Installation of boiler equipment and its efficient operation is impossible without a chimney.

The correct choice of materials and compliance with standards when connecting is the key to your safety.

Gas services strictly control the commissioning process and may fine violators or forcibly disconnect the user from the gas supply.

Material requirements

Basic requirements for materials:

- fire resistance;

- anti-corrosion properties;

- resistance to the effects of acid formed as a result of the interaction of condensate with combustion products;

- long period of use.

Brick chimney. It has low draft and is prone to rapid destruction due to the formation of abundant condensation on the surface, which turns into an ice crust during the cold season. Ideal only for fireplaces or as a kind of cover for a stainless steel chimney.

Made from stainless steel . It has a lot of advantages, which makes it one of the first in popularity among its peers. It has good traction, fire resistance and anti-corrosion, and a long service life (especially dual-circuit models). The modular assembly method allows you to create steel chimneys of different configurations and is accessible even to a non-professional. Compatible with high-power boilers. Will serve you for 15 years.

Chimneys made of galvanized steel behave much worse during use. Galvanization is susceptible to rust. Service life – maximum 5 years.

Ceramic chimney. Externally, it is as massive as brick. The installation option is strictly vertical only. Austrian manufacturers have developed models of ceramic chimneys with an external contour not only made of ceramics, but also of metal. They are much lighter, but when installing them you need to calculate the loads on the foundation and walls. Warranty up to 30 years.

Asbestos cement pipes . Short service life (5 years), difficult to install, not environmentally friendly. Even the low price of the material cannot serve as a compelling reason to choose such a chimney. Overheating can simply rupture the pipe. Suitable for occasional use in the countryside.

Coaxial - made of aluminum in the form of two sandwich pipes with different diameters, located one inside the other. The external one is intended for supplying air, and the internal one is for removing combustion products. The structure is prefabricated. The location is most often horizontal.

Advantages of a coaxial chimney:

- Safety

- Increased efficiency of the heating system

- Environmental friendliness

A useful article on the topic - do-it-yourself ventilation in a private house, diagram and drafting. Do-it-yourself air conditioner installation and rules for its use, details here.

Troubleshooting

On frosty days, condensate may freeze at the outlet of the smoke removal system. The most difficult situation is when ice fills the space between the pipes, making it difficult to supply combustion air. This phenomenon significantly reduces the efficiency of boiler equipment.

Insulation helps to some extent. But the most effective solution is to attach a nozzle to the exhaust pipe, lengthening and narrowing it.

Due to the creation of additional draft, the condensate literally flies out along with the flue gases. Some modern boilers are equipped with such nozzles as standard.

The second solution is to supply the chimney with a condensate collector, which is a small-diameter outlet at the bottom of the coaxial chimney.

Chimney elements

Regardless of the material, the design includes the following elements:

- Tee with revision - a fitting for condensate is installed at the bottom of the tee

- Adapter for connecting the gas boiler pipe and the chimney

- Fastenings - brackets and clamps

- Cone shaped tip

- Bends - installed no further than 2 meters from the beginning, otherwise the boiler draft is reduced;

- Feedthrough

- Telescopic pipes

Maintenance and cleaning

One of the main advantages of a gas chimney is the small amount of soot that is formed during the operation of such equipment. Much more appears when boilers operate on solid fuel. However, pipes need to be cleaned periodically to keep them from becoming dirty. At the moment, experts recommend using two methods of cleaning equipment:

- Mechanical method - cleaning of pipes is carried out using rollers and brushes. In this case, the tools must be chosen carefully - such cleaning should not damage the internal walls of the chimney. A vacuum cleaner would be an excellent option.

- Chemical method - a special composition is sprayed onto the inner walls, which destroys the accumulated soot.

How to calculate the chimney diameter

Key parameters are cross-sectional area (outlet F cm2).

The calculation is made using the formula F = (K ∙ Q) / (4.19 ∙ √ˉ N) , where: K is a coefficient calculated empirically (0.02-0.03);

Q is an indicator of the performance of a gas appliance (indicated in the technical characteristics of the boiler);

H - chimney height.

The resulting number is adjusted by building codes and regulations.

For example, if brick is used , then the cross-section is 0.5 x 0.5 material. For asbestos cement, the diameter is at least 10 cm.

The diameter of the round chimney with a boiler power of 24 kW should be 120 mm, 30 kW - 130 mm, 45 kW - 170 mm, 55 kW - 190 mm, 80 kW - 220 mm and 100 kW - 230 mm. The minimum cross-section of rectangular channels depends on the thermal power of the boiler:

- Up to 3.5 kW - 14 by 14 cm.

- 3.5 to 5.2 kW - 14 by 20 cm.

- From 5.2 to 7.3 kW - 14 by 27 cm.

Design rules for boilers with natural removal of combustion products

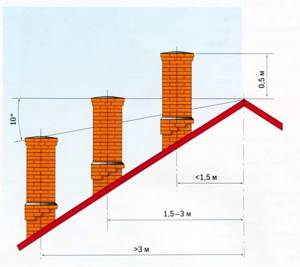

- The chimney pipe must be located above the roof ridge , at least 0.5 meters higher than it, provided that its axis is close to the ridge or parapet (less than 1 m and no more than 1.5 m).

- If the pipe is located further from the ridge (from 1.5 m to 3 m), then its height should be level with the ridge.

- If the chimney is located at a distance of more than 3 m , its height must not exceed the boundary of the line laid down from the ridge at an angle of 10° to the horizontal.

- If you have a flat roof , the height of your chimney should also have a minimum limit of 0.5 m, and in the case of a combined roof - 2 m.

A smoke removal pipe outside the building cannot be erected without insulation: the resulting condensate will destroy the chimney.

- The system for ejecting combustion products must be fixed to the wall at intervals of no more than 2.5 meters, in areas with a slope - every 1.5 meters.

- The clamp must be used on any connecting section of an insulated chimney.

- The chimney elbow must have a slope angle of at least 15° and no more than 90° (no more than three rotary elbows are allowed in the system). The vertical section following the turn must be clearly secured with fastenings. It is prohibited to load inclined sections of the pipe or its bends.

- It is mandatory to equip the chimney with a condensate drain , which must be accessible for maintenance.

- The chimney must be insulated from flammable materials using brickwork or asbestos board . The distance from the connecting pipe to flammable surfaces must be at least 25 cm, and if a protective layer is applied - from 10 to 5 cm.

- Stable traction can be ensured if the pipe is erected above the wind support zone.

- Smoke exhaust systems built inside the building do not need to be additionally insulated , but it is necessary to take care of the tightness and ventilation system. Toxic smoke can easily seep even through the brickwork of the protective casing.

- Areas located outside the structure are insulated . In the absence of thermal insulation, the gases quickly cool, the draft decreases, and the boiler power drops. Condensation forms on the walls.

How to arrange a drainage system around the house? Details here. We assemble an air dehumidifier with our own hands: diagram and principle of operation.

If the air in your child's room is too dry, you should consider buying a humidifier.

Water supply heating installation services

LLC DESIGN PRESTIGE 8(495)744-67-74

In addition to fast and high-quality repair of heating pipes, we provide professional installation of turnkey heating systems. On our heating page > resant.ru/otoplenie-doma < you can view and get acquainted with examples of our work. But to be more precise, it is better to check with an engineer about the cost of work and equipment.

To contact us, use the contact number of DESIGN PRESTIGE LLC 8(495) 744-67-74 , which you can call around the clock.

note

Heat loss calculator

Calculator for the number of radiator sections

Heated floor calculator

Our company DESIGN PRESTIGE LLC is part of the non-profit organization ANO INTERREGIONAL BOARD OF FORENSIC EXPERTS. We also provide independent construction technical expertise services.

Heating of private houses in detail by cost

- Heating 100 m² Cost of work 49,500 rub.

- Heating 150 m² Cost of work 52,500 rub.

- Heating 200 m² Cost of work 72,500 rub.

- Heating 250 m² Cost of work 87,500 rub.

Heating 100 m²

| Cost of work | from 49,500 rub. |

| Cost of equipment | from 120,000 rub. |

Heating 100 m²

Heating 150 m²

| Cost of work | from 52,500 rub. |

| Cost of equipment | from 200,000 rub. |

Heating 150 m²

Heating 200 m²

| Cost of work | from 72,500 rub. |

| Cost of equipment | from 250,000 rub. |

Heating 200 m²

Heating 250 m²

| Cost of work | from 87,500 rub. |

| Cost of equipment | from 300,000 rub. |

Heating 250 m²

Heating services: Baseboard heating, Water heated floor, Radiator heating, Warm wall

Installation of heating systems for a private house

For safe operation of a gas boiler, it is necessary to ensure complete removal of combustion products. If the chimney diameter is incorrectly selected, they can enter the room, which will lead to carbon monoxide poisoning. The danger is aggravated by the fact that combustion products are odorless and colorless, so it is impossible to determine the location of the leak without a special device.

Requirements for installation of coaxial chimneys

When installing the smoke duct of such boilers, it is necessary to keep in mind that:

- When the length of the coaxial pipe is no more than 1 meter, it is necessary to install a tapering diaphragm on the air duct . The power of the fan in the chimney is designed for a certain pipe length and, if it is less, there will be a loss of draft with all the ensuing consequences.

- The pipe is located in a horizontal plane , but still must have a slope of 1 cm for each meter of total length and no more than two bends.

- The head of the pipe can protrude outward no more than the length of its tip - to protect against freezing, and no lower than 2 meters from the surface of the earth.

Pipe slope

Horizontal chimneys can be installed either with a slope towards the ground or towards the boiler. In the first case, condensate under the influence of gravity will be discharged outside the low-rise building and go into the soil. Thus, chimneys are usually installed in the southern regions of the country.

In the northern regions of Russia it is impossible to install pipes in this way. During the winter season, draining condensate can form ice at the end of the chimney. At the same time, due to ice, air will stop flowing to the heating unit, which will sooner or later lead to its breakdown.

In the middle zone and in the north of the country, coaxial chimneys are still installed with a slope towards the boiler. In this case, it becomes necessary to use a condensate collector. Without it, moisture will begin to flow directly into the boiler, which, of course, will negatively affect its operation and service life.

In any case, wherever the pipe is directed - towards the ground or towards the boiler - its slope, according to the standards, must be at least 3°.