Materials for sealing sewer pipes ↑

Installation of the sewer system is carried out using plastic, ceramic or cast iron pipes. The choice of material for sealing joints is much wider. Most often, acrylic, silicone or polyurethane sealants, self-adhesive tapes, resin ropes (heel), bitumen mastics, technical sulfur, and Portland cement are used for sealing. Among the “available” materials, rags filled with cement mortar or paint, and epoxy resin are used. Which sealant to choose, how to work with it, the advantages and disadvantages of each - the information collected below will help you understand these issues.

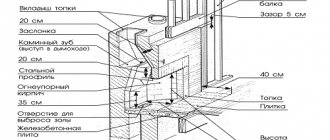

Socket connection of sewer pipes

How to seal a pipe with cement mortar and resin rope

It is possible to seal the sewerage system with these materials. The method itself consists in caulking two-thirds of the depth of the socket with a resin rope. And the remaining third is filled with cement mortar mixed in a ratio of one to nine. It is necessary to use a cement composition with the M300 grade.

For people who want to seal drain pipe joints at a minimal cost, expanding waterproof cement is the best choice. In this case, the use of a resin rope will not be required. After all, such cement sets quickly, while expanding. The composition must be prepared immediately before use by mixing the base with water in a ratio of 1 to 2.5.

Main types of sealing materials (characteristics)

Previously, oil paint and plumbing linen were used as sealing materials. But modern technologies offer a much wider selection of different sealing materials.

Sealing tapes

These are self-adhesive tapes, somewhat similar to a roll of white tape. They can have different widths and are mainly used for plastic pipes in residential areas. Such tapes not only protect against water leakage, but also help strengthen various related elements such as plugs, joints, and so on.

The main advantages of this sealant include the following: lack of electrical conductivity, reduced risk of corrosion of sewer pipes, ease of use and at the same time a high level of reliability of the material.

Example of sealing tape

It is important to remember that such tapes quickly deteriorate when exposed to ultraviolet rays, which is why they are recommended for use only inside residential premises. However, if there is still a need to use it in the sun, then the tape is covered from it, for example, with a special protective film

In order for this material to have the intended effect, the pipes must be cleaned of dust and dirt, and then thoroughly wiped or dried. Immediately before gluing the tape, a primer is applied. After this, the tape is wrapped around the pipe in a spiral, tightly, without folds, with a half overlap.

Polymer sealants

Otherwise known as silicone, since the main material in this case is silicone rubber. They are considered one of the most popular sealing agents, including because, if desired, you can choose such a material of any color, including the same as that of the sewer pipe. They are mainly used to strengthen joints and seal fistulas. They can have both neutral and acidic compositions. Acid options are cheaper, but some pipes are not resistant to acids, and in general such compositions are not recommended for use on fragile elements. Neutral options are used in all cases where acidic options cannot be used.

Among the advantages of this type of product are the following: when used, mold and rot do not appear, even over time; when hardened, the composition becomes like rubber and perfectly protects sewer pipes from leaks. In addition, silicone sealants adhere well to the pipe material, they are durable, resistant to moisture and temperature changes, and also last quite a long time.

Polymer sealant for sewer pipes

The sealant is squeezed out with a special gun for installation, however, if you don’t have one at hand, you can use an ordinary hammer.

Mastics based on petroleum products

Also good for sealing sewer pipes, especially for filling sockets. There are several main varieties: bitumen-polymer, bitumen-talc, bitumen-rubber, bitumen-asbestos-polymer. Mastics come in both cold and hot application methods. Those with a cold method are a little more expensive, but they are simple and safe to use. Before using such products, it is advisable to turn off the water supply, and the pipes themselves must be cleaned, degreased and dried.

Epoxy resin

This variety is often used at home. In essence, resin is a universal glue. Before use, it is mixed with a special hardener. The required mixing proportions are indicated on the packaging by the epoxy resin manufacturer. By the way, you cannot deviate from the specified proportions; this can lead to unexpected and unpleasant consequences. From the mixture suddenly boiling, to the resin's lack of effectiveness as a sealant for sewer pipes.

Portland cement

It is a dry mixture of gypsum, clinker and calcium silicates with special additives to increase the reliability of sealing. Before use, the composition is diluted with water to a thick solution. The resulting slurry must be used immediately, as it hardens quite quickly (from 5 to 10 minutes) and turns into a monolithic structure with frost resistance, high strength, and the ability to repel water.

Advantages and disadvantages

The advantages include the following qualities:

- Moisture and frost resistance, which allows the mixture to be used, including for external pipes;

- High strength and reliability of the hardened mortar;

Portland cement is one of the sealants for sewer pipes

And as a disadvantage, it is worth noting the fact that it is necessary to work with the diluted mixture very quickly, otherwise it will harden and will be useless.

Category No. 2: seals for heating systems

We all have to install a new heating network, change radiators and thread seals shortly before the heating season. Find out from my article which sealants can now be used for this.

Flax tow

Flax fibers on paint are now little used as a sealant.

At the moment, there are many seals for radiators and pipes of heating systems that belong to different generations. One of the oldest sealants is flax tow, planted on paint.

However, this material was good many years ago; now it is of little use. I'll explain why:

- Linen is natural, i.e. degradable, therefore a short-lived sealant. Previously, cast iron radiators could be used quietly for 40 years. However, now the service conditions of heating networks have become different. This sealant will have to be changed after 3-4 years.

- Current paints have a composition that is different from that of their Soviet counterparts. They are absolutely not suitable as impregnation of flax fibers. Silicone is also not suitable for this. It contains vinegar, which causes thread corrosion.

It is better not to use linen sealant in high-rise buildings - it is not suitable for high pressure.

- Modern high-rise buildings are not Khrushchev buildings with 2-5 floors. During pressure testing (testing of pipelines for strength and tightness) and operation of the network of such a building, a pressure of up to 16 atmospheres is turned on. Linen sealant can be used at pressures up to 8 atmospheres.

As a result, the connections on the flax seal burst due to its swelling or cannot withstand the operating pressure in the heating system.

For apartments in a 1-5-story apartment building, linen sealant can be used. There are only a few connections in the dwellings. In your own home or cottage, the number of threaded connections on pipes can approach several hundred. It is highly undesirable to use flax sealant in them.

More modern means - polymer threads and anaerobic sealants

The photo shows the sealing of a pipe fitting with a polymer thread.

Flax planted on paint is gradually becoming a thing of the past. Now there is a more modern, reliable, safe and durable method of sealing pipes and elements of heating systems. It is based on the use of polymer threads and anaerobic gels.

- The anaerobic sealant for heating polymerizes in contact with the metal, completely filling the entire thread. The connection will last as long as the pipes, without replacements or leaks. He will not be afraid of high pressure and temperature, shock and vibration loads.

- Polymer threads are also an excellent sealant for threaded units of heating systems. They are suitable for sealing metal, PVC and polypropylene pipes, the mating of which is undesirable using gel materials. The operating temperature of the threads is not limited, and dismantling is easy.

Anaerobic gels produced by PCT.

In the lower table I present to you the technical characteristics of high-quality anaerobic gels from the Russian company RST (Region Spetstekhno).

| Name | Purpose | Characteristics |

| Gel "Santech-master" (green) | Anaerobic sealant for metal flange and threaded connections up to 1.5 inches. | Polymerization period: 20/30 min. Application temperature from +15º. Dismantling is easy. Volume: tube – 60 g, blister – 15 g. Operating temperature range -60/+150º. Ingredients: dimethacrylate polyglycol and modifiers. |

| Gel "Santech-master" (blue) | Anaerobic sealant for metal threaded and flanged connections up to 2 inches | Polymerization period: 15/20 min. Installation temperature from +15º. Dismantling requires medium force. Volume: tube - 60 g, blister - 15 g. Composition: dimethacrylate, polyglycol and modifiers. Operating temperature range -60/+150º. |

| Gel "Stop-master" (red) | Anaerobic sealant for metal flange and thread connections up to 3 inches. | The polymerization period is 5 minutes. Installation temperature +5º. Heating is required for dismantling. Volume: tube - 60 g, blister - 15 g. Composition: dimethacrylate, polyglycol and modifiers. Operating temperature range -60/+150º. |

No. 3. Polyvinyl chloride (PVC) sewer pipes

For arranging internal sewerage, PVC pipes are considered almost the most suitable option. During the production process, some other substances are added to polyvinyl chloride, which include stabilizers and polymers. Elements of the required shape are formed from the heated mass.

PVC pipes can be of two types:

- pipes made of plasticized PVC (PVC) have good elasticity and low strength;

- pipes made from unplasticized PVC (PVC-U) are more rigid and resistant to aggressive influences.

Of course, it is better to use unplasticized PVC, but in practice both types of pipes are used. The diameter of the products ranges from 2 to 20 cm.

Main advantages:

- affordable price;

- light weight;

- ease of installation. Separate sections of pipes are connected by couplings and connecting rings - everything is done without welding;

- low temperature coefficient of expansion. With a short-term or constant increase in the temperature of the drains, the pipes will not sag;

- sufficient strength and durability up to 50 years;

- sufficient resistance to ultraviolet rays, so that some sections of pipes can not be afraid to run on an open surface;

- resistance to corrosion and some aggressive substances;

- Thanks to the smooth inner surface, the walls do not silt over time.

Minuses:

- limited operating temperature range. With constant exposure to negative temperatures, pipes become fragile and lose their tightness, and with constant exposure to temperatures above +60...+70C, the material can deform and also lose integrity;

- insufficient fire resistance;

- The inner walls of PVC pipes are smoother than those of cast iron, but over time they will still develop plaque. In addition, the internal diameter changes over the years. As a result of exposure to high temperatures, the circular cross-section is transformed into an ellipsoidal one, and this impairs the throughput and contributes to the occurrence of leaks;

- some aggressive substances contained in drains can still lead to the gradual destruction of pipes.

To install internal sewerage from PVC pipes, appropriate connecting elements are used. These include an elbow designed to rotate the pipeline at an angle from 20 to 87 degrees, a tee for arranging branches, a cross for connecting four pipes, and a reduction for connecting sections of pipes of different diameters.

Cast iron pipes

When listing the types of metal pipes used for the installation of sewerage systems, one cannot fail to mention cast iron products. Since cast iron pipes have been the main material for assembling sewer networks for decades. The main advantages of this material are:

- Durability and long service life;

- Corrosion resistance.

The disadvantages of the material include:

- Heavy weight, which makes it difficult to transport the material and install it.

- Relatively high fragility. Cast iron pipes do not withstand shock loads well.

- It is impossible to use for laying an external pipeline in saline soils, since soil brine quickly destroys the material.

- Rough inner surface, which causes pipes to clog faster.

Asbestos cement pipes

To produce such pipes, a mixture of asbestos fiber and Portland cement is used. Advantages of these products:

- Resistance to corrosion processes.

- Simplicity of machining, which greatly facilitates installation.

- Long service life.

- Smoothness of the inner surface.

- Asbestos cement is a dielectric, so this material is not subject to electrochemical corrosion.

Asbestos-cement pipes have disadvantages, these are, first of all:

- Fragility of the material. When working with pipes made from asbestos cement, you have to be extremely careful and careful.

- Under the influence of soil, the outer surface of the pipes quickly collapses, so protective measures must be taken.

Ceramic pipes

Ceramic pipes resemble cast iron pipes in their properties, however, they are lighter and one hundred percent resistant to corrosion. The undoubted advantage of ceramic pipes is their resistance to high temperatures and aggressive environments - acids and alkalis.

However, the material is quite fragile, so you need to handle the pipes carefully during loading, transportation and installation. In addition, mechanical processing of pipes (cutting) is difficult; if you try to cut the pipe, it may simply split.

Pipes made of polymer materials

Today, various types of plastic pipes for sewerage are widely used. For the manufacture of such products, three types of polymers are used:

- Polyvinyl chloride.

- Polypropylene.

- Polyethylene.

PVC pipes are designed for gravity sewer systems. The material is quite durable and can withstand high loads. PVC pipes are widely used for the installation of external systems, as they are inexpensive, can withstand aggressive environments, and are resistant to ultraviolet radiation. But pipes cannot withstand exposure to temperatures above 70 degrees; at very low temperatures, PVC becomes brittle, so it is recommended to insulate them.

Various types of polypropylene pipes are widely used for assembling sewerage systems. These pipes have a long service life and can be used for both gravity and pressure systems.

It is necessary to distinguish between the types of propylene pipes intended for internal and external pipelines. The first type of pipes was created for use at home; they are quite durable, but are not able to withstand the effects of low temperatures and loads exerted by the soil.

For external pipelines, special types of pipes are produced - two-layer ones. Their inner layer is perfectly smooth, and the outer layer is corrugated, so the pipes are characterized by increased strength.

When assembling sewerage systems, different types of polyethylene pipes are increasingly used. This material is mainly used for the installation of non-pressure systems. The great advantage of this material is its high elasticity; when the liquid in the pipe freezes, the polyethylene does not collapse, but only deforms.

Metal-plastic pipes

For the assembly of various systems, including sewerage systems, different types of metal-plastic pipes are widely used. These pipes are coated with plastic, so they are one hundred percent corrosion resistant, chemically neutral and fairly easy to process.

At the same time, the presence of a metal core gives these products increased mechanical strength. The disadvantages of the material include their rather high cost.

Sealing the junction of cast iron and plastic pipes

To perform such an operation, you will have to follow this algorithm. First, adapters are purchased that are used to connect pipes made of different materials. A cast iron pipe must be thoroughly cleaned, and for better sealing, the socket should be degreased. Its internal cavity is subsequently sealed with sealant, as is the outer part of the structure. The adapter is placed in the socket, after which you need to wait until the sealant hardens. Then you can insert the pipes with each other, and they will be properly sealed. After some time, you need to test the sewer for leaks.

Conclusion

Sealing sewer pipes is not the easiest process, but there is nothing special about it: just follow the instructions and know what should happen in the end

Of course, choosing the right sewer pipe sealant is important. If everything was done correctly, the sewage system will work perfectly, providing a high degree of comfort to users. A sewer system that does not leak is considered reliable.

Therefore, good sealing of sewer pipes at home or in an apartment is a guarantee of no troubles in the future.

A sewer system that does not leak is considered reliable. Therefore, good sealing of sewer pipes at home or in an apartment guarantees the absence of troubles in the future.

The age of the sewerage system, its wear and tear (for example, cast iron pipes in the risers of high-rise buildings), outdated materials, of course, can leak due to age and require complete replacement. However, as practice shows, during operation the most vulnerable point, whether when laying new or when repairing old communications and drainage systems, is the place where they are connected. And the question remains of how to seal sewer pipes at the joints.

Previously, linen winding or plaster bandage and oil paint were used to seal cast iron pipes in risers and basements of houses and apartments. But today, construction stores sell a lot of modern materials and sealants, to select which you need to understand the differences, purposes and properties applicable to drainage systems.

Self-adhesive tape is a modern material for sealing joints in the sewer system. It is a white film wound on a spool and has different widths.

Advantages of self-adhesive tape:

- Convenience and ease of use;

- Good resistance to corrosion, thereby protecting the sewage system from rusting;

- Does not conduct electricity;

- High reliability and efficiency.

Disadvantages of self-adhesive tape:

Lack of UV resistance. This makes it impossible to use this material in open spaces.

Experienced craftsmen and builders use self-adhesive tape not only for sealing joints of sewer systems. It is often used when working with fittings and various shaped elements.

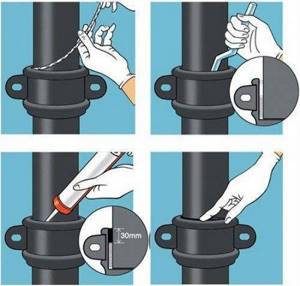

Features of working with tape

In order to perform the work efficiently, it is necessary to first prepare the pipes. They are thoroughly cleaned from layers of dust, dirt, etc., and dried well. Cover with a layer of primer and dry again. Once the surfaces have been prepared, you can apply the tape.

The tape is wound around the desired area in a spiral with a half overlap for greater tightness. After this, you can wind the second layer in a similar way. The pipes are sealed!

Why do you need sealing of sewer pipelines?

Sewage pipelines in the private sector, unlike urban conditions, require improved sealing for the following reasons:

- Ground instability. Loosely connected pipes placed under a layer of soil may separate when flooded with groundwater or during a spring flood as a result of weakening or subsidence of the soil, which will lead to depressurization of the joint and wastewater entering the soil.

- Temperature effect. In winter, when severe frosts occur, the soil may freeze to the area where the sewer line is located - this will lead to freezing of the sewer and the formation of a traffic jam. With the subsequent influx of liquid, the pipe elements may separate under pressure or when ice expands as a result of thawing.

- Temperature changes. When hot wastewater enters the sewer system, the hotter areas at the joints can expand, leading to leaks.

- Temporary aging. Over time, the tightness of the sewer line connections decreases due to the loss of their physical properties by the manufacturing material and the rubber rings in the pipes. This can cause the connection to become depressurized and drains to leak.

Fig 2. Method of sealing cast iron pipes

- Difficulty in repairing leaks. Since a private sewer line is usually located underground with a slight slope, it is quite difficult to determine the location of the leak - if it occurs at a high point, the drains will flow down the slope, making it difficult to find. In most cases, you will have to dig up the entire highway to carry out repair work.

- Increased damage from leaks. When sewage gets into the soil, together with groundwater, it can reach the aquifer if the well or borehole is shallow. This will lead to contamination of the water with pathogenic bacteria, as a result of which residents may be left without drinking water.

- Strong regular leaks can cause an unpleasant odor due to the presence of gases harmful to humans in the air: hydrogen sulfide, ammonia, methane.

Almost the same problems will have to be faced, with the exception of contamination of water, soil and unpleasant odors, in the event of depressurization of an underground water main, if it consists of sections of pipes and does not have a welded joint.

Characteristics and use of neutral sealants

This version of sealing agents is a composition based on silicone rubber. The consistency is viscous, viscous, hardens during contact with moisture in the atmosphere. The drug has good plasticity. Because of this, it can be used during the processing of joints that may be subject to deformation. In addition to pipe processing, it is used in the field of finishing work.

Neutral compositions do not have an aggressive effect on the surface, but it is not possible to paint them

Advantages of neutral sealants:

- have a high degree of adhesion to all construction materials;

- are not completely afraid of water;

- are not afraid of ultraviolet radiation - can be used in the open rays of the sun;

- resistant to organic solvents;

- not exposed to aggressive environments of acids and alkalis;

- remain productive in the temperature range from –60 to +300 degrees;

- durable.

Helpful tips for proper use

Experts make the following recommendations:

- Before applying plumbing sealant, the surfaces must be completely cleaned of any grease or residue from the previous solution. Otherwise, the composition may move away from the threads or begin to crumble if solid dirt particles get into it.

- The amount of winding is determined experimentally. There should not be too much of it so that the parts can fit into each other. But if the quantity is insufficient, water leaks may occur.

- Brass and bronze pipes are very fragile, so be careful when tightening them.

- Before putting the water supply system into operation, the water pressure is started in test mode.

We recommend videos on the topic:

Main types of sealing materials

A variety of materials can be used to seal butt joints:

- self-adhesive sealing tapes;

- sealants based on modified silicone;

- technical sulfur;

- linen or jute rope;

- asphalt bitumen;

- Portland cement solution;

- epoxy resin.

Each of these materials has its own tasks, features and scope of application.

Scotch tape

Scotch tape is made on an acrylic or bitumen-rubber base, it contains a copper or aluminum layer and a protective film, which is removed during the installation process. This is a simple and effective product with a long service life (over 10 years).

It provides high connection strength, protects pipes from corrosion and is a good dielectric. The scope of application is the sealing of inserts, functional plugs, pipeline rotation angles, and bends.

Silicone sealants

The composition of such sealants includes rubber, so they are distinguished by increased elasticity and good adhesion to the surface. There are one and two-component formulations.

The first, depending on the components, are of two types:

- Acidic. The polymerization process is accompanied by the release of acetic acid, but after hardening the odor disappears. The elasticity of the material is maintained at temperatures ranging from -50 to +200 °C. They are not used to seal metal elements, as they strongly oxidize the metal and can cause corrosion.

- Neutral. Suitable for all types of connections.

In two-component compositions, along with the base, there is a catalyst that accelerates polymerization, and the solidification process does not depend on the thickness of the layer. But the cost of such sealants is higher.

Technical sulfur

Most often, technical sulfur is used to seal cast iron pipes. Lumpy sulfur or a substance in powder form is sold in the retail chain.

Before use, the material must be crushed and heated to the melting temperature (130°C), after which it is filled with the joint surface.

We recommend that you read: Which gas torch to choose for soldering copper pipes - a review of the best

After 10-15 minutes, a dense waterproof surface is obtained.

Low elasticity is the main disadvantage of this sealant. To increase it, add white clay (10-15%).

Linen or jute strands

This type of material is characterized by low cost and ease of use, but their technical and operational characteristics are inferior to modern types of sealants.

To create a strong connection, a 6-50 mm rope is used, which is an ordinary twine or twine impregnated with bitumen or resin, which makes this material unusually strong and impenetrable. Previously, before the advent of modern sealants, this was the most popular method for strengthening and sealing pipe joints.

Mastic and bitumen

To seal the joints of ceramic pipes and fill sockets, compositions are used whose main components are asphalt mastic or petroleum bitumen. Rubber-bitumen, asbestos-polymer-bitumen, talc-bitumen mastics performed well.

Based on the type of application, the mixtures are divided into cold and hot. The former are easier and safer to work with, they contain 50-70% bitumen and are more expensive.

When using hot applied mastics, they are heated to the required temperature at which the solution becomes plastic. The result is a quick-setting, seamless surface. When hardened, it does not shrink and is cheaper than cold applied mastic.

Portland cement solution

Portland cement consists of gypsum, clinker and calcium silicate. The working solution is prepared by mixing the dry mixture with water. It sets quickly and forms a durable water-repellent surface. To increase elasticity, special additives are used. The material is resistant to sudden temperature changes and can be used for outdoor use.

Epoxy adhesive

To obtain a sealing composition, universal adhesive is mixed with a hardener in a ratio depending on the grade of pipeline material.

All standards are contained in the instructions for the epoxy resin; they must be observed; violation of the proportions will lead to a decrease in the performance characteristics of the finished coating and will affect the hardening time.

Methods for eliminating leaks

Before carrying out work, it is necessary to warn residents not to use the sewer system. Then you should turn off all appliances that use water, such as a washing machine. After covering the leaking area, thoroughly dry the leaking area with a hairdryer.

Before starting work, it is worth understanding the material from which the sewer system is made. Today it is metal (steel, cast iron) or polymeric materials - polyvinyl chloride or polyethylene. How to cover a sewer pipe joint depends on the material.

The leaking joint must be thoroughly cleaned of any cementitious residue. Then treat with an aqueous solution of cement and PVA glue. Be sure to use gloves when doing this. The solution will take about a day to dry. Accordingly, you cannot use the sewer system at this time.

It is advisable to use a repair coupling to perform the work.

Seal the joints with tape

Self-adhesive tape is a modern and reliable waterproofing material that allows you to quickly and efficiently seal sewer joints. The strength of the tape is given by the base made of polyethylene. Additionally, the product provides corrosion protection and good dielectric properties. The tape can be used to seal various parts of the plumbing system, such as bends, taps and plugs.

Toilet plumbing involves the use of various means of sealing, and self-adhesive tape is the first way to wrap a leaking joint (but not the only one).

We use sealants to eliminate leaks

Silicone or rubber based sealants are an excellent option for waterproofing sewer structures. The high level of adhesion to the surface of the elements is explained by excellent adhesion. Moreover, sealing of pipes can be carried out without pre-treatment with primers and primers.

The type of hardener used in sealants imposes restrictions on use in different conditions. The cheapest, acidic ones cannot be used everywhere because of a possible chemical reaction with acids. Neutral sealants are universal.

We can safely recommend the use of such sealant for most types of pipes. To be safe, after the work you will need to cover all joints and possible leaks with silicone.

The best silicone sealants

Of course, self-adhesive tape is a very good material for processing joints, but other substances are also used in construction. For example, silicone sealants are special materials that are applied to the area that requires sealing and harden when exposed to oxygen. Silicone sealant for sewer pipes has several advantages:

- good adhesion to the pipe material;

- high resistance to different temperatures;

- excellent resistance to moisture;

- excellent mechanical strength;

- long service life.

Sealant for sewer pipes can be made from different materials. The most popular material is silicone, or siloxane. The material contains silicone rubber and some additives that increase the adhesion and strength of the sealant. In the manufacture of the material, vulcanizing admixtures are also used to accelerate the polymerization of the substance. As a result, after applying silicone sealant, the output is an elastic material with characteristics similar to rubber. Neutral sealants are suitable for any coating, so they are used in difficult cases. In general, silicone sealants work great in conjunction with plastic and metal pipes. To squeeze out the sealant, a special device is used - a mounting gun. Sometimes this device is missing and cannot be used - in such situations, the plumbing sealant for the sewer can be removed using a hammer: its handle is inserted into the tube and pressed, acting like a piston. Silicone sealant contains silicone polymer and additives that increase its strength, adhesion and accelerate polymerization time. Silicone is mainly used for internal sealing of joints; its advantages are the following factors:

- High adhesion of the material to metals, plastics, ceramics, glass, enamel, stone.

- The material provides a long-term elastic connection without cracks.

- The temperature range of silicone is from -50 to 180 C, high-temperature domestic varieties are capable of operating at temperatures up to 260 C and briefly up to 350 C.

Paste-like materials based on various silicone rubber. They are characterized by high sealing ability and are able to provide resistance to possible deformations. During the polymerization process, silicone sealants turn into a rubber-like substance that is highly resistant to various influences. There are two main types of silicone:

- Neutral, which is used in most cases, ensures reliable sealing of the elements.

- Acidic silicone is necessary for the installation of pipelines working with aggressive media.

Sealing sewer pipe connections with silicone is affordable, while ensuring guaranteed quality and durable operation of the joint. Today, this material is most popular both among professionals and when solving various everyday issues.

Silicone sealants are traditionally used to seal joints between tiles in the bathroom. Due to their high degree of adhesion to most materials, they are perfect for any type of bathtubs, showers and exterior decoration. The main advantages of this type of sealant are resistance to moisture, UV rays and temperature changes. They demonstrate a long period of operation, and shrinkage, according to statistics, does not exceed 2 percent.

How and with what to seal a joint when switching from cast iron to plastic

One of the common problems in sewerage is replacing outdated cast iron pipes with plastic ones.

In apartment buildings, when carrying out major repairs, a cast-iron wastewater riser is almost always left, to which a plastic sewer pipeline is then connected. When carrying out work, dismantle the old cast iron tee and insert a new one made of PVC in its place; dismantling and installation are carried out in the following sequence:

- Remove the old tee. It is held in a cast-iron socket by means of chasing - that is, a recessed tarred flax rope is covered with cement on top or filled with sulfur.

- The tee can be cut or notched with a grinder and then broken with a hammer (this is very dangerous, you can damage the socket) and then gradually remove the remaining sealing materials using a chisel, a sharp screwdriver and a hammer.

Rice. 13 Dismantling the cast iron tee

- If you don’t have a grinder, you can melt the sulfur with a gas burner (while ensuring good ventilation and respiratory protection from sulfur fumes), and then remove the tee by gradually loosening it.

- If the embossing is made of cement, it is gradually knocked out with a thin flat-head screwdriver and a hammer.

- A universal way to clean the bell from the embossing can be to drill it out with a drill with a thin long drill bit.

- Clean the bell. After removing the old tee, the bell of the hole is cleaned of dirt with sharp objects, a metal brush and wiped dry.

- Place the adapter ring on the sewer sealant. Sealant is applied to the inner surface of the cast iron socket and a rubber adapter is inserted (make sure that it fits tightly to the socket), after which a plastic tee is easily attached to it.

Rice. 14 Connection of plastic and cast iron water pipes

Selecting a sealant

Maximum compaction when assembling sewer, heating or water supply systems can only be achieved by using a correctly selected sealant.

Two types of sealants are used to assemble pipelines:

- silicone;

- acrylic.

Silicone sealants

Silicone sealant is based on silicone rubber, to which are added:

- compositions to increase adhesion;

- compositions to increase strength;

- impurities to accelerate vulcanization.

Silicone based sealing compound

The advantages of silicone-based sealants are:

ease of use. The sealing material is applied to the surface of the pipe using a special gun or squeezed out by hand (small packages of material);

Device for easy application of sealant

- durability. Thanks to such qualities as elasticity, excellent adhesion, resistance to deformation, water resistance and heat resistance, the service life of silicone sealant is 15 - 20 years;

- wide scope of application. Silicone-based sealants can be used in the assembly of pipelines from various types of pipes. The sealing composition is suitable for the construction of internal or external pipelines, since the sealant is resistant to aggressive environments and direct exposure to sunlight.

Among the disadvantages of the sealing material are:

- seams treated with sealant cannot be coated with paint, since its composition negatively affects the sealant, reducing the service life;

- It is not recommended to use sealant when constructing a pipeline in cold weather, since low temperatures significantly reduce the vulcanization (hardening) period of the composition;

- The sealant should not be used on pipes larger than 4 inches (100 mm) in diameter.

To increase strength, silicone sealant can be used in combination with flax thread.

Silicone sealants, depending on the chemical composition, can be:

- acidic. This type of sealing compound is not suitable for sealing pipes made of non-ferrous metals, since a chemical reaction occurs between the materials;

- neutral.

Acrylic sealants

To seal water supply pipes, heating pipes, and so on, a separate type of acrylic sealant is most often used - anaerobic.

Anaerobic sealant is used to seal threaded connections. When it comes into contact with metal, the sealant hardens. The final polymerization of the substance, which imparts strength to the joint, is carried out after assembling the pipeline system assembly without access to air.

Sealing compound for threaded connections

The advantages of anaerobic sealant for heating systems, sewerage, water supply and so on are:

ease of use. The sealing compound is applied to the thread (flange connection) without the use of additional devices;

Using sealant

- resistance to vibration, which allows you to extend the service life of the threaded connection by 4 - 5 years;

- resistance to high temperatures and high pressure;

- no need to use additional sealing materials;

- additional protection of the metal surface of the thread from corrosion.

However, this type of sealant also has its disadvantages, which include:

- Can only be used on metal surfaces. For plastic pipes connected into a socket, this composition is not suitable;

- difficult to dismantle. If a specific section of the pipeline needs to be replaced, preheating will be required to separate the pipes and remove the sealant;

- the possibility of using sealant for pipes whose diameter does not exceed 8 cm;

- high price.

Depending on the strength of the resulting connection, all anaerobic sealants are divided into three groups:

- standard strength. The composition is used in the manufacture of pipelines with low pressure and not subject to vibration;

- medium strength. This sealant is used for the construction of a pipeline with average operating parameters;

- increased strength. Used to seal joints that are under high pressure and do not require constant dismantling.

For the construction of household pipelines, it is sufficient to use standard or medium strength sealants.

When choosing an anaerobic sealant, it is also worth considering the composition of the mixture and the diameter of the pipes, which may vary depending on the product line or manufacturer.

Selection of sealant according to parameters

Primers and protective films

When applying heat shrink tape to insulate pipes, no preliminary preparation of their surface is required. Self-adhesive waterproofing materials based on asmol and bitumen are applied only after priming.

Before applying asmol primers, the pipe surface must be cleaned. The operation is carried out before wrapping with asmol-bitumen or bitumen-polymer waterproofing film. These materials ensure reliable connection of the insulation layer to the base.

Bituminous mastic is applied before gluing the insulating tape. The material is completely ready for use. Can be diluted with solvent before use and does not require heating.

If during operation the pipeline is exposed to aggressive media, then additional protection is required. For this purpose, PVC wrapping or polyethylene film is used. Thanks to the thin protective layer, the integrity of the waterproofing material is maintained.

Types of sealants

Sealant (polyurethane and silicone)

The material is more often used for pipes made of polyvinyl chloride or metal for internal and external installation. Special rubber seals are provided for PVC tubes. The sealant additionally takes care of preventing leaks. All silicone-based products are classified as follows:

- Acid sealants. They are not used everywhere; they tend to react with aggressive environments.

- Neutral. Ideal for sealing sewer pipes. They have a higher cost.

All silicone products are made on the basis of rubber. This makes them elastic even when used in low temperatures. In addition, rubber increases the level of adhesion of the product to the surface being treated.

Silicone sealant should be applied in one continuous line to avoid gaps when forming the gasket. You can further smooth out the seam after joining the two elements. To do this, use a special spatula.

Self-adhesive tape

All self-adhesive materials are produced on the basis of bitumen-polymer inclusions. Therefore, their structure resembles rubber. This type of waterproofing does not allow water to pass through.

Depending on the operating temperature, the tape is divided into the following types:

- Heat resistant. Designed for sealing systems transporting media at temperatures up to +1500 degrees. The tape is marked “T”.

- Winter. Used on pipes that operate in a temperature range from -200 to +100 degrees. It is marked “Z”.

- Summer. Withstands high temperatures up to +300 degrees. Marked with the letter "L".

Wind the tape in a spiral overlapping, avoiding gaps and displacements. Lasts up to 30 years if installed correctly with a good seal. The tape is considered so reliable that it is even used when laying and sealing oil pipelines.

Technical sulfur

The sealant can be used for metal tubes. It is advisable to simultaneously mix sulfur with kaolin when heating it. The two substances are mixed in proportion (1:10).

Sealing is carried out as follows:

- Heat the sulfur at a temperature of 140-150 degrees;

- add kaolin;

- pour the mixture into the socket of the system and join the elements.

Technical sulfur has low elasticity.

Epoxy resin

It is a ready-made waterproof adhesive that can be used when installing sewer systems. When preparing the product, you need to mix the epoxy with the hardener according to the instructions.

It is important to strictly adhere to the recommendations, otherwise the curing time of the resin may vary

Bitumen mastic

To seal cast iron sewer pipes, it is better to use bitumen-based mastics. They have good elasticity, do not allow water to pass through, and last more than 20 years. All bitumen sealants are classified according to the installation method - hot and cold. The first ones are more difficult to work with. And the danger of burns is great. Both types of bitumen products are available for free sale in construction stores.

The need for sealing

Sealing is ensuring complete impassability of gases or liquids from pipes to the surface. This process is mandatory for the construction of sewer systems. Some home craftsmen neglect sealing, but repeating it is considered a more difficult task than the initial processing of tubular joints.

Why is sealing of plastic and cast iron sewer pipes necessary:

- To prevent leaks that occur due to high pressure of wastewater;

- To protect connections from changes in ambient temperatures and water in pipes;

- To ensure the protection of pipes from the penetration of water from outside. This could be groundwater, precipitation, etc.

Despite the external strength of the joints, they require additional support.

Ribbon

One of the most popular sewer sealants is tape. The most commonly used is self-adhesive tape. It can be either regular or foil. Using tape has many advantages:

- Does not deform during operation. Correctly applied tape will last a long time and there will be no bubbles underneath it.

- Non-conductivity of electricity. Quite often, the cause of corrosion is electric current; the tape will perfectly reduce conductivity and protect the pipe.

- Resistance to external influences. The tape is highly resistant to various substances and factors, so you can rest assured about the sewage system.

- Mechanical strength. The chance that a joint treated with tape will begin to diverge is very low.

The tape is multi-layered and its basis is a bitumen-polymer material, which allows it to be absolutely waterproof. Depending on the temperature to which the connection will be exposed, there are several main types:

- Summer ribbon. Perfect for hot water pipelines, as it can withstand temperatures up to plus 300 degrees Celsius.

- Winter ribbon. This tape can be used at temperatures from -2000 to +1000 C.

- Heat resistant tape. This is a special tape that can withstand liquid temperatures up to plus 1500 degrees Celsius. In this case, the difference in ambient temperatures is allowed within the range from -100 to +2000 C.

There is no need to use heat-resistant tape at home. Both summer and winter ribbon are perfect; if the pipe is located outside the room, it is better to choose the winter option.

The service life of such a tape is about 30 years. Due to its high technical performance and affordable cost, the sealant is quite popular. Before applying the tape, attention must be paid to surface preparation. They need to be thoroughly cleaned and degreased. If the tape is applied correctly, you will get two layers of protection, this can be achieved by applying the tape in wide overlaps.

Polymeric

Polymer sealants are the usual polyurethane or silicone sealants. They are used quite often in plumbing. The big advantage is its versatility - it can be used for sealing and gluing various structures and elements. The best option would be to choose the composition of the silicone sealant, taking into account the specifics of the structures for which it will be used.

The composition most often includes special rubber, which is characterized by high elasticity and good adhesion. Another undoubted advantage is that its use does not require careful preparation of surfaces.

There are two main types, based on the composition of the hardener:

- Neutral. The composition excludes acids, this allows it not to destroy the pipe, and expands its scope of use. The downside is the high cost.

- Acidic. Unlike neutral ones, it contains acids, which is why it can enter into a chemical reaction with the surface. It combines low cost and good quality well, but cannot be used for all surfaces.

Polymer sealants are excellent for metal and plastic pipes. After hardening, they form a strong rubber-like compound. High elasticity helps to bear loads and not crack.

Most often, sealant is sold in a tube for a gun (special tool). It should be applied around the entire circumference. It is required not to leave empty areas, but to fill the entire joint. After application, you can remove the residue with a special spatula.

Sealing tapes

This type of sealant is a metallized tape on a bitumen-rubber base. An aluminum or copper layer provides sufficient strength and reliable sealing.

To achieve the required quality of connection using such a tape, you must remember the basic rules for its installation:

- Before use, it is necessary to carefully prepare the pipes or fitting; the tape simply will not stick to a dusty or damp surface.

- Winding should be carried out in a spiral, with an overlap of approximately 50%, this will ensure that the entire surface can be covered with two layers of tape.

- The winding should be carried out with a significant stretch of the self-adhesive, this will prevent the possibility of its spontaneous sticking after removing the protective layer and ensure uniformity of the coating (no wrinkles or other defects).

Today, self-adhesive tapes for sewer pipes are considered the easiest material to use, while they provide a high degree of sealing of various types of connections. Allows you to significantly simplify the elimination of emergency leaks.

Materials for sealing sewers that should not be forgotten

Along with the described new products, traditional materials are also widely used for sealing joints of cast iron sewer pipes.

These include:

- Tarred tow (flax fiber).

- Ordinary Portland cement.

In addition, technical sulfur and petroleum-based bitumen can ensure the reliability of the connection. Epoxy resins are highly reliable and durable. And even ordinary paint can seal sewer pipe joints.

Whatever material is chosen, it should be remembered that the main role is played by preparing the surface of the pipes for its application. Only compliance with technological nuances can ensure high reliability of sealing.

What is better for sewerage

The main question remains: what to pay attention to when choosing and how to seal the sewer pipe. The choice of sealant will largely depend on the material from which it is made. In order to make the right choice, let's look at the main types of pipes that are used in sewerage systems and what sealing method is suitable for them.

For cast iron

For cast iron pipes, Portland cement sealant and technical sulfur are often used. This use is due to the low cost of the material and its reliability. Using a polymer option would also be appropriate, but the cost of sealing will be much higher.

For PVC

To seal a PVC plastic pipeline, it is recommended to use rubber or silicone-based sealant. This material is perfect for plastic and will last quite a long time. It will stick to plastic like glue. This sealant is also perfect for metal-plastic pipes. Another common sealant for such pipes is epoxy resin.

For the junction of cast iron and plastic

To seal the joint between pipes made of cast iron and plastic, you need to use special adapters made of rubber or polymer. Before making the joint, it is necessary to clean the pipe socket from dirt and rust and degrease the surface.

For sealing, it is better to use silicone sealant; it should be applied to the inside and outside. After drying, the joint will be securely sealed. To perform the pipe transition process correctly, we recommend watching the video clip.

Ceramics

For ceramic pipes, silicone sealant must be used. Petroleum bitumen and asphalt mastic are widely used on a production scale.

Cast iron and ceramics

For joints of cast iron and ceramic pipes, jute and hemp rope are perfect. A polymer sealant would also be a good option. Before purchasing the latter, be sure to tell the seller for what purposes it is needed. They will help you choose the most suitable composition.

How to properly process a pipe

The key to high-quality sealing is the correct preparation process. Depending on the type of sealant, you will need to use a special tool, this could be: a mounting gun, a stationery knife, etc.

Before applying the material, it is important to properly process the pipe:

- Clean the pipe from any contamination.

- Degrease the joint with gasoline or solvent.

- Allow time for the surface to dry.

- Apply sealant.

- Join the sockets.

- Once dry, remove excess sealant.

If you follow these simple steps, the joint will be reliably sealed and will last for a long time.