An autonomous home heating system is becoming one of the most common methods of heating a home.

Among the many options, preference is given to gas boilers as the most efficient and economical units.

European companies are recognized leaders in the production of gas units, but their products are not always able to work effectively in Russian conditions.

Domestic manufacturers, having analyzed the experience of their foreign colleagues, decided to use a completely different approach to the design and functionality of boilers.

Let's consider one of the models of the Russian gas boiler - Zhukovsky AOGV 23.

What functions does the Zhukovsky gas boiler AOGV 23 have?

The abbreviation AOGV 23 stands for Domestic Gas Heating Apparatus with a power of 23 kW. This is a single-circuit floor-standing unit capable of efficiently heating a room up to 200 m2 .

Such possibilities are optimal for use in a private house, cottage or other premises. The boiler is designed to perform only one function, which allowed the manufacturer to eliminate all unnecessary parts and unused design elements.

This increased reliability and reduced the number of failures and breakdowns. In addition, a feature of AOGV 23 boilers is energy independence.

In the event of a sudden power outage, the boiler will continue to operate as usual, which is important in the Russian winter . This feature significantly increases the reliability of the home heating system.

At the same time, the lack of power supply requires a specific location of the radiator system, since the coolant will circulate naturally.

The combustion chamber of the boiler is atmospheric type, with air intake directly from the room and natural smoke removal using stove-type draft.

Household antifreeze is used as a coolant, which increases the reliability of the heating system in severe frosts.

How to remove air locks

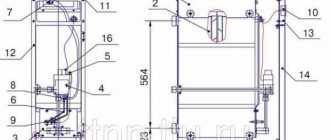

Diagram of the correct location of the boiler and chimney.

Simply connecting the system by filling it with water is not enough. It will not work or its effectiveness will become extremely low. To carry out a full first start-up of the equipment, it is necessary to bleed all the air that has accumulated in it from the system. A modern gas boiler may have a special system for automatically releasing air when filling, but the efficiency of such systems is low. This means that manual bleeding of the main and other systems is required during connection. Only after this can you start.

We recommend: How to disassemble a boiler with your own hands - step-by-step disassembly instructions

Removing air pockets during connection is carried out not only in the circulation pump, boiler, but also in all heating radiators. In this case, it is recommended to start the process with radiators. Especially for this purpose, they are equipped with so-called Mayevsky taps, which you simply need to open by placing a basin under them. At first, a slight whistle will be heard - this is the air gradually leaving the system. If the plugs are removed, water begins to flow. If the batteries are free of air masses, then the taps must be closed. This simplest procedure is carried out with each radiator; it must be checked and cleared of plugs. When air has been removed from all radiators, the pressure gauge needle will be set to the desired value. Before turning on the gas boiler, you need to add coolant to the system, that is, feed it with liquid.

Next, you need to completely remove all air pockets from the circulation pump, which requires disassembling some parts of the boiler. This work is simple, you just need to remove the front panel of the boiler, and then find a cylindrical part that has a lid in the middle of the body, it has a slot for a screwdriver. The boiler must be started, that is, power must be supplied, and the heating regulator must be set to the required operating position. After this, a faint hum will be heard - this will start the circulation pump. You can hear gurgling and other sounds. Using a screwdriver, you need to slightly unscrew the lid of the found part; this should be done until water flows out. As soon as the liquid begins to seep out, the lid must be screwed back on. This procedure needs to be carried out 2-3 times, after which the air pockets will completely leave the system, the sounds and gurgling will disappear, and the pump will begin to operate quietly. Immediately after this, the electrical ignition of the equipment will work, and the gas boiler will begin to operate independently.

The pressure in the heating system must be equalized by adding water to the required level. The system gradually warms up and begins to enter normal operating mode. Connection and first start-up for any heating equipment is a complex and demanding process. How effective the heating will be depends on proper preparation, startup, and adjustment of the system.

Specifications

Let's look at the technical characteristics of the Zhukovsky AOGV 23 boiler:

| Options | Values | ||

| AOGV 23-2 Economy | AOGV 23-2 Universal | AOGV 23-2 Comfort | |

| Boiler type | Gas heating | ||

| Fuel type | Natural gas with the possibility of conversion to liquefied gas | ||

| Functions | Heating (coolant supply to the radiator system) | ||

| Efficiency | 89 % | ||

| Boiler power (max) | 23 kW | ||

| Gas consumption | 2.55 m3/h | ||

| Heated area | Up to 200 m2 | ||

| Coolant temperature | 50°-90° | ||

| Power supply | Absent | ||

| Boiler weight | 52 kg | ||

Design features and equipment characteristics

ZhMZ products now represent about 30 types of boilers. Among them are modifications with a power from 11 kW to 68 kW - AOGV, KOV, AKGV. Certified devices that have permission to manufacture and use are capable of heating up to 610 m² of area.

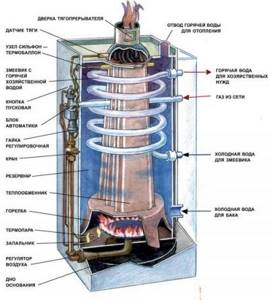

Operating principle of AGV

Advantages and disadvantages of the model

The advantages of Zhukovsky AOGV 23 boilers are:

- Reliability, simplicity of design.

- Independence from the power supply system.

- Simple and intuitive controls.

- Designed for use in Russian conditions.

- Designed to work in harsh climatic conditions.

- The service life is 14 years (or more).

- The cost of boilers is much lower than that of European analogues.

The disadvantages of the units should be considered:

- The heat exchanger of the units is made of steel, which is inferior in thermal conductivity to cast iron.

- The appearance of the boilers is inferior to European models.

- The mechanical automation of the boiler is quite weak.

- The dimensions and weight of the unit require installation in a separate room.

NOTE!

Most of the shortcomings are, to one degree or another, common to all atmospheric models, so they can be attributed to a specific design feature.

Varieties

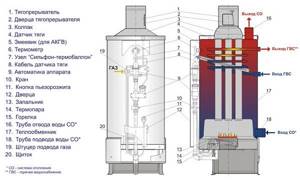

There are three modifications of Zhukovsky AOGV 23 boilers:

- Economy _ Floor-standing unit with Russian automation, tubular heat exchanger. There is a temperature sensor.

- Station wagon. Italian SIT automatic equipment, modulated burner, coolant overheating sensor are installed.

- Comfort. In addition to all the options of the Universal models, the boilers have the possibility of remote control, a room thermostat, and protection against exceeding the coolant temperature.

Boilers of the Comfort modification can be distinguished from other varieties in appearance - they have a rectangular cross-section of the body, while Economy and Universal are round.

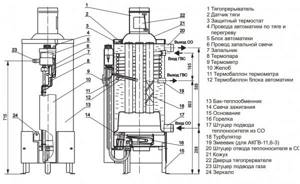

Device

The operating principle of the AOGV 23 boiler is based on heating the coolant using an atmospheric burner . Entering the tubular heat exchanger, the liquid reaches its maximum temperature, after which it is discharged into the heating system.

The movement of the coolant occurs under the influence of the upward thermal movement of heated layers, therefore the placement of all pipelines must be planned with a certain slope. To set the temperature to a given value, a three-way valve is installed, which mixes a certain amount of colder return water into the heated coolant.

Natural circulation is unstable and ineffective, so many owners install an external circulation pump to stabilize the system.

Preparatory stage

Before starting the heating unit, it is necessary to carry out a number of preparatory work, including:

- filling the heating circuit;

- eliminating air jams;

- additional check of equipment serviceability.

Filling the system

If a modern gas boiler is installed, then the process of filling the heating system circuits is not particularly difficult. For this purpose, a special pipe is used, to which the coolant supply is supplied. After opening the tap, the circuits will begin to fill with water.

The condition of the heating system is monitored by special devices - pressure gauges. The readings of these devices allow you to monitor the operating pressure in the system. After the pressure gauge shows a pressure value of 1.5-2.0 atmospheres, you will need to stop the coolant supply.

Advice! The exact operating pressure values can be found in the technical data sheet of the boiler, since indicators for different models may vary.

Removing air

The presence of air pockets does not allow the coolant to circulate freely in the system. Many models of modern boilers are equipped with a device that allows you to automatically release air trapped in the system.

But often the operation of such devices is not efficient enough. Therefore, experts recommend venting air from radiators and the circulation pump. To remove air pockets from radiators, the latter are equipped with Mayevsky taps. To remove the blockage, you must:

- place any container under the tap;

- open the tap;

- bleed the air until water begins to flow;

- Close the tap.

This procedure must be done with each heating radiator.

Advice! After the air is released, the operating pressure in the system will drop slightly. Therefore, you will need to add a little more water, focusing on the pressure gauge readings.

A more complex operation is to bleed air from the circulation pump; for this you need to:

- remove the lid from the boiler;

- find where the pump is installed, it looks like a cylinder with a cover with a slot;

- put the boiler into operation (how to do this will be described below);

- when the unit is turned on, the circulation pump will also begin to operate;

- if this unit is air-filled (and this usually happens if the first start-up is carried out after filling the system with water), it will make gurgling sounds during operation;

- Using a screwdriver, you need to carefully begin to unscrew the lid with the slot;

- first, air will begin to come out from under the lid, and after the water flows, you need to screw the lid back;

- if the gurgling sounds do not stop, then you need to repeat the operation;

- after the air lock is eliminated, the pump will operate quietly and the boiler will go into operating mode.

Checking and flushing the system

In order to ensure the high quality of the work performed and prevent possible water leaks, plumbers recommend performing a pressure test of the system before starting the boiler. This procedure will require expensive equipment - a pressure pump. However, there is no need to buy it, as it will only be needed for half an hour to check the system.

You can borrow such a device from friends or rent it. You can also use the service of an on-call technician who will independently check the system and correct any problems that have arisen if necessary.

The purpose of pressure testing is to identify leaky areas of the system and eliminate them. A system that has gone through this process is guaranteed to serve for a long time and will not fail at the most inopportune moment.

There are two methods of crimping: with a water column or with compressed air. The essence of the procedure is pumping air or water into the system to establish a pressure level in it approximately one and a half times higher than the working one. After pumping, it is necessary to record the pressure value on the pressure gauge and wait 10 - 15 minutes.

Before performing pressure testing, it is important to take into account the characteristics of all elements that make up the heating system. In addition to checking the functionality of the system, it is also important not to damage its structural elements with excessively high pressure.

If at the end of this period of time the pressure remains at the same level, then the system is considered pressurized and has no leaks. If the pressure has dropped, then you need to identify the place where water is leaking and eliminate this problem. Then carry out the procedure again.

We recommend: Gas boiler room: design standards, diagram

Please note that before installing a new unit, flushing a circuit that has been in operation for several years must be done. All manufacturers of gas equipment warn that installing a gas boiler in an old circuit that has not been cleared of mineral deposits is prohibited. Failure to comply with the rule will result in the boiler owner losing his warranty.

This process is carried out in two stages. Initially, rough washing is carried out. In this way, the largest contaminants are removed. The pressure in the system when flushing should be about 3.5 atmospheres. After the water is agitated under pressure, it is released from the system through a drain valve.

In this case, the coarse filter often becomes clogged. It may need to be washed once or twice. Finish washing is carried out using pressure pumps.

After finishing washing, you need to check the coarse filter. It must be uncontaminated. Supplying contaminated water to the boiler is highly undesirable

After completing the preparatory work, you can start launching the device.

additional verification

Before starting the unit, you must:

- make sure that the gas pipeline is sealed, that is, the meter does not record gas consumption when the gas valve on the unit is closed;

- check whether the automation system works, turning off the boiler in the event of an emergency;

- check for traction.

If at least one of the above conditions is not met, the launch cannot be performed.

For which rooms is it best suited?

AOGV 23 boilers are optimal for use in private homes, public or commercial premises. They require a separate room with ventilation, so installing the units in apartments is not recommended.

Also, production workshops with a large number of openings and technological hatches that disrupt the air exchange regime and create drafts are not suitable for operation. They often cause flames, which stops the heating system from working and creates the risk of gas leaks.

The best option is a separate room in the basement (ground) floor, with a window opening and an area of at least 8 m2.

Start-up and operating instructions

The boiler is started after installation on a flat horizontal surface and connection of all communications:

- Gas supply.

- Forward and return lines of the heating system.

After installation, the system should be filled with coolant. The filling level is monitored using a signal pipe . The boiler is ignited using a piezo ignition unit or a lit match (Economy series).

IMPORTANT!

To start the boiler, you must first ventilate the room for 15 minutes. After this, open the gas tap, turn the knob to the “igniter on” position and push it in all the way. Wait in this position for 10-15 seconds, then press the piezo ignition button.

When a flame appears on the igniter, wait another 20-30 seconds, then release the handle . The pilot light should continue to burn. After this, you can set the required coolant temperature.

During operation, the user is not required to take any specific actions other than periodic cleaning of dust and soot.

Once a year you should invite a specialist to perform maintenance. For all problems, you must contact the warranty or service workshop .

The most common automation malfunctions and methods for eliminating them

Before setting up the automation on the boiler, it is necessary to diagnose it. As a rule, serious malfunctions occur that will require specialist intervention. The adjustment can also be entrusted to a gas technician. Or you can do it yourself by reading the instruction manual.

Attention! Before each seasonal operation, it is necessary to check the operation of the safety sensors.

Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to power surges, and a gas leak is detected. Proper cleaning of the filter should be done by a professional. You can try to replace electronic elements yourself by carefully studying the operating instructions for your boiler.

In order to replace the temperature sensor, you need to turn off the gas boiler and cool the water to a temperature of 40 degrees. Shut off the flow of coolant, remove the control knob by unscrewing the screw. Next, remove the PTV adjustment screw. Remove the sensor bellows with the support washer. Unscrew the union nut of the sensor thermal bulb. Install the thermal bulb of a working sensor into the boiler jacket and screw it tightly. Install the sensor bellows into the pipe socket, install the support washer on the bellows, install the PTB adjustment screw and adjust the temperature.

If problems arise with igniting the igniter, then one of the possible causes is a malfunction of the draft sensor. In this case, it must be dismantled, diagnosed, checked contacts, cleaned, and, if necessary, replaced with a new one.

Also, common reasons why the pilot light does not light may be:

- gas valve malfunction;

- clogging of the hole in the igniter nozzle (it can be cleaned with wire);

- strong air draft;

- low gas inlet pressure.

When the gas supply is turned off, it is necessary to check the chimney (it may be clogged), the electromagnet, and the gas pressure at the inlet to the gas boiler.

Attention! To diagnose and repair the gas boiler automation, you must invite a specialist. Inept actions can aggravate the problem and lead to undesirable consequences.

For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element.

In Arbat and Orion, you can only replace the thermocouple and draft sensor, as well as the solenoid valve (rarely). The automation unit is practically beyond repair. In Arbat, the system shutdown button often breaks down.

Typical problems for SABC automation are damage to the main valve membranes and drying out of the thermostat stuffing box, resulting in gas leakage. Impulse tubes, bimetallic plates, and ball valves are subject to control.

In conclusion, I would like to emphasize once again that automation is designed to maintain the operation of heating equipment in a safe mode. Therefore, it is simply necessary for owners of gas boilers.

This video shows how to troubleshoot an automatic boiler AOGV, step-by-step assembly process and testing the result.

The most affordable energy resource with the lowest level of harmful emissions in the modern world is gas. The use of AGV for space heating is the most effective option in terms of efficiency and harmlessness. Independence from power supply and low cost of maintenance allow AGV water heating boilers to take their rightful place among similar devices.

Price range

The cost of the Zhukovsky AOGV 23 boiler depends on the specific model and ranges from 20-24.4 thousand rubles. This price does not include the chimney. When purchasing, you should immediately clarify the equipment of the unit so that you do not have to urgently look for the necessary components.

In addition, additional costs will arise for concluding a warranty agreement.

It is not recommended to neglect this action, since subsequently you can spend a much higher amount on repairs.

NOTE!

Many users rely on their own skills and knowledge, intending to repair the boiler themselves. It must be remembered that unauthorized actions with gas equipment may entail administrative liability.