Firewood: 250 g - 1 kW/h.

- Alder briquettes: 290 g - 3.5 kW/h.

- Sawdust: 300 g - 1 kW/h.

- Wood for making briquettes: 300 g - 3 kW/h.

Each of the listed materials has its own furnace design. Also, to achieve maximum savings, you need to take into account the cost of fuel.

Free area

The specific power of the unit is taken to heat 10 m² of space. Accordingly, when calculating equipment, the area of heated rooms is taken into account.

If the boiler is hot water

When purchasing such a heating unit, experts recommend adding 30% to the received power.

The main figure is heat loss

The calculated parameters of a gas boiler installed in a house directly depend on the size of heat loss. The main sources of significant loss of thermal energy in any private houses are represented not only by the ventilation system (20-25%), but also by:

- roofing;

- windows;

- walls;

- floor.

At the junctions of walls and floors, about 28-30% of heat is lost, and approximately 25-30% of thermal energy is lost through roofing structures. Uninsulated walls, floors and windows cause losses of 10-15%. It should be noted that in old households, heat loss through structural elements often reaches 40-70%, and adjoining areas, which are cold bridges, must be subject to mandatory insulation.

As a rule, the insulation of basements and floors in private households is not done well enough. At the same time, the uninsulated base part is characterized by very good thermal conductivity. Thermal insulation of the basement of an already built and operating house involves significant financial and labor costs, which is due to the need to carry out insulation in accordance with the depth of soil freezing, approximately 80-90 cm. In such a situation, it is advisable to use thermal insulation of the floor and basement.

Calculation of boiler power based on the volume of water in the system

Many people calculate the power of a solid fuel heating boiler based on the square footage of the premises, based on the fact that one kW of heat is needed to heat 10 m². This calculation is correct, but not entirely accurate. Since the main task of a heating boiler is to heat the required volume of water to the required temperature.

Another calculation applies here: 10-15 liters of coolant in the heating system, per 1 kW of the actual power of the heating device. At the same time, you need to understand that the actual power of the heating boiler largely depends on what will be used to heat it.

If this is firewood, then you can safely take up to 25% of the declared power. If the firewood is also wet, the power will be even lower. Therefore, when choosing a solid fuel boiler, it is recommended to focus on the following: the displacement of the heating system, the type of fuel, and also how well the building is insulated.

Why Excessive Power Reserve Is Harmful

Even after continuous operation, if the equipment’s performance is insufficient, it will not be possible to obtain the desired heat. But no less interesting is the dangers of performance with too high an indicator. I have repeatedly noticed how the consequences of this trouble were expressed in the following:

- Increased consumption and low efficiency of the device. The burners cannot modulate smoothly in such a situation.

- Starting and shutting down the drum boiler too frequently, as a result, reduces the service life of important components.

- Spending on unnecessary equipment purchases increases.

- Too much weight and dimensions will cause discomfort when moving around the rooms.

I see only one reason for installing equipment that will have increased reserve indicators. If the house has a buffer tank, and the thermal power of the boiler is high and it burns fuel too quickly, producing maximum heat, which must be preserved by any means. It is in this case that you cannot do without a storage system.