Modern gas equipment is attractive because it does not require frequent repairs or any serious maintenance. All maintenance work is performed by representatives of the gas service, with which the home owners enter into an agreement. But when there is no longer a need for heating or water heating, it’s not difficult to turn off the boiler yourself, right?

Why not perform the equipment shutdown procedure yourself, rather than paying to call a specialist? In this article, we will analyze all the intricacies of this process - consider information on how to turn off a gas boiler while observing safety rules.

Especially for those who are used to doing household chores with their own hands, we offer 4 ways to preserve the boiler, which will reliably protect the heating system during downtime. After all, it is not enough to simply dial a combination of buttons to turn off the unit - it is necessary to properly preserve all connected equipment. Let's take a closer look at how best to do this.

General instructions for use

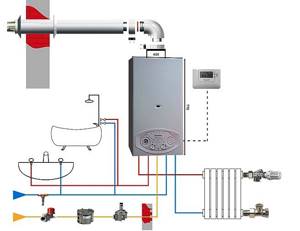

Before you start using a gas boiler, you must connect it to the gas network, heating pipes, cold and hot water supply (if the unit is double-circuit and is also intended for preparing hot water), and electrical network, which must meet the technical characteristics of the machine. Gas connections are made only by certified gas service workers. The water is connected and the boiler is started for the first time by representatives of a specialized organization for servicing heating systems. When connecting, strictly adhere to the requirements of the warranty card and operating instructions, otherwise the warranty will be void.

A gas boiler can only be used for the purposes for which it is intended.

Table of the required boiler room volume depending on the boiler power.

The manufacturer is not responsible for improper operation of the boiler, violation of operating rules and for damage associated with this. This will also void the warranty.

Installation, service and other work must be carried out in full accordance with the regulatory and technical documentation and user manual. Only original spare parts must be used.

If a malfunction is detected in the operation and/or breakdown of the unit, you must immediately turn off the gas supply at the tap and call a qualified specialist. It is strictly prohibited to carry out any work on the gas boiler yourself.

When performing any work on or near air ducts and chimneys, it is necessary to turn off the device and turn off the gas. After completing the work, before turning on the boiler, you should check the functionality of the air ducts and chimneys.

When the gas boiler is turned off for a long time

- turn off the gas tap;

- when the boiler automation is powered from the mains and there is an electric water pump, disconnect them from the line;

- turn off the taps of the cold and hot water supply system, heating system;

- if the heating system is filled with water and the ambient temperature is expected to drop below 0°C, the water must be drained from the heating system;

- The final shutdown of the unit should be entrusted to a specialist.

When cleaning the boiler, turn it off. The device can be cleaned with damp cloth rags, a mild detergent, and soapy water. Do not use aggressive chemicals for cleaning, including detergents, insecticides, and other toxic substances.

The use and storage of flammable substances in the same room as a gas unit is strictly prohibited.

Step-by-step instructions for disabling

If the gas burner does not light or goes out immediately after switching on, automatic shutdown often occurs for inexplicable reasons, popping noises occur, the temperature of the water in the circuit does not correspond to the indicators, noise uncharacteristic for the operation of the unit is heard, there is a water leak in the housing, the pressure drops - the equipment should be turned off immediately .

If, upon entering the house, you smell gas, do not turn on the lights, electrical appliances or light a fire. Immediately call your service provider, turn off the equipment and turn off the gas

The shutdown procedure for boilers is carried out differently, but the main stages are similar.

Using the Baxi model as an example, let’s look at how to properly and quickly turn off a gas boiler:

- Shut off the fuel supply by turning the gas shut-off valve.

- Leave the fan running for another 15 minutes.

- Turn off the fan, stop the smoke extraction system.

- Wait until the temperature in the circuit is below +30 °C and turn off the circulation pump.

- Turn off the power by turning the switch to the “Off”, “0” or other position specified by the manufacturer.

- Carry out conservation work on the boiler and related equipment.

Not all systems drain the water completely. Some manufacturers recommend adding a liquid to the coolant that prevents the formation of lime deposits. Propylene glycol or antifreeze are recognized as the most effective for household communications .

When force majeure situations occur, you have to quickly figure out how to quickly turn off the gas boiler, while maintaining the functionality of the system and not harming yourself. Next we will consider special cases.

Sometimes, when there is overheating or lack of draft, the boiler automatically turns off. It stops working, and accordingly, the heating of the house stops. If automatic shutdown occurs very often, 5 times in 15 minutes, you should turn off the gas and contact the service department.

When gas equipment automatically turns off, an error code is displayed on the electronic display. In this case, you need to find this code in the instructions and act according to the manufacturer’s recommendations

Problems in the smoke removal system also automatically stop the unit. It usually shows an error on the display and stops working for 12-15 minutes and then turns back on. If the problems are not resolved during this time, an automatic shutdown occurs again - and so on until the problem is completely eliminated. To clean the gas exhaust channel, turn off the gas and turn off the boiler.

Many boilers are protected from freezing by automatic means. The protection works if the boiler sensors are connected to the power supply, the system pressure is normal and the gas is not shut off.

In case of any malfunction, if the temperature of the coolant in the circuit drops below + 8-10 ° C (depending on the model), the operation of the unit is suspended. As a last resort, if you cannot quickly cope with the circumstances - turn on the boiler and get it functioning - you can try to drain the water so that the pipes and parts of the unit do not rupture.

Requirements for use

Before you start using the boiler, you need to make sure of some very important points. The heating system must have the right amount of fluid. The boiler itself must be connected to the atmosphere through an expansion tank. The safety valve and burner field must be in working order. The latter should be freed from foreign objects and other debris. The boiler valve must be opened.

Before starting ignition, it is necessary to remove the protective film, if any, from the burner. How is ignition carried out? First you need to make sure that there is no smell of gas in the room. In addition, such phenomena as an open pipeline supply valve and the presence of draft in the chimney are unacceptable. Immediately before ignition, the burner viewing window opens. The burners bring fire to the middle of the field. If ignition has occurred, a slight pop should appear. As a rule, this happens within 5-7 seconds.

If, after these steps, ignition still does not occur, then you should immediately turn off the valve and ventilate the room. The next attempt can be made no earlier than 10 minutes later. This is what the operating rules say.

The temperature during boiler operation must not fall below 65°C, as this may lead to condensation.

It is important to ensure that no specific gas odor arises in the room during work. At the same time, the temperature cannot be higher than 90°C

The boiler burner must be periodically cleaned of dirt.

This is what the basic operating instructions for this unit look like. It is important to be careful when using a gas boiler and not to deviate from the rules of use. Use it correctly!

Methods for preserving gas boilers

Let's consider the main methods of preserving heating equipment, but with one caveat - not all are used in home maintenance. Some of the methods are more suitable for equipment installed in production plant workshops.

For home maintenance, alkalis are used - caustic or soda ash. It is not recommended to use acidic reagents on your own; hydrochloric or sulfuric acid can only be used by qualified specialists

The process of preservation of the heating circuit is preceded by a preparatory stage, which includes several points:

- Disconnecting the boiler from the gas main and central water supply, installing plugs. If water is supplied by the pumping station, the pump stops.

- Removing water or other coolant from the system.

- Cleaning internal surfaces from scale.

- Washing boiler parts and circuit.

Professional cleaning of calcium deposits can only be carried out by specialists - and the service organization has such a service. There are two most effective and simple ways to remove scale - chemical , mechanical (manual cleaning), but the first is recognized as the most effective.

The internal parts of the boiler, on which large deposits have appeared, are ground with a power tool, and scale in hard-to-reach places is removed manually, with brushes or scrapers.

Method #1 - dry stop

Dry preservation is carried out in production, usually for maintenance activities or during routine inspections, when it is necessary to stop production for up to 30 days. It consists of completely freeing equipment and pipelines from liquid and further drying.

The procedure is called "dry stop". It is applicable to any models of boilers, regardless of pressure, but is contraindicated for units in which the drums are connected to the pipeline with rolling connections

Procedure:

- Natural coolant cooling.

- Stopping the boiler.

- Displacement of liquid under pressure of 0.8-1.0 MPa.

- Drying the system naturally or by ventilation.

- Installation of trays with desiccants in the collectors - quicklime or calcium chloride grains.

- Closing the firebox and flue, plugs - complete sealing of the system.

At home, water is drained through special taps installed at the bottom of the pipeline. Then they carry out repair or maintenance work and leave the equipment in a “dry” state until the next heating season.

The drain valve is a shut-off valve that must be installed when installing a heating system. Most often, brass models are used, selected according to the diameter of the pipe.

The circuits are refilled with coolant using a pump. The heating function is activated only after the pipeline has been completely filled with water, circulation has been checked and diagnostics have been carried out.

This method is the only correct one if it is necessary to stop the boiler operation for the winter or for an even longer period.

Method #2 - wet preservation option

I use wet preservation if I need to stop the boiler for a short period. The main goal is to keep the equipment in working condition, protect against corrosion, and prevent oxygen from entering the circuit.

To fill pipes at home, a special liquid is used that prevents the formation of rust. It is sold in specialized stores in concentrated or ready-to-use form.

For regions with severe frosts, liquids that do not freeze at low temperatures are used. For example, concentrated antifreeze is in a liquid state down to -60 °C. To prevent the substance from thickening, it is diluted with water. But we must remember that the freezing point of an aqueous solution increases.

Antifreeze has other disadvantages:

- “eats” rubber;

- has a high degree of fluidity;

- cannot tolerate overheating - turns into acid;

- expensive.

Instead of antifreeze, use a solution of sodium sulfate at a rate of 10 g/liter of water. The liquid poured into the system is heated to displace the air, and then all holes are hermetically sealed. A pressure test pump is used to pump water into the circuit.

Method #3 - gas preservation

For private houses, the gas preservation method is not used, since this requires special equipment and professional skills.

The essence of the technology is that gas is released into the pipes, which, when in contact with metal, unlike oxygen, does not cause corrosion. Such gases include argon , ammonia , helium , and nitrogen .

Some types of gas are hazardous to health, and without following safety regulations, you can easily get poisoned or get burned. All procedures are carried out strictly according to the instructions and in protective clothing.

The conservation process is complex and is carried out in several stages:

- the system is washed with deaerated water;

- connect a gas cylinder and a pressure reducer;

- fill the circuit with gas, displacing water;

- close the drain valve;

- when the indicator is 0.013 MPa, the gas supply is stopped;

- close the pipe, turn off the cylinder.

The main condition for gas preservation is the absence of air in the system , so throughout the entire period of inactivity it is necessary to monitor its tightness.

Method #4 - applying excess pressure

High-pressure preservation technology is usually used in enterprises where all conditions are created for this. It is used for water heating and steam equipment.

The main task is to prevent oxygen from entering the system. To do this, a pressure above atmospheric is created inside the circuit, while the usual coolant is replaced with deaerated water

The overpressure method is suitable if it is necessary to stop the operation of a gas boiler for a short period of time - up to 10 days. Typically, during this period, repair work not related to water heating equipment is carried out.

Accommodation requirements

These requirements will directly apply to the room in which the gas boiler is to be located. What does the instruction manual say about this? Thus, the room must have a total area of more than 7.5 m². Ceiling height - at least 2.2 m.

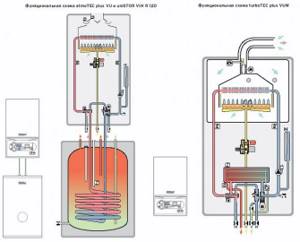

Diagram of a gas boiler from Vaillant.

In addition, the room must have a window that can be opened if necessary. It should go outside. This is required by fire safety.

As for the door in this room, it should open in the direction of movement from the room. There should be no switches in the room itself. They should be moved outside the room.

A ventilation system (supply and exhaust) is required. Approximately 15 m² of air per 1 m² of gas burned is required. Three air exchanges are also needed.

When installing the boiler itself in a room, fire safety precautions must be strictly observed. So, from the boiler to the combustible elements of the room, you need to measure a distance of no less than 25 cm. As for non-combustible elements, a distance of 5 cm is allowed here.

The distance between the chimney and combustible parts is 40 cm, and between the chimney and non-combustible parts - 15 cm.

The gas boiler must be installed on a perfectly flat surface on which there are no slopes

This is important for safe use.

Who makes the decision to disconnect and on what basis?

Decisions on turning on and off the centralized heating system are made by local governments, and not by utility services or CHP workers.

In the spring, when the heating season ends, the municipality, based on the weather forecast, sets the date on which the CHP employees will turn off the heating.

The document that regulates the heating season schedule is RF PP No. 354 dated May 6, 2011 (last amended dated December 29, 2020). What determines the shutdown date:

- The air temperature is not lower than 8 oC for 5 days. This condition is relevant for houses in which heat is supplied through central networks. If an apartment building is heated autonomously, then the decision to turn off the system is made by the owners during a meeting.

- Region. For example, for the southern regions the optimal date is the beginning of April, for the middle zone - April-May, in the northern regions heating can work until the end of May.

- Weather forecast. Even if the conditions from RF PP No. 354 are met, the municipality consults with meteorological services before disconnecting. If, according to the forecast for the next 10 days, a sharp drop in temperature is possible, then despite the fact that the temperature remains above 8 oC for 5 days in a row, the heating will not be turned off. In such situations, the system power is reduced.

The municipality is obliged to report on the decision made to turn off the heating. The order must be published:

- on the website of local authorities;

- in the media.

Citizens can find out the date from free sources, as well as by calling the management company or the municipality help desk.

Service life

The service life of gas equipment is determined in the technical passport of the boiler and ranges from 10 to 15 years. However, with regular maintenance and prevention, it can last much longer. The regulatory services may establish additional requirements for service life.

This may be due to the presence (or absence) of spare parts that are needed in the process of maintaining full operation of the boiler. If during the repair some part is required, and the manufacturer has stopped producing them, it may be necessary to replace the boiler as a whole with a more modern one and one equipped with spare parts.

Heating shutdown progress

Disconnection of consumer objects from heating networks occurs in stages. This is due to the heavy load that the equipment experiences during the process of starting and stopping the heat supply.

- First of all, the heat supply is stopped to industrial facilities, enterprises, and factories.

- Heating is turned off in apartment buildings and other residential buildings.

- The end of the heating season occurs with the shutdown of batteries in kindergartens, schools, hospitals, and shelters.

Note:

In some cases, a gradual decrease in temperature in residential premises is acceptable, which is the preferable choice in unstable climates.

First start

Before starting the gas water heating boiler for the first time, it is necessary to check the correct installation and installation, in compliance with all instructions. The installed boiler must be inspected by a gas service inspector and sealed. After which you can begin preparing for the first launch. Before starting, the automation is configured with the required parameters set, following the operating instructions supplied with the boiler.

We recommend: Thermocouple for a gas boiler: detailed instructions on the design and principle of operation, checking the serviceability of the thermoelectric sensor with a multimeter, restoration and replacement

Filling the system with coolant

Step one is to fill the system with water or another coolant. The entire circulation circuit is checked for the presence or absence of “air” plugs in the system.

If present, air pockets must be vented by slowly releasing air through a special valve. Most often this is found on heating elements. Etching must be carried out with caution, with the readiness to close the valve in time.

Checking the supply lines

Step two is to check gas pipes, valves, and shut-off valves for leaks. The inspection is carried out by a gas service employee. But if you smell a specific gas smell, you can check it yourself before a specialist arrives and find the leak. For this, use a regular soap solution.

By applying it to welds, at the joints of pipes and shut-off valves, you can detect gas leaks.

Putting the boiler into operation

Step three is the direct start of the gas water heating boiler itself. Carry out strictly according to the attached instructions. If you can’t figure it out on your own, then it’s better to contact specialists who have access to this type of work.

Boiler shutdown

At the end of the heating season, if the boiler is not planned for use in the hot water supply system, then it must be turned off for a long period. To do this, follow a few simple steps:

- turn off the gas supply, make sure that the burner in the boiler goes out completely;

- turn off the power supply to automatic ignition and automation;

- shut off the water supply to heating and water supply.

No special additional actions are required. Do not drain the entire coolant circulation system to avoid corrosion.

What rules must be followed?

When carrying out measures to preserve boilers in production, they are guided by the requirements set out in RD 34.20.591-97 “Guidelines for the preservation of thermal mechanical equipment.”

The same standards should be observed by owners of equipment installed in private homes.

If you are not confident in your knowledge or skills, contact your service organization. Specialists will carry out work to shut down the boiler and preserve the equipment in compliance with all safety requirements

What you need to remember if you decide to mothball your heating or hot water equipment yourself:

- Before any repair work, the gas must be shut off. The main valve is installed at the gas pipeline entry into the house.

- Even the slightest ingress of oxygen into the system will cause corrosion of boiler parts and pipelines, so you need to choose one of the preservation methods and follow it strictly according to the instructions.

- When working with chemical reagents, you must protect your body parts with thick clothing, wear comfortable shoes, gloves and a mask.

- To keep the pipes and components of the unit in working condition, it is necessary to observe the dosage when diluting concentrated compounds and dry chemicals.

- Work with explosive or flammable substances may only be carried out by specialists.

- Upon completion of work, it is necessary to turn off the power supply to additional equipment - for example, a pump.

The above rules must be followed to protect your own health and preserve the equipment.

After a long period of inactivity, the heating and water heating system will require re-preservation - a process that also requires compliance with certain rules.

Safety system

Gas-powered appliances require serious monitoring. It is provided either by a person or an automation system. The latter is capable of providing multi-stage protection that prevents dangerous situations and increases equipment safety. The main task of the protection system is to turn off the device in time by stopping the fuel supply.

Let's look at the stages of protection using the example of the Proterm Wolf KSO floor-standing boiler. These modern devices have multi-stage protection. One of the stages is an ionization sensor that controls the flame. If the fire goes out, a signal will be sent to the control unit, it will shut off the fuel supply and prevent an accident.

The combustion chamber has a temperature sensor that monitors the heating of the coolant and prevents the firebox from quickly burning out. “Wolves” are equipped with a KTD system - chimney draft control. It prevents the accumulation of carbon monoxide. If there is no draft, combustion products begin to accumulate in the chimney, and the thermostat heats up. When the temperature limit is reached, the thermostat contacts open and the flow of fuel stops.

Automatic protection

Modern heater models are equipped with electronic control and measuring instruments that generate signals for the control unit. Automation, receiving signals from sensors, coordinates the work of all nodes. Elements that prevent various types of malfunctions and problems are safety valves, expansion tanks, air valves, smoke detectors and other devices.

Safety regulations

Remember, gas is a common cause of explosions and fires. Therefore, treat fire safety techniques with respect, follow the requirements and instructions.

Frequently encountered dangerous malfunctions and methods of elimination according to safety rules:

- flame failure is a moment during which the flame extinguished, but the gas supply did not stop. The solution is to turn off the gas supply and open the room in which the boiler is located for ventilation. During ventilation, it is strictly forbidden to use open fire, turn on and off electrical appliances, lighters, etc.;

- decrease in the filling of the circulation circuit with water - occurs when there is a water leak. If a leak is detected, turn off the boiler, but under no circumstances start filling the circulation circuit. Wait until it cools down completely, find the leak, and fix it. After which you will have to fill the circulation circuit again;

- the draft in the chimney has disappeared - stop the boiler and clean the chimney. Ventilate the room. When the draft resumes, return the boiler to operation;

- The pilot light goes out - turn off the boiler, carry out the switching procedure according to the passport and the attached instructions.

Do not forget that a gas boiler is a high-risk device; such equipment must be operated strictly according to the instructions, in compliance with full fire safety measures.

What to do if problems occur

Let's look at breakdown situations using the example of Italian Baxi boilers. Italian wall and floor heaters are an example of quality and efficiency. But even with proper use, malfunctions may arise that require prompt correction.

The following problems may appear in Baksi models:

- the burner does not light;

- during operation, popping noises are heard in the firebox;

- the boiler overheated;

- the device is very noisy;

- The sensor has failed.

The probable causes of breakdowns are associated both with violations of operating rules and with reasons beyond the control of the user:

- moisture has entered the device;

- low quality coolant;

- the pressure in the gas pipeline has decreased;

- voltage drop in the electrical network;

- errors were made during installation.

Violation of at least one rule or norm leads to breakdowns, incorrect operation and unnecessary costs.

Low gas pressure

The gas pressure in the gas main varies significantly depending on the time of year. In winter, when the maximum number of consumers is turned on, gas pressure often approaches the minimum permissible. Old-style domestic equipment may completely shut down in such situations due to low pressure.

Modern boilers still function, but they can no longer produce their full power. This is not as noticeable when heating the heating system as when the boiler is operating to heat hot water, when consumers notice that the water coming from the tap is lukewarm. Only a service engineer who has a special knowledge of the equipment. And if the static pressure is 130 mm. vd. Art. at the inlet to the gas valve, then we can immediately assume that there will not be enough gas in the dynamics, and the boiler will not produce its full power if necessary. With a further decrease in pressure, the power of the equipment will also decrease.

This value can be determined from a graph of the dependence of thermal power on gas pressure at the burner, provided by the equipment manufacturer. They are considered the most resistant to a decrease in gas pressure. In the event of a drop in blue fuel pressure, the service engineer is unable to influence the situation and must contact the gas utility.

Reasons for turning off the gas boiler

A gas boiler is the real “heart” of a private home. It provides the building with heat, and double-circuit models with hot water.

Thanks to the electronic filling, the main processes - turning on, turning off, switching to another mode, adjusting the temperature - are carried out automatically, without human intervention. The owner needs to set the program by pressing, depending on the manufacturer’s instructions, the appropriate buttons or keys.

Gas boilers are preferred because of the cheapest fuel - gas. Solid fuel units or wood stoves are more often installed if there is no gas main nearby

Shutting down may be necessary for various reasons:

- moving to another place of residence;

- seasonal shutdown for the warm period;

- emergency shutdown due to boiler breakdown and the impossibility of quick repair or replacement;

- planned stop for maintenance - removing deposits, flushing the internal circuit or cleaning soot;

- connection of other heating or hot water equipment;

- disabling one of the functions - for example, heating, etc.

Most often you need to turn off the heating. To do this, the operation of 1-circuit units is completely stopped, and for 2-circuit units, only one line is shut off - the heating line.

Double-circuit models perform 2 functions: heating and hot water. Since hot water is also required in the summer, the water heating circuit is left in operation, and the hot water supply line continues to be operated as usual

Many modern models have the option of switching to summer mode . At the same time, the boilers do not fail - they also continue to work, maintaining the optimal temperature and keeping the system “ready” for active start-up at any time.

In summer, especially in the northern regions, there are also cold snaps and even frosts, so the existing equipment turns out to be useful.

Requirements for the chimney and other parts

The chimney needs to be made of steel, preferably stainless. There must be cleanout hatches and the ability to drain condensate. At the bottom of the chimney there is a pocket intended for deposits.

We recommend: How to turn off the water heater when hot water is supplied: at night, for a long time

The outside of the chimney is subject to additional thermal insulation. The insulation material must be protected from precipitation and condensation.

The chimney should be 2-3 cm higher than the boiler outlet. The height of the chimney must be at least 5 m. The chimney is installed in the receiving plate of the vapor trap. In this case, condensate should not get inside the boiler.

The pipe cut should not fall on the wind support area.

What about an atmospheric expansion tank? It must be installed at the highest point of the entire structure. It is preferable that it be located inside the room.

The boiler supply pipeline must be equipped with a safety group and a thermometer. The boiler itself is strongly not recommended to be installed in openings, niches and other similar hard-to-reach places.

Regulation of gas supply to the boiler and water circulation in the system

If you screw the gas burner on, the gas will flow in a smaller volume, the flame will become smaller and the resulting temperature will be lower.

In modern boilers, this process occurs automatically: the temperature is controlled and switches to the required mode independently. If the burner goes out, the incoming gas will not be able to burn and will pose a danger to the premises and its occupants. There are auto mechanisms that can regulate this process and determine whether the system is ready to supply gas. If not, the gas simply does not flow. To heat the room faster by circulating water in the heating system, boilers are equipped with pumps. Thus, depending on the type, class and model of the boiler, the following can be installed in it:

- pump;

- control system;

- safety system;

- protection and diagnostic systems.

Most modern models are equipped with automatic gas supply, emergency protection and temperature control: they independently monitor the operation of the pump, the current state of the thermal level and switch modes and states without manual intervention. The person who bought the boiler does not have to interfere with its independent operation, unless, of course, the device is working properly. And in case of failure of one or another unit or mechanism, maintenance of gas boilers is provided.

Approximate schedule for heating shutdowns in Russian cities in 2021

Approximate dates for the end of the heating season in large cities of the Russian Federation are presented in the table.

| City | Heating shutdown schedule |

| Moscow | May 7 |

| Saint Petersburg | 26 of May |

| Novosibirsk | 26 April |

| Ekaterinburg | May 7 |

| Kazan | April 27 |

| Nizhny Novgorod | May 7 |

| Chelyabinsk | April 30 |

| Samara | April 28 |

| Omsk | April 21 |

| Rostov-on-Don | April 24 |

| Ufa | May 3 |

| Krasnoyarsk | May 10 |

| Voronezh | April 30 |

| Permian | May 4th |

| Volgograd | April 29 |

The dates indicated in the table are estimates. Information is based on statistics for 2021. The exact shutdown dates for heating systems may differ from the dates indicated. Moreover, they may be different for different settlements of the same region.

What can you save on when using a gas boiler?

Saving and its reasonable calculation is a particularly pressing issue when it comes to heating and choosing a boiler. In terms of savings, expert reviews of floor-standing boilers agree - floor-standing ones are less resource-consuming.

Competent installation

Experts also agree that efficient, reliable and economical operation of the boiler is only possible with proper organization of not only the installation of the boiler itself, but also the entire heating system

In addition, it is important to take into account all measures to prevent equipment failure, since repairs and servicing of gas boilers are also significant material costs, which in turn can also be reduced by promptly contacting a gas boiler service center, as well as by drawing up a service agreement gas boiler.

Do-it-yourself boiler cleaning

Washing heat exchangers yourself can also reduce costs if you choose the appropriate type of device that allows you to do this procedure yourself. It is important, also from the point of view of economy, that the gas boiler in a private house must be grounded. You can get acquainted with the main types of gas boilers for heating a private home here. Even if the boiler has been in operation for a long time, but this requirement has not been met, it should not be neglected: it is worth learning how to ground a gas boiler in a private house and carry out this procedure.

Choosing a gas boiler

A means of saving is the choice of boiler itself. Cheap, more expensive, with or without automation, what you can win at the very beginning and in subsequent operation - all this is important to take into account and calculate. A striking example of the ambiguity of calculating savings on heating can be the purchase of an AGV type boiler (gas water heating unit), which means the cheapest type of old, Soviet-style boiler with primitive automation. The standard AGV gas boiler has a very low price, but also low efficiency, but does not require electricity. Only an accurate calculation will help determine the degree of savings when using this device. You can read about domestic gas boilers in our article “Russian-made gas boilers: varieties and properties”. It is also important to determine the potential problems of certain boilers when choosing the optimal model. For example, a MORA gas boiler will constantly suffer faults until it fails in conditions of instability of the electrical voltage, with the slightest setting errors and lack of water in the system. And the reviews for the Master Gas Seoul gas boiler are contradictory at first glance, but they provide information about the vulnerabilities of this model - the accumulation of combustion waste in the boiler, which leads to noisy fan operation, leaks and unstable water temperature during supply, while with its main functions, heating, this model copes well. Probably, every budget model has features of this kind that, under certain conditions, may not appear, thus justifying savings on the purchase, and with knowledge of the structure of the boiler, as well as the strengths and weaknesses of each model, you can not remain indifferent and not let the situation go left to chance, but to manage the level of comfort and the amount of costs when operating heating equipment.

Normative base

The main document establishing the norms and rules for providing citizens of the Russian Federation with centralized heating through the provision of services of a single heat supply organization in 2021 is Federal Law No. 190 “On Heat Supply” dated July 27, 2010. The legislative act considers issues related to legal relations, the obligations of companies providing heat to citizens: how, in what time frame and to what extent they are carried out, what responsibilities the organization has for the timely repair and replacement of outdated communication systems.

An equally important regulatory act is Decree of the Government of the Russian Federation dated 05/06/2011 N 354 “On the provision of utility services to owners and users of premises in apartment buildings and residential buildings”, as well as the “Rules for the provision of utility services to owners and users of premises in apartment buildings and residential buildings” included in it. residential buildings." The set of rules covers in detail issues related to troubleshooting during heat supply interruptions, acceptable repair periods, and situations when the provision of services may be suspended.

Attention

Government Decree No. 354 sets clear temperature standards in residential premises: +18 °C (+20 °C in corner rooms). A decrease in temperature within 3 °C is considered acceptable, but only at night.

Basic recommendations for the operation and repair of gas boilers

- Do not open the gas valve under any circumstances. All work related to gas must be performed by a specialist. You shouldn't put your life in danger.

- As a last resort, if you have basic knowledge about the operation of gas boilers , you can check the filter at the gas pipeline inlet. Before doing this, be sure to turn off the tap, unscrew it and check the gasket.

- 80% of problems during operation of a gas boiler occur due to phase zeroing when the wire plug is incorrectly connected to the socket. For example, one of the family members unplugged the boiler and unknowingly put the plug back in the wrong position. First of all, you should pay attention to this and try to put the fork in the correct position. If this is the problem, the system will reset the error and the boiler will start working. This completes the repair of the gas boiler. In order not to get confused about the correct phase setting, you can make marks on the plug and socket with a marker, mark the pin and the corresponding hole.

- It is necessary to check the gas pressure; this can be done visually, for example, by the boiling time of the kettle. If the kettle boils longer than usual, half an hour instead of ten minutes, then the pressure is low.

- Coolant circulation. Filters are installed at the inlet to protect the boiler from debris and scale that enters it from old or low-quality systems during operation of the gas boiler. A layer of dirt forms inside the pipes, and circulation in the boiler is disrupted. In this case, you need to make sure that the system is not clogged with debris - unscrew the filter and check it. In case of contamination, rinse the filter thoroughly and replace it.

- Be sure to check the chimney. Various contaminants may appear inside the pipe during operation of a gas boiler, for example, wasps can nest comfortably in it or build a hive right in the chimney. In addition, if water enters the chimney from the outside, ice may form, preventing air from escaping. A sign that the problem is in the chimney will be a strong spread of flame when the boiler is turned on. In this case, the pipe must be cleaned and the ice removed. Clean the chimney pipe regularly.

- Before first use and throughout the operation of the gas boiler, you should turn the rotor of the circulation pump as follows: unscrew the washer, place a piece of cloth and use a screwdriver to turn the rotor clockwise. Due to the tightness of the pump, movement will be difficult, but after that the work will be restored.

- Check the operation of pressure, temperature sensors, etc., after turning off the boiler. Make sure the contacts are connected - disconnect the wire from the sensor and insert it back, this way the electrical connection is restored.

- There is a burner inside the boiler that requires regular cleaning. This can be done using sandpaper, carefully clean the ionization and ignition contacts and the burner field from plaque.

- If during operation of a gas boiler there is loud noise and vibration coming from it, it is necessary to check the fan, which may become clogged from dust getting into it. If there is dirt on the fan blades, operation will be disrupted. Contamination must be eliminated to restore normal air circulation and normal operation of the gas boiler. Lubricate the bearings. If the fan continues to spin poorly, then the bearings need to be replaced.

- The system is equipped with a press control - a mechanism that serves to close the circuit when the fan is turned on, which protects the boiler from fire. Two tubes supplying pressure and vacuum are connected to it. This element also needs to be checked. When the fan is turned on, a click is heard, indicating that the contacts in the press control are closed. If the fan malfunctions, the press control will also be faulty.

We recommend: Primer of pipes, heat-resistant compounds for stoves, batteries, heating radiators, video, photo

How does this happen

Due to the nature of the central heating system, it is turned off simultaneously for objects of the same type. That is, it is impossible for the heating to be turned off in two houses belonging to the same combined heat and power plant on different days.

However, CHP workers do not turn off the heating at the same time. A sequential algorithm is used:

- Industrial facilities (factories, warehouses, etc.) and public buildings (shops, shopping centers, etc.) are the first to be turned off.

- Then residential buildings are switched off.

- The last thing to do is turn off the heating system in social institutions (hospitals, clinics, universities, schools, kindergartens, etc.).

How is the work inside the boiler regulated?

If the boiler is turned on and in working condition, sensors built into the control system check the temperature of the heating system and transmit the results to the thermostat.

A thermostat is a device responsible for automatically regulating a heating device in terms of maintaining the temperature set by the consumer. Sensors are an integral part of the thermostat. If the temperature based on the measurement results is below normal, the automatic system switches the heating device to heating mode, the water is heated in the heat exchanger and, using a pump, if any, is supplied to the pipes, distributing heat throughout the room.

The heating system is closed, that is, water, which acts as a coolant, constantly circulates through the pipes without changing its volume.

If the volume is disrupted, the entire system may not function correctly. Usually this is noticed in one way or another, for example, if a gas boiler is noisy, this may be evidence of a lack of water in the heating system, which in turn leads to overheating of the boiler. In such cases, check the thermostat adjustment (the device responsible for maintaining a constant temperature), if it is normal, check the water level and add it if necessary, providing the system with the necessary volume for normal functioning.

How a gas boiler doesn't stop working

- Pros and cons of double-circuit

- The working principle of a double circuit to heat water with a primary and secondary type pipe coil

- The working principle of a double circuit to heat water with a bithermal pipe coil

- Malfunctions and breakdowns

Now there are two types of heating boilers: single-circuit and double-circuit. Single-circuit units can be floor-mounted or wall-mounted and are intended for heating premises. Depending on the power, they can heat rooms of any size. A double-circuit heating system can also heat any room, but it is also intended to heat water. Therefore, such a device will be much more expensive. But you won’t need to spend money on water heating equipment, because... you get a “2 in one” device.

Rice. 1. Hydraulic diagram in heat supply mode: A - Supply line, B - DHW, C - DHW, D - Return line, 1 - Gas burner, 2 - Circulation pump, 3 - Three-way valve, 4 - Secondary pipe coil, 5 - Pipe coil primary coil.

The main work in boilers is performed by:

- pipe coil;

- eagle;

- thermostat;

- one or two circulation pumps;

- control device;

- expansion tank;

- thermometer;

- a device for determining pressure.

Pros and cons of double-circuit

The double-circuit unit is the most common and sold on the heating equipment market. Its uniqueness lies in the dual connection of space heating and water heating. A gas boiler, which has two pipe coils, copes with two similar functions.

Let us indicate their main positive qualities:

Rice. 2. Hydraulic diagram in water heating mode: Fig. 2. Hydraulic diagram in water heating mode: A - Heat supply line, B - Hot water supply line, C - tap water, D - Heat supply return line, 1 - Gas burner, 2 - Circulation pump, 3 - Three-way valve, 4 - Pipe secondary coil, 5 - primary pipe coil.

- when using such devices, gas consumption is significantly reduced;

- installation is quite simple due to its compactness and light weight;

- can be installed in any place, which means the boiler does not require a separate room;

- Quiet operation of the device is ensured by a water system;

- routine machine maintenance and operation;

- you can choose a double-circuit to heat water with absolutely any power, which is why both a small room and a large country house can be successfully heated;

- The device allows you to use hot water without purchasing water heating equipment.

The dual circuit also has disadvantages:

- Such a heating boiler does not usually perform these 2 functions simultaneously, due to this, when heating the room, the water heating is turned off, and vice versa;

- heating of the liquid occurs in flow mode, there is no direct connection with a storage electric water heater;

- It takes up to 1 minute to heat up; before that, cool water will come out of the tap, which means there will be little water loss.

to come back to the beginning

In Fig. Figure 1 shows the hydraulic diagram in heat supply mode. Explanation of the picture:

A. Supply line

D. Return line

- Gas stove.

- Circulation pump.

- Three way valve.

- Secondary pipe coil.

- Primary pipe coil.

Navien boiler, instructions.

Rice. 3. Diagram of the heat supply mode: A - Supply line, B - DHW, C - Cold water, D - Return line, 1 - Gas burner, 2 - Bithermic pipe coil, 3 - Circulation pump.

During the operating period of the apparatus in heat supply mode, the gas burner transfers heat to the primary pipe coil. The pump circulates the liquid. This means that liquid does not penetrate into the secondary pipe coil due to the three-way valve. The heated liquid leaves through the heating line (A). For subsequent heating, the liquid is returned via (D) the heating return line.

In Fig. Figure 2 shows the hydraulic diagram in water heating mode.

Here the three-way valve closes the heating line. Warm water moves from the primary pipe coil to the secondary one. Tap water (C) is heated as it passes through the secondary pipe coil and enters the hot water supply line (B). There is an advantage of using double-circuit heat exchangers.

Here, ordinary tap water is used, which contains various salts and deposits. From chemistry class we know that as soon as the temperature increases, salts precipitate, thus forming a strong layer of deposits. These deposits clog the pipe coil, interfering with the passage of liquid through the pipes and reducing the service life of the device. However, in the primary heat exchanger, water passes in a closed circle and at the same time it does not change the chemical parameters, thus not exposing the gas boiler to rust. But the fluid passing through the secondary pipe coil puts its own salts in it, which can cause it to get dirty. Due to this, it will need to be repaired or completely replaced over a period of time.

If the second pipe coil breaks, the gas boiler will be able to continue operating in heat supply mode, which plays a big role when it’s cold outside.

The only disadvantage of two-stage boilers is their high cost when compared with devices based on a bithermal pipe coil. Its bad quality can be called double load, because... it needs to work in both heat supply and water heating modes.

In order for a room to be heated to a specific temperature, a thermostat is needed that changes operation depending on the ambient temperature. Whether the device turns on or not depends on whether the liquid has reached the set temperature. To ensure that the device always turns on at the required temperature, you need to adjust the thermostat manually at different periods of time.

to come back to the beginning

Rice. 4. Diagram of the hot water preparation mode: A - Supply line, B - DHW, C - Cold water supply, D - Return line, 1 - Gas burner, 2 - Bithermal pipe coil, 3 - Circulation pump.

In Fig. Figure 3 shows the hydraulic diagram in heat supply mode.

In Fig. Figure 4 shows the hydraulic diagram in the hot water preparation mode.

A. Supply line

D. Return line

- Gas stove.

- The pipe coil is bithermic.

- Circulation pump.

During operation in water heating mode, heat from the gas-powered burner and from the combusted gases is supplied to the coolant, and then to the DHW circuit, but at the same time, the circulation of liquid in the heating circuit stops.

During operation in heat supply mode, heat is supplied to the coolant from combustion products. While the device is operating in water heating mode, heat is supplied to the thermal carrier, and then to the DHW circuit. Fluid movement should not occur in two circuits at the same time.

to come back to the beginning

A gas boiler is a complex system, and the main danger lies in the use of explosive fuel. To control the operation of the boiler, specialized automation is turned on, which changes the ideal operation of the unit. If your boiler doesn't work when you turn it on, make sure someone hasn't accidentally turned on the thermostat. You need to turn it on, set the temperature and wait until it rises to this temperature. You need to check whether the warning light turns on and turn off the gas supply.

If your device does not stop working due to overheating, then in this case the repair of AOGV boilers will consist of cleaning the pipe coil. If your overheating meter trips, you need to immediately turn off the boiler and call a repairman. Prevention, repair and safety

When using boilers to heat water, it is recommended to follow these rules:

- To prevent scale from appearing in the heat exchanger very quickly, you should use water at a temperature of no more than 45°C;

- clean the pipe coil once every 2-5 years, depending on the hardness of the water, the heating temperature and the amount of water used;

- install a filter at the cold water inlet, which should be cleaned and changed occasionally.

As for safety, we recommend buying a gas boiler to heat water with additional safety components. It can be:

- blocking thermostat that turns off the gas supply if the water overheats;

- flame meter when the fire dies out, turns off the gas supply;

- a meter that controls the thrust;

- shutdown device when the liquid level is insufficient;

- blockers that are triggered when the electrical power supply changes, when the gas supply is turned off, when the water supply is turned off.

Condensation in the impulse tube

Symptoms of this situation - when there is a request for heating or domestic hot water, the burner does not ignite, but the circulation pump and fan turn on. There may be several reasons, from malfunctions of equipment components (fan, differential smoke relay, electronic board), to the influence of external factors, moisture ingress or condensation. Water in the boiler can be formed due to an incorrect slope of the coaxial set (for traditional boilers it should be negative, that is, 2-3° down from the boiler). The operation of the fan in the boiler unit is controlled by the control board using a device such as a differential smoke relay (or presosstat ). It is connected to the fan by pulsed silicone tubes (or one), depending on the manufacturer and operating scheme.

The pressure switch measures the pressure difference between the outlet of the blower side of the fan and the pressure inside the sealed combustion chamber. When the fan is turned on, a pressure difference is created in the pressure switch cavity, while the diaphragm acts through the rod on the microswitch and switches it. The cold air that enters for combustion is slightly heated by hot flue gases passing through the inner pipe to the outside. By acting on the chamber elements, it leads to their cooling and, under certain conditions, condensation of water vapor occurs. Even a small drop of condensate formed in the impulse tube can lead to equipment shutdown, because it will interfere with the transmission of the impulse to the pressure switch.

If this situation occurs, you must call a service engineer for repairs. But if the engineer cannot immediately arrive at the site, you can use a temporary solution - dry it with a household hairdryer. After opening the plug in the boiler, turn on the hairdryer and let it work for about a quarter of an hour. Thus, the combustion chamber warms up, which leads to evaporation of condensate. As a rule, this problem is solved by installing, instead of one connecting impulse tube, a set consisting of a tee and three tubes, where two are connecting impulse tubes, and condensate is drained through the third, or Just put on some insulation that will prevent the tube from cooling down significantly. This design is already used in many boiler models already in the factory version.