With the onset of summer, the need for heating the home disappears. The question arises of how to turn off the gas boiler for the summer. It must be remembered that many models are dual-circuit, that is, they heat not only the coolant for the batteries, but also water to supply the bathroom and kitchen. This is especially true for dachas and country houses where there is no main hot water supply. Typically, double-circuit boilers have a special summer mode that leaves only one circuit in operation.

Reasons for turning off the boiler

First you need to figure out what are the reasons for turning off the boiler in the summer and whether it needs to be done at all. They do this for reasons related to gas saving. But it seems so only at first glance: in fact, frequent boiler shutdowns affect the condition.

This increases wear on the equipment and can cause breakdowns:

- Firstly, the longer the system is idle in the cold, the lower the temperature of the coolant and the harder it will be to heat up when the boiler is ignited. In this case, fuel consumption will be significant.

- Secondly, the temperature of the heat exchanger decreases. When reheated, drops of water will accumulate on its surface. This is condensation, which can cause destruction and corrosion of the heat exchanger.

- Thirdly, drops of water also settle on the burner. This significantly reduces its operating efficiency and, as a result, increases fuel consumption.

Corrosion of the main components of the boiler structure requires their replacement in most cases. The possibility of repair by soldering is unlikely. Correct smooth startup of equipment after long periods of inactivity will help reduce the risk of such problems. Most boilers have special operating modes. If available, it is important to be able to turn them on correctly on various types of automation and units of different brands.

Important! To save fuel, you can leave the boiler on during the summer. There are many ways to save. One of them is the use of modulating burners. When deciding whether or not to turn off the heating system in the summer, you need to evaluate the possible risk and the amount of gas saved.

The main stages of setting up Buderus boilers

- Checking and adjusting automation.

This includes not only diagnostics of the operation of the control system, but also of various sensors, including those for weather-dependent operating modes. - Setting up the burner device.

Our specialists will not only carry out all the necessary work, but will also check the correct selection of the burner for your type of boiler. Using special equipment, specialists will adjust the supply of air and fuel for optimal combustion. - Hydraulic balancing.

Proper operation of pressure sensors, pump, valves and auxiliary fittings will achieve maximum efficient and safe operation.

Commissioning of boilers by qualified specialists will ensure proper and safe operation of the entire heating system. The scope of work includes pressure testing when the heating unit is supplied in separate sections; filling the heating system; tightness control; checking the location of the flue gas guide plates (not for all models); turning on the burner and control system; flue gas temperature control; checking the flue gas exhaust system; control of operation in all modes.

Rules for turning off heating on the boiler

Each type of automation has its own rules on how to turn off a gas heating boiler for the summer:

- EuroSit 630. Turn the knob until the mark on it is aligned with the asterisk on the body. Then close the gas valve.

- MiniSit 710. Turn the thermostat knob clockwise until it stops. Click "Off". Turn off the gas.

- "Kare." Turn the thermostat all the way to the left and turn off the gas.

- Sit 820 NOVA. Turn the adjuster first to the sprocket and then to the white dot on the body.

How to turn off the heating boiler

Heating equipment of various brands is switched to summer operation in various ways.

"Proterm"

Many people ask how to turn off the heating on the Proterm boiler. To briefly interrupt the operation of a unit of this brand, you need to set the main control switch opposite the inscription “off”. If the equipment will be turned off for a long period, then it is additionally necessary to turn off the gas and limit the access of electricity to the boiler. In the summer, it is not mandatory to drain the coolant from the system and it is not recommended to do this again, since numerous refills contribute to the formation of deposits and scale inside the device and batteries.

The products of this manufacturer have a “Summer” mode. To turn it on, you need to press the mode change button until the crossed out battery icon appears on the screen. After this, you need to confirm your choice by pressing the “OK” key. Next, you need to make the mode active (this will happen when “ON” appears on the screen). This is done with the + and - keys. The selection is confirmed again with the “OK” button.

When this mode is turned on, the heating circuit and the coolant circulation pump stop working. All other automation, power supply, timer continue to operate in the same state.

Note! Thanks to this, the supply of hot water is not interrupted even in summer.

"Ariston"

This manufacturer also produces mainly dual-circuit equipment. To stop the operation of the circuit responsible for heating the air in the room, you need to turn the lever number 5 to the inscription “O”.

Complete shutdown of the heating system is carried out differently:

- On the main panel you will have to find the on/off button and hold it down for a while until the display goes out.

- In the off position, the external two-pole control lever must be moved.

- Gas access to the boiler is blocked.

"Buderus"

If you are interested in how to turn on or off the Buderus boiler, then the products of this brand are no different from others. The transition to summer mode has its own characteristics; it is distinguished by its simplicity:

- Most models have a knob for adjusting the temperature. It must be turned to the left until it stops.

- Check the availability of cold water pressure for the FGP and do not turn off the electricity.

"Baltgaz"

The boiler is turned off in several stages, performed one after another in strict sequence:

- By pressing the corresponding key, the system goes into standby mode.

- then the power supply is turned off (an option is to simply pull the plug from the network, the operation of the automation will not become worse after this).

- close all taps and valves, limiting gas access and coolant circulation.

"Beretta"

It is necessary to place the regulator in the position opposite the icon that looks like a faucet. This means that the heating is turned off, but the boiler will produce hot water if necessary.

Among the boilers, there are also those that are not recommended to be turned off during the summer. One of these is a boiler of the Navien and Sigma brands. In the summer they continue to work on one circuit, which is used for domestic hot water. In Vailant boilers, you must select a mode whose code is S31.

Diagnostic procedure for a turbocharged boiler

In a boiler that is equipped with a fan to remove combustion products, ensuring safe operation is somewhat more difficult. The draft is checked by an external device - a pneumatic relay. A device for measuring air flow (Venturi device or pitot tube) is also installed in the exhaust pipe, which is connected to the pneumatic relay through plastic tubes. That is, in this case, the principle of draft control is as follows: if the air flow created by the fan in the exhaust duct is greater than the minimum value to which the pneumatic relay is set, then the relay contacts close and the board gives a signal to ignite; if the air flow is less (draft is not sufficient) - the contacts open and the boiler operation will be stopped.

That is, in a typical smoke removal scheme for such a boiler there will be:

- inlet pipe

- fan

- control devices

- exhaust pipe

The inlet pipe is a pipe through which air enters the combustion chamber (it is closed in a turbocharged boiler). If, for example, the head of the pipe is covered with frost in winter, there will be no inflow, while the fan is characteristically quieter and the boiler will not start. Provided that everything is in order with the exhaust pipe and there are no other problems, if you open the combustion chamber, the boiler will start in normal mode.

The operation of the fan can be assessed visually (the blades are visible without dismantling). If the fan does not start when the boiler is turned on, then in most cases either there is no signal coming from the board (the board is faulty), or the fan itself is faulty. Damaged wiring does occasionally occur, but is rare. Service workers check the operation of the fan by directly applying voltage to it. If the fan operates, diagnostics and repair of the control board will most likely be required.

If the fan turns on and air flows normally into the combustion chamber, but the boiler does not start due to a smoke removal error, you need to check whether the pneumatic relay operates. You can check that the relay is activated visually (the relay makes a characteristic click) or, even better, with a tester - check the closure of the contacts in the wiring, because the relay may operate, but for some reason the signal does not reach the control board.

If the pneumatic relay does not operate, you need to make sure that there is no contamination or condensation in the supply pipes and that they are not damaged. As an option, you can independently create a vacuum in the supply tube and make sure that the relay operates. If it does not work, it is likely that it is faulty and must be replaced (in most cases they are not dismountable and cannot be repaired).

If the relay is forcibly activated, but normally, when starting the boiler it is not, then the Venturi (or Pitot) device should be inspected for damage or contamination. The slightest deformation or contamination can lead to malfunction.

Since the Venturi device is located in the exhaust pipe, it could be deformed by the high temperature of the exhaust gases.

Problems with the exhaust pipeline may be the same as with the intake pipeline, but you can, perhaps, verify that there is no blockage only visually or by measuring the actual vacuum with a device through specially provided control holes.

The air flow control device is installed inside the exhaust pipe. There is a possibility of heat damage (tube deformation) or contamination.

Some modern boilers can be equipped with fans with adjustable rotation speed, which is set in the settings depending on the type of chimney used and its length (for example, in some Buderus and Ariston models). Therefore, it would be a good idea to study the operating instructions for the equipment, since in practice there were cases when incorrect board settings were the source of the problem.

This article describes the most common and obvious causes of gas boiler malfunctions associated with the removal of combustion products. Different boilers can be equipped with different control schemes - we have looked at the most popular ones.

Please also note that it is unacceptable to disable control devices - all of them are provided for the safe operation of the equipment. If there is a problem, it needs to be fixed!

Recommendations and tips for caring for the boiler after switching off

The heating system, led by the boiler, is a large and complex mechanism that provides the home with heat and hot water. In winter, it is almost impossible to live without this in a private house, especially in the harsh Russian climate. But you need to prepare for the heating season in the summer after the boiler is turned off.

Note! First of all, annual preventive measures significantly reduce the risk of accidents and breakdowns.

Also, such frequent work meets safety standards. Anyone who has gas equipment at home should know the main stages of preventive maintenance:

- visual inspection of all systems.

- cleaning all parts of the mechanism.

- cleaning the inside.

- burner regulation.

These activities are in most cases carried out by specialists. At home, these operations are carried out independently as follows:

- The coolant is drained from the entire system, and not just from the boiler.

- visual inspection of the entire system.

- the location of structural units that must be replaced is determined.

- replacing gaskets.

- removal of deposits and scale.

- lubrication of the circulation pump and forced ventilation fan.

- The most important point: checking for gas fuel leaks.

Turning off the boiler in the summer is not always necessary. The feasibility of this event is assessed by the owner independently. The choice to turn off the home fire or not depends, first of all, on the brand and type of boiler.

A newly installed Buderus logamax U072-24k double-circuit gas wall-mounted boiler is in operation. House 80 sq. m., 2 floors, non-permanent residence, Leningrad heating system, additional pump on the return line. When I first started it, it constantly turned on and off, the house warmed up to 24 degrees. Then ZONT control with supply and air temperature sensors was installed. The comfort temperature is set to 26. The boiler turns on once every 3-4 minutes, heats the coolant to 80 and drops to 26. The temperature in the house does not rise above 20. Not all batteries warm up. Pump speed 2. Boiler power reduced by 50%. They were installed by specialists. I don’t know where to get normal ones. What could be the reason, in the settings of the device or ZONT? Should the boiler turn on so often? Why could there be such a big difference in the supply and return temperatures?

Clean the mud trap, reduce power to 30-35% (for now). With your area there is no need for a second pump. Unless something is wrong with the heating. And the built-in one with 2-3 reserves is enough. Turn off the 2nd pump for now.

I installed and connected the gas boiler Buderus Logamax U072-24K (single-circuit with the ability to connect a boiler). I am planning to install an indirect heating boiler. 1. My boiler mode is not active now - will this need to be programmed later or as soon as I connect the sensor to the boiler, will it become active? 2. What sensor in the boiler should be used for this device (ideally with a code, maybe there are analogues or sensor parameters)?

Connecting a wall-mounted boiler to the electrical network

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which requires virtually no intervention from the owner. Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a conventional socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then the individual socket for the gas boiler should be located next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

Photo 3: Installing a voltage stabilizer for a wall-mounted boiler

A gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Boiler automation is very sensitive to the quality of the supply voltage. If the level of the sinusoid at the input is insufficient or the shape is not ideal, the devices quickly fail. To prevent frequent breakdowns and extend the service life of the unit, it is necessary to connect voltage stabilizers for gas boilers. To avoid shutdowns of heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

How to set up a Buderus gas boiler

The basic adjustment of Buderus boilers is carried out at the manufacturer. After purchase, you only need to make some adjustments necessary for the most efficient operation of the unit under the given conditions .

As a rule, it is necessary to set operating limits for gas pressure and heating water temperature.

Gas supply parameters are adjusted using the adjusting screws of the gas fittings, while simultaneously monitoring the result of the actions on the control panel. A U-shaped pressure gauge is connected to the measuring fitting, with which the gas pressure limits are determined.

At this time, you need to start service mode 1.2.F (maximum performance).

Temperature setting is done from the control panel . By pressing the “-” button, winter mode is called up (the heating circuit is turned on).

Then press the “OK” button, the temperature of the extract air (direct or supply line) will then appear on the display.

Using the “+” or “-” buttons, enter the required values and press the “OK” button again.

To set the summer mode, the same steps are performed, only when setting the value, press the “-” button until dots appear on the display. Then press “OK”, the crossed out radiator icon will be constantly lit on the display, indicating that the coolant heating is not functioning .

Kinds

Buderus double-circuit boilers are predominantly wall-mounted.

All floor-standing installations are single-circuit, but have the ability to connect an external indirect heating boiler, which allows you to obtain a full-fledged hot water circuit. There are different design options for dual-circuit installations.

According to the type of thermal energy transfer, they are:

- Convection. Heating is carried out in the usual way, in the flame of a gas burner.

- Condensation. A new technology that makes it possible to use thermal energy obtained by condensing water vapor contained in flue gases. The coolant is preheated in the condensation chamber, due to which it enters the primary heat exchanger already prepared. As a result, it becomes possible to reduce the intensity of the main heating, reduce gas consumption and achieve an efficiency of 108%.

NOTE! From a theoretical point of view, such efficiency is impossible. This is a common marketing ploy designed to increase demand. However, condensing boilers can only operate effectively under appropriate conditions - if the indoor temperature is +20°, then the temperature outside should not be below 0°, otherwise the boiler will work like a regular convection unit

However, condensing boilers can only operate effectively under appropriate conditions - if the indoor temperature is +20°, then the temperature outside should not be below 0°, otherwise the boiler will work like a regular convection unit.

According to the type of combustion chamber there are:

- Open (atmospheric). Air enters the boiler directly from the room, and smoke is removed using natural draft.

- Closed (turbocharged), the air supply and smoke exhaust are produced by a turbocharging fan.

For use in private houses or apartments, turbocharged boilers are more convenient, which are capable of providing stable draft that is independent of external conditions.

How to start the device correctly

The first start is made after connecting all pipelines:

- Direct (left) and return (right) lines of the heating circuit.

- Hot water supply.

- Gas pipeline.

In addition, you need to connect the power supply using a special socket with a grounding electrode.

The boiler electronics are very sensitive to voltage surges or surges, so it is important to protect the control board from them.

You must use a standard voltage stabilizer manufactured by Buderus, or something similar (which is somewhat worse).

The boiler is started either when it is first turned on or after the summer break.

In both cases, you must first fill the system with water . Checking the pressure gauge readings, fill the system to a value of 0.8 bar. The standard operating pressure is from 1 to 2 Bar, but it must be taken into account that when heated, the volume of water will increase, which will cause a rise in pressure.

After this, set the required coolant temperature on the control panel, which will cause the burner to start and the boiler to start operating.

Before turning on, it is necessary to bleed the air from the radiators using Mayevsky taps, otherwise an error will appear during startup. It is reset by pressing and holding the “OK” button, after which attempts are repeated until a positive result is obtained .

It is impossible to fill a hot heat exchanger with water, as this can lead to cracks and failure of the unit. Before filling, you must wait until the boiler has cooled down, and only then fill the system.

Electric boiler installation

Installation of this equipment in a house does not require a chimney and approval from regulatory authorities. The only requirement is that the electrical wiring is in good working order. The connection diagram is quite simple. In addition to the boiler, it includes temperature sensors on the pipelines, a heating radiator, drain and shut-off valves, an expansion tank and a filter with a circulation pump. You will also need a voltage stabilizer, since electric boilers are sensitive to voltage drops, and they are inevitable in the electrical network.

When installing, you must try to isolate it from the water supply system so that if a pipe breaks, water does not enter the unit, causing a short circuit. The installation room must be thermally insulated to prevent the formation of condensation - it can also lead to serious damage. The boiler must be installed on a flat surface.

Connection

To connect equipment, couplings and adapters are used. First, you need to turn off the water supply in the water supply using ball valves. The connection is made in accordance with the installation diagram attached to the accompanying documentation. The circuit assumes the presence of grounding, installation of a circuit breaker, as well as an RCD for short circuit protection.

Cables must be installed in cable ducts, and the electrical part of the equipment is protected by a casing. The unit itself must be securely fastened. And only after that you can let water into the heating system and check the functionality of the equipment.

How to turn on after shutdown

The boiler is turned on by pressing the corresponding button . If the shutdown occurred due to external reasons (lack of gas in the main line, water or electricity outage), then you must first make sure that the supply of the necessary resources is restored.

If any components or parts fail, causing the boiler to shut down, the cause must first be eliminated - replace or repair the problematic component or part, restore oxidized contacts, etc. Otherwise, the boiler will not start, and the installation will immediately be blocked by the self-diagnosis system .

Basic faults

The design of Buderus boilers was created on the basis of the most advanced technical developments.

They are stable in operation, but no insurance has yet been invented against the occurrence of malfunctions . Buderus boilers are equipped with a self-diagnosis system, which is a network of sensors connected to the most important and critical components or parts of the boiler.

The operation of all elements is constantly monitored by these sensors; if any inconsistencies or changes in the normal mode occur, an alphanumeric code for a particular error appears on the display. In addition, other malfunctions are possible.

Let's look at the most common:

- The burner does not light. The reasons for this may be disconnected starters of heating or control systems, failure of circuit breakers, failure of the boiler regulator or temperature limiter. The boiler may be blocked due to problems with the flue gas control equipment.

- The burner turns on, but immediately gives an error. Most often, the problem is a closed gas valve, or the presence of air in the gas pipeline. In both cases, you need to open the valve and let out the air.

- After the burner starts, a signal indicating the absence of ionization current appears. Usually the problems are oxidation of the contacts or mixed-up connections of the “N” and “L” electrodes. It is also possible that the ionization electrode is shorted to the housing or the burner automatic is broken.

- After ignition, the burner gives an error - the current is less than 1.5 mA. Here the cause may be oxidation or the appearance of soot on the ionization electrode, which should be cleaned.

- Boiling sounds are heard from the heat exchanger. This is a sign of the appearance of a thick layer of scale, or an insufficient amount of coolant in the system.

What series and models are wall mounted?

Buderus wall-mounted boilers are represented by one large Logamax line, which consists of 4 series:

- Buderus Logamax U042 / U044. Double-circuit installations with a power of 24 kW. Equipped with a bithermic heat exchanger, which allows you to simultaneously heat both the coolant and hot water. There are models with a closed (042) and open combustion chamber (044).

- U052 / U054 K. Single- and double-circuit boilers with an open (054) and closed (052) combustion chamber. For dual-circuit models, the designation contains the letter “K” (combined). Two models are available with a power of 24 and 28 kW.

- U052 T / U054 T. 24 kW model with open or closed combustion chamber. A special feature is the presence of a 48-liter hot water storage tank, which allows you to meet high demands for hot water.

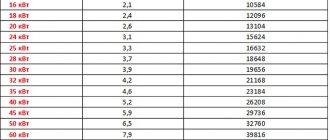

- U072. The most popular series of turbocharged boilers with a capacity of 12, , and kW. Single and double circuit models are available. High demand is due to the relatively low cost of boilers. Equipped with two heat exchangers - primary (for coolant) and secondary (for hot water supply). The most popular boilers are 24 and 35 kW, producing up to 12 and 16 liters of hot water per minute, respectively. Capable of heating 240 and 350 m2 of residential, public or commercial areas.

When choosing a boiler, you should compare its characteristics with the size of the room and the family’s need for hot water. The manufacturer provides a choice for any conditions, which allows you to get the best option.

Date: September 25, 2020

All main error codes and their interpretation

Let's look at the main error codes for Buderus boilers:

| Code | Decoding | Ways to fix the problem |

| H11 | Problems with the DHW temperature sensor | Check the contact group, determine the functionality of the sensor, and replace if necessary |

| 2P | Coolant overheating | Check the contacts, determine the condition of the circulation pump |

| 3A | Fan stop | Check the contacts, replace the fan with a new one |

| 4C | Heat exchanger overheating | Stop the boiler, check the functionality of the circulation pump and the extract air temperature sensor, call a technician |

| 4U, 4Y | Short circuit or break in the forward line (supply) temperature sensor | Check the condition of the sensor and contacts, clean and reconnect them, if necessary, replace the sensor |

| 6A | No flame | Check the presence of gas in the system and in the boiler equipment, call specialists |

| 3C, 3L, 3P, 3Y | Fan failure | Check connection and functionality, replace |

| 6C | The system sees a flame on an idle burner | Moisture on contacts or control board, poor ground contact |

User manual

Operating the boiler is not particularly difficult . The user is not required to perform any special actions other than the current temperature setting or switching the boiler to winter or summer mode.

In addition, in the summer you need to drain the water from the heating system, and at the beginning of the next season you need to fill the system again. This is also performed by the user, guided by the readings of the pressure gauge on the unit body .

If an error appears on the display, you must reset it by pressing the “OK” button and holding it in this position until the error disappears.

This is done because the control panel often perceives voltage surges as signals from the corresponding self-diagnosis sensors. If it appears again when you restart it, you need to call a technician.

Service

Buderus boilers are serviced by specialists from service organizations.

It must be done annually; the necessary procedures include cleaning the heat exchanger, removing soot from the chimney, inspecting and adjusting the contacts of the control board.

It is not recommended to perform independent maintenance of the boiler; you can only clean the body of dust or soot that appears on it during operation.

For which rooms is it best suited?

Buderus Logamax u072 24k boilers are designed for use in rooms with a maximum area of 240 m2.

This is optimal for private houses, apartments, commercial or public premises, offices.

It can be used in industrial buildings if they do not have a large number of openings or technological hatches that disrupt the heating mode and change the temperature in the room.