Among the many heating systems produced in European countries, one of the leading positions is occupied by gas boilers from Vaillant.

They demonstrate exemplary performance, with a service life of 20 years or more.

The high quality of the equipment is due to the long history of the company, which dates back about 140 years.

During this time, extensive technological experience has been accumulated, which has made it possible to create installations known for their quality and operational stability throughout the world.

Let's consider the features of operation of gas boilers ]Vaillant[/anchor].

Installation of a Vaillant gas boiler

The main condition for ensuring correct and stable operation of the boiler is the correct choice of room. If the installation is not in the kitchen or other living room, it is necessary to provide frost protection.

At the same time, it is necessary to organize high-quality ventilation and install grounding, without which the unit will not be able to operate. When installing, you must observe the established gaps and distances from the nearest walls or window openings.

Connecting pipelines must be done carefully so as not to confuse them with each other . All gas connections are checked for leaks using a soap solution.

NOTE!

It is not recommended to install Vaillant boilers yourself, as this excludes the possibility of warranty service for the boiler. It is necessary to entrust the installation to technicians from the service center.

Types of boilers for heating Vailant

All modifications of Vailant gas boilers, according to reviews, have proven themselves in operation. The main rule is to follow the manufacturer's recommendations. For example, condensing heaters last longer if the coolant temperature does not exceed 50 degrees. This is ideal for heating your home with underfloor heating.

Convection gas boilers Vailant

Sectional view of a convection boiler.

Vailant convection gas boilers are available for wall or floor mounting. There are single-circuit and double-circuit. There are differences in combustion chambers: open or closed. Units with a closed combustion chamber are equipped with turbocharging.

The boiler burner is always steel. The heat exchanger is made of copper or cast iron. Malfunctions of the Vailant boiler are mainly related to the quality of the coolant. If the water is too hard, water settles on the walls of the heat exchanger, as a result of which the efficiency drops significantly. The solution to the problem is acid washing.

These are modern heaters that are equipped with everything necessary for the correct and safe operation of the heating system:

Before connecting an electric boiler to the heating system, you need to find out whether your network can handle such a load.

Read about selecting the power of an electric boiler for heating your home in this article.

There is also a built-in liquid crystal display, which displays information from the control unit. Boilers are produced with power from 15 to 47 kW. Natural gas is used as an energy carrier. The cheapest model costs 45 thousand rubles, the most expensive – 500 thousand rubles. Units with a cast iron heat exchanger are more expensive than those with a copper one.

Condensing heating boilers Vailant

The operating principle of Vailant condensing heating boilers is completely different from convection boilers. In a conventional boiler, a fire burns on the burner, which heats the heat exchanger. This produces smoke, which is immediately discharged into the chimney. The temperature of the exhaust gases is 140-200 degrees. The gas does not cool below the lower limit.

Sectional view of a condensing boiler.

Vailant condensing boilers have a heat exchanger that heats up from the fire and then cools the smoke, taking away thermal energy from it.

That is, the smoke goes outside already cooled, and accordingly, most of the heat goes to heating the room. But there is also a by-product of such work - condensation, which forms when the smoke cools.

Condensate is removed from the boiler through specially designed channels and enters the sewer system.

Thanks to this operating principle, the efficiency of the heater increases. Reviews of Vailant gas boilers confirm the efficiency of the units is 98%. Manufacturers' statements about 104% efficiency are complete nonsense. The heaters differ:

- by installation method - floor and wall;

- by the number of circuits - double-circuit and single-circuit;

- according to the design of the combustion chamber - open and closed type;

- possibility of use in cascade installations;

- power – from 4 to 294 kW.

There may be several options for the wiring diagram of an electric heating boiler. Surely you can only determine it by location.

To understand the design of an electric heating boiler, click here.

The cost starts from 97 and ends at 700 thousand rubles. Condensing units require a special acid-resistant chimney. If you use a regular one, then malfunctions of the Vailant gas boiler are simply inevitable. All heaters are equipped with an electronic control unit, a display and many sensors that make the boiler safe to operate.

Electric boilers Vailant

The Vailant company produces exclusively single-circuit wall-mounted electric boilers, which differ only in power. It can vary from 6 to 28 kW. The power is adjustable, so the unit can operate in both high-temperature and low-temperature heating systems. The latter includes the “warm floor” system.

An electric heating element acts as a heater.

Features of this boiler:

- there is a built-in expansion tank and pump;

- you can connect an indirect heating boiler;

- there is a mechanical pressure gauge;

- It is possible to synchronize the operation of the boiler according to the weather.

The main malfunctions of the Vailant boiler are associated with the failure of the heating element. This is not a serious breakdown and replacing the heating element takes about 10 minutes. It is undesirable to use antifreeze in such boilers, since the heating element overheats it and the antifreeze turns into acid.

Indirect heating boilers Vailant

According to technical characteristics, Vailant single-circuit gas boilers cannot heat water for domestic hot water supply, so an indirect heating boiler is connected to them. This is a container that contains water for household needs. It heats up thanks to a built-in coil through which coolant from the boiler circulates. There can be several coils:

Indirect heating boiler for DHW system.

- one for the boiler;

- one for solar collector or heat pump.

The indirect heating boiler tank is covered with enamel from the inside. There is a magnesium anode inside, which prevents corrosion processes. The anode is a consumable material that needs to be changed periodically (every 2-3 years depending on the operating mode).

Additionally, the tanks can be equipped with fittings for connecting an electric heating element, temperature sensors, and a DHW recirculation circuit. The boiler is insulated with polyurethane foam, all models are floor-standing. The tank volume can be from 117 to 500 liters. Price from 49 to 255 thousand rubles, depending on the volume and configuration.

Source: https://utepleniedoma.com/otoplenie/otopitelnye-kotly/kotlu-vajlant

How to configure it correctly before launching

Setting up a boiler is a complex procedure that includes a number of items:

- Setting the minimum and maximum gas pressure.

- Setting the pump run-on, which determines how long after stopping it still pumps water, helping to cool the heat exchanger.

- Setting the maximum heating power (power limitation helps save gas).

- Burner blocking time, etc.

All these parameters are adjusted in accordance with the design features of a given boiler model and require the presence of a specialist.

IMPORTANT!

It is imperative to ask the technician to show the location of all shut-off devices in order to be able to shut off the flow of gas or water in an emergency.

Choosing a Vaillant boiler yourself

- »

- News

- »

- We choose a Vaillant boiler ourselves.

April 13, 2017

Many of our clients want to figure out for themselves what kind of boiler they are buying.

What is the difference between one and the other? It is for you that today we will tell you about all the features. We will also describe what each letter and number in the name of your future boiler means. First, let's look at the names.

Letter designations.

AtmoTEC are boilers with an open combustion chamber in which smoke is removed naturally through a vertical chimney. When installing such a boiler, the room where it is installed is subject to fairly stringent requirements for the presence of fresh air ventilation. These boilers receive combustion air directly from the room where they are located.

TurboTEC are turbocharged boilers with a closed combustion chamber, the exhaust gases from which are forcibly removed using a special built-in fan. Such boilers are easier to install - there is no need to run a chimney through the roof.

The standard chimney option for turbocharged boilers is to lead a horizontal pipe to the street through a hole in the wall directly next to the boiler. Chimneys for turbocharged boilers consist of two pipes located one inside the other and are called coaxial.

Through one pipe the boiler receives the air necessary for combustion from the street, and through the other it discharges combustion products back to the street.

VU - these letters indicate single-circuit Vaillant boilers that provide heating only. If, in addition to heating, water heating for a hot water supply system is required, an indirect heating boiler is connected to such boilers using a special kit.

Hot water heated in the boiler passes through the boiler coil, thereby heating the water in it. This heating system option is suitable when large quantities of hot water are needed. You just need to select the volume of the boiler according to your hot water needs.

VUW - Vaillant boilers with this letter designation are double-circuit. They have two heat exchangers, one of which is responsible for heating, and the second for heating water for hot water supply in flow-through mode. This option is more compact, does not require a boiler room and is more economical to purchase, since there is no need to purchase a boiler.

PLUS – this is how boilers of improved configuration with a high level of comfort when preparing hot water are designated. Comfort is achieved thanks to the “quick start” function. Vaillant boilers of this series always have a small amount of hot water ready, and the user does not have to wait for it to heat up when turning on the tap.

PRO – letter designation for boilers in economical configuration. Boilers of this series are produced with a power of only 24 kW and only in a double-circuit version. Purely externally, they differ in the absence of a decorative plastic cover covering the control panel.

The main internal difference from the Plus series is the lack of a quick start function. Also, these boilers have 4 liters less volume of the built-in expansion tank than Plus series boilers.

Thanks to these differences, the price of PRO series boilers is significantly lower than their PLUS series counterparts, and they are most widespread among consumers.

INT is a marking of Vaillant boilers manufactured specifically for the CIS (which have modifications and improvements necessary to work in our conditions. For example, in the secondary heat exchanger the distance between the plates has been increased to 3-4 mm to increase the time between cleanings).

Digital symbols.

Let's look at the digital designations using the example of boiler 242/5-5

The first two digits indicate the boiler power, in our example it is 24 kW. The third number indicates the type of boiler. 0 – atmospheric, 2 – turbocharged, 3 – condensing. In our example, the number 2 is in third place, which means this is a turbocharged boiler.

The fourth digit indicates that the boiler belongs to a certain generation of boilers. So, 3 is the designation of boilers of the previous generation (which were on sale until mid-2015). If your boiler has a 2 in the fourth place, then it is a boiler of an even earlier MAG generation.

In 2021, Vaillant launched 5th generation gas boilers on the market, which are now on sale.

Both the appearance of the boiler has undergone changes (it began to look even more modern and elegant, in particular due to the new control panel with bright backlighting), and its “filling”.

The number of error codes has been increased, so now it is even easier for the technician to identify the cause of problems in the boiler without disassembling it. There is no longer a pressure gauge on the front panel of the boiler; its readings can be seen on the screen.

The last digit shows whether the boiler belongs to the PRO (3) or PLUS (5) series. In the example of the latter there is a number 5, which means this is a PLUS series boiler. The full designation 242/5-5 refers to the Vaillant TurboTEC PLUS VUW 24 kW boiler.

Story

The German company Vaillant has been producing heating equipment since 1899. Gas boilers are the main direction of its activity. The first double-circuit gas boiler was released in 1967. In 1996, the first representative office was opened in the Republic of Belarus.

Certification

Vaillant gas boilers have a domestic certificate of conformity and other certificates and permits necessary for their installation in the Republic of Belarus (fire safety certificate, sanitary-epidemiological conclusion and permission to use the state service for technological supervision). They meet the requirements of GOST.

Advantages

Vaillant boilers belong to premium class products. Their range of properties guarantees the consumer maximum comfort and safety. According to the manufacturer, each Vaillant gas boiler has a continuous operation life of 5-10 years, already confirmed by experience in the Republic of Belarus.

A specific assembly engineer is responsible for the quality of each device at the plant, whose actions are additionally controlled by a computer. 90% of boiler components are produced at European factories owned by Vaillant.

No spare parts or components are supplied from China.

Important advantages of these gas boilers are their efficiency, reliability and environmental friendliness. Vailant gas boilers are compact and have a modern, stylish appearance. Therefore, many place them directly in the residential area. Its compactness allows you to place this device in almost any room, for example in a pantry.

An additional advantage of these boilers is the possibility of creating a modern automated home heating system with them, the participation of a person in the operation of which is minimal. This is achieved by connecting weather-sensitive heating controllers and outdoor and room temperature sensors.

Built-in time programs allow you to program the boiler for a long period of time.

Work on liquefied gas

The factory equipment of Vailant gas boilers implies operation on main gas. If necessary, any boiler can be converted to liquefied gas. To do this, you need to purchase a special reconfiguration kit, which is a frame with jets.

Guarantee

The manufacturer provides a 2-year warranty for Vailant gas boilers. 2 years are calculated from the moment the boiler is put into operation.

For the warranty to be valid, it is necessary that the first start-up of the boiler is carried out by a certified specialist, who will put a note about this in the device passport.

The buyer receives a completed warranty card when purchasing the boiler and presents it to the service center for warranty work if necessary.

Use of antifreeze

The manufacturer recommends that users of Vailant gas boilers refrain from using antifreeze as a coolant.

The chemical composition of these fluids is such that they can corrode seals and cause other damage. Also, the presence of antifreeze in the heating system can cause noise in it.

Therefore, it is unacceptable to install these boilers in rooms where freezing is possible.

Here you and I got acquainted with Vailant boilers in more detail. If you have any questions, you can always call us at +375 (33) 66-11-471 (MTS) or write to us by E-mail: [email protected]

Well, if everything is clear to you, then we suggest you move on to choosing the Vaillant boiler you are interested in.

We wish you a pleasant shopping experience.

Source: https://vodateplo.by/news/vybiraem-kotel-vaillant-samostoyatelno-

User manual

The boiler is turned on by simply pressing a button. After this, the display will turn on.

A flashing symbol will indicate low water pressure. Having opened the feed tap, fill the system, checking the flashing indication . When the nominal pressure is reached, the indicator will stop flickering.

If the pressure drops, then there is a leak in the system that needs to be found and repaired.

By double pressing the left button of the “I” group, the current and permissible pressure values will be displayed, which is very convenient and useful for the operation of the boiler.

Download instructions

Vaillant boiler operating instructions.

Connecting an indirect heating boiler

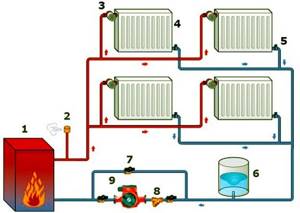

If the heating system is built on the basis of a single-circuit boiler, it is necessary to determine the source of hot water. The simplest solution is to install a regular electric boiler in your home. But it will consume expensive electricity, which is not very profitable. It is much cheaper to connect an indirect heating boiler to the heating circuit.

The easiest way to connect a boiler to a boiler is to install small collectors and connect to them a pipe with a circulation pump and a check valve, which will go to the water heater, as well as a return pipe. By controlling the operation of the circulation pump, the boiler will turn the coolant supply on and off, regulating the temperature in the built-in tank. It is also possible to implement this circuit without a collector.

It is also possible to connect an indirect heating boiler through a three-way valve - it switches the flow of coolant from the heating circuit to the water heater itself. This ensures that the set temperature is maintained.

The efficiency and safety of a gas boiler largely depends on its correct connection to the heating system. This process, also called strapping, consists of several stages. Due to the fact that gas is a very dangerous fuel, some work must be carried out by certified gas service employees, but much can be done with your own hands.

Connecting a wall-mounted gas boiler is a complex of works that includes: piping in the heating system, connecting to the gas and electrical networks, and installing a chimney. In this article we will try to talk about each of the stages.

First start

The first start of the boiler will require filling the system with water, the quality of which must meet all existing requirements.

To start you need to do the following::

- Open the valves of all radiators in the system.

- Slowly fill the system with water to allow air to escape.

- Bleed remaining air from the radiators and boiler.

- Check the pressure on the display and fill in the missing amount (or remove excess).

- Turn off the feed tap and disconnect the system from the supply pipeline.

Before starting, you must once again check the tightness of all connections. If the check shows that everything is in order, the boiler is turned on using the button and the required temperature of the heating system is set.

From this moment the system will begin to work.

How to connect a gas boiler to water heating in a private house

Let's start looking at examples. In order not to duplicate information, we will consider a diagram for connecting a double-circuit gas boiler to a heating system (we use a turbocharged boiler). Single-circuit modifications are connected in a similar way, only minus the DHW circuit (which only simplifies the task). In our example, we are installing a closed-type heating system without heated floors, additional circuits and boilers.

The heating boiler connection diagram includes the following steps:

- Connection of equipment to the chimney.

- Connection to the gas main.

- Connection to water supply.

The procedure begins with marking the location for installing the boiler. A stable base is made for the floor-standing device, for example, from a concrete screed. Installation on flammable substrates is not permitted. Wall-mounted models are hung on special brackets. The fasteners must be strong enough to support the weight of the boiler.

Connection to the gas main

To connect the heating unit to the gas main, use a flexible hose connected to the gas pipe. You can also “plant” the device on a rigid metal pipe, but this is not so convenient. The circuit must include a filter that prevents the smallest debris from entering the gas units. When using volatile boilers, dielectric insulators are installed here.

Connection to chimney

Coaxial chimneys act as air intakes and at the same time ensure the removal of combustion products. Even inexperienced installers can cope with their connection.

The boiler is connected to the home chimney using pipes of a suitable diameter - they are sold in any specialized stores. The easiest way is if the heating system uses turbocharged units (with closed combustion chambers). Their advantage is that they require traditional chimneys. Instead, coaxial chimneys are used here - double, pipe in pipe.

In most cases, these chimneys are led outside the wall on which the boiler itself is mounted. It is also possible to remove them behind any other walls (with extension).

Connection to the water supply system

We continue to connect the gas boiler in a private house to an autonomous heating system. Our next task is to connect both circuits. First, let's look at the hot water supply circuit. Everything is simple here - we install a tap and a coarse filter at the inlet to avoid contamination of the secondary heat exchanger with small mechanical inclusions. We install another tap at the hot water outlet and connect a pipe to it through which water will flow to the water collection points.

How to increase or decrease the temperature?

The temperature is adjusted using the corresponding buttons located on the control panel.

In the display menu, select the “temperature setting” area, after which the “+” or “-” buttons adjust the value of this parameter . It is necessary to take into account that the temperature in the room rises gradually; you should not expect an instant change.

You can check how successful the adjustment is only after 20-30 minutes, after which you can make additional adjustments.

How to raise or lower pressure?

The pressure in the boiler should be between 0.8-2 bar (0.08-0.2 at). For adjustment, use the feed tap and buttons on the control panel.

By double pressing the “I” button, the system pressure menu is called up, where the current parameter value will be displayed. Using the make-up valve, the pressure increases to the required value, after which the valve is closed.

To reduce, a relief valve is used, which can also be activated automatically when the limit value is reached.

Systems with two boilers

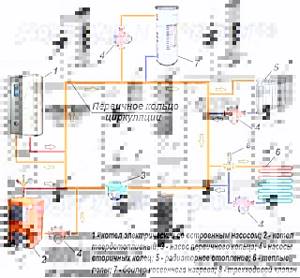

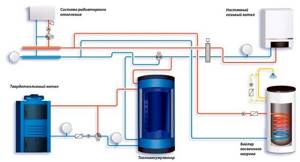

If it is necessary to organize heating of the coolant in a closed circuit from two heat generators, use the parallel connection principle. Let us explain the algorithm for the joint operation of two boilers - electric and solid fuel (the piping is shown in the figure):

- The main heat source is a TT boiler, connected in the standard way through a three-way valve. To prevent flows from looping in the other direction, a check valve is installed on each branch.

- When a stack of firewood burns out, the air in the house begins to cool. The temperature drop is detected by the room thermostat and starts the electric boiler with a pump.

- A decrease in the temperature in the supply line of the TT boiler to 50-55 °C causes the overhead thermostat to turn off the circulation pump of the solid fuel circuit.

- After the next loading of firewood, the supply pipe heats up, the temperature sensor starts the pump and heating priority returns to the solid fuel unit. The room thermostat no longer turns on the electric boiler because the air temperature does not drop.

It is also necessary to install a safety group at the output of the electric boiler; it is not shown in the figure.

Important point. The above-described piping option can be used for any pair of boilers. When installing a wall heater, a second pump is not installed.

Two heat generators, for example, gas and electric, are easily connected through a heat accumulator. The turning on and stopping of both boilers can be organized in various ways - by the temperature of the water in the tank, by time using a timer. Check valves are not needed here.

If it is necessary to connect 2-3 units of thermal power equipment with several heating circuits, it is better to assemble a diagram of primary / secondary rings. The principle is as follows: all heat sources and consumers with their pumps are connected to a common ring made of a pipe of increased diameter Ø26...40 mm (depending on the number of branches). Circulation inside the ring is provided by a separate pump.

The order of equipment installation matters: the water heater receives the hottest coolant, followed by the batteries, and finally the TP (along the water flow)

In a system with natural coolant movement, two boilers are also combined in parallel. Here it is important to withstand slopes of pipes Ø40...50 mm, and also to avoid sharp turns, using bends at an angle of 45° or bends with a large bend radius.

The water diverges along two parallel branches with boilers. But the unit that is currently turned on will make it move by gravity; the pump starts at the request of the owner

Advice. A series connection of 2 units has a right to life, but it is better not to use such a connection. Water heated in the first boiler will pass through the cold heat exchanger of the second and will certainly lose some of the heat.

Connecting a room thermostat

A room thermostat is a device that controls the temperature in a room and regulates the heating system accordingly.

Using this device allows you to save about 20% on heating. This effect is achieved through more rapid adjustment of the system temperature. The boiler's own sensor is guided by the temperature of the coolant.

When it warms up outside, the house becomes too hot, but no changes occur for the boiler system as long as the coolant temperature is within the specified limits.

The room thermostat is guided by the air temperature, so it immediately sends a command to change the heating mode.

To connect the device, the corresponding contacts on the control board are used, connected in normal mode by a special jumper.

NOTE!

Connection and initial setup should be entrusted to a specialist from the service center.

Design, electrical and hydraulic circuit, operating principle of the Vailant gas boiler

Construction of Vailant boilers

Electrical diagram

Let's look at the design of the Vailant boiler using pictures and diagrams from the installation manual. For correct settings during installation and troubleshooting, a circuit diagram is required. It shows exactly where all the components of the device are connected to the electrical control board.

The electrical circuit for a specific model of gas heating apparatus may differ slightly from the standard one. To make repairs and adjust a specific model, you need to use the operating instructions that come with each device.

Hydraulic circuit

The hydraulic diagram of the boiler operation shows all the nodes that the liquid passes through during the heating process. There are five pipes located below, two each for hot water supply and heating and one supplying gas.

Cooled coolant from the heating system enters the right outer pipe. The liquid passes through a three-way valve, a circulation pump and enters the primary heat exchanger. There it heats up and exits through the filter from the left outer pipe into the heating system. If hot water supply priority is set, it passes through a secondary heat exchanger, heating water for domestic use. A three-way valve controls the direction of coolant flow.

In the second pipe on the right side, cold, clean water enters, goes into the secondary heat exchanger, and from there the already heated water exits into the second pipe on the left.

Features of single and double circuit models

Single-circuit wall-mounted boilers, such as Vaillant Turbotec plus VU, are characterized by their simple design and compact size. Their main disadvantage is that they do not provide the user with hot water supply. In order to heat running water with it, you will have to additionally purchase and install an indirect heating boiler.

Vaillant Turbotec plus VU boilers

Double-circuit models such as the Vaillant 240 are equipped with a steel secondary heat exchanger with thin walls, allowing heat to be transferred from the coolant to running water.

Double-circuit devices with a built-in boiler are also available. They are large in size. The water tank is located at the bottom of the body. This is how Vailant models such as AtmoCompact and AtmoVit Combi are designed. Let's look at how a typical double-circuit boiler works.

Principle of operation

Let's look at the operating principle of Vailant gas boilers. They are designed for space heating and water heating for domestic use. They are connected to a heating system with radiators located throughout the house. When the coolant inside cools down to a certain temperature, the thermostat is activated. It sends a signal to the control board.

From there comes a signal to turn on the circulation pump, open the gas valve and supply electricity to the ignition electrodes. The gas begins to burn in the burner, above which the main tubular heat exchanger is located. In it, heat is transferred from the combustion of gas to the coolant in the tubes.

When the water in the heating system heats up to the temperature set in the settings, the thermostat is activated again and the boiler stops operating. When you turn on a hot water tap, a three-way valve is activated, which directs the heated coolant to the secondary heat exchanger. There, through the thin walls, heat is transferred to the tap fluid.

In some series, for example, Vailllant Turbo, it is possible to connect an external room thermostat. In this case, you can adjust the heating to the desired room temperature.

Vaillant Turbo boilers

Condensing models such as Vailant ecoTEC have a specially designed heat exchanger that allows additional use of the heat of volatile combustion products during their condensation.

Area of use and technical characteristics

Vailant gas boilers are designed for heating domestic and industrial premises. Depending on the model they have different power ranges. From small devices, for example, Eco Compact at 4 kW, to devices with higher power, for example, Eco Craft VKK at 294 kW. Also, if necessary, a number of models can be connected in a cascade to accumulate the generated thermal energy.

Both wall-mounted and floor-standing units are available. Depending on the type of combustion chamber, atmospheric and turbocharged series are produced. For example, Vailant T3 and T4, where T3 is equipped with an atmospheric combustion chamber, and T4 is equipped with a closed combustion chamber. The heat exchanger is made of copper, stainless steel or cast iron.

All devices are equipped with modern protection devices: against freezing, overheating, fire extinguishing and lack of draft. Some devices can operate on both natural and liquefied gas. All boilers have an electronic control system and automatic ignition. Modulating burners allow you to smoothly change the required work intensity.

boilervdom.ru

Optimal operating mode

The boiler operating mode must be configured in such a way that all parameters are within the limits permitted by the instructions.

At the same time, the design of the unit is such that the very concept of “optimal” is vague and very vague. The installation works perfectly in any mode, the main thing is that the gas and water pressure is not below or above the limit values.

In addition, Vaillant boilers are sensitive to a stable power supply voltage and are phase-dependent - when connected, the phase must be connected to the desired electrode, otherwise the boiler will not start.

Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside directly through the wall of the house.

Photo 4: Installation of a coaxial chimney for a turbocharged boiler

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heating device is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their operation. It is supplied inside the device through one of the channels of the coaxial chimney. The second channel is used to discharge flue gases into the atmosphere. A coaxial chimney is very easy to install and you can connect a gas boiler to it yourself.

Return to contents

How often and how to properly service

Vaillant boilers are serviced annually. For this purpose, a specialist from the warranty workshop with the appropriate qualifications and approval is invited.

He cleans and makes the necessary adjustments to the boiler and performs other necessary work. Maintenance (scheduled work) should not be confused with repairs, which are carried out as necessary at any time.

To perform this, you should also use the services of technicians from the service center.

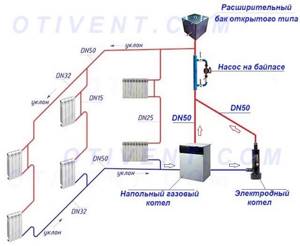

Forced circulation circuits

If forced movement of the coolant in the network is provided, then the previous piping scheme for a floor-standing gas boiler is supplemented with a circulation pump. As a rule, in networks with 1-2 branches, the pump is installed on the return line before entering the heater, and it is recommended to install a strainer before it. In this case, the diameters of the pipes will be smaller, as will the slopes (at least 2 mm per 1 m of main line). The expansion tank can be used closed and also connected to the return:

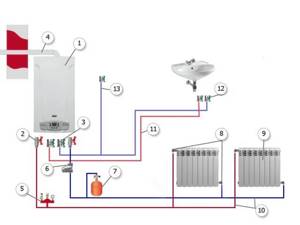

1 – floor gas heater; 2- safety relief valve; 3 – radiator thermostatic regulator; 4 – radiator; 5 – balancing valve; 6 – expansion tank; 7 – bypass with ball valve; 8 – filter – mud collector; 9 – circulation pump.

Many models of modern heating boilers are equipped with a built-in circulation pump, which simplifies their connection. In a situation where there are several different heating systems in the house (radiators, underfloor heating, indirect water heating boiler), we recommend a piping scheme for a gas heating boiler with hydraulic division into circuits (hydraulic arrow).

The division into contours is necessary for two reasons:

- Heating circuits A, B and C require coolant with different temperatures, and its flow rate in each branch is different.

- A hydraulic arrow device is the best way to balance the entire system.

Ideally, the operation of all branches (except for DHW) is controlled by a single automation unit (controller). Connected to it are sensors located in all rooms and recording the air temperature. They transmit impulses to the controller, which maintains the temperature in the house by turning on or off the circulation pumps of each branch. The boiler circuit operates hydraulically independently, heating the coolant as needed.

Recently, wall-mounted heat generators have become increasingly popular. They are compact, easy to use and, as a rule, have the function of heating water for household needs. The functional diagram for connecting a mounted gas boiler is as follows:

1 – wall-mounted gas boiler; 2 – ball valve of the heating supply/return line; 3 – shut-off valve for cold water supply; 4 – chimney; 5 – safety group with safety valve; 6 – mesh filter; 7 – membrane expansion tank; 8 – connections to heating devices; 9 – sectional radiators; 10 – supply and return coolant lines; 11 – heated water pipeline to domestic hot water consumers; 12 – shut-off valves; 13 – cold water replenishment.

It is assumed that the double-circuit heating installation is equipped with its own circulation pump and expansion tank for domestic hot water. Otherwise, these elements will have to be installed additionally.

In order to use different types of fuel to heat their homes, homeowners began to install several different heaters in furnace rooms. Accordingly, the question arises, how to connect a wall-mounted gas boiler together with a solid fuel one? The latter type of heat generators is gaining increasing popularity, so it is worth considering just such a tandem in the diagram:

This connection diagram for an electric heating boiler is proposed because of its efficiency and cost-effectiveness in the use of energy resources. The heat accumulator tank accumulates thermal energy during operation of the solid fuel unit, and after the firewood burns out, it begins to release it into the heating main and for the needs of the hot water supply. And only after a long period of time has passed, the coolant in the pipes will cool down and the gas wall installation will come into operation.

Basic error codes and their interpretation

The operation of all boiler components is constantly monitored by a sensor system. When abnormal situations occur, they give a signal to the control board, which is displayed on the display.

The most common error codes:

| Code | Decoding |

| F.00 | Supply thermistor circuit open |

| F.01 | Open return thermistor circuit |

| F.02-03 | Opening the temperature thermistor or storage sensor |

| F.04 | Return thermistor break |

| F.10 | Supply thermistor short circuit (exceeding 130°) |

| F.11, F.14 | Short circuit of the return thermistor (exceeding 130°) |

| F.22 | Dry running (pump fault) |

| F.23 | Lack of water. Determined by the temperature difference between the forward and return lines |

| F.27 | Parasitic Flame |

| F.28 | Ignition lock |

| F.29 | Failure in operating mode (occurs when the flame goes out and the ignition attempt fails) |

| F.35 | Error in gas outlet |

| F.37 | Unstable or abnormal fan speed |

| F.72 | Error in forward and/or return line sensor readings |

| F.75 | The pump is unable to raise pressure |

| F.76 | Primary heat exchanger overheating |

The appearance of one or another error does not always mean a breakdown. You need to restart the boiler and see if the error appears again or not.

If after several attempts the error appears again, you should contact a repair company..

Boiler repair Vailant - answers from experts

___________________________________________________________________________

- Gas heating boilers Vaillant Turbotec / Atmotec

- Vaillant Turbotec / Atmotec - Operating functions

- Vaillant Atmotec – Instruments and automation

- Vaillant turbotec 242 - Design and installation

- Errors and malfunctions of Vailant boilers

- Buderus and Vaillant - Information

Question:

The Vaillant AtmoTEC pro boiler has stopped working and shows error F28. When you turn it off and on, it makes some sounds and that’s all, when you turn on the water, it also doesn’t react at all.

I once had the same problem, I decided to turn the socket plug 180 degrees. Now it doesn't work. The boiler is connected through a stabilizer. What could it be? Answer:

Error in the gas supply line, for example: - the gas meter or device for monitoring gas pressure is faulty.

- air in gas.

— gas exhaust pressure is too low.

— the fire hydrant worked. Gas fitting error (main gas magnet or operator faulty), incorrect gas setting, faulty ignition system (ignition transformer, ignition cable, ignition plug), interruption of ionization current (cable, electrode), incorrect gas fitting setting, incorrect grounding of the device, faulty electronics . Question:

Please tell me, the vaillant TurboTEC boiler changes pressure when the temperature changes, I think this is due to the pressure in the expansion tank, what can be done? Answer:

Pump up the expansion tank. Question:

The Vaillant turbo TEC pro VUW INT 202-3M R1 boiler takes 30 cubic meters of gas per day at a temperature of 50 degrees. Is this a lot or a little? There is very hot air coming from the chimney; it is impossible to hold your hand. Answer:

Perhaps the upper heat exchanger needs to be cleaned and rinsed; it would be better to measure the temperature at the chimney, otherwise for some they can’t keep it at 50 degrees either. Question:

There is an AtmoTec VUW INT 240/3-3 boiler, born in 2010. The call was about a leak (this is nonsense, the gaskets on the connections were leaking). The device itself turned out to be frozen along the DHW circuit.

After defrosting, an attempt was made to start the boiler: P = 1.1 bar, according to self-diagnosis, the boiler is at S97 (pressure sensor poll), after three attempts error F75. I removed the capacitor, measured the capacitance, and got 1.6 microfarads, instead of the required 2.6. I changed the condenser, the pump starts, again S97 and then again F75.

I rinse the supply filter, rinse the bypass (which turned out to be stuck), check the 3-way valve (it works), rinse the main heat exchanger along with the pipes, change the pressure sensor to a new one, connect the supply with the return hose (for circulation), start it up, and again I still get what I had, the boiler polls the sensor (S97) and then issues F75.

So what should we do with it? And the second question, about the pressure sensor, what is there at its ends? voltage (what value?), digital signal or resistance change? (again, what is the meaning?) Answer:

The pressure sensor there monitors not only the pressure in the system, but also the change in pressure after turning on the pump by changing the resistance of the sensor. Otherwise - error F75.

If the hydraulic resistance of the coolant flow is low, then the manufacturer recommends pressing the tap on the supply to the system. Question:

I have a problem with the Viallant TurboTEC pro 242 boiler, error f28, but it doesn’t even try to ignite (no spark, no gas flowing). I disassembled the gas valve and cleaned it (there were some small “chips”, but overall everything looked fine).

Then I noticed that there was no power to the 22V valve itself - generally 0V. I tried to supply external power to the inlet gas valve - it clicks audibly - that is, it works, but this did not change the situation.

When turned on, you can hear that it moves the actuator of the gas regulator (which is directly on the gas valve) and also clicks something, but does not try to ignite - there is no spark, it immediately gives an error.

I checked the power supply - the grounding is in order, the only thing is that the voltage itself is increased - 260V. What else can you check? How to check the ignition trans and ionization module? Answer:

If there is no spark, why clean the gas valve? The problem is clearly with the board. Question:

I have a Vaillant turbo tec pro boiler. When I open the hot water tap, the temperature quickly heats up to 60 degrees and the boiler turns off, and until the water turns on again it comes out cold and repeats again. The pump is working, the heat exchanger has cleaned everything clean.

I noticed that the gas valve increases the flame, and when the water heats up, it does not reduce, but turns off the flame, so by the time it turns on again the ox is already cold. Please tell me what to do? Answer:

The gas valve is not adjusted correctly or the hot water flow is very small. Set the minimum gas pressure on the burner. Check the three-way valve and secondary heat exchanger. Question:

The boiler is Vailant Turbotek VUW INT 322/3-5, it has a turbine with adjustable rotation speed, like on condensers, and a simple pressure switch 80/68 Pa.

The boiler takes a very long time to turn on the heating, the draft check indicator lights up, but does not go into trouble (the heating may start after 5 minutes, or maybe after half an hour).

On DHW it works normally, since the turbine immediately begins to rotate at high speed. All pipes and tubes are intact, clean and dry. Before this, it worked fine for two and a half years.

As I understand it, the problem is in the pressure switch, if you have any other ideas, please pay attention. And the question is, if you change the pressure switch, then to the same one (with the same parameters), or maybe it would be better to take, for example, 67/57, so that it will definitely work? Answer:

First, clean the turbine blades. Install a more sensitive pressure switch or adjust this one. Question:

Can anyone explain what the difference is between F36 (exhaust alarm) and S52 (boiler waits for 20 minutes due to exhaust), under what conditions do they trigger? Answer:

Vaillant boilers have a very interesting system for controlling the removal of combustion products (chimney boilers); they have two NTC sensors that measure the combustion temperature and the draft sucked in by the draft stabilizer.

Depending on the temperature difference that becomes less than a certain value at the moment the burner burns, the automation decides to delay state S52 for 20 minutes and tries to start the boiler again.

If, after a number of attempts, the removal of combustion products does not satisfy the requirements of the automation, it blocks the device and issues ERROR F36. Without human intervention, the boiler will not start. (On the priority of anti-freezing, you need to further raise the information).

The same applies to boilers with a closed combustion chamber. Only there the pressure switch is triggered and first again S52 and then F36. That is, the unit is not immediately blocked, but gives the chimney a chance to think, maybe the weather will change, the wind will subside. Question:

Boiler Vaillant TurboTec pro VUW INT 242/3-3. Service life is more than 5 years. About once every six months I clean the secondary heat exchanger and once a year the primary heat exchanger from scale.

Three days ago, when filling the bath with hot water, the water stopped heating. The green LED does not blink when the hot water tap is opened. The heating works properly. Turning the boiler on and off did not help. Checking the sensor contacts - everything is clean.

I did not visually detect any defects on the control board. Cleaned the secondary heat exchanger from scale. The water does not heat up and the green LED does not blink. Please tell me what could be wrong? Answer:

You need to check the flow sensor. Question:

Boiler Vailant 242/3-3M. After dispensing hot water from the boiler, the sound of water can be heard for some time, as if it was pouring from above. Then the pump stops, switches to heating and everything is ok. The same situation occurs with all closed radiators and heated towel rails. Does it push water through the bypass? And where does the sound of water come from? Answer:

Something like this, and a little more air in the pump. You need to open the automatic air release cap on the pump. You can also unscrew the plug on the pump drive and let out the air.

Question: Can I put anything other than water into the Vaillant boiler? Our power often goes out and we are afraid of the system freezing. Answer: It is recommended to fill the system only with water or, in extreme cases, coolant intended for this brand of boiler. To avoid the consequences of a power outage, we strongly recommend purchasing an uninterruptible power supply. The UPS allows you to maintain correct operation of the boiler for several hours. Question: We have a floor-standing gas Vaillant in our private house. It stopped working, the control panel went out. I want to check the fuses, but where are they located? Answer: To begin with, you can do the following yourself: unscrew the cap on the left, there will be an overheating fuse or an STB button - press it with something thin like a match. Another fuse is located in the underground part; the compartment can be opened with a screwdriver. Or unscrew the panel, there is also a fuse there not far from the board. Question: During a severe thunderstorm, the Vailant gas boiler stopped, although it was connected through a stabilizer. The house is very far away, you will have to figure it out yourself. Where to begin? Answer: Start by checking the fuses: they could have blown due to a sudden power surge in the network. The board may have burned out, and the boiler will be completely extinguished. Replacing the board is easy and you can actually do it yourself.

You just need to know exactly the part number of the board and the boiler model. For the future: the stabilizer does not contain voltage surges due to the long response time. We recommend purchasing a UPS. Question: There is a problem with a 2-circuit gas boiler: a large flame immediately lights up, but gradually goes out and soon the boiler stops. After a restart everything repeats. Can you tell me the reason? Answer: To accurately determine the cause, it is necessary to diagnose the boiler. In this case, it is necessary to measure the pressure in front of the gas valve and behind the valve at the moment of starting the boiler. It is necessary to measure the voltage supplied to the solenoid valve. And make adjustments. Perhaps the problem will be corrected after proper adjustment. Question: The Vaillant 240 device does not start: it clicks a little and the “flame” icon blinks, but it does not turn on. What is the reason? Answer: The boiler signals that the heating system is clogged. Perhaps the dirt filter on the system is clogged or there are problems with the sensors. Question: The floor-standing gas Vailant has been operating for more than 10 years, but recently it has sometimes started to light up with a bang. How serious is this violation and why does it appear? Answer: There are several possible reasons for gas popping when starting the boiler. The burner elements may have burned out, or the gas supply in the system may be unstable. Sometimes the draft in the boiler room “overturns”: there is not enough circulation through the chimney at the time of startup, and cold air descends into the pipe, causing an accumulation of gases and a characteristic bang. Question: In our country house, a Vaillant 11 kW boiler gives error F9. What do you advise? Answer: Judging by the error code, the fan in the boiler has failed. The first reason is that the chimney is clogged, and condensation and build-up need to be cleaned. But it is possible that the draft relay in the chimney has burned out or the sensor has failed. Question: I have a Vaillant VUW INT 240/2-3 boiler installed in my private house. Works for 2 months without problems. The heated area of two floors is 90 sq. m. m. Does it make sense to reduce the boiler power (let's say up to 12 kW)? And in this case, will there be savings in gas consumption? Answer: Yes, you definitely need to reduce the power. The factory default setting of the boiler is 24 kW. You need a maximum of 10-12 kW. You will achieve gas savings. The boiler will operate in a smoother (more correct) mode. If you leave everything as is, then the formation of a “clocking” of the system is possible. When the boiler fails due to rapid heating. Question: Vaillant TURBO TEC PRO double-circuit boiler, when drawing hot water, the boiler does not ignite, the water is cold, but the heating works normally, the boiler ignites. What could have happened? Answer: It seems that the boiler “does not see” the need for DHW, so it does not switch the three-way valve to heat DHW. Most likely, the aqua sensor needs to be replaced. Question: I have a Vailant VUW INT 240/2-3 boiler, tell me why the pressure of hot water in DHW mode is bad and the boiler constantly goes out and comes on (with an interval of 5-10 seconds). Although the cold water pressure is very good. Answer: If the cold water pressure is good and the hot water pressure is poor, then most likely your DHW heat exchanger is clogged. It is there that the pressure is lost due to the narrowing of the passages, and it is because of this that your boiler either works or turns off. There is a temperature sensor on this heat exchanger and in your case it turns off the boiler when the heat exchanger overheats - heating is coming from the coolant. but there is no heat removal. Most likely, you will need to change the heat exchanger. Question: Hello. I have a Vaillant atmo TEC pro boiler, what pressure should be in the expansion tank? Answer: If we talk specifically about the pressure in the expansion tank, then it is 0.75 Bar. If we talk about pressure in the system, then the norm is 1-2 Bar. Question: We use a Vaillant VUW INT 240/2-3 boiler in a country house. When operating in heating mode, sometimes strong popping noises occur during ignition (not always). In DHW mode it works fine. Tell me what is the problem? Answer: Popping noises usually occur due to late ignition. The boiler makes several attempts to light the burner, releases gas each time, and then when ignition succeeds, all the accumulated gas bursts. This is not the correct operating mode and it is not connected to the DHW whether the boiler is running or heating. To eliminate this problem, try cleaning the ignition and flame control (ionization) electrode. Quite often this helps. If possible, observe how the boiler ignites with the lid removed.

If the problem does not go away, then you can change the electrodes - after all, your boiler is no longer new and has worked for at least 6 years (these boilers were no longer supplied in 2007). But the problem could also be in the ignition unit - it is on the boiler’s electronic board. It does not provide enough voltage and the spark is weak. In this case, only replace the board. Perhaps the gas pressure is simply weak and the boiler does not have enough volume that is initially supplied for ignition. Question: When the VAILLANT atmo TEC pro 240/3-3 boiler is closed, the pressure on the water sensor goes off scale. the boiler turns off and says f75. what is the reason? Answer: Error F 75 indicates the following: The water pressure sensor and/or pump is faulty. A pressure surge is not recognized when the pump is turned on. Most likely, the water pressure sensor needs to be replaced. It happens that they fail. If possible, remove it, dry it and blow it out. Try installing again. Question: The Vaillant 28 kW Tek Pro Plus boiler after three attempts goes into error F28. On the gas valve, the gas pressure at the inlet is 160 mm w.c. at the outlet after the first ignition attempt 30 mm water column 2 attempt 50 mm water column 3 attempt 80 mm water column Art. The burner does not ignite even from an open flame during ignition. Answer: Vailant supplies PRO series boilers only with 24 kW of power. Regarding your error, here is what is given in the installation instructions: Error in the gas supply line - the gas meter or device for monitoring gas pressure is faulty, there is air in the gas, the gas outflow pressure is too low, the fire hydrant has tripped.

Gas fitting error: (main gas magnet or operator faulty), incorrect gas setting, faulty ignition system (ignition transformer, ignition cable, ignition plug), interruption of ionization current (cable, electrode), incorrect gas fitting setting, incorrect grounding of the device, faulty electronics. Question: Valliant turbo pro boiler, wall-mounted. Three days ago this problem appeared. When you open the hot water tap, the boiler heats it up 15 degrees above the set value, then turns off and continues in a circle again. Does not depend on the set temperature or how far the tap is open. What could be the reason, before this I heated the water evenly. Answer: Does the boiler display any error on the control panel? It can be assumed that the boiler fails due to overheating of the heat exchanger. Firstly, the temperature sensor on the secondary heat exchanger is not working correctly. Secondly, the temperature sensor on the main heat exchanger is not working correctly. Question:

I installed a Valliant VCW 180E boiler. It is double-circuit, and the water is heated to a maximum of 40 degrees, while the entire system is also cooled to 40 degrees. What to do? Are there options for adjusting hot water? Answer:

Vaillant T-4 VCW boilers do not shut off the three-way valve, most often this is observed due to inadequate operation of the pump in which there is a 2.5 µF capacitor. Capacitors lose capacity up to 0.6 µF.

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and design of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and installation of the Baxi Slim boiler

- Adjustments and maintenance of the Beretta Chao boiler

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the Termet gas boiler

- The meaning of error codes and malfunctions of Vailant boilers

- Determination of malfunctions and errors of Visman boilers

- Questions about servicing Navien boilers

- Questions about malfunctions of Kiturami diesel boilers

- Junkers boilers - Experts answer user questions

- Experts answer questions about Electrolux boilers

___________________________________________________________________________

___________________________________________________________________________

- Answers from Nova boiler repair experts

- Questions about Hermann boiler service

- Answers from Daewoo boiler service technicians

- Questions about servicing Ferroli boilers

- Questions from users regarding the repair of electric boilers Evan

- What causes an AKGV gas boiler to light up and immediately go out?

- What is wrong with the Alpha Color boiler if it shows error code E01

- Why does the AOGV boiler light up and go out quickly?

- How to eliminate error E01 on the Baltgaz boiler

- What is the problem if Dani’s boiler lights up but immediately goes out?

- Why does a Danko boiler light up but quickly go out?

- The Demrad boiler has stopped holding pressure, what is the problem?

- Why did the Gaslux boiler start to get hot and make noise?

- What is the reason if the Keber gas boiler lights up but quickly goes out?

- How to eliminate error code 01 on the Kiturami boiler

- What causes a Conord boiler to light up but immediately go out?

- What is the reason if the Lemax boiler lights up and goes out quickly

- Why does a Mimax boiler light up but suddenly go out?

- Why does the Hearth boiler light up but immediately go out?

- Why does a Ross gas boiler light up but go out quickly?

- What is the problem if the Siberia boiler lights up and goes out suddenly?

- Why does the boiler Signal light up and suddenly go out?

- What can cause a Termet boiler to make noise and get hot?

- Why does the Termotechnik gas boiler light up but suddenly go out?

- How can you eliminate error E01 on a Thermon boiler?

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons does a Ferroli gas boiler display an error code A01?

- For what reason does the Immergaz boiler not operate on hot water supply?

- Why does the Navien gas boiler constantly turn off when heating and then turn on immediately?

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Heating boiler piping

- STS boilers

- KVT boilers for solid fuel

- Pellet boiler Peresvet

- Steel floor standing boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the Termet gas boiler

- Termona boiler repair

- Boiler repair Nova

- Hermann boiler service

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Daewoo boiler maintenance

- Demrad boiler malfunctions

- Mora boiler malfunctions

- Westen boiler repair

- Malfunctions of Immergaz boilers

- Types of solid fuel boilers

- Models and design of combination boilers

- Liquid fuel and double-circuit boilers

- Cast iron boilers on coal

- Boilers with modeling burners

- Imported boilers for heating systems