When installing pipelines, thermal insulation for pipes is necessary to reduce heat losses or maintain the temperature of communications. This is necessary for daily safe operation. If this is not done, then no one will be able to guarantee that in winter the system will work uninterruptedly and will not fail at one point.

Protecting metal pipes from heat loss using insulators

Thermal insulation of metal pipes prevents the possibility that the liquid contained in it will not freeze at low outside temperatures. This will also prevent condensation from forming on the surface of the pipe.

Important! Thermal insulation requirements are set out in the safety regulations. If gas is transported through a pipeline, then heat insulators are used in various versions.

You can insulate such a pipe by covering it with a special varnish or paint. But in practice, protective material is more often used, so that certain requirements can be met:

- Monolithic insulators are used that lie evenly on the pipe.

- Working materials must have a low moisture absorption coefficient, and waterproofing properties must be at a high level.

- The material must be well resistant to the destructive effects of ultraviolet radiation.

Insulation is clearly regulated in the relevant regulatory documents, which are called building codes and rules (today these are sets of rules, which are an updated version of SNiPs). These documents specify the technical characteristics of the material for the heat insulator and detailed methods for performing the work.

Applying thermal insulation during pipe production at a factory

Type of heat insulator

*

This type of work is carried out using heat insulators in the following forms:

- separate segment;

- cylinder;

- mat;

- half cylinder;

- roll

The pipeline can be thermally insulated using the following types of insulators:

- Mineral wool.

- Shell.

- Polyurethane sealant.

- Pipe insulation.

- Liquid expanded clay.

- Basalt wool.

This is not a complete list of heat-insulating materials. The construction market is subject to constant updating with the advent of new, more modern materials.

Use of mineral wool

This is the cheapest material with which it is easy to carry out installation work. It is difficult not to agree that this circumstance is a pronounced positive point. The work is carried out in compliance with the following requirements:

- A cross section of the roll is made. Strips 200 mm thick are formed, which are used to wind the pipe. First, mineral wool is laid, and fiberglass is placed on top of it.

- The technology of laying mineral wool is carried out evenly, preventing it from being crushed.

Large diameter pipes are insulated in this way. Since cotton wool actively absorbs moisture, it quickly rots. Therefore, insulation of pipelines with mineral wool is carried out only in cases where the heating main passes above the ground or indoors. This method is not used for insulating sewer systems and pipes with small diameters. It can ignite at high temperatures, so you should refrain from using it near stove heating, as well as in places where electrical cables pass.

Use of mineral wool for pipe insulation

Mineral wool exists in two types:

- stone;

- glass.

In the first case, the material for its manufacture is rocks. To make glass wool, broken glass or staple fiber is used, the basis for which is quartz sand.

External heat pipes

*

If pipes are laid externally, then roll-type mats are used for thermal insulation. The application of liquid insulation has a certain ease of use. These include epoxy pipe insulation.

Powder or liquid coating has advantages over other types:

- Increased resistance to abrasive wear.

- Impact resistance.

- High temperature resistance.

- Anti-corrosion protection.

Linear sections of the pipeline are covered with a heat insulator with a galvanized casing.

Process pipelines are insulated with tubes or rolls of foam rubber. Insulation is carried out in several layers. Their number depends on the total required value.

Thermal insulation with the application of a covering layer is of particular interest.

Using thermal insulation to insulate pipes prevents hot water from cooling down during its long journey from source to consumer. They are used for almost all types of pipes:

- Plastic.

- Metal.

- Polymer composite.

- Metal-plastic.

- Composite

When performing such work in a private house, it is better to use pipes that are pre-insulated. In this case, self-adhesive insulation is used. Additional winding, which can be used as aluminum tape, will help.

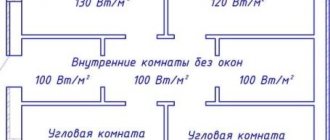

Before carrying out work, it is necessary to calculate heat losses. This takes into account the temperature of the coolant and the temperature parameters of the surrounding air.

Good thermal insulation properties can be observed in polyurethane foam and glass wool. They are highly effective.

Insulation of metal cold water pipes has the main purpose of preventing moisture from appearing on the surface. Protection against condensation is necessary to prevent rust from developing. It leads to metal corrosion and, as a result, to complete failure of the pipe.

Insulating the water supply with cold water in the basement

DIRECTORY

Table for selecting the ratio of pipe diameters (copper pipes, steel pipes, polyethylene pipes) with standard sizes of thermal insulation (foam rubber insulation, polyethylene foam insulation, mineral wool cylinders).

This table for selecting thermal insulation for pipes will help you avoid making mistakes in selecting insulation.

Basically, three types of pipes are used for thermal insulation: steel, copper and plastic. To designate the diameter of steel and copper pipes, three methods are used: in millimeters, inches and nominal diameters - DN*. DN is a “conditional diameter” that is used when calculating various parameters of pipeline systems. For example, parameters such as pressure, flow, consumption, drain, etc., i.e. internal diameter of the pipe.

Very often, the use of high pressure in a pipeline system is not required, so the thickness of the pipe wall is reduced so that you can save on metal consumption during production, and vice versa, if high pressure is needed in the pipeline or for threaded connections, the thickness of the pipe wall is increased.

The diameter of the pipes is called conventional because there are pipes of square rather than round cross-section. In this case, for pipes with a square cross-section, the conditional passage is calculated through the cross-sectional area of a particular pipe; the calculation should be reduced to the formula for the area of a round pipe and accepted for further calculations as if the pipe were round and had such and such a nominal diameter. In pipes with a circular cross-section, the nominal bore - DN completely coincides with the internal diameter of the pipe.

As a rule, the nominal diameters (DN) of steel pipes are indicated up to size 50, after which it is customary to indicate the outer diameters of the pipes. But for plastic pipes, only the outer diameters are usually indicated.

Technical insulation for pipes, which is supplied in the form of heat-insulating tubes (tubular elements), is presented in standard sizes that take into account Dout - the outer diameters of the pipes (not to be confused with the Dy - nominal diameters) of the pipes.

Example:

Let's say your technical specification indicates a steel pipe with a diameter of DN 20 and a thermal insulation layer 13 mm thick. Do not rush to order pipe thermal insulation with internal diameters of 20 mm or the closest to it 22 mm (insulation sizes 20x13 and 22x13, respectively).

Be sure to pay attention to the fact that if you have a steel pipe with DN 20, then taking into account the thickness of the pipe wall, its outer diameter will be approximately 28 mm, therefore the required thermal insulation size is 28x13, and if a copper pipe with DN 20 is used, then its outer diameter will be about 22 mm, and the size of the thermal insulation will be 22x13 (where 13 mm is the thickness of the thermal insulation layer).

Use of polyurethane foam

*

Foam-polymer-mineral insulation has excellent environmental properties and is highly effective in its use as a heat insulator.

This type of insulator has many positive aspects:

- neutral smell;

- not susceptible to the damaging effects of fungus;

- resistant to aggressive substances;

- does not have a harmful effect on the human body;

- manifests itself as an excellent dielectric;

- has good resistance to various mechanical influences.

If the pipes have a large diameter, then it is applied by spraying. In this case, the insulating layer is continuous, without a seam. Using this method ensures that maximum heat loss is eliminated. Spraying is carried out using special equipment. The spraying process is simple and short in time.

PPU pipeline insulation

For small diameter pipes installed in an apartment, a polyurethane foam shell is used. At the same time, a high level of thermal insulation is achieved. This method is relatively low cost.

Material advantages

It is not for nothing that Energoflex insulation ranks first in the list of the most effective thermal insulating materials for pipes. It has a number of advantages that make it stand out from its analogues. But do not forget about the main functions that any insulation performs:

- Protection of the pipe from corrosion, which is a consequence of the harmful effects of external factors (condensation, rain, precipitation, etc.);

- Temperature regulation in winter. It is necessary in order to avoid freezing of the water pipe with subsequent rupture due to ice expansion.

- Reducing heat loss in parts of heating systems that are located outside.

But in addition to these standard functions, Energoflex surprises with a number of advantages that are not typical for many insulation materials:

- resistance to various chemical influences;

- prevents the development of bacteria;

- excellent strength indicators, which eliminate the need for additional pipe protection;

- ease of installation, which does not require special knowledge and skills;

- environmentally friendly;

- safety for human health;

- no toxins;

- high level of corrosion protection;

- high flammability class, minimizing the likelihood of ignition;

- the ability to reduce energy and resource consumption;

- maintaining the required temperature in the pipes.

Important! Energoflex has a fairly wide range of operating temperatures. The material functions well at temperatures from -40 to 100 degrees. At the same time, all properties and characteristics remain at the same level.

One of the main advantages is a large range of materials for various needs. You can find insulation from the manufacturer for insulation of water supply, sewerage, heating or ventilation pipes. The required diameter of Energoflex pipes is always available.

Use of polyethylene foam

Today it occupies a leading position in the market of such materials. Used for insulating pipelines for any purpose. It has the appearance of a finished shell, which has been shaped into a pipe. It seems to envelop the pipe, protecting it from harmful factors.

Using polyethylene foam as pipe insulation

This shell has a seam along which the cut is made during installation work. After their completion, the shell is glued back together.

Application of glass wool

*

This material has all the properties that meet the requirements for heat insulators. Rolls are used for thermal insulation. If we consider this material as the main means for thermal insulation, then its use slightly increases the cost of work. This is due to the need for additional measures. Such work takes longer.

Positive aspects of using glass wool:

- the material can be used for a long time;

- is highly resistant to vibration;

- high resistance to chemical and biological substances.

Before carrying out work on thermal insulation of pipelines, it is necessary to draw up an estimate. It will reflect the step-by-step production of the entire volume of work. The result will be the total cost.

Glass wool casing with foil protection

Thermal insulation work is carried out in accordance with current regulatory construction documents. When carried out correctly, it is guaranteed that the desired energy efficiency will be achieved. The useful life of the pipeline will increase significantly.

Various materials are used during installation work. In this case, it is necessary to take into account certain factors. The purpose for which the pipeline is planned will be of decisive importance.

For example, if the pipeline is expected to contain a high-temperature coolant, then it is better to use cylinder insulation. A polyurethane foam shell is quite suitable for these purposes. As an additional means, laminated foil cardboard or foil is used.

Purposes of application

Energoflex is used for various purposes, in each of which it manifests itself as a very thoughtful and effective material. Let's look at known uses.

Reduced heat loss

Energoflex is thermal insulation, which means this is precisely its function. When applied, the material allows you to maintain for a long time the temperature that is necessary for the transferring liquid or gas. Energy losses are reduced, which reduces the consumption of all resources that are designed to heat water. So heating and hot water supply will be very efficient.

When working on thermal insulation yourself, it is important to remember that only those pipes that are not located directly in the heated room need to be protected. So all heating fittings in the basement or outside can be insulated. The rule is due to the fact that unprotected pipes heat rooms by transferring heat to the environment.

Insulating pipes that are parts of hot water supply or heating systems seems quite logical. But is it necessary to insulate sewer outlets? To answer this question, we need to consider where exactly these pipes go. If they are not buried deep enough and touch the area where the soil freezes, then insulation must be done. Only in this case will it be possible to achieve full provision with all the amenities necessary for life.

Important! It is recommended to protect against freezing not only through thermal insulation, but also using a special heating cable.

*

Fighting condensation

Condensation can cause home owners no less problems than freezing of a pipeline. It appears to be the result of an increase in air humidity with temperature changes. Small droplets begin to accumulate in water supply areas, which can lead to corrosion or destruction of the material. This is exactly what happens to many cold water pipes in the summer. The temperature difference between inside and outside does not pass without leaving a trace, but is transformed into drops of water.

In addition to corrosion, other unpleasant consequences may also occur. For example, puddles under pipes that form due to prolonged formation of condensation. Such operation significantly reduces the service life of products, making them more vulnerable to other environmental influences.

To avoid all the unpleasant consequences of condensation, it is recommended that all cold water supply pipes be insulated using heat-insulating materials. It is best to use Energoflex insulation. Additional polypropylene fittings may be required for installation.

Noise protection

Replacing sewer pipes from cast iron to plastic led to the appearance of a booming sound that accompanied the operation of all drainage systems. And this sound was capable of causing quite a lot of inconvenience to all the inhabitants of the houses. The situation was analyzed and experts came to not the most comforting conclusions. Since plastic sewerage was made from pipes with a thinner wall thickness, and the material itself had a much lower density compared to cast iron, the sound travels much faster. At the same time, all the noise is reflected repeatedly from the surface of the pipes, constantly increasing the volume. The result is a loud hum, which can easily disturb the quiet life in the house.

In order to reduce the impact of noise on life, it is recommended to use Energoflex insulation. The company offers special materials with enhanced sound insulation properties. Also effective in this case is conventional roll insulation, attached to pipes with glue. Sometimes the manufacturer applies glue to one of the surfaces in advance, so the builder only needs to properly secure the material to the pipe.

Inner coating

*

Application of internal insulation for metal pipes is carried out only in factory conditions, in strict compliance with regulatory standards. Internal insulation allows you to maintain all the operational characteristics of the pipeline. Most often, products with this type of insulation are used for laying underground pipelines.

Reinforced internal insulation

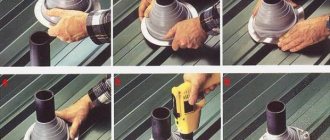

Separate stages of work production

Work is carried out in compliance with the following rules:

- It is necessary to begin thermal insulation of the pipe only after complete completion of all installation work (metalwork, welding).

- The pipe surface is manually cleaned using special brushes. Mechanical sandblasting can be used. After this, the surface is degreased.

- It is necessary to test the strength and tightness of welded seams. In addition to visual inspection, hydraulic tests are carried out under high pressure. Special equipment can also be used for control.

- Then special compounds are applied to the surface. An example is epoxy primer.

Recently, the method of insulating water supply and sewerage pipes using a heating cable has gained quite a popularity. This method is most relevant in regions with harsh winters. There are types that independently regulate the heating temperature. For greater energy savings, it is necessary to install a thermal relay. But the presence of such a cable still implies the need for high-quality thermal insulation. Without this, uncontrollable expenses will occur.

Requirements for insulation. Types of insulation

First of all, it should be noted that today two types of materials are used for insulation of pipelines:

- Roll or slab type.

- Shells (cylinders).

In order for pipelines to operate efficiently, it is necessary to select the right thermal insulation material that meets a number of requirements.

- The insulation should be intended specifically for thermal insulation of pipes. Usually, there are no problems with roll and slab materials during their installation. But the shells must be precisely matched to the diameter of the pipe.

- Low water absorption. The thing is that wet insulation completely loses its ability to control temperatures.

- Compliance with fire safety and sanitation standards.

- Good service life.

- The ability to carry out installation yourself, without using the services of specialists.

- Optimal price-quality ratio.

Today, manufacturers of thermal insulation for pipes produce large quantities of materials that meet the requirements from this list. Let's indicate the most popular ones.

Foamed polyethylene

A striking representative of this type is Energoflex insulation. It is presented on the market in rolls, sheets, and shells. Currently, the manufacturer offers 6 types of material:

- Energoflex Super is a shell with a longitudinal cut. Its main purpose is to insulate water supply and heating pipes inside buildings. The shell joint is closed either with self-adhesive tape or with adhesive. Can be used for insulating pipes with a diameter of 15-160 mm. Material length 1-2 m, thickness 0.6-2 cm.

- Super SK is essentially the same insulation 2 m long, only the ends of the joint are treated with glue.

- Super Protect. This is the same shell, only covered with an insulating film of red or blue color. The first is used for insulating pipes of the heating system, the second is used for water supply. Can only be used inside buildings.

- Black Star. This is the latest development, specially manufactured for insulating pipes of air conditioning and ventilation systems. There are two types: for indoors and for outdoors. The second type has a special polymer coating that resists the negative effects of sunlight.

- Super series roll material. Its purpose is thermal insulation of large diameter pipes, as well as containers for various purposes.

- Roll material from the Black Star series. Mainly used for outdoor work. Currently, the manufacturer offers the so-called laminated version - this is insulation with a foil layer and marked “AL”.

The technical characteristics of Energoflex confirm its high popularity. This is a low price, zero water absorption, the material does not rot over time, colonies of microorganisms do not form on it, it tolerates various loads well, the service life is almost eternal (guaranteed - 25 years). The only drawback is the fear of sunlight, under the influence of which it decomposes, therefore, when using Energoflex outdoors, it is recommended to cover it with a protective coating (roofing felt, polymer film, foil).

Fiber insulation

This type of heat insulator is based on materials such as basalt wool, glass wool and slag wool. All of them belong to the category of mineral wool. Most often, the roll type was used for pipe insulation; for large diameter pipes, special slabs and blocks were used. Currently, manufacturers also offer cylinders.

Slag wool insulation is prohibited for indoor use due to the negative impact of its particles on the human body.

In many respects, mineral wool is one of the best insulation materials with a low price. Its disadvantage is high water absorption, which is why it is recommended to use it only in dry rooms or carry out thermal insulation with the installation of a protective coating. By the way, this material is most often used for insulating chimneys, because it can withstand high heating temperatures - up to +700C. At the same time, the main purpose of mineral wool for a chimney is to create a barrier that would prevent the appearance of condensation, which reduces the service life of the chimney.

Foamed polystyrene

A prominent representative of this category is Penoplex. It is available in plates and cylinders. Rigorous testing has shown that today this is the best thermal insulation material with a low price. Repeated testing by freezing and thawing did not reveal any changes in its technical characteristics. Today you can buy Penoplex of different densities, which correspond to its different purposes. The only drawback is the fear of ultraviolet radiation.

Foamed polyurethane (FPU)

This is the most expensive, but also the highest quality pipe insulation. There are three options here:

- slabs;

- cylinders;

- spraying

Most often, cylinders are used for thermal insulation of pipes. For interior spaces - without external finishing, outdoors you can install material with foil, with reinforced foil, with a fiberglass coating.