Autonomous heating of a house using a radiator system or underfloor heating requires the installation of a boiler unit and equipment connected to it. Usually, a special room is allocated for this purpose inside the building, an additional extension or a separate structure is erected. For safety reasons, a boiler room in a private house must comply with the current requirements of SNiP; in addition, this ensures ease of operation of heating equipment. If a gas boiler is chosen as a heat source, then the design of a boiler room for a private house requires approval.

What are the requirements for installing a boiler room?

Primary requirements

The boiler unit (depending on the size and type) can be installed in a separate room on the ground floor, in the basement of the house or in the attic (but this must be provided for by the layout of the house, determined at the design stage).

It is also possible to use an autonomous module (container with a mini-boiler room), erect a special extension or a separate building. As a separate structure, a ready-made mobile boiler room can be used, mounted from sandwich panels and finished with non-combustible materials.

The heating unit can be solid fuel, liquid fuel or gas. Depending on the type of heating unit, the requirements for a boiler room in a private house have some differences.

The design standards for a boiler room in a private house provide

:

- compliance with requirements regarding room size;

- installation of no more than two boiler units in one room;

- absence of flammable materials in the finishing of surfaces and roofing;

- the presence of doors to the street and to the house (for an extension);

- competent selection and installation of doors: they must be included in the fire category and open outward, like the door of an adjacent room in the house;

- unobstructed access to all heating equipment;

- installing a window with a window for natural light and emergency ventilation, the window sashes should swing outward, and the glass area should correspond to the volume of the room (0.03 m2 per 1 cubic meter);

- the presence of natural or forced ventilation, which is calculated as follows: (room width x ceiling height x room length) x 3. As a result, we get the volume of air that needs to be replaced in one hour;

- the presence of a chimney, if required by the type of boiler (for units with a power of less than 30 kW, the chimney pipe is allowed to exit through the wall);

- connecting the water supply (for filling and recharging the heating circuit) and sewerage (for draining water from the system);

- installation of a separate foundation for boilers weighing more than 200 kg (installation of lighter models on a reinforced concrete floor is allowed).

For wooden walls of built-in and attached boiler rooms (which are common with the rest of the house) a non-combustible finish is needed that can increase the fire resistance limit of structures to 0.75 hours. To build an extension, it is recommended to use bricks, blocks and other non-combustible materials.

Boiler room plan in a private house

Basic standards regarding room dimensions

:

- ceiling height: should be from 2.5 m with a heating unit power over 30 kW, for less powerful boilers the figure is at least 2.2 m;

- boiler room volume: from 15 m3 (if the heating unit is planned to be installed in the basement, then when calculating the volume of the room you need to add 0.2 m2 for each kW of boiler power);

- The boiler room area must be at least 6 m2.

The minimum area makes it possible to ensure the safe operation of the equipment, but for ease of installation and maintenance of the heating system, it is still recommended to equip more spacious boiler rooms.

In the boiler room of a private house, the layout of which is developed taking into account the characteristics of the selected unit, it is necessary to provide free access to the boiler piping elements, control valves, and electrical equipment.

Rules for boiler houses with power up to 350 kW.

The height from floor to ceiling must be at least 2.5 meters, otherwise it will be kirdyk. The volume of the boiler room must be at least 15 cubic meters. To calculate the cubic meters of the boiler room, it is necessary to calculate the dimensions of the boiler room in meters. That is, if it is an area of 2x3 meters = 6 square meters and multiplied by a height of 2.5 meters. 2x3x2.5=15m3. Try to do a little more by 1 cubic meter, so that there is no reduction in these meters in the future due to the laid plaster.

Built-in boiler rooms can be located at a distance of at least 12 meters from the front door of the house. A built-in boiler room is an extension to the house of additional space for boiler equipment. The distance is necessary so that in case of an accident or fire it is possible to leave the house.

The boiler room must be separated by fire-resistant walls. (Non-combustible walls: Brick, cinder block and similar walls). This means that in cases of fire in the boiler room, the fire will not spread to the living room. Even if the fire passes, the time at which the boiler room can burn without harm to the person in the living space is indicated. This time is at least 0.75 hours. If the boiler room is located inside the building, then the boiler room must be planned where it will be located further from the front entrance, preferably at the opposite end from the front entrance. In the boiler room it is necessary to make an exit door. Each boiler room equipment is subject to a passport or operating and installation instructions, which must clearly state how much to retreat from the walls, ceilings and floors for its subsequent repair maintenance and its convenient operation. Window opening 0.03 m2 per 1 m3 of boiler room. This means, if your boiler room volume is 18 m3, then the window opening should be no less than 0.54 m2. It is located like this:

That is, it is necessary to accept that the area is not the window, but the glass. Then you definitely can't go wrong. Try to plan with a margin so that there are no nuances with fractions of meters. Example:

The volume of the room is 16 m3 16x0.03 = 0.73 m2 The square root of 0.73 will be equal to: 0.86 m, add 15 cm on each side and then 30 cm in height and width. In total, your window opening will be equal to: 1.16 x 1.16 m. That is, in any case, the window must be at least 1 m2. The window serves to protect against gas explosions. That is, if gas accumulates in a room and it explodes, the first thing that will fly out is the window, thereby not destroying the walls of the room. That is, it will be safe from the destruction of the building. The boiler room in which the gas boiler is located must be equipped with supply and exhaust ventilation. Ventilation of air into the room should be 3 times the volume per hour. That is, if the volume of the room is 18, then three times more air should pass through per hour. This is: 18x3=54m3/hour. You also need to take into account that if your boiler takes air from the room, then add this air for gas combustion to 54m3/hour.

The exhaust pipe should take air from above (top of the ceiling), and the supply pipe should be from below (near the floor). The diameter of the exhaust pipe is indicated in the gas service project (Ask gas services). It must also be at least 130mm in diameter. The area of the supply openings is 0.01 m2 for every 10 kW of gas boiler power. That is, if you have a 30 kW boiler, then the hole should be 0.03 m2. If you calculate it on a calculator using the square root, you get 17x17cm. Ventilation is necessary so that in cases of gas leakage, gas does not accumulate in the room and is safely removed from the room through ventilation. This in turn will prevent a gas explosion in the room. The chimney pipe must have a cross-section no smaller than that of the boiler. It is prohibited to connect two boilers into one chimney pipe, even if the cross-section of the chimney is twice as large. They make two independent chimneys. For floor-standing boilers, a good floor base of at least 50mm is made. This is necessary to avoid emergency situations when a floor-standing boiler falls into the floor and causes a rupture of the chimney and other unpleasant consequences. The distance of boiler equipment from combustible materials must be at least 400 mm. If you have wooden walls, then the boiler should be 400 mm from the wooden walls. Under no circumstances should the boiler be hung on wooden walls. Fire barriers are also possible - metal sheets with asbestos fireproof sheets, which reduce this distance by half. But it is better to additionally consult with gas fire services about screens. There must be a free area of at least 1 m2 in front of the front side of the boiler. This is necessary for boiler maintenance and operation (convenient control). The door in the boiler room must open outward. It must be fire resistant. In cases of explosion, the door will open outward and reduce damage to the walls of the building. Access to gas shut-off devices must be free. For quick emergency gas shut-off. The gas heating unit must be grounded.

Standards for boiler houses of different types

Since 2003, the parameters of boiler rooms in private houses have been regulated by SNiP 42-01-2002. It is this document that needs to be used when the furnace is designed independently.

Correct boiler room design

Note! It is recommended to entrust the development of a gas boiler house project to a specialized organization, since regulatory authorities will not approve the project if there are errors in it.

Requirements

:

- The floor in the boiler room must be concrete or lined with non-combustible tiles.

- If the walls are made of flammable material (in the case of wooden or frame houses), they are plastered or lined with tiles, metal panels, etc.

- A non-flammable heat insulator (usually basalt cardboard) is installed under the cladding of the floor, walls and ceiling.

- For a boiler room located in the basement or ground floor, the requirements are much stricter: the finish must be vapor and gas tight.

Construction of a gas boiler room

SNiP standards allow the installation of a low-power gas boiler (no more than 30 kW) directly in the house: in the kitchen or other room that meets all safety requirements (including requirements regarding dimensions, ventilation and glazing).

Gas boiler room in the house

This option is primarily suitable for units with a closed combustion chamber, which are equipped with a coaxial chimney vented outside through the wall. This makes it possible to install the heater in any convenient place.

In this case, you need to take into account:

- minimum room dimensions: area - 6 m2, volume - 15 m3, ceiling height - 2.5 m;

- minimum window glass area - 0.5 m2;

- door width - from 0.8 m;

- For ventilation, holes must be provided at the bottom of the door or wall structures to ensure free movement of air flow.

If gas boiler units with a capacity of more than 30 kW are installed in private houses, a separate room inside the house must be allocated for such equipment or a boiler room must be installed outside (in an extension or a separate building).

The gas boiler house project must be approved by the supervisory authorities.

The dimensions of the boiler room for a gas boiler in a private house are regulated by SNiP. For a powerful heating unit, it is recommended to build a separate building made of fire-resistant materials.

Gas double-circuit boiler

Requirements for a gas boiler room in a private house include

:

- the foundation of an extension or a separate structure should not be common with the foundation of the house;

- under a floor-mounted boiler unit, it is necessary to mount a foundation separate from the foundation of the boiler room (reinforced concrete pad);

- the podium on which the unit is planned to be installed can rise above the floor level (taking into account the installation of the covering) by 10-15 cm.

Important! The latest version of SNiP has introduced a new rule: if a gas heating unit with a power of more than 60 kW is installed, boiler rooms must be equipped with a gas control system. When the system is triggered, the gas supply automatically stops.

Arranging a room for a solid fuel boiler

Boiler rooms that are designed for equipment operating on solid fuel are subject to less stringent requirements, since the unit in this case is not classified as explosive. Therefore, design and construction work can be done independently.

Heating a country house with a solid fuel boiler

You can install a boiler room in the basement or basement.

When arranging, you need to take into account the following requirements:

- The size of the boiler room depends on the power of the unit and is regulated by the general requirements of SNiP - the minimum area is 8 m2.

- A steel sheet is laid on the floor in front of the solid fuel boiler on top of a non-flammable thermal insulation substrate. The rest of the floor surface must also be non-flammable, so concrete or fire-resistant coating is used.

- Installation of a home boiler room for a solid fuel boiler must include a stationary vertical chimney, the diameter of which must correspond to the size of the boiler outlet pipe. It is necessary to provide an inspection hole in the chimney to monitor and clean the exhaust channel for combustion products.

Important! In order to comply with fire safety rules, a brick chimney is plastered or a metal sandwich pipe is used, the double walls of which contain a heat insulator. These measures help to avoid the risk of fire in building structures when accumulated soot ignites when the temperature of the flue gases reaches 800-1000 degrees.

- Particular attention is paid to the exhaust system, since combustion of solid fuel requires air to enter an open combustion chamber. This can cause carbon monoxide to enter the air in the room. The plan should provide for the arrangement of an exhaust duct. Its cross-section is calculated as follows: 8 cm2 per 1 kW of boiler power for a furnace room on the ground floor and 24 cm2 per 1 kW for a room located in the basement.

- The requirements for the furnace room also include the presence of fire-fighting equipment - the room is equipped with a shield with a fire extinguisher, etc. The list of mandatory fire extinguishing agents is specified in SNiP.

Installation of an electric boiler room

If an electric boiler is used as a heating unit, then a boiler room in a private house is not required.

When electrical equipment operates, no combustion products are emitted, which is why the room does not require additional ventilation or installation of a chimney. You can install an electric boiler in any convenient place in the house.

Electric heating

The installation requires electrical installation work, during which it is important to follow the equipment manufacturer’s recommendations regarding cable products for connecting the boiler to the electrical network.

Important! A separate circuit breaker must be installed in the electrical panel, and if the voltage in the electrical network is subject to fluctuations, then a stabilizer must be additionally installed. These measures will lead to uninterrupted operation of the heating unit and extend its service life.

Freestanding furnace

A separate boiler room is intended for high-power units - over 200 kW. But if you need to preserve the architectural appearance of the house, then building such a structure makes sense for a boiler of lower power.

Modern polymer materials and technologies make it possible to lay underground communications for supplying heated coolant and hot water from the boiler room - a high degree of thermal protection will minimize the loss of thermal energy when transporting heated liquid.

A separate boiler room is built from:

- fire-resistant materials (building blocks of various types, brick);

- it is allowed to use metal sandwich panels with a non-flammable thermal insulator inside;

- fireproof roofing material is used;

- Reinforced concrete covering is used for the floor.

Premises requirements

:

- the ceiling height in a separate building should be from 2.5 m;

- when calculating the volume of the room, 0.2 m2 is added to the minimum value (15 m3) for each kilowatt of heat generator power;

- for a boiler weighing more than 200 kg, a foundation is installed separately from the base of the building, the height of the podium above the floor level is up to 15 cm.

There are standard requirements for doors, ventilation and chimney installation.

Detached boiler room in a country house

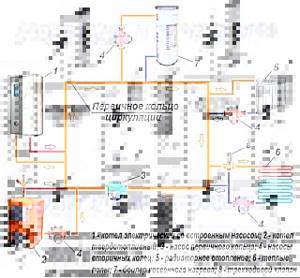

Technological diagram of the boiler room

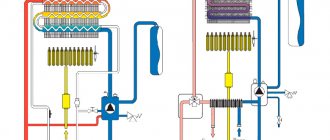

After installing the heat generators, it’s time to connect the devices to the utility networks of the country house - heating, water supply, electricity. It will not be possible to consider all possible schemes, but we will present the main options for piping boilers and water heaters in a boiler room:

- The simplest option is to connect one double-circuit wall-mounted boiler. Since the unit is initially equipped with its own pump, expansion tank and automation, it can be placed in the kitchen or in the hallway, and communications can be hidden in the walls. There is no need to separate or attach the room.

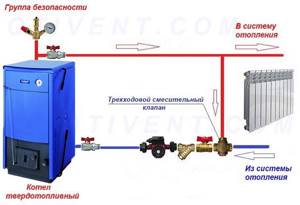

- The boiler room design with a solid fuel boiler provides protection against cold “return” and condensation inside the firebox. The key role is played by the three-way valve, which prevents coolant from the radiators from entering the jacket until the bypass circuit warms up to 50–55 °C.

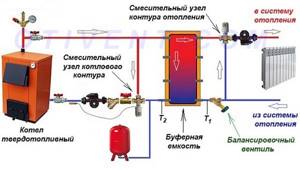

- Connection with a heat accumulator increases the efficiency of the TT boiler, which operates in maximum mode, transferring most of the energy to the buffer tank. The second three-way valve limits the water temperature at the inlet to the radiator network, the balancing valve is used to adjust the layer-by-layer loading of the tank.

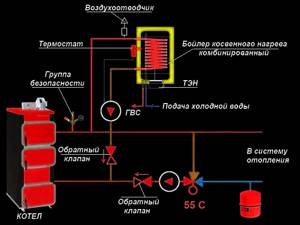

- Typical connection diagram for a wall heater with an indirect heating boiler. The temperature in the tank is monitored by a thermostat, which sends a signal to the boiler controller. The electronics switches the three-way solenoid valve and alternately directs the coolant to the coil of the water heater or radiator.

- If necessary, the indirect boiler is connected to the small circulation circuit of the TT boiler, as shown in the following picture.

- A scheme with two boilers - electric and wood - is often used when there is no gas in the house. The wood-burning heat generator serves as the main source of heat, the electric boiler as an auxiliary one (it automatically turns on after the solid fuel burns out).

- When it is necessary to combine several power plants and consumers in a boiler room, a scheme of primary and secondary rings is practiced. In residential buildings of small and medium area, this option successfully replaces the more expensive hydraulic arrow with a manifold.

A more detailed description of each technological scheme is given in the relevant articles - methods of piping heat generators and installing an electric boiler with your own hands.

Features of choosing and installing doors

If the boiler is installed in an extension or one of the rooms of the house (including the basement), then the door to the boiler room from the house must be fireproof. That is, the structure must withstand at least 15 minutes of exposure to open fire - this will allow people to evacuate in the event of a fire. Fireproof doors must be made of metal and open towards the living space.

External doors in the boiler room of a private house (free-standing or in an extension) must be unreinforced (weakly reinforced). This will allow the blast wave to blow the door outside - the energy of the explosion will be directed to the street, and not to the internal walls of the house. In addition, gas will escape through the torn doors.

The door for the boiler room also serves as one of the ventilation elements - the leaf with a grille in the lower part ensures air flow into the room. The use of such a design may be a mandatory requirement of the boiler room installation project.

If the furnace room is a separate room

If the boiler room is planned to be equipped separately, it can be located anywhere in your country house - in the basement, in any of the existing floors, in the basement, etc. At the same time, it is extremely important that not only the basic requirements are met, but also a number of additional ones.

- The fire resistance of walls separating rooms must be at least 3/4 hour.

- The lighting here must be natural.

- The ventilation system must provide air replacement at a frequency of three times per hour.

- A separate exit is needed.

- The boiler, as well as additional equipment, must be provided with convenient maintenance.

- The volume of this room must be at least 15 cubic meters.

Installation video

Basic standards and recommendations of SNiP for heating systems, see here

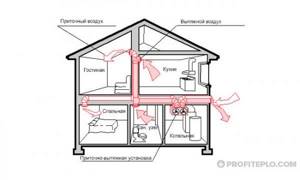

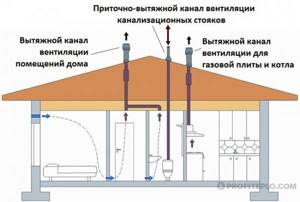

Ventilation arrangement

When organizing a boiler room in a private house, the ventilation requirements should be fully met, since the safety and efficiency of the heating unit depends on this.

Boiler room ventilation diagram

Natural ventilation may not be enough, so it is worth considering installing a system for forced air supply into the furnace room.

Poor ventilation contributes to

:

- settling of soot on the walls and ceiling of the boiler room,

- reduction of draft in an open firebox (this is associated with excessive energy consumption and the accumulation of soot in the chimney of a solid fuel unit),

- accumulation of carbon monoxide indoors.

Creating natural ventilation

If the house is heated by a boiler with a power of up to 30 kW, in home boiler rooms it is enough to ensure air flow by creating a channel at the bottom of the wall or door. They serve as a hole in the wall with a diameter of 10-15 cm.

How to create a channel at the bottom of a wall or door:

- a piece of plastic or asbestos cement pipe is inserted into the hole;

- a protective mesh is attached to it from the outside, protecting against the penetration of insects and dust;

- It is advisable to install a reverse draft valve on the inside of the channel;

- air flow is ensured through the lower part of the street door covered with a grille;

- the exhaust duct is discharged through the roof. It is a pipe of the same diameter, which in the upper part is equipped with a protective mesh and an umbrella that prevents precipitation;

- It is recommended to place the inlet opening near the firebox, at the bottom of the wall. In this case, the air will enter the combustion chamber directly without raising dust in the room;

- the location of the hood is also “tied” to the heating unit. Since combustion products rise, the exhaust duct is installed near the chimney.

Ventilation device in the boiler room

Creating forced ventilation

Natural ventilation in a boiler room with a powerful heating unit may not be sufficient. Its operation is unstable because it depends on weather factors, and control of air flow into the combustion chamber becomes impossible.

Installing a fan on an exhaust pipe will ensure the required air flow intensity and protect the boiler room from the accumulation of volatile combustion products. The fan power is selected in accordance with the maximum needs of the boiler - 30% is added to the parameter indicated in the passport.

Requirements for a boiler room in a wooden house

Gas boilers are allowed to be installed in private households, if they do not belong to the category of multi-apartment buildings or old buildings. In this case, all fire safety rules must be fully observed.

The main requirements include:

- furnace rooms are located on the ground floor or in the basement;

- partitions are made using non-combustible materials or covered with them;

- the furnace room should not border on residential premises;

- the boiler room must be equipped with personal protective equipment and primary means for extinguishing fires; it is mandatory to install control sensors and fire alarms;

- It is necessary to have hoods with access to the outside through the roof or wall;

- the presence of windows is mandatory, and with opening transoms or sashes;

- it is recommended to install protective screens on the walls or floor;

- it is possible to build a low foundation (about 100 mm).

Rate this article

House boiler room heating construction

Project approval

If we compare the costs of installing boiler houses of the same type, then for heating units operating on different energy sources, organizing a boiler house for gas heating will cost the most. This is due to the fact that the project needs to be approved by regulatory authorities, and it is advisable to entrust its development to professionals.

In addition to the project documentation itself, the homeowner must provide the following package of documents:

- technical passport of the boiler unit;

- sanitary and hygienic conclusion;

- certificate of boiler compliance with current requirements;

- operating instructions for the selected gas boiler.

Video on the topic: