Electric boiler automation Protherm

What can automation do?

Performs a function such as equithermal temperature control in the heating system.

What it is.

This is regulation of the heating of an electric boiler depending on the outside temperature. Naturally, to perform this function, an outside air temperature sensor must be installed in the electric boiler circuit.

If you use the equithermal control function, for example, when it is zero degrees outside, the temperature of the heating water will not exceed 50 degrees Celsius.

Indeed, why “fry”, heat at full power if it’s warm outside?

At -10gr. the electric boiler will only heat up to +62-63 degrees no more. All this is selected in the settings using special equithermal curves; more details can be found in the boiler operating instructions.

Further, the automation can maintain the set temperature in the range from +25 to +85 degrees - whatever number you set in the control panel, this temperature will be maintained.

You can also adjust the boiler power.

Let’s say the power of a 14-kilowatt boiler is set to 7 kW, then in any case the boiler will not turn on at full power and will be limited to a power of 7 kilowatts.

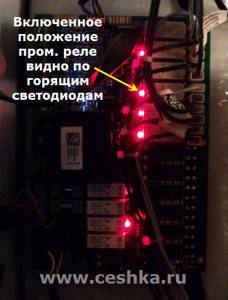

Automation allows the use of an electric boiler in conjunction with a load relay.

A special relay is installed and when the load exceeds the permissible limit (for example, a washing machine and an iron are turned on at the same time), the relay gives a command and the electric boiler automatically reduces its power.

When the load returns to within the permissible limits, the electric boiler will increase power.

It is very important that the load is turned on smoothly and gradually.

Even if, for example, you immediately set the full power in the settings, the heating elements will still turn on gradually.

First one heating element will turn on, then the second, then the third, etc. This is specially programmed so that there is no sharp increase in the electric current in the network when the Protherm boiler .

The heater switches off smoothly too. Therefore, when the electric boiler is operating, there are no sudden abrupt changes in the electric current.

Electric boiler for home heating Protherm

March 08, 2012 News, Expert advice, Home electrical, Home electric heating

In addition to homemade electric boilers , in my practice I also have to connect factory-made boilers, both domestic and imported, such as the Protherm boiler .

This is the brand of electric boilers I want to tell you about.

The price category for such electric boilers is quite high, about 20 thousand rubles. depending on the power there are plus or minus several thousand.

the electric boiler Protherm Skat 14K impressed me in practice .

Boilers are made in Slovakia, in the city of Skalica.

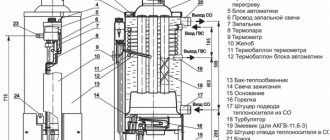

It is made of very high quality and soundly, all parts are mounted very compactly and at the same time accessible for maintenance.

It is clear that manufacturers have puzzled over the internal structure of the electric boiler a lot.

All electrical wires and connections to them are also of very high quality, and almost all the internal contents of the electric boiler, from manufacturers of leading companies in the world, are at the highest level of quality.

To be honest, it’s nice to look at; a professional can immediately determine the high reliability of the operation of such a boiler, even from the component parts.

So, on the front, front part of the boiler there is a digital display with control buttons and indication:

The interface itself is very clear and it’s very easy to understand the settings.

Tips for restoring the device

After unlocking, you should bleed the air from the radiators in every corner of the house where there are taps.

Don't forget about the heated towel rail: it may have such a tap. If there is an automatic valve on the heating, you need to loosen the cap to bleed air.

You should check the pressure in the system again; it should be at least 1.5 bar at the initial stage of operation. When heating, the desired pressure value is up to 2.5 bar, since too high a value damages the system elements responsible for the connections and leads to its overload.

Installation Features

Proterm Skat 9 kW boilers are supplied with all necessary fasteners and elements. In addition, the kit includes instructions that describe the process of connecting and setting up the unit step by step . It is worth noting that models that differ in power have exactly the same principles of installation, operation, and configuration.

Before installing Proterm Skat heating equipment, it is necessary to coordinate all work with electrical distribution services.

Proterm Skat electric boilers with a power of 9 kW can be connected to a conventional 220V power supply . Installation of such heating equipment is carried out using a mounting strip. Such a unit has no certain restrictions on the choice of installation location. Of course, there are some requirements - you need free access for service, maintenance, adjustment and repair of heating equipment.

How to install

The Proterm Skat electric boiler is connected to the pipe system using pipes. The heating device is connected in such a way that the coolant can be easily drained in case of failures during operation without affecting the entire system. Additional valves allow you to fill the system with coolant and drain it. Also, in order to prevent freezing of water in houses with seasonal residence during cold periods, experts recommend removing the coolant completely from the system before temperatures drop.

The Proterm Skat boiler is connected to the electrical network through a power line supplied separately. The network cable is connected to the terminals, which are located in the lower corner of the case. All screws on the connectors must be carefully tightened. A boiler with a power of 9 kW can be connected to a single-phase network.

Launch

This stage is especially important for creating a home in the house. In order for the AGV to serve for a long time and work without breakdowns, it is necessary to correctly organize the startup process the very first time. During this procedure, the entire system is filled with water and air is removed from the pump and all heating radiators. To facilitate this work, Mayevsky cranes are used. They must be opened until all the air has left the system and water flows out of them.

To check whether there is air left in the pump, you need to remove its panel from the front side. If there is still air, then the necessary adjustment work must be performed automatically. When the air pockets are removed, the pump should start working immediately.

Before starting the boiler, you need to make sure that it is installed correctly and securely. It must be installed in accordance with safety requirements. It should be no closer than twenty centimeters from any gas appliances. The same goes for flammable items.

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

Problems with the chimney part

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the ridge.

Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Line pressure drop

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

Fan fault

All boilers with a closed combustion chamber - such as Buderus, Wolf, Danko, Lemax - are equipped with fans. They forcibly discharge combustion products into the street. If you hear strong noises when the blades rotate or do not hear operating sounds at all, carry out diagnostics and replace the element if it breaks.