For uninterrupted operation of the sewerage system, insulation for sewer pipes is used. To ensure that wastewater can end up in the septic tank, special attention should be paid to the laying of the external structure of the pipeline. This will be discussed in this article.

Buying your own home has always been considered an excellent investment option. However, such an acquisition is associated with the improvement of the building itself and the surrounding area. The owner gets the opportunity to choose whether to build a septic tank on his own, or buy and install a ready-made treatment facility.

Thermal insulation of drains

In most cases, external sewerage is laid in trenches. This is due to the fact that the principles of operation of the system are based on the gravity flow of wastewater. For this reason, for their normal passage it is necessary to create a height difference in the pipeline. But don’t forget about insulation, which helps protect system elements from freezing or mechanical damage.

SNiP requirements

According to the requirements of SNiP for thermal insulation of sewerage systems, to determine the minimum depth for laying pipes, the experience of operating networks in the area should be studied. If the required information on the minimum depth is not available, then a pipe with a diameter of up to 50 cm is laid to a depth of no more than 0.3 meters. Any part with a circumference greater than 50 cm must be laid in the ground at a distance of at least 0.7 m. To determine the minimum installation depth for collectors with fluctuating wastewater flow rates, static and thermal calculations should be carried out.

Note

In this case, all parts placed at a depth of at least 70 cm must be protected from freezing or mechanical damage.

The above SNiP requirements assume that the external sewerage system was not insulated.

In cases where the pipeline is protected from mechanical stress, or the depth of installation of the system allows it, the sewer system can be located at a shorter distance. This will significantly reduce the amount of work performed, and will also provide access to the drainage system for repairs if the need arises.

Insulation of external sewer pipes - generally accepted methods

When deciding how to insulate a sewer system in a private house, a number of methods are considered, the main ones being:

- Depression in the ground. To implement this method, a prerequisite is to place the pipe outdoors in a trench below the maximum freezing point for the given area.

- Using an electrical cable. This technology for insulating external sewers is easily implemented thanks to the manufacturer, which produces reliable moisture-resistant electric heating cables placed inside the pipeline or special sockets in the pipes.

- The use of insulation. This method of thermal insulation can be quite simply implemented thanks to the shells produced from various types of insulation with a diameter suitable for sewer insulation.

- Combined methods. An excellent solution for thermal insulation of sewer pipelines is the use of additional insulation by placing them in a shell of insulation at an average depth in the ground. Another common option is to place the heating electric cable in a sheath of insulation, while the sewer line is located at a short distance from the surface of the earth.

Rice. 3 Installation of pipes in a trench

Laying the pipeline below the freezing depth

When laying a sewage system on your own, you can try to lay the parts to a depth that will be 10 centimeters below the soil freezing level. With this arrangement, additional thermal insulation of sewer pipes will not be required. Naturally, this is considered an ideal option, but it is used extremely rarely.

Causes:

- The presence of a large amount of work that will have to be carried out when preparing a trench for laying, as well as for digging a hole for a septic tank. If special equipment is not involved, then it is extremely difficult to make such a volume with your own hands.

- In the middle zone, the depth of soil freezing is one and a half meters. It turns out that the pipes will have to be laid to a depth of 1.6 m. In addition, the pipeline must be laid with a slope, so the septic tank must be laid at a depth of two and a half or three meters. The use of such a drainage system is irrational.

- When sewer pipes are too deep, it will be impossible to repair the drain, especially in winter.

It turns out that the choice of the option of deepening below the soil freezing level can be selected only in the case when it is possible to attract special equipment for the work.

Insulation using materials

In order to protect the sewer system from freezing, you can use one of the following insulation materials.

Mineral wool

This insulation for sewer pipes is considered a classic insulation option. However, when constructing a large sewer system, using mineral wool is not economically feasible. The fact is that the material consumption is too high, and the pipe itself must be completely waterproofed, because the material is hygroscopic, and if moisture gets in, it completely loses its insulation properties.

Polyurethane foam

Polyurethane foam

Such insulation is more often used to protect pipes from freezing, because it is not afraid of water ingress. This material is produced in the form of a half-cylinder and has a special recess inside for parts of the sewage system. Insulation of external sewer pipes occurs due to the presence of special connections on the parts that allow them to be snapped together. Working with such material will not cause difficulties. In addition, we are pleased with the excellent insulation efficiency and low cost.

Penoizol

Penoizol

This insulation is available in liquid form. After hardening, a solid sealed shell is formed on the surface of the pipe, which can effectively prevent freezing of the pipe underground. The disadvantage of this insulation option is the need to use special equipment that is used to apply penoizol. It is for this reason that insulation is not used in the construction of private houses.

Foamed polyethylene

An effective and practical material used for sewer insulation. These products are manufactured in the form of a pipe and have different diameters. To make it easier to put on the insulated element of the system, a special cut is used, which is subsequently sealed with ordinary tape.

Foamed polyethylene

Insulation of the sewage system can also be done using other thermal insulation materials made from foamed polymers and having foil as a protective screen. This type of insulation is often found in industrial construction, since this option will be very expensive for owners of country houses.

Requirements for thermal insulation materials

Before you start choosing insulation, you need to understand what properties it must have in order to cope with the task assigned to it.

- For safe operation, the material must be non-flammable;

- A prerequisite is water resistance. Since wet insulation in most cases loses its thermal insulation properties;

- There is no doubt about durability.

- It is not recommended to choose materials that contain cellulose, as it quickly disintegrates upon open contact with the ground;

- Installation of the material should be simple and not require the purchase of expensive fasteners;

- Reusable. Imagine that the installation of the pipeline was not hermetically sealed, and a leak formed at the junction of two pipes. To eliminate it, you must first remove the insulation layer from the pipe. It will be much more economical if the material retains its shape and you can reuse it in the repaired area;

- For high-quality insulation, the material must have a low thermal conductivity coefficient;

- It should also not react with any biological or chemical compounds that may be present in the surrounding soil;

- If we are talking about insulating a pipeline running underground, the material must be rigid enough to withstand the pressure of the earth, not deform and not put additional pressure on the pipes;

- Do not react to sudden temperature changes and other environmental factors;

- It is also worth paying attention to materials that have an additional foil layer, which acts as protection against moisture. Such materials are more expensive, but sometimes you can’t do without it;

- Well, and most importantly, the cost of insulation should not be such that the insulation work turns out to be “golden”.

Application of special cable

Insulation of sewer pipes in the ground is carried out using a cable that can be run along the surface of the pipe or along the inner wall. In the second option, the gasket is made in a special channel made of protected material. In the case of active insulation of the sewage system, pipes can be laid to a depth of half a meter. However, it is important to remember that such a sewage system will be energy independent. If there is a power outage in the area, the pipes will stop heating. For insulation, you can choose a self-regulating or regular cable. Of course, the second option will be much cheaper. However, the pipe will heat up along its entire length, which will lead to uncontrolled energy consumption.

Heating cable

Principle of operation

The principle of operation of a self-regulating cable is based on cyclicity, that is, only those parts of the system are heated where the temperature level drops below the permissible norm. The high price of a self-regulating cable will quickly pay for itself due to the low costs of maintaining performance.

Installation procedure and pipe insulation

When the insulation material has been selected, you can proceed directly to the installation and subsequent protection of the pipes from freezing. The work must be performed in the following sequence:

- The trenches are being prepared. They should be dug at least 60 cm wide (when the 110 mm sewer pipe is subsequently insulated for external sewerage), and the depth should be 0.1 m greater than the initially planned parameter. It is important to maintain a slope of several degrees when digging trenches.

- A margin of 10 cm will be required to prepare sand cushioning. To do this, you need to pour sand into the trench, in a layer of the indicated ten centimeters, and compact it well.

- Pipes are laid out along the entire length of the trench, as well as the elements necessary to connect them at each section.

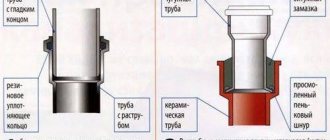

Connections

- Connections are being made. In most cases, during the assembly of parts of the future pipeline, a connection is used, which is popularly called “into the socket”. The contact points between the parts should be well sealed. For these purposes, you can use any known means or special cuffs.

- The insulation of the sewer pipes is put on and secured. It should be fastened so that the material does not allow free play, that is, it fits tightly to the part. To do this, you can simply wrap insulation tape around each drain pipe. Such a simple fastening will be an additional guarantee that the material will not move due to soil movements that occur during freezing and subsequent thawing.

You may also like - Sewerage in a private house - do-it-yourself step-by-step installation

Let's fall asleep

- A layer of sand is poured over the finished pipeline. Compacting should be done on the sides, since dense compaction of sand above the pipe itself will cause mechanical damage to the structure.

- At the last stage, the trench is completely filled with soil. In this case, you should definitely make a small hill, since the soil will certainly subsidence over time.

Insulating sewer pipes is considered an activity that not all installers recommend. However, when building your own home, it is better to devote some time to completing these works.

The cost of materials will not greatly affect the overall financial investment in construction. And the insulation itself will protect the owner from freezing of external pipes and such negative consequences as a sewer break, the elimination of which will have to spend a much larger amount.

Everything useful about sewerage -

GidKanal | Yandex Zen

Good or bad

The high price of a heat-insulating material does not always indicate its excellent properties. There are unscrupulous manufacturers, and among sellers there are those who like to “inflate” the price. Before choosing and buying insulation, you need to thoroughly study its characteristics and think carefully about everything. It is very good if you can get a sample and conduct some experiments:

- Bring a small piece of thermal insulation material to a bright lamp. Translucent - bad. If sewer pipe insulation allows light to pass through, heat will also pass through it. Such a check is not necessary for materials with additional coating (foil and the like).

- If we are talking about foam material, you need to look at the cut. The air cells should be small, ideally approximately the same. Large air chambers will not retain heat well.

- Set the sample on fire. High-quality insulation does not burn. Some materials for heat insulators are initially flammable, which can be eliminated with the help of special additives.

- Try to pull and tear a fragment of the heat insulator. If this happened very easily, the strength is in doubt. Such material can simply be accidentally damaged during the installation process.

This due diligence will help you make your final choice.