Stainless steel corrugated pipes for heating began to be used relatively recently, although they have already gained well-deserved popularity in plumbing. Unique technical characteristics give it numerous advantages over products made from other materials. In this article we will familiarize ourselves with them in detail, and also consider the main features of installation work.

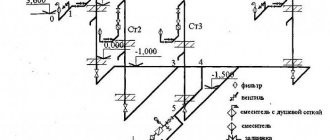

Photo of a heating system made of stainless corrugation

Installation methods

When laying water supply or communications for other purposes using stainless steel pipes, several types of connections are possible, namely:

- welded;

- use of flange type connecting elements;

- crimping.

To connect using water supply and heating networks, you will need not only special equipment, but also a qualified specialist. Such a process is usually carried out, and the welding itself is performed in an inert gas environment. The most modern method that allows high-quality joining of stainless pipes is plasma welding, which also requires the use of special and expensive equipment.

Press fittings provide high-quality connections and quick installation, but are expensive and require special tools

In domestic conditions, it is not always possible to use welding, since for this you need not only to have special equipment at your disposal, but also to attract a qualified specialist to operate it. In this regard, in such cases, threadless flange or threaded fitting connections are used.

Flanges are essentially two ring-shaped elements connected to each other using studs or bolts. To achieve tightness when using flanges, use a special sealing element made of rubber or other soft polymer material. Parts such as flanges, which are quite large in size, are used mainly when pipeline elements need to be periodically dismantled and maintained, spending a minimum of time. The disadvantages of connections of this type are that they react rather poorly to temperature changes and pressure surges in the pipeline.

The service life of fittings for corrugated pipes is practically unlimited; you only need to change the seals, which can last up to 30 years

A more reliable option are fittings, the design of which includes a silicone gasket that ensures tightness. You can dismantle such connections several times without worrying about their reliability.

Specifications

Seamless stainless steel pipes are distinguished by their strength and resistance to rust. The absence of welds guarantees protection of products from heat-affected corrosion.

In comparison with electric-welded analogues, a number of advantages can be identified:

- The pipe does not have a weld, which is the most vulnerable area of the product.

- Has the same strength throughout.

In addition, such pipes are effectively operated at high media pressures and are able to withstand destructive external influences. This makes it possible to use them in conditions of high humidity, high and low ambient temperatures. The threshold temperature for a simple carrier is 800°C, for aggressive chemicals - 350°C.

Other important characteristics include:

- The tensile strength of the material is no less than 529 N/sq.mm.

- The relative elongation indicator is at least 40%.

- The sulfur content in steel is not less than 0.02%.

The permissible curvature of products is also strictly regulated and should not exceed the following values:

- Pipes with a wall thickness of more than 0.5 mm - 1 mm per 1 m of length.

- Products with a wall thickness of less than 0.5 mm and a cross-section of more than 15 mm - 2 mm per 1 m of length.

When purchasing, you should give preference to large hardware stores and products from popular brands. Perhaps the final cost will be slightly higher, but the buyer is guaranteed to receive a quality product with the required characteristics.

Features of connecting seamless stainless pipes

The main competitive advantage of such products is the absence of welds, which are the most vulnerable point of any welded pipe. For this reason, increased quality and reliability requirements are placed on the connection procedure.

Pipes are joined only by welding, and the process can be carried out manually, semi-automatically or automatically. One of the following technologies is used:

- TIG. Welding is performed in an inert gas environment, which protects the treated area from oxidation. The heat source is an electric arc formed between the tungsten electrode and the welding point. If the technology is followed, the seam will be smooth, uniform and not inferior in strength characteristics to the material of the pipe itself.

- HF. A less expensive technology, which, however, does not provide similar strength indicators. Welding is performed using high-frequency current.

- Laser Laser welding is not inferior to TIG technology in terms of seam strength, while making it possible to reduce the melting zone and make the seam less noticeable.

Thus, seamless stainless steel pipes can be safely called one of the most practical, strong, durable and environmentally friendly pipe materials, allowing you to implement any project: from the installation of industrial pipelines to the manufacture of elegant furniture. The only disadvantage of such pipes is the justifiably high cost.

Production technology

High-precision technology is used to create stainless steel corrugations. The pipes are made of alloy steel; the high content of nickel and chromium provides the coating with anti-corrosion qualities.

The technology includes several stages:

- installation on equipment of the required sizes and configurations;

- cutting elements and connecting them;

- creating a corrugated surface;

- package.

The structure is created from steel sheets, pipes of a given configuration are formed using special devices. The edges of the elements are joined by welding. The quality of connections is checked with a laser device.

Choosing a stainless steel chimney

The stainless steel chimney design includes cylindrical sections 1.0 and 0.5 meters long, as well as numerous additional elements:

- turns at an angle of 90, 120, 135 and 150 degrees;

- adapters for connecting pipes of a different size;

- adapters for connecting sandwich and single-wall pipes;

- tees for connecting junctions;

- gates or internal dampers for adjusting draft;

- clamps for strengthening the joints of pipe sections during installation;

- brackets for attaching the external chimney to the wall of the building;

- transition glasses for crossing ceilings and roof structures with a chimney.

In the delivery set, sellers offer various fasteners for mounting and installing the chimney.

In addition to the above, you must definitely purchase a pipe head or deflector. For solid fuel units, in some cases it is necessary to use a head with a spark arrester.

If the chimney is intended to remove wood combustion products, it can be equipped with a protective cap with a mesh spark arrester

The listed components for the chimney allow you to assemble a channel of any configuration. The following requirements must be taken into account:

The total length of the chimney must be more than 5 meters. Only if this condition is met can you count on normal traction. If it is necessary to install a horizontal transition on the chimney, its length should not exceed one meter. The use of more than two turns at gentle angles in the design is undesirable. This can negatively impact your cravings. When crossing interfloor ceilings and the roof, a fire-proof crossing is required. The design of the roof penetration depends on the angle of inclination of the slope

Here it is important to ensure not only fire safety, but also tightness.

The chimney inside the boiler room is made of single pipes without insulation; all its parts located in the cold room and the external component need thermal insulation, for example, using a sandwich pipe.

When purchasing materials, pipes and components must be checked with a magnet. Suitable quality stainless steel is not magnetic. It belongs to the austenitic class, resistant to heat and aggressive environments. A similar material of the ferritic or semi-ferritic class is susceptible to corrosion, although it belongs to the stainless steel family.

The internal size of the chimney pipe is always indicated in the technical documentation for the heating unit. If a homemade boiler or stove is installed, then the cross-section of the chimney is selected in a ratio of approximately 1:10 to the size of the combustion chamber. In private homes, pipes measuring 140–150 millimeters are usually used.

The data provided will be useful in selecting the material and completeness of the device.

Stainless steel corrugation for heating system

Technological progress does not stand still. He did not bypass the construction industry in terms of equipment for heating systems. Twenty years ago, specialists mastered the technology of installing plastic and bimetallic pipes.

And now corrugated stainless steel analogues for heating systems appear. True, this is considered a novelty only for the post-Soviet market, but they were invented at the end of the last century. Let's study in more detail the development of Japanese engineers.

Technical Specifications of Corrugated Stainless Steel Pipe

Standard stainless steel products for heating systems are produced with diameters of 15, 20, 25, 32 mm. All other sizes are possible, but only by individual agreement with the manufacturer. Let's take a closer look at the characteristics of corrugated pipes with parameters of 15 and 20 mm:

- Stainless steel product with an indicator of 15 mm:

- outer diameter – 18.1 mm;

- internal effective diameter – 14.1 mm;

- wall thickness – 2.5 mm;

- minimum permitted bending radius – from 35 mm;

- operating coolant temperature at a pressure of 10 bar – from 0 to 100 °C;

- pipe length in a coil is 50 meters;

- coil weight – 7.8 kg.

- Stainless steel product with an indicator of 20 mm:

- outer surface diameter – 25.6 mm;

- internal diameter – 21.0 mm;

- wall thickness – 2.5 mm;

- minimum bending radius – from 50 mm;

- operating temperature of the carrier at a pressure of 10 bar – from 0 to 100 degrees Celsius;

- the length of the corrugation in the bay is 30 meters;

- coil weight – 6.0 kg.

The products can withstand short-term temperature surges up to 150 °C and pressure up to 210 atmospheres, although such indicators can cause destruction.

The thermal conductivity of such pipes is higher than even copper ones, and due to the corrugation, the percentage of heat transfer increases by more than 30 units.

What product shortcomings should we not forget?

- The downside is the high price - this is a controversial issue, since the material itself is not cheap, plus a unique manufacturing technology.

The low price of such a thing should alert you, most likely it is a fake. When making a purchase, check the integrity of the packaging - there are markings on it, there are no inscriptions on the pipe. - Another feature manifests itself during operation and saddens housewives: dust accumulates in the depressions of the pipe, which is difficult to wash out.

- The products are afraid of external mechanical damage; special screens will provide protection.

- The disadvantages of the connections include the fact that the fittings require regular maintenance.

- If part of the heating system is located in an open room, additional insulation is required to avoid heat loss.

- Twisting is not allowed.

- There is a possibility of corrosion caused by electrochemical processes (grounding saves).

Advantages of using stainless steel corrugation in heating systems

Corrugated stainless steel pipes have features that set them apart from other types of heating pipes:

- They bend in all directions (a large bending radius even helps to build a radiator or heated towel rail from corrugated material). This property of the product allows it to be used in rooms of different configurations, eliminating the need to purchase rotating corners as in products made of plastic and metal.

- They are not afraid of negative temperatures (if your heating system is frozen, the integrity of the pipe will not be compromised, and you can thaw it using any available methods).

- They have high strength (withstand pressure over 200 atmospheres).

- Do not react to atmospheric influences (do not rust).

- They have good heat dissipation.

- Suitable for laying heated floors and laying in the wall.

- Withstands temperatures up to 150 degrees.

- Not exposed to fungus.

- They have a low roughness coefficient, which maintains high throughput without the use of additional equipment.

- They are not afraid of rodents.

- Easy to install, require a minimum of connecting elements, cut with a pipe cutter.

- Convenient to transport.

- Can be dismantled without difficulty.

Subject to operating rules, manufacturers set a minimum service life of 20 years.

Price

Prices depend on the country where they are produced, the company, the diameter, whether the products are annealed or not, as well as the presence of a polypropylene coating.

When using a small piece of pipe for connecting to a heating boiler or connecting radiators, you should opt for the budget option, and if you are a wholesale buyer and require at least a whole coil, then do not be lazy to look at the price lists of different companies. Sometimes you can get discounts.

Let's compare the prices of two well-known brands in this industry (per meter):

- Flexor Group of Companies (official distributor of Hydrosta). The minimum prices in rubles for annealed, unannealed and polypropylene-coated pipes are listed, respectively.

- HF20 – from 185.80, from 153.14 (with discount), from 240.96;

- HF25 – from 243.14, from 270.72, from 308.46;

- HF32 – from 464.50, from 524.01.

- “Lavita” (only annealed corrugation is presented), cost in rubles:

- HF20 – from 222;

- HF25 – from 277.50;

- HF30 – from 516.15.

The prices given are not a public offer and may vary.

The pipe and its components must be from the same company.

How to make a corrugated pipe from stainless steel

High quality steel strip is sent to the forming line. There, on bending machines, it is given the outline of a cylinder. When rolling, special clamps are used, and the cylindrical blank becomes a corrugated pipe.

The product blank is placed in a chamber, filled with a special gas mixture, in the environment of which welding takes place. The entire process is automated, which allows you to achieve a high-quality weld and eliminate the human factor.

To achieve plasticity, the products are additionally annealed: heated to 1000 degrees, then cooled to 200 °C.

The pipe is cut into pieces ranging from 20 to 50 meters in length, which are rolled into a coil, packaged and labeled.

Manufacturer's choice

Corrugated stainless steel pipes were invented at the end of the twentieth century in Japan, but manufacturers in the post-Soviet space mastered the technology recently – a few years ago. Products are produced both at the parent enterprises and in companies that are their official divisions. The quality of the products does not suffer, since production is carried out on imported equipment in compliance with all standards.

Manufacturers

KOFULSO is a company from South Korea that produces corrugated stainless steel pipes with a special polyethylene coating in different colors.

NEPTUN is a Russian company that produces high-quality products at affordable prices.

INOFLEX , a German branch of MEIBES, offers finished products in coils up to 80 meters. They are also used in solar-powered installations.

LAVITA is another company from South Korea. Corrugated stainless steel pipes are produced in annealed and unannealed form.

What to look for when purchasing

When purchasing a corrugated stainless steel pipe, you need to look at the packaging of the coil - its integrity should not be compromised. The products are expensive, and unscrupulous sellers are tempted to offer counterfeits. This may affect operational safety.

The integrity of the packaging is also important because there are no markings on the corrugated pipe itself, so keeping the packaging will help you not make a mistake in choosing the desired diameter of the corrugated pipe.

You should carefully examine the product itself and hold it in your hands. High-quality corrugation bends easily, and what is important is that it does not spring back, trying to return to its previous state. A good pipe has an even butt seam and uniform distances between the corrugation rings. There should be no dents, chips or scratches on it. If you find defects, look for the product in another store.

When purchasing a corrugated pipe for connecting to plumbing fixtures or a heating boiler, you can estimate the size by eye. To use the product in heating systems, accurate calculations are required. Having decided on the size, add another meter - one and a half for “seam allowances”.

To avoid troubles when operating the heating system, you need to approach the selection of components for the corrugated pipe no less responsibly. Experts recommend using “original” fittings manufactured by the same company that produces the corrugated pipe. You should also check all parts for defects.

Conclusion

An engineering development combining the strength of steel and the flexibility of corrugation has resulted in a qualitatively new product for heating systems. Whether to choose a stainless steel corrugated pipe is up to you.

There are undoubtedly more positive qualities that this product has than disadvantages. The ease of installation, the ability to install in hard-to-reach places and the absence of fear of destruction due to freezing of the heating system incline towards the purchase of this product.

Expensiveness, difficult cleaning and unique appearance may hinder the purchase.

If preference is given to a corrugated pipe, with the correct selection of components and proper installation of the heating system, you will receive a reliable product that will last for many years.

Source: https://VseProTruby.ru/otoplenie/gofra-nerzhavejka.html

Our advantages

Our company has chosen the installation of stainless pipelines as its main activity. The highest demands are placed on such work, and we fully meet them. We have everything necessary to carry out high-quality installation, namely:

- a permanent staff of qualified specialists who hone their professional skills by installing stainless steel pipelines at numerous sites both in the CIS and abroad;

- modern high-tech equipment designed for the installation of process pipelines made of stainless steel, which meets the high requirements of the market;

- the desire to become the best among competitors;

- confidence that our many clients, having appreciated the installation of stainless steel pipelines produced by our company, will turn to us again and again, and will also recommend us to their partners.

Customers often face a dilemma: to install a stainless pipeline using a company that has extensive successful experience in such work, or to entrust the work to a little-known company that is also ready to perform this work at a slightly lower price. At the same time, Customers should not forget that by entrusting the installation of a stainless steel pipeline to unqualified performers, they risk encountering serious problems during the commissioning of the equipment and during the production of the final product. Therefore, we recommend entrusting such responsible work to companies whose specialists have real experience in installing process pipelines.

Another confirmation of the company’s high professionalism is the number of its staff. Our company, unlike some of our competitors, has its own large and permanent staff. This confirms our focus on the high professional training of our specialists, who are always ready to install stainless pipelines for you with high quality and in the shortest possible time, regardless of the amount of work, the remoteness of the site and the complexity of the tasks.

Our goal and main priority is the Customer’s satisfaction with the result of cooperation with PUE “RViMA”. Installation of stainless pipelines, carried out at a high professional level, is the key to positive feedback about our work and contributes to the dynamic development of our company.

Manufacturers and what to look for when purchasing

There are currently the most Korean companies in our market:

- KOFULSO (“Kofulso”) - according to experts, the best quality, since it was the first to appear on the market and has quite a lot of production experience. It has twice the thickness of the seal rings in the fittings, and the weight of the fittings and coils of pipes of the same name is greater. So the increased cost (compared to Hydrosta and Lavita) is justified.

- Lavita (“Lavita”) - performs quite well, but there may be problems in the fittings - sometimes when tightening, the metal ring cuts through the wall (may be due to an installation error - tightening the clamping ring), which causes leaks (per 100 fittings 1-2) - costs less than Cofulso.

- Hydrosta (“Hydrosta” or “Hidrosta”) is in the same price category as Lavita, but there are complaints about leaking fittings: for every 100 installed, 5-7 pieces leak.

- Neptune (“Neptune”) – characteristics and reviews could not be found;

- Meibes (Meibas) - there are no complaints about the quality, but there are some for the price - very expensive with approximately equal parameters to those given above in the list.

The reliability data was taken from the installer’s post on the forum, this is the result of several years of use: first we worked with Cofulso, then switched to the cheaper Lavita and Hirostat, after replacing fittings and, accordingly, customer complaints, we weighed, looked, and returned to KOFULSO.