A chimney is an integral part of a single system, including a heat generating unit, air ducts and gas ducts. The chimney ensures the dispersion of harmful emissions contained in flue gases into the atmosphere. An aerodynamic calculation of the boiler room chimney parameters must be carried out in order for the system to effectively perform its functions and not pose a threat to human health.

The choice of pipe for the boiler room and its installation are made only in accordance with the results of preliminary calculations, for which special formulas or computer programs are used

How to calculate the parameters of a boiler room chimney using computer programs

Carrying out an aerodynamic calculation of a chimney for an industrial boiler house is a very complex and troublesome process. Currently, such calculations are made using various computer programs that take into account many operating conditions of the equipment. The calculations are aimed at ensuring that, at maximum load of the boiler room, the emission of combustion residues of processed fuel freely leaves through the pipe for subsequent disposal in the atmosphere. Using computer calculations, it is possible to reliably determine the minimum throughput of chimneys. Errors when carrying out such calculations are extremely undesirable, as they can result in a dangerous accumulation of gases.

Calculation of a chimney using a computer program involves introducing into the system the declared indicators related to:

- to boiler power;

- the gas formation temperature at the outlet indicated in the passport. If these data are not available, it is customary to use a value of 200º C;

- temperature outside. To turn on the heating it will reach +8º C, hot water supply - +20º C;

- Efficiency of boilers of this type. In the absence of this data contained in the equipment passport, the calculation is carried out with a value equal to 0.92;

- coefficient of excess air mass for the wick. If the data is not provided, then use the indicator 1.4;

- type of fuel;

- the length of chimneys coming from boiler equipment;

- the material used to make the chimney;

- room temperature;

- chimney shape;

- chimney dimensions, etc.

The type of pipe and its dimensions depend on the type of heating boiler and its power

After entering all the data, the computer program performs a calculation of natural draft (gravity). If it turns out that large losses occur, then it is necessary to make changes to the design related to its shape, diameter, and height.

Chimney device

All chimneys, regardless of the material used, location and design, have a similar structure.

They always contain the following components:

- Chimney is a vertical or partially inclined channel (pipeline) of rectangular, square or round cross-section for the removal of combustion products. Made from durable fire-resistant material.

- Condensate collector - located in the lower part of the chimney after the boiler flue is inserted and serves to collect condensed vapors contained in the flue gases. Equipped with a dump valve. Absent in mounted chimneys, made double-walled with a heat-insulating layer.

- The draft control device is a rotary or retractable damper.

Calculation of chimney parameters

Correctly selected height and cross-sectional area of the chimney is the key to its reliable operation. Almost all industrial boilers have recommendations regarding these values.

For equipment with thermal power up to 90 kW, the following values are recommended:

| Boiler performance, kW | Chimney diameter, cm | Pipe cross-sectional area, cm2 | Pipe height, m |

| 20 | 13 | 196 | 7 |

| 30 | 15 | 196 | 8 |

| 45 | 18 | 378 | 9 |

| 65 | 20 | 540 | 10 |

| 90 | 25 | 729 | 12 |

Indicators for practical aerodynamic calculation of a chimney

Chimneys of boiler houses and private houses with solid fuel boilers (fireplaces) require careful calculations taking into account a number of indicators:

- climatic features of the area;

- the terrain and type of soil on which the building is being built;

- regional seismic activity;

- wind speeds and precipitation rates, as well as critical values;

- type of furnace masonry;

- dynamic vibrations of equipment;

- the material from which the chimney will be built and its thermal expansion;

- type of fuel, its heat transfer;

- technical characteristics specific to the boiler;

- outlet gas temperatures.

Using such data, you can calculate:

- height of the structure;

- optimal diameter;

- the permissible weight that the chimney being built may have and, therefore, select a material suitable for arranging the structure.

The calculation results will allow you to determine the diameter of the future chimney, its height and weight

Correctly calculated height and permeability, selection of shape and materials will contribute to natural traction, ensuring good heat transfer. Correct calculation is facilitated by the involvement of professional specialists. Negligence will result in design errors resulting in:

- internal surfaces will be subject to excessive settling of soot and ash;

- the internal cross-section will gradually decrease, which will lead to a weakening of draft and the penetration of carbon monoxide formations into the interior;

- the possibility of ignition of accumulated resins and pipe deformation caused by temperature changes will increase;

- fire hazard will increase.

Chimney for a boiler room: design and types (types)

Calculating the height of the chimney of a boiler room and its other parameters is impossible without taking into account the features of its design, compiled by:

- foundation and support;

- gas outlet;

- thermal insulation;

- anti-corrosion protection;

- a device that introduces gas ducts.

Brick, ceramic, galvanized or stainless steel pipes are used to install the chimney

The flue gas, having cooled in a cleaning device - a scrubber, to 60º C, is cleaned in absorbers and released into the atmosphere.

For the construction of chimneys the following can be used:

- brick. A brick structure installed by a professional stove builder practically does not accumulate soot. It has sufficient fire safety, mechanical strength and heat capacity. Due to the destruction of brick by reactions that occur when sulfur oxides deposited on the walls come into contact with water, the use of brick structures has sharply decreased;

- steel. Allows you to simulate the pipe configuration. It will last about ten years, provided that fuel with a low sulfur content is used;

- ceramics. Resistant to condensation and fire retardant. But a structure weighed down with metal rods is characterized by excessive massiveness, which makes installation difficult ;

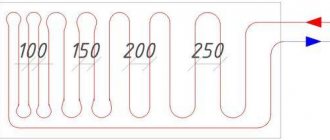

- polymers. Used for installation on geysers and in a boiler room with a temperature of no more than 250º C.

Depending on the characteristics of the supporting structure, chimneys can be:

- self-supporting, made of sandwich pipes. They are easily mounted on roofs with fastening inside the building and, if necessary, transported, but have significant limitations in use - in terms of temperature (350º C), snow and wind load, level of chemical aggressiveness of combustion products;

- columned. It is possible to install a multi-barrel steel structure with a diameter of up to three meters when connected to several boilers;

- (near) façade. The design is considered the most economical, since it does not require a powerful foundation or the use of load-bearing elements, and the use of modules ensures ease of replacement;

- farm They are usually used in areas with increased seismic activity;

- mast The use of steel guys gives additional stability to the support tower of three to four masts with attached chimneys.

Tall pipes are subject to wind loads, so you need to take care of additional fastening

Chimney materials for boilers

The choice of material for a chimney is not only a technical, but also an aesthetic issue: it is desirable that these elements not only do not discord, but even emphasize the overall style. And yet, the main task solved by a chimney is the stable extraction of combustion products. Reliable, non-smoking, fireproof, without condensate leaks. To do this, you need to choose the right section and material of the pipes, which can be made from:

- of stainless steel;

- sandwich pipes;

- ceramics.

Stainless steel is preferable to other materials and is suitable for smoke removal from boilers with a closed combustion chamber. Sandwich pipes are a convenient solution that does not require additional thermal insulation work and are a successful element of modern design. Ceramic chimneys – high accumulation and resistance to caustic condensate. Chimney ceramics can become separate design objects in a classic interior.

Each material has its own advantages, weaknesses, and its own price category. You can ask our managers questions about the appropriateness of choosing the material or design of the chimney for the boiler, or the completeness of its components.

How to calculate the height of a chimney

The correct calculation of the height of the chimney affects the performance of the heating unit, resulting in the achievement of the required amount of natural draft. According to the standards set by SNiP, the height cannot be less than five meters. Neglect of this instruction leads to a drop in the level of natural draft and ineffective operation of the heating system. By installing a pipe that is too high, we will also reduce natural draft, because smoke passing through an excessively elongated channel will cool and move at a decreasing speed. Incorrect calculations lead to air turbulence and problems associated with the wind support zone. Strong gusts of wind can even extinguish the fire in the firebox.

Calculations made during the construction of industrial construction projects are very complex and involve the introduction of a large number of different indicators. When determining the height of the chimney for a private construction project, it is advisable to follow the following recommendations:

- the length should be at least five meters on the segment connecting the base and the highest point. With such a length, sufficient fire safety is ensured;

- a chimney installed on a flat roof must rise above its surface by at least half a meter;

- when erecting a chimney on a pitched roof, a pipe located at a distance of less than one and a half meters from the ridge is installed half a meter above it. In this case, it is mandatory to additionally strengthen the structure with guy wires to increase stability, otherwise it may be damaged by strong gusts of wind. At a distance of up to three meters from the ridge, the pipe is installed at the same height as it. If the distance exceeds three meters, then the angle between the horizontal line of the roof ridge and the virtual line drawn between the ridge and the upper edge of the chimney should be 10º;

- the distance between the pipe and tall trees and buildings should be more than two meters;

- if the roofing material is flammable, then the height of the chimney should be additionally increased by half a meter;

- on a multi-level roof with height differences, when carrying out calculations, they are based on the height of the ridge;

- when the boiler room is located in a house extension, the head of the pipe must rise above the wind pressure zone, located in the space defined by a line drawn at an angle of 45º from the top point of the house to the surface of the ground.

If the roofing material does not have fire-resistant properties, the length of the outer part of the chimney must be increased

The documentation supplied with the heating equipment contains the values of parameters that influence the selection of the chimney height.

Carrying out calculations involves using the formula:

Hmin = √A*Mi*F/(Спдкі*Сфі*√V*T)

This formula provides for the use of the following parameters: A – coefficient characterizing the regional meteorological situation; Мi – masses of gas formations passing through the chimney per unit time; F – settling rates of particles formed during combustion; Spdki and Cfi - indicators reflecting the level of concentration of substances that flue gas contains; V – gas volume; T – difference in air temperature values when entering the pipe and leaving it.

Requirements for chimneys

The chimney removes and disperses harmful combustion products into the atmosphere

It is important to design and build it correctly. Otherwise, the internal walls will become clogged with soot, ash, soot, blocking the outlet channel and preventing the removal of smoky masses, making it impossible for the boiler room to operate

There are technical standards that clearly regulate the parameters of chimneys:

- Brick structures must be made in the shape of a cone with a height of 30 to 70 m, a diameter of 60 cm. The minimum wall thickness is 180 mm. The lower part must be equipped with gas ducts with audit points for inspection.

- Metal pipes used for the installation of chimneys are made from sheet steel 3-15 mm. The connection of individual elements is carried out by welding. The height of the chimney should not exceed 40 m. The diameter can be from 40 cm to 1 m.

- To ensure the stability of metal structures, brackets or anchors are installed at a distance of 2/3 from the height of the pipe, to which guy wires are attached.

- The height of the chimney (regardless of the material of manufacture) must be 5 m higher than the roof of buildings located within a radius of 25 m.

The dimensions of the structure are calculated taking into account the volume of the furnace and climatic conditions, so that draft is ensured at any air temperature.