As an advertisement

Demand is increasing both from individual developers and from heads of technical services of enterprises, where the issue of energy efficiency and environmental friendliness is acute. Thanks to their design features, these devices are 30-35% more economical in fuel consumption compared to standard convection devices and emit 70% less harmful substances into the atmosphere.

Today, heating equipment manufacturers offer a large selection of condensing boilers, varying in price and stated characteristics. Each brand focuses on some benefit without explaining how significant it is for the consumer. In particular, this point concerns heat exchangers.

The key point is the inside of the boiler

So, let's simulate the following situation. You wanted to buy a good wall-mounted gas boiler in a certain price segment. You have selected several key models for yourself, and now all that remains is to choose one, that very only model that will stand in your home and will not cause any trouble. Naturally, you want a boiler that is reliable and will serve for many years. To understand which heating boiler you should buy, you need to look into its insides. Remember, never choose a boiler based on its external characteristics. Almost all boilers are “freaks”. Rarely does a manufacturer manage to create an aesthetic model. Basically, these are unified devices that are no different from each other. And if you see a beautiful model, perhaps they are trying to show off your eyes. Remember: appearance is the last thing you need to pay attention to when choosing a good gas boiler for a private home. Its main function is high-quality heating of the home.

Single-circuit floor-standing gas boilers

Such boilers are intended only to create a heating system. At the same time, such a system cannot provide the room with hot water. This requires separate heating elements. Single-circuit boilers in our time can be arranged as an economical or optimal option.

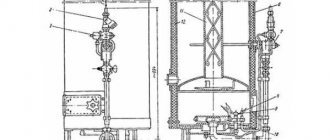

Scheme: energy-dependent floor-standing gas boiler

- An economical option involves the addition of a gas instantaneous water heater. Such a system will allow two water supply elements to operate simultaneously with low fuel consumption.

- In the optimal option, the heat exchanger is installed in an indirect heating boiler. This method requires proper coordination of the power of both devices for operation.

Heat exchanger

Pay attention to the heat exchanger material. The heat exchanger is located in the combustion chamber. Sellers can display it either open or closed. In any case, you will not be able to carefully examine the heat exchanger. You will only be able to see its edges, the burner and the space where the gas burns. Water circulates along the circuit of the gas boiler and passes through the heat exchanger, where key heating occurs.

In wall-mounted gas boilers, there are three types of heat exchangers:

- copper;

- aluminum;

- heat exchangers made of stainless steel.

Copper heat exchangers are still the most popular in the best wall-mounted gas boilers. In high-quality models, copper is coated with a special protective silumin composition, which, according to manufacturers, extends the life of the heat exchanger, increases corrosion resistance and heat resistance. In practice, such heat exchangers should last longer.

Copper heat exchanger with a protective layer for the Italtherm City Class gas boiler

Thus, the first thing you need to pay attention to is the material of the heat exchanger; if it is copper, pay attention to whether a silumin composition is applied to it or not. If there is no composition, then the manufacturer has decided to save a little money. If there is, then the manufacturer has tried and spared no expense in covering the heat exchanger.

It is copper heat exchangers that have the highest efficiency, the best efficiency indicator is achieved with copper heat exchangers in wall-mounted gas boilers. Plus, these heat exchangers are the most durable. In practice, they “live” much longer than aluminum and stainless steel ones. But copper ones have one main disadvantage. It lies in the fact that copper is an expensive spare part; if you say goodbye to your heat exchanger after a long time, then as a spare part it will cost as much as possible.

Aluminum heat exchangers

They are used quite rarely. They are mainly used by the Ariston and Fondital brands. According to the manufacturers of Ariston equipment, heat exchangers made of aluminum are in no way inferior to heat exchangers made of copper. And in terms of efficiency they are inferior by only 0.8. Therefore, aluminum ones are practically no worse than copper ones. But in fact, using aluminum means reducing the cost of production, yes, with aluminum you can achieve great heights in terms of the production of heat exchangers, but in practice such heat exchangers last less. But the plus is that aluminum heat exchangers are cheaper as spare parts. Therefore, in principle, they have the right to exist.

Stainless steel heat exchangers

Navien boiler stainless steel primary heat exchanger

They are easy to notice, they have a characteristic shine and are noticeably different from the rest. And in general, manufacturers do not hide what their heat exchangers are made of. They do not “live” for long, as spare parts are quite cheap. Thus, if there are several gas boilers on your list, the winner should be the one that uses a copper heat exchanger, ideally coated with a silumin protective compound. If you want to save money, take a boiler made of aluminum or stainless steel, but if it is the same price category, the difference in cost is small, copper is your choice. In our opinion, it is better not to buy wall-mounted gas boilers with aluminum and steel and copper for the same price.

Step-by-step instructions on how to install a heat exchanger with your own hands

The Kuznetsov heat exchanger is installed instead of one of the chimney sections - for this part of the chimney will have to be dismantled. If a chimney is installed from one long pipe, you will have to cut out part of the chimney and install the structure using welding.

Installation methods

The heat exchanger is installed at a certain distance from the heating unit - 200-500 mm, more is possible.

If the chimney is prefabricated, then it is necessary to disassemble part of the chimney. The heat exchanger pipes are cut so that the length of the heat exchanger structure is equal to the dismantled chimney section. The heat exchanger is mounted in the chimney and sealed using heat-resistant sealant. The top of the heat exchanger is painted with heat-resistant paint.

Hydraulic group materials

The hydraulic group of the boiler is almost always located at the very bottom. There is a supply and return part of the boiler. The reverse part is where the pump is located. The hydraulic group can be made of brass. Now it is used less and less. Composite versions of the hydraulic group have begun to be used more often. This is ordinary heat-resistant black plastic. It can be seen in many boilers, it is used in many models, that is, there is a gradual transition to a more affordable material. There is nothing wrong with a plastic hydraulic group: it is cheap as a spare part, lasts a long time and runs. It happens, of course, that the connections in the plastic hydraulic group dry out and begin to leak. But this is not a problem: they can be easily disassembled and reassembled using flax and plumbing thread.

Baxi luna 3 gas boiler with brass hydraulic group

If you see a brass hydraulic group in a wall-mounted gas boiler, it means the manufacturer has decided not to save money and do everything very reliably. To this day this is the best solution. For something to happen to brass, you have to try. In addition, brass can always be restored and repaired. However, brass can be destroyed by the aggressive coolant environment. But for such an environment to exist, you need to be as negligent as possible about your heating system in a private home. Therefore, the brass hydraulic group still has priority.

composite hydraulic group. Boiler Baxi Eco 4s

How to make your own device

It’s easy to make a simple coil yourself from a copper tube. For a chimney with a diameter of 100 mm, a copper pipe with a diameter of ¼ inch and a length of 3-4 m is suitable. Threaded fittings should be soldered to the ends of the pipe. Then the tube is filled with fine sand, twisted and wrapped around the chimney.

It is advisable to leave a small distance between the turns - then the pipe from the chimney will be heated by both heat transfer and infrared radiation. It is convenient to do this work with an assistant. The sand is then washed out of the pipe with water under pressure. Connect the pipes leading to the radiators and expansion tank.

The Kuznetsov heat exchanger is made using welding. The simplest option is to make a housing from a gas cylinder or large diameter pipe.

For manufacturing you will need the following materials:

- Gas cylinder, large diameter pipe (300 mm) for the housing.

- Pipe with a diameter of 32 mm (it is better to take one piece with a larger diameter - up to 57 mm). The length of the blanks is 300-400 mm, the total quantity should be sufficient for cutting the blanks.

- Two small pipes of the same diameter as the chimney; It is advisable to use a chimney pipe - if the chimney is prefabricated, then on one side of the structure the pipe will have a socket, which is necessary for installing the heat exchanger.

- Two pieces of steel sheet, sufficient to cut out the end caps of the housing.

Air heat exchanger manufacturing technology:

- A large pipe or cylinder is cut to the required size.

- 9 blanks of the same length are cut from thin pipes.

- Circles are cut out for the plugs.

- 9 holes for small diameter pipes are cut in the circles; if one tube of larger diameter is taken, then a hole for it is cut in the center.

- Thin pipes are inserted into the holes of the plugs, attached by welding, and then welded.

Holes with a diameter equal to the diameter of the chimney are cut in the sides of the body.

A structure of thin tubes and plugs is inserted into the body and welded at the junction of the plugs and the body of a large pipe.

The pipes are inserted into the holes on the sides of the body and also boiled.

What materials can be used

The ideal option is stainless steel (for example, food grade austenitic stainless steel 08Х18Н10 or AISI 304) or copper. Industrially produced products are sometimes made from titanium. But the price of these materials is quite high. But they are durable, do not rust, are reliable and durable. If you have a potbelly stove in the garage or a homemade heater from scrap materials in the bathhouse, it is quite possible to use ferrous metal (carbon steel).

You can use a high-quality corrugated stainless steel pipe. Galvanized corrugation is an undesirable and short-lived option. Aluminum pipes can also be used for the coil (just not for chimneys of solid fuel stoves).

Sometimes galvanized steel is used, but it should be borne in mind that during welding work the zinc layer evaporates, and all the advantages of galvanizing (corrosion resistance) come to naught. At temperatures above 400 °C, zinc begins to evaporate (zinc vapor is toxic), so you should not use galvanization for heat exchangers on the chimneys of solid fuel boilers.

Circular pump factor

Don't forget about the circulation pump factor. More precisely about the final brand that produces these pumps. For European boilers, everything is quite simple: most often they install Grundfos and Wilo brand pumps into their boilers. Other manufacturers equip gas boilers with incomprehensible pumps. And there are such pumps in gas boilers that are quite good, but there are others that are not so good. Grundfos have proven themselves well; their pumps are very durable. A Grundfos brand pump is an indicator of a good quality gas boiler boiler. If you see a pump of an unknown brand in a boiler, it is worth considering whether you need such a boiler, but again you need to take into account the other factors that we are talking about.

The Italtherm City Class boiler uses a hydraulic group with a Grundfos pump

Floor-standing gas boilers, double-circuit

Such units are of the flow type and combined with a boiler.

Flow-through boilers are used quite rarely, because their ability to provide hot water is small, only up to 15 liters per minute.

Electricity-independent floor-standing gas boiler

Most often, they use a boiler with a boiler, the volume of which is selected independently and depends on the needs of the residents. The disadvantage of such a unit is that they take up quite a lot of space in the room. However, they will be able to fully provide hot water to those living in the house.

Pipe materials

Pay attention to the pipeline materials used in the wall-mounted gas boiler. The pipe can be made of copper; it is used most often. The pipe is:

- thick-walled;

- thin-walled.

Manufacturers tried to save money on thin-walled ones; when pressed, the walls are dented. The pipe can also be made from:

- aluminum;

- stainless steel;

- corrugated pipe

If you see a corrugated pipe in a gas boiler, the manufacturer has saved a lot; this is the cheapest piping option. And if such a gas boiler costs the same as the option with a copper pipeline, then it is better not to buy it. Not the best solution.

It is not a fact that this is an unreliable option, but copper pipes are a sign of reliability and longevity and competence of the manufacturer. A corrugated pipe consists of joints, the material is unclear and very controversial. Therefore, we can conclude that if you come across a corrugated pipe, you can put the boiler in last place.

Advantages and disadvantages

Like any technology, gas boilers have their positive and negative sides.

A floor standing gas boiler requires sufficient space for installation

The advantages floor-standing gas boilers include:

- Easy to use. Gas boilers do not require continuous monitoring and are easy to maintain.

- Sufficiently high efficiency with inexpensive fuel.

- Large coverage area. The boiler is capable of heating large houses.

Flaws:

- A fair amount of documents and permits, without which it is impossible to install the boiler.

- The need to construct a chimney before installation.

- Installation should only be carried out in sufficiently ventilated areas.

- It cannot be installed tightly against a wall or placed between two walls, so as not to disrupt the flow of oxygen to the burner.