On the eve of the heating season, the issue of purchasing a gas boiler for heating becomes relevant. And choosing what suits best in terms of characteristics and cost can sometimes be very difficult, so many people carefully study reviews of certain brands and their descriptions before purchasing.

Today we will talk about Danko gas boilers : you will find out what categories they are divided into, what their advantages are, how to install them and much more. You will also read reviews from those who have already installed them at home.

About company

is engaged in the production of heating equipment of various types - it produces gas, electric and solid fuel boilers, heaters and converters. The first products entered the market in 2002. The batch consisted of only 49 units of equipment. Today the company has about 850 thousand units of products sold. The production uses advanced equipment from foreign companies from Italy, Denmark, and Finland.

About the manufacturer

The Danko trademark is managed by PJSC Agroresurs; the first batch of boiler units was produced in 2002. The company is represented in the markets of Ukraine, Russia, Belarus and Moldova, where it has established itself as a manufacturer of relatively reliable and efficient gas boiler units for their price. It’s not uncommon to find the first batches of 2002 in homes.

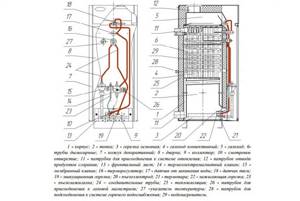

The design and principle of operation of Danko gas boilers in a section using the example of a double-circuit steel model 12VSR.

Heating boilers are produced using modern foreign equipment, automation is imported from Italy in finished form. Almost all boiler units have high efficiency - over 90%. However, there are also disadvantages - the assembly is of insufficient quality, problems with the automation are possible during operation, due to the simplicity of the device and low cost, the boilers do not have a wide range of functionality or a set of protective systems. Installers note the relative complexity of installation and connection.

In practice, during strong gusts of wind in versions with a horizontal gas duct, the burner often blows out and the flame goes out, but the automation does an excellent job and turns off the gas supply. After this, the boiler must be ignited manually. The above-described disadvantages are typical for any inexpensive boilers of Russian, Ukrainian or Belarusian production.

Advantages

- The assembly is carried out in accordance with European technologies.

- Good technical characteristics - the manufacturer achieves a high level of efficiency and cost-effectiveness due to innovative technologies involved in production.

- Works stably and without noise.

- Can be used in a heating system without forced circulation - it operates energy-independently.

- Simple installation - you can handle it yourself, without the help of specialists.

- The kit includes instructions explaining how to light the device, how to connect it to the heating system, how to carry out repairs and maintenance, as well as other useful information.

- Equipped with reliable automation that ensures the safety of the equipment.

- The coil is made of copper. The water heats up quickly.

- The heat exchanger is made of steel. Characterized by high heat transfer.

- Three years warranty. Cast iron ones last an average of 25 years, steel ones – 15 years.

How to choose?

Boilers are divided into the following types:

- Double-circuit wall. Their main advantage is their low weight and compactness. Combustion chamber - any type. Ignition is electronic. The device is protected from water freezing and has automatic diagnostics of faults. Rated power 23.3 kW. The wall-mounted option can heat an area of up to 210 square meters. Consumes 2.76 cubic meters. gas per hour. The capacity of the membrane container is 6 liters.

- Double-circuit floor. In them, the developers provide automatic safety equipment that stops the operation of the device in the absence of fuel, in case of insufficient thrust, or when the flame goes out. The power varies between 20-40 kW, and the heated area is 180-360 sq. m. A wide range of models is represented by modifications with heat exchangers made of cast iron or steel. The floor-standing version costs from 10 to 20,000 rubles, depending on the power and the automation used.

- Parapet. Water heating is provided. There is a sealed chamber. Chimney version. The parapet version has piezo ignition and automatic protection. Burners are micro-flare. Heats 60-140 square meters.

- Steel floor. Single or double circuit. Gas duct – vertical/horizontal. 8-24 kW. Area – 701-90 sq. m.

- Cast iron floors. Open combustion chamber. Used in closed and open heating systems. Type of circulation – any, natural or forced. High heat transfer of cast iron heat exchanger. 16-50 kW. Area – 150-460 sq. m.

A little about production

Danko gas boilers are almost entirely produced using imported equipment - it is supplied from Japan, Finland, Denmark and other countries. This allowed us to improve the quality of our products and make them more reliable and durable. The production involves modern assembly and metalworking machines, powder coating equipment, cutting equipment and much more. Most operations are automated, but some are performed manually.

Danko boilers are presented in two categories:

- Floor-standing models – a wide range of equipment with power from 8 to 96 kW;

- Parapet (wall-mounted) models - wall-mounted models with closed combustion chambers with a power of 7 to 15 kW.

The manufacturer also produces additional equipment - these are thermostats, programmers, kits for converting Danko boilers to liquefied gas and water converters.

The lineup

The line is represented by five series:

- Wall-mounted. Two modifications - 23 ZKE and 23 VKE. Double-circuit modifications. Each circuit has its own heat exchanger. For heating - copper, for hot water supply - steel.

- Parapet. 8 modifications - 7, 10, 12.5 and 15.5 kW. They are compact. Single-circuit. No smoke. Can be installed in apartments with an area of 140 square meters. Heat exchanger – steel.

- Steel. 22 models differ in power, number of circuits and location of chimneys.

- Cast iron. All have an open chamber. Cast iron radiators last approximately 25 years.

- With pump. 4 modifications. They work to heat the room and heat hot water. Steel heat exchangers. Related security systems.

Boiler design using the example of Danko 10/12

The model has a built-in water heater - it can be used to heat a private home and heat hot water. Appearance: rectangular cabinet. The facade is equipped with a door that closes and provides access to the elements responsible for ignition. Comprises:

- burners;

- heat exchanger;

- gas automation;

- decorative casing.

The automatic unit is responsible for supplying fuel to the burners - main and ignition, and for regulating the water temperature. Gas flow stops immediately if:

- the flame went out;

- the gas pressure has dropped below the permissible value;

- there is no draft in the chimney;

- The coolant temperature reached 90 °C.

Double-circuit modifications consist of structural elements:

- chimney duct;

- blower fan;

- gas burner;

- heat exchangers – primary and secondary;

- hydraulic unit;

- connecting fittings;

- pump for forced water circulation;

- expansion tank;

- an automation unit that controls the units of the device.

A distinctive feature is that all components are produced by European companies. This is a plus in favor of the reliability and cost-effectiveness of Danko brand products.

Additional systems

In the design of gas heaters, the manufacturer has additionally provided:

- water temperature sensors - triggered when boiling, turning off the system;

- a protective block that shuts off the gas supply when the wick goes out;

- a block that stops equipment operation in the absence of traction;

- draft control unit - to adjust the flame;

- multifaceted protection unit – turns off the device in case of any type of threat;

- intelligent block - for distributing liquid flows.

Installation

It is necessary to take into account the rules for installing gas equipment:

- The power is selected according to the heating.

- There must be at least 25 cm between the housing installed on a fire-resistant horizontal platform and a non-combustible wall.

- The device can be installed near fire-resistant walls if they are sheathed with steel sheets.

- The width of the passage in front of the facade is from 1 m.

- To improve water circulation, the installation should be lower than the level of heating devices.

- The expansion tank is located at the very top of the system.

- The minimum length of the chimney is 5 m.

- If the chimney is located outside, it must be insulated.

- The diameter of the smoke outlet must exceed the diameter of the smoke outlet pipe.

- At the junction of the boiler and the chimney, it is necessary to seal it with a solution of cement or clay.

Boiler installation

Installation of Danko gas boilers and connection to the gas main is quite easy. For comfortable operation, the housing includes left and right connections. When installing, it is very important to follow the following expert advice:

- The gas supply is regulated manually using automation. To increase the power of the unit, set the required mode using a rotating wheel.

- The Danko wall-mounted gas boiler is mounted using anchor bolts. During operation, the maximum weight of the device is 80-100 kg. It turns out that the fasteners must be very reliable to withstand such a load. With proper installation of the boiler, possible excessive fuel consumption and other problems can be eliminated.

- To minimize gas consumption, an external temperature sensor can be used. The operation of the device is to determine the ambient temperature, as well as auto-adjust the specified mode of the boiler equipment. The temperature sensor works in this way: it records the ambient temperature and transmits information to the controller. Automation detects changes and introduces them into the specified temperature regime. As a result, gas consumption becomes lower.

- Chimney – can be connected to a classic and coaxial smoke exhaust system.

Fire safety requirements for the installation of parapet devices are not as high as for atmospheric models. Therefore, in apartments it is recommended to install models with a closed combustion chamber.

The article described all the distinctive features of the brand’s heating devices, the installation of boilers, and examined their possible operating problems: why a Danko gas boiler goes out, goes out and takes up a lot of fuel. Take note of the recommendations of experts, reviews of owners, and the heating unit will serve you for a long time.

Operation and Maintenance

Commissioning is possible after acceptance by representatives of the gas service. An installation diagram is attached to the instructions. Installation is quite simple, but it is better to trust it to specialists. Gas workers who take the device into operation provide appropriate instructions. The modification is selected according to the project completed by the gas service, which necessarily notes the power of the device and its type. Safety regulations:

- Maintenance of the device can be performed by those who have attended the instructions.

- In the event of a breakdown, immediately turn off the taps.

- If you smell gas, turn off the valve, open the windows and call the gas workers.

- Keep the device clean and in good working order.

- Clean the chimney as often as indicated in the instructions.

- Check the fullness of the system weekly to see if there is water in the expansion tank.

- At the end of the service life of the device provided by the manufacturer, invite a specialist for advice on whether it can continue to be used.

How to light a Danko gas boiler

Identification of boiler control elements.

- Turn the mechanical temperature regulator counterclockwise until it stops.

- Make sure that the tap on the gas pipeline inlet is open.

- Press and hold the start button, then press and release the piezo button (several clicks may be required, repeat until the pilot burner lights up). Hold the start button for at least 30 seconds until the burner goes out when it is released. If the boiler has not been adjusted previously, it may be necessary to adjust the air supply by turning the nut on the ignition burner until the burner flame turns blue.

- Turn the thermostat knob clockwise until the main burner turns on, then set the desired power.

The startup process differs slightly for configurations with different automation; the algorithm is described in detail in the operating instructions, an electronic copy of which is attached in the description of each model on the official website.

What problems happen?

The simplicity of Danko's design allows its owners to carry out minor repair work on their own. One of the most common problems is the burner blowing out. This is especially common in strong winds. Usually no fault is found, the wind is the culprit of the problem, but it is better to check the following points:

- Is there a check valve installed in the chimney? If not, then there will be no reverse thrust, which is why attenuation occurs.

- If the chimney is installed incorrectly, it becomes clogged with soot and other combustion products - it needs to be cleaned.

It happens that before the attenuation, extraneous noise is heard or increased fuel consumption is observed - this may indicate a failure of the controller. The task is to repair or replace a spare part.

Important! If you don’t want to deal with flame extinction, choose not a single-circuit, but a double-circuit boiler - wall-mounted or floor-standing. 2-circuit models do not have such disadvantages.

Another common problem is the pilot light going out. It goes out due to the activation of the thermostat, which shuts off the gas supply if the burner does not heat up to the desired temperature.

Owner reviews of Danko gas boilers: advantages and disadvantages

| Advantages | Flaws |

| Affordable, not high cost | Noisy operation, especially in comparison with models from foreign manufacturers |

| Reliability - in practice, it is not uncommon to see cases of operation for more than 8, 12 and even 15 years | Modifications with a horizontal flue suggest the possibility of flame extinction in strong winds |

| High technical characteristics and efficiency | Regular cleaning and maintenance required (at least annually). If there is no cleaning, problems with the automation may occur. |

| Energy independence – equipment operates regardless of the availability of electricity. | According to reviews from owners, double-circuit models, with high water consumption, do not always cope with its heating |

| Economical - in models with a power of up to 20 kW, gas consumption is in the range of 0.8-1.7 cubic meters. m/hour | |

| The range includes models with a cast iron heat exchanger, the service life of which is more than 25 years. In other models it is made of stainless steel | |

| Due to the simplicity of design and automation, they are easy to use |

Model overview

Danko-8 S

A new improved model, in which, unlike previous versions, a vertical chimney is provided. The heat exchanger also has an improved design. The tubular radiator is made of 3 mm thick steel. Thanks to changes in the design, the developers achieved:

- reduction in size;

- acceleration of warming up;

- simplifying the connection of the chimney;

- improved traction;

- increasing efficiency.

Single-circuit. Floor type. Open combustion chamber. Designed to heat a room of 70 square meters. Specifications:

- Thermal power - 8 kW

- Efficiency – 92%

- Weight – 50.5 kg.

Imported security automatics installed. Imported low-flame injection-type burners are also used - they are made of stainless steel. The flame remains stable even if the pressure in the pipes drops to 635 Pa.

18 Sun

Single circuit option. Floor installation. Open camera. 18 kW. Efficiency – 92%. Heats up to 179 sq. m. Weighs 66 kg. Evrosit automation was used.

16 HP

Single-circuit floor-standing device. 16 kW. Open combustion chamber type. No auto-ignition. Consumption – 1.9 m3/h. The modification is quite weighty – 97 kg. Efficiency 90%. Heats water up to 90 °C.

Popular models

Gas steel boiler Danko-12

The Danko 12C floor-standing boiler with a thermal power of 12 kW is in demand on the market. It is made of steel. It is intended for heating only. Has Eurosit gas automatics. In modern conditions of gas supply, this energy-saving unit perfectly meets the requirements of consumers.

Let's look at the technical characteristics of the Danko 12C gas boiler.

| Power | 12 kW |

| Heated area | 110 m² |

| Maximum coolant temperature | 90 °C |

| Recommended coolant temperature | 60-80 °C |

| Nominal gas flow | 1.4 m³/h |

| Connecting pipes to the heating system | 50 mm |

| Connection to the gas supply system | 15 mm |

| Nominal pressure of natural gas | 1274 Pa |

| Overall dimensions of the boiler: HxWxD | 850x297x497 mm |

| Chimney diameter | 110 mm |

| Efficiency | 92% |

| Boiler weight | 57 kg |

Equipment for heating and hot water heating - double-circuit gas boiler Danko 10UVS. The model is distinguished by new wall-mounted boilers with mechanical controls. The power of the device is 10 kW, which can easily heat an area of 100 m². The efficiency is 90%, natural gas consumption is up to 1.2 m³/h. The unit has a minimal number of controls and is housed in a neat rectangular body. The kit includes a chimney. Control is not difficult - just light the igniter and set the required heating level. The boiler comes with detailed startup instructions.

Double-circuit gas boiler Danko-10

Technical characteristics of Danko 10UVS.

| Power | 10 kW |

| Heated area | 100 m² |

| Max. hot water output (at dt=35 °C) | 220 l/hour |

| Gas consumption (max. in continuous mode) | 1.2 m³/h |

| Automatic gas supply | Sit (Eurosit, Italy) |

| Working pressure in the heating system | 0.1 MPa |

| Connection to the hot water supply system | DN 15 mm |

| Nominal pressure of natural gas | 1764 Pa |

| Overall dimensions of the boiler: HxWxD | 690x540x320 mm |

| Chimney diameter | 240 mm (270 mm) |

| Efficiency | 90% |

| Supply and return connections | DN 40 mm (left and right) |

Another popular model is the Danko 15C/CP single-circuit gas boiler with a power of 15 kW. Designed for heating residential and other premises with a total area of up to 140 m². They have a steel structure and a vertical flue. The main welded tubular heat exchanger is made of high quality steel with a thickness of 3 mm. In modern conditions of gas supply, an economical Ukrainian-made boiler perfectly satisfies the needs of users. When installing a circulation pump, more uniform heating of the heating system is achieved, therefore, a comfortable room temperature is ensured with less gas consumption.

Single-circuit gas boiler Danko-15 S/SR

Technical characteristics of Danko 15C/CP.

| Power | 15 kW |

| Automatic gas supply | Sit (Eurosit, Italy) |

| Heated area | up to 140 m² |

| Nominal gas flow | 1.7 m³/h |

| Efficiency | 92% |

| Temperature control range | 60 - 90 °C |

| Heating circuit operating pressure | 0.2 - 1.9 bar |

| Chimney diameter | 125 mm |

| Gas supply system pipe diameter | 1/2″ |

| Diameters of heating system pipes | 1 1/4″ |

| Overall dimensions of the boiler: HxWxD | 850x405x540 mm |

| Weight | 71 kg |