The tightness of the sewer system is one of the main conditions for the normal operation of this type of communications. The possibility of leakage must be completely eliminated so as not to pose a threat to nearby networks, structures and the environment.

Sealant for sewer pipes will prevent leaks - the product is used for both internal and external work. How does it work and which one is better to choose? Agree, it's worth finding out.

So that you can find and purchase a suitable sealant, we will identify the popular options and describe their specific use.

The article discusses in detail the technologies for using sealing materials. There is a rating of manufacturers of the best products produced for this area of construction. Photo applications and video reviews will help you get comfortable with the topic.

Types of sealants and methods of their application

It is necessary to approach the sealing procedure especially responsibly when installing external sewer pipes buried in the ground, since correcting defects associated with pipeline leaks will be as difficult as laying pipes from scratch.

It must be taken into account that leakage is not allowed not only from the cavity of the sewer pipes, but also inside them (in the case of high-flowing groundwater), since this may affect the durability and normal operation of the external drainage system.

Silicone based sealants

Sealing sewer pipes with this type of sealant is currently more common than others.

These materials have the following features:

The main component of sealants is silicone rubber, supplemented by a whole composition of various substances and additives that provide them with excellent sealing properties.

Working with silicone sealant

- Manufacturers offer two types of silicone sealants - acidic and neutral - the first of which are cheaper, but are not suitable for surfaces that can interact with acids; the latter are more universal and suitable for all cases.

- Silicone-based sealants can be used to seal joints of both plastic pipes and metal products. During the vulcanization process, silicone paste turns into a substance similar in properties to rubber. The vulcanization process occurs with the participation of moisture in the air.

Tapes for sealing pipe joints

Anti-corrosion self-adhesive tapes are an innovative product designed specifically for sealing pipe joints. They are distinguished by high efficiency combined with ease of use.

In addition to sealing, tapes can also serve as a means of comprehensive pipe protection, including dielectric and anti-corrosion protection.

With the help of tapes it is possible not only to seal pipe joints, but also taps, plugs, turning corners, bends and many other pipeline elements.

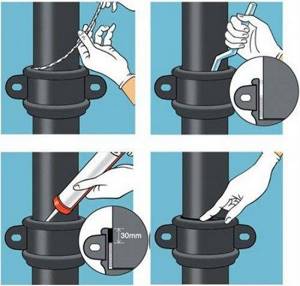

Sealing with tape is carried out as follows:

- Prepare for applying the tape to the surface by cleaning and drying the latter.

- When winding, keep the tape under constant tension to avoid the appearance of folds and wrinkles.

- The tape is applied in a spiral, ensuring an overlap of 50%, as a result of which the insulated surface of the pipe must be covered with two layers of insulating film.

It should be noted that sealing films are generally vulnerable to direct exposure to UV radiation. For this reason, when treating an open external section of a sewer pipeline, it is necessary to cover the pipe wrapped with tape with any additional protective material.

Repair methods for cast iron pipes

When craftsmen decide how to coat a cast iron sewer pipe, they have several options to choose from:

- wind the strands;

- to settle the strands;

- use asbestos cement solution as putty.

However, before starting any work, the pipe should be cleaned to a metallic shine.

In cases where sewer pipes made of cast iron are morally and physically worn out, they are completely dismantled for replacement.

This work is carried out in several steps:

- using a grinder, cut off a section of pipe to the joint;

- the socket is freed from cement and packing residues;

- the remaining section of pipe is cut with a grinder in several places to make a stop for the lever;

- insert a crowbar into the slots and loosen the pipe along the axis;

- the last piece of pipe is removed from the socket;

- the rubber adapter coupling is mounted in the old socket;

- A new plastic sewer pipe is installed in the adapter.

Types of materials for waterproofing sewer pipes

To protect the joints of sewer pipes from internal and external influences, today the construction market provides a large selection of materials, including:

- self-adhesive tapes;

- silicone sealants;

- Portland cement;

- technical sulfur;

- epoxy resins;

- bitumen mastics;

- jute rope.

In everyday life, sealant tapes and construction silicone are the most widely used, due to the availability of the material and the ease of its use. However, other options also deserve attention, since they allow you to achieve sealing of sewer pipes at the same or higher level.

The result of poor-quality pipeline sealing

Materials intended for sealing

Sealing tapes

Both regular and foil tapes are available

Self-adhesive tapes, which have anti-corrosion properties and are specifically designed for sealing pipe joints, are one of the newest modern means of sealing. They have many positive properties:

- Self-adhesive anti-corrosion tapes are quite highly effective and easy to use.

- Sealing films, thanks to their high-strength polyethylene base, are characterized by good operating properties.

- They are used to provide protection for various types of pipelines as a whole, as they have dielectric and anti-corrosion properties. In addition, sealing films are used to seal linear elements of sewer pipes.

- Sealing using tape is possible not only when sealing the joints of sewer pipes, but also when sealing plugs, taps, turning corners, bends, etc.

Before sealing a sewer pipe using sealing tapes, remember that sealing is carried out in the following sequence:

- To apply the tape, surface preparation is necessary: it must be dry, dust-free and clean;

- it is necessary to ensure constant tension of the tape that is wrapped around the pipe, and also to prevent the appearance of folds and wrinkles;

- the tape must be applied, providing an overlap of 50%, in a spiral, as a result of which the entire surface to be insulated will necessarily be under two layers of film.

Sealing sequence (some tapes require primer treatment)

Pro tip:

Such films are not resistant to UV radiation. That is why, when placing sewerage pipes in an area that is exposed to the sun, an additional protective layer must be provided over the film.

Silicone sealants

Silicone is the most well-known material for sealing

Silicone rubber forms the basis of silicone sealants. Silicone sealants in general are a composition of different substances that provide high sealing qualities. Silicone sealants have good adhesion to surfaces, without requiring them to be pre-treated with primers.

Based on the type of hardener in its composition, sealant for sewer pipes made of silicone is divided into:

- Acid. Acidic silicone sealants are quite inexpensive, although they cannot be applied to some surfaces that can interact with acids.

- Neutral. In this regard, neutral silicone sealants are considered more universal.

Using silicone sealants, it is possible to seal the joints of sewer pipes:

- made of metal;

- made of plastic.

After vulcanization, the silicone paste turns into a substance that is similar in properties to rubber. The vulcanization process of silicone sealant involves moisture in the air.

Pro tip:

Squeezing out the sealant is quite simple - using a mounting gun. If it is not available, you can use an ordinary hammer by inserting its handle into the tube and pressing as if on a piston.

How to squeeze out silicone sealant without a mounting gun

Sealing sewer pipes with other sealants

In addition to the above means, sealing sewer pipes is also done using other means:

- Epoxy resin - at home, like glue based on it, serves as the most common means used for connecting sewer pipes.

- Portland cement is a fairly common component of most sealing mixtures - it is used in the preparation of asbestos-cement mixtures and when caulking the socket joints of cast iron sewer pipes.

- Petroleum bitumen and asphalt mastic will be required to prepare the fill, which is intended for sealing joints and filling sockets of ceramic pipelines.

- Hemp or jute rope, resin strand - are used when sealing the sockets of cast iron and ceramic sewer pipes. Using a combination of rope and resin impregnation would be preferable.

- Technical sulfur - is used to ensure tightness, mainly at the joints of cast iron sewer pipe sockets. Before pouring it into the joint gap, it should be crushed and then heated until melting.

Technical sulfur can also be purchased in crushed form.

With such an abundance of materials, the question is unlikely to arise: “How to cover a sewer pipe?”

Ribbon

One of the most popular sewer sealants is tape. The most commonly used is self-adhesive tape. It can be either regular or foil. Using tape has many advantages:

- Does not deform during operation. Correctly applied tape will last a long time and there will be no bubbles underneath it.

- Non-conductivity of electricity. Quite often, the cause of corrosion is electric current; the tape will perfectly reduce conductivity and protect the pipe.

- Resistance to external influences. The tape is highly resistant to various substances and factors, so you can rest assured about the sewage system.

- Mechanical strength. The chance that a joint treated with tape will begin to diverge is very low.

The tape is multi-layered and its basis is a bitumen-polymer material, which allows it to be absolutely waterproof. Depending on the temperature to which the connection will be exposed, there are several main types:

- Summer ribbon. Perfect for hot water pipelines, as it can withstand temperatures up to plus 300 degrees Celsius...

- Winter ribbon. This tape can be used at temperatures from -2000 to +1000 C.

- Heat resistant tape. This is a special tape that can withstand liquid temperatures up to plus 1500 degrees Celsius. In this case, the difference in ambient temperatures is allowed within the range from -100 to +2000 C.

There is no need to use heat-resistant tape at home. Both summer and winter ribbon are perfect; if the pipe is located outside the room, it is better to choose the winter option.

The service life of such a tape is about 30 years. Due to its high technical performance and affordable cost, the sealant is quite popular. Before applying the tape, attention must be paid to surface preparation. They need to be thoroughly cleaned and degreased. If the tape is applied correctly, you will get two layers of protection, this can be achieved by applying the tape in wide overlaps.

Polymeric

Polymer sealants are the usual polyurethane or silicone sealants. They are used quite often in plumbing. The big advantage is its versatility - it can be used for sealing and gluing various structures and elements. The best option would be to choose the composition of the silicone sealant, taking into account the specifics of the structures for which it will be used.

The composition most often includes special rubber, which is characterized by high elasticity and good adhesion. Another undoubted advantage is that its use does not require careful preparation of surfaces.

There are two main types, based on the composition of the hardener:

- Neutral. The composition excludes acids, this allows it not to destroy the pipe, and expands its scope of use. The downside is the high cost.

- Acidic. Unlike neutral ones, it contains acids, which is why it can enter into a chemical reaction with the surface. It combines low cost and good quality well, but cannot be used for all surfaces.

Polymer sealants are excellent for metal and plastic pipes. After hardening, they form a strong rubber-like compound. High elasticity helps to bear loads and not crack.

Most often, sealant is sold in a tube for a gun (special tool). It should be applied around the entire circumference. It is required not to leave empty areas, but to fill the entire joint. After application, you can remove the residue with a special spatula.

Technical sulfur

Sulfur is a hard and at the same time fragile material. To obtain elasticity, you must not overheat the pipe, and you can also add ground kaolin. The material is made from recycled petroleum products.

Sulfur is often used for sewer joints. A huge plus is the extremely low cost compared to analogues.

Divided into two main types:

- Powder.

- Lumpy.

If you buy lump sulfur, it must be crushed before use. Sulfur is heated to a temperature of 130-1500C and poured into the bell space. After cooling, an excellent water-resistant mass is obtained. The disadvantage of this sealant is low elasticity.

Portland cement

Portland cement is indispensable for many jobs. It is also successfully used in sealing. It includes:

- Clinker.

- Gypsum.

- Calcium silicate.

The presence of such components allows us to obtain a sealant with good properties: frost resistance, high strength and water resistance. Special additives are added to the cement mixture and mixed until a thick solution is obtained. Due to its properties, it is successfully used as a sealant when installing sewers.

Epoxy resin

Epoxy resin is a versatile adhesive that is used in sealing sewer pipes. In order to obtain the desired composition, you will need to mix the glue and hardener. The proportions depend on the brand and are indicated in the instructions. When preparing the mixture, be careful; the wrong proportion can ruin the entire composition.

Bitumen mastic

The sockets of a cast iron pipe are quite often filled with a special bitumen material. This is a liquid sealant; according to the type of application it is divided into two categories:

- Cold mastics.

- Hot mastics.

At home, it is better to use cold bitumen mastic (cold welding), as it is easier and safer to work with. Unfortunately, its high cost will be its big disadvantage. This type of sealant is widely used in the installation of stormwater routes and cable drains.

Jute and hemp rope

The use of ropes as a sealant has been used for many years. Today they are noticeably inferior to modern types of sealing substances, however, low cost and ease of use remain a significant advantage.

For many generations, this sealant has justified its costs, but today it is inferior to its analogues in all respects.

Methods for eliminating leaks

Before carrying out work, it is necessary to warn residents not to use the sewer system. Then you should turn off all appliances that use water, such as a washing machine. After covering the leaking area, thoroughly dry the leaking area with a hairdryer.

Before starting work, it is worth understanding the material from which the sewer system is made. Today it is metal (steel, cast iron) or polymeric materials - polyvinyl chloride or polyethylene. How to cover a sewer pipe joint depends on the material.

The leaking joint must be thoroughly cleaned of any cementitious residue. Then treat with an aqueous solution of cement and PVA glue. Be sure to use gloves when doing this. The solution will take about a day to dry. Accordingly, you cannot use the sewer system at this time.

It is advisable to use a repair coupling to perform the work.

Seal the joints with tape

Self-adhesive tape is a modern and reliable waterproofing material that allows you to quickly and efficiently seal sewer joints. The strength of the tape is given by the base made of polyethylene. Additionally, the product provides corrosion protection and good dielectric properties. The tape can be used to seal various parts of the plumbing system, such as bends, taps and plugs.

Toilet plumbing involves the use of various means of sealing, and self-adhesive tape is the first way to wrap a leaking joint (but not the only one).

We use sealants to eliminate leaks

Silicone or rubber based sealants are an excellent option for waterproofing sewer structures. The high level of adhesion to the surface of the elements is explained by excellent adhesion. Moreover, sealing of pipes can be carried out without pre-treatment with primers and primers.

The type of hardener used in sealants imposes restrictions on use in different conditions. The cheapest, acidic ones cannot be used everywhere because of a possible chemical reaction with acids. Neutral sealants are universal.

We can safely recommend the use of such sealant for most types of pipes. To be safe, after the work you will need to cover all joints and possible leaks with silicone.

The purpose of sealing system elements

The sewerage system is reliably sealed during the installation stage. During operation, the internal system is regularly inspected in order to detect and eliminate leaks in time.

Wastewater should not flow out, and nothing should get into the sewer system from the outside, because... this can disrupt its operation and lead to serious damage.

Particular attention should be paid to sealing pipes laid underground, as they are much more difficult to repair if leaks occur. If the operation of the system is disrupted due to groundwater entering it, a lot of effort will have to be made to determine this.

Repairing the underground part of the sewer system is almost as labor-intensive and expensive as installing a new section of pipeline. It involves a large volume of excavation work, replacement of damaged system elements

Careful sealing during the construction phase of the sewer system prevents a number of problems:

- Leaks to the outside. Once in the soil, wastewater can contaminate water in drinking wells and cause serious illnesses. The unpleasant smell of sewage in premises is also dangerous, because... rotting organic matter releases gases harmful to humans: hydrogen sulfide, ammonia, methane.

- Flooding of buildings and structures. In case of severe leaks, soil erosion may occur. Sewage water floods foundations, cellars, cellars, and basement floors. Due to the high content of chemically active substances, they accelerate the destruction of building materials and provoke corrosion.

- Leaks into the system. If atmospheric or groundwater enters the system, the pressure in the pipeline increases. Due to the strong pressure of wastewater, the operation of pipes is disrupted, and treatment or storage facilities may not be able to cope with the additional load and fail.

- Leaks at joints due to temperature changes. If the system is initially installed efficiently, the joints are reliable and do not leak even without additional sealing. However, processing is still necessary, because Temperature changes over time lead to a decrease in tightness.

Various types of pipes are used to install sewerage systems. A suitable sealant should be selected for each pipe material. The choice also depends on the installation technology and the intended purpose of each individual element of the system.

Main types of sealing materials (characteristics)

Previously, oil paint and plumbing linen were used as sealing materials. But modern technologies offer a much wider selection of different sealing materials.

Sealing tapes

These are self-adhesive tapes, somewhat similar to a roll of white tape. They can have different widths and are mainly used for plastic pipes in residential areas. Such tapes not only protect against water leakage, but also help strengthen various related elements such as plugs, joints, and so on.

The main advantages of this sealant include the following: lack of electrical conductivity, reduced risk of corrosion of sewer pipes, ease of use and at the same time a high level of reliability of the material.

Example of sealing tape

It is important to remember that such tapes quickly deteriorate when exposed to ultraviolet rays, which is why they are recommended for use only inside residential premises. However, if there is still a need to use it in the sun, then the tape is covered from it, for example, with a special protective film

In order for this material to have the intended effect, the pipes must be cleaned of dust and dirt, and then thoroughly wiped or dried. Immediately before gluing the tape, a primer is applied. After this, the tape is wrapped around the pipe in a spiral, tightly, without folds, with a half overlap.

Polymer sealants

Otherwise known as silicone, since the main material in this case is silicone rubber. They are considered one of the most popular sealing agents, including because, if desired, you can choose such a material of any color, including the same as that of the sewer pipe. They are mainly used to strengthen joints and seal fistulas. They can have both neutral and acidic compositions. Acid options are cheaper, but some pipes are not resistant to acids, and in general such compositions are not recommended for use on fragile elements. Neutral options are used in all cases where acidic options cannot be used.

Among the advantages of this type of product are the following: when used, mold and rot do not appear, even over time; when hardened, the composition becomes like rubber and perfectly protects sewer pipes from leaks. In addition, silicone sealants adhere well to the pipe material, they are durable, resistant to moisture and temperature changes, and also last quite a long time.

Polymer sealant for sewer pipes

The sealant is squeezed out with a special gun for installation, however, if you don’t have one at hand, you can use an ordinary hammer.

Mastics based on petroleum products

Also good for sealing sewer pipes, especially for filling sockets. There are several main varieties: bitumen-polymer, bitumen-talc, bitumen-rubber, bitumen-asbestos-polymer. Mastics come in both cold and hot application methods. Those with a cold method are a little more expensive, but they are simple and safe to use. Before using such products, it is advisable to turn off the water supply, and the pipes themselves must be cleaned, degreased and dried.

Epoxy resin

This variety is often used at home. In essence, resin is a universal glue. Before use, it is mixed with a special hardener. The required mixing proportions are indicated on the packaging by the epoxy resin manufacturer. By the way, you cannot deviate from the specified proportions; this can lead to unexpected and unpleasant consequences. From the mixture suddenly boiling, to the resin's lack of effectiveness as a sealant for sewer pipes.

Portland cement

It is a dry mixture of gypsum, clinker and calcium silicates with special additives to increase the reliability of sealing. Before use, the composition is diluted with water to a thick solution. The resulting slurry must be used immediately, as it hardens quite quickly (from 5 to 10 minutes) and turns into a monolithic structure with frost resistance, high strength, and the ability to repel water.

Advantages and disadvantages

The advantages include the following qualities:

- Moisture and frost resistance, which allows the mixture to be used, including for external pipes;

- High strength and reliability of the hardened mortar;

Portland cement is one of the sealants for sewer pipes

And as a disadvantage, it is worth noting the fact that it is necessary to work with the diluted mixture very quickly, otherwise it will harden and will be useless.

Technology for sealing pipes with tow

The simplest option for solving the leakage issue is to use specially impregnated flax tow. Moreover, this method is quite popular among professionals. But before you get started, you should pay attention to a few points:

- choosing the right material, as it should be thin and soft, without any inclusions;

- when using special impregnations, you should do everything carefully, since traces of such a paste are not always easy to remove;

- After all work is completed, there will be visible parts that require careful removal.

Instructions for sealing joints are as follows:

- First, you need to divide the tow into several strands. In this case, each thread should be approximately 0.1 cm. but this moment should be selected in accordance with the existing thread. After this, the strands are cleaned of possible inclusions and straightened.

- The impregnating agent is applied to the threaded ends, but not in large quantities, and is evenly distributed over the entire surface. This paste will act as glue for tow.

- If the thread is right-handed, then the fiber is wound clockwise. You should know that the closer to the pipe, the greater the winding density should be.

- As soon as the tow is completely wound, it is impregnated with the product on top.

- After this, the pipes are connected together.

Manufacturers

Among the most popular companies producing sealants, it is worth highlighting four main ones.

- Ceresit. German products with European quality, standards and practicality. The sealants of this brand are known for their best adhesion to the surface being treated, excellent waterproofing properties and the presence of special additives that protect the room from mold and germs.

- "Moment". The brand, founded by a German chemical company in Russia, has a large number of necessary construction assistants. Among them is the very popular “Moment-Germent”. A large number of varieties of sealants from this company allows any craftsman to choose his own product. Unique products include frost-resistant, high-temperature and restoration options.

- Ciki Fix. The Turkish manufacturer is also among the top four leaders in the Russian construction market. A characteristic feature of this company’s sealants is its extraordinary ability to bond surfaces of different textures together. The seams are waterproof and elastic, but do not protect against fungus and mold.

- Makroflex. Another high-quality brand comes from Germany, but with Russian production. This is a modern and timely solution to any construction and finishing tasks. The company produces a variety of sealants that cope with both internal and external use.

Insulation of pipe entries: the most effective methods

The main task when laying a pipeline is to create a waterproofing barrier that will ensure dryness of the holes in the partitions and walls through which utility networks are installed. There are several most effective ways to isolate them using modern sealing adhesives and solutions:

- sealant + protective cuff (if the wall hole has uneven edges, it is additionally protected from the ingress of contaminants (earth, stones), for which a cuff is installed on the outside that can withstand hydrostatic pressure up to 5 bar, and on the inside it is sealed with epoxy sealing sealants) ;

- end seal + overlay flange (if the concrete wall or partition is covered with microcracks, a remote insulating element consisting of an overlay flange sleeve in which the end seal is placed will help prevent moisture from penetrating through them);

- embedded sleeve + sealant (the method is optimal when running a power cable through the wall, which is passed through a sleeve made of plastic or fiber cement, and the space between its walls and the electrical wire is filled with a sealing compound);

- adhesive sealant (the gap between the pipeline and the edges of the hole can be completely filled with a waterproofing solution without installing additional parts - this method is cheap and reliable, since synthetic elastomers will penetrate into all irregularities and voids, harden in them and provide 100% waterproofing of communication inputs).

Order a job

Not a single method of establishing communications is complete without the use of special insulating compounds. But how to choose a material and what characteristics to pay attention to?

Technical sulfur

Sealing an old cast iron drain can be very difficult. Technical sulfur was often used to repair cast iron pipes. But to apply it, it was necessary to heat the composition to a plastic state. A special vessel was used (bath for heating sulfur). In addition to the high temperature and risk of fire, there was another risk factor during such work - toxic gas was released during combustion. Therefore, I had to work in a respirator. Nowadays, pipes can be sealed in safer ways, so technical sulfur is practically not used.

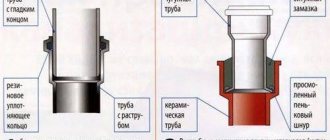

How to ensure the tightness of the joint between cast iron and plastic pipes

Polyvinyl chloride is used for the manufacture of modern sewerage systems. Often there is a need to join PVC pipes with old cast iron ones. Such a connection can be made in several ways, which depend on the condition of the socket of the cast iron product.

If the old system is in good condition, the bell is cleaned of dirt and rust. Install a new pipe through a rubber adapter, having previously covered all connecting surfaces with silicone sealant. You can use the method of compacting with tow or a rope, followed by filling with special mixtures.

If there is no socket, the connection is made through a plastic adapter and rubber seals. To do this, the edge of the cast iron pipe is leveled and cleaned. An O-ring is placed on the socket adapter. This is followed by a rubber cuff and another ring. The entire structure is inserted. At each joining stage, silicone is applied to the surface. All that remains is to apply a layer of sealant to the end of the PVC pipe and push it tightly into the constructed socket.

When joining, you can use a press fitting - an adapter with a thread on one side and a socket on the other. The edge of the cast iron pipe is leveled with a grinder, cleaned, lubricated with grease or oil and threaded. Tow or fum tape is wound onto the formed furrows. Lubricate the joint with silicone and screw on the adapter.

You can combine means of sealing sewer pipes, thereby improving the quality of the connection.

Tips for choosing

It is quite difficult to independently calculate the appropriate diameter for external sewerage in certain conditions, but there are general recommendations that will help solve the problem.

- A 5-centimeter diameter is quite enough for a shower, drainage from a sink and similar elements.

- From the toilet, drains are discharged into 11-centimeter structures.

- To equip a full-fledged bathroom in apartments and private houses, the minimum size is also 11 cm. If the house is multi-story, then craftsmen often choose vertical systems with a diameter of up to 15 cm. If they are made in accordance with GOST 51613 2000.

- 20 centimeters should be equal to the cross-section of the pipeline, if we are talking about a pipeline in a horizontal plane, which collects and discharges wastewater from the entire house.

- The branch through which drains flow from plumbing fixtures to the pipe vertically should not be smaller than the riser.

Video

PVC plumbing pipes with pressure

They are relevant for systems in which pumps are responsible for forced circulation of liquid. This creates artificial pressure, and then the flow becomes continuous.

The installation of pumps will be especially relevant where there are many apartments and large premises.

The wall of a pipe with a size of 50 mm increases in thickness, otherwise they will not be able to withstand the increased load. The use of multilayer products is allowed. And here the characteristics are regulated by GOST 51613 2000.

Non-pressure type of PVC pipes

They are most often used in modern sewer systems. Their design is standard. They are not recommended for use in systems with artificially created pressure.

It is possible to install pressure pipes along the entire length of the external sewer system, but this solution is too expensive. Similar non-pressure materials are 25 percent cheaper than pressure materials.

Watch the video

About corrugated varieties

They have the most unusual appearance. The walls look like an accordion. This allows installation even in places where access is difficult.

The structure has an inner and outer layer. A smoother material is used to make the inside so that blockages do not appear inside. The outer layer is standard PVC.

How to connect plastic pipes to cast iron?

A regular rubber adapter will suffice if you need to connect a system that has a socket. Plastic external adapters are needed where there is no socket.

When using rubber cuffs, replacement is carried out as follows.

- We clean the 250 mm bell from plaque and dirt if they appear on the surface.

- Apply a layer of sealant to the outer surface of the socket. After which the part is inserted.

- A plastic pipe for the sewer system is connected to a cuff.

Plastic connecting elements require a slightly different procedure.

- We level the edge of the pipeline by 250 mm using a grinder if part of it bursts during operation.

- We put a 250 mm rubber cuff on the structure. Its surface is pre-coated with a composition for high-quality sealing.

- A plastic adapter is placed on top.

Video

https://youtube.com/watch?v=39fa3je7waI

What other adapters are there for plastic products?

The range of plastic external adapters on the modern market is quite wide. They are less reliable than metal ones, but they are more affordable. And their installation can be easily done with your own hands.

250 mm adapters are produced from polyvinyl chloride and polyethylene, which are mounted in systems with rubber cuffs.

Strong fixation is created due to the elastic ring inside; no additional tools are needed for installation.

PVC fittings for adhesive mounting are also not able to withstand high pressure. Although they are more reliable than the previous version.

Video

250 mm polypropylene adapters are produced, for installation of which welding is used. Form permanent connections. To work, you need to use special soldering irons complete with nozzles. They are made in the same size as the diameter of the pipeline.

Finally, some manufacturers produce 250 mm designs in which plastic elements are inserts, and the product itself is metal or made of composite.

These are also quite popular plumbing pipes and PVC adapters for sewerage.

What is better for sewerage

The main question remains: what to pay attention to when choosing and how to seal the sewer pipe. The choice of sealant will largely depend on the material from which it is made

In order to make the right choice, let's look at the main types of pipes that are used in sewerage systems and what sealing method is suitable for them.

For cast iron

For cast iron pipes, Portland cement sealant and technical sulfur are often used. This use is due to the low cost of the material and its reliability. Using a polymer option would also be appropriate, but the cost of sealing will be much higher.

For PVC

To seal a PVC plastic pipeline, it is recommended to use rubber or silicone-based sealant. This material is perfect for plastic and will last quite a long time. It will stick to plastic like glue. This sealant is also perfect for metal-plastic pipes. Another common sealant for such pipes is epoxy resin.

For the junction of cast iron and plastic

To seal the joint between pipes made of cast iron and plastic, you need to use special adapters made of rubber or polymer. Before making the joint, it is necessary to clean the pipe socket from dirt and rust and degrease the surface.

For sealing, it is better to use silicone sealant; it should be applied to the inside and outside. After drying, the joint will be securely sealed. To perform the pipe transition process correctly, we recommend watching the video clip.

Ceramics

For ceramic pipes, silicone sealant must be used. Petroleum bitumen and asphalt mastic are widely used on a production scale.

Cast iron and ceramics

For joints of cast iron and ceramic pipes, jute and hemp rope are perfect. A polymer sealant would also be a good option. Before purchasing the latter, be sure to tell the seller for what purposes it is needed. They will help you choose the most suitable composition.

How to properly process a pipe

The key to high-quality sealing is the correct preparation process. Depending on the type of sealant, you will need to use a special tool, this could be: a mounting gun, a stationery knife, etc.

Before applying the material, it is important to properly process the pipe:

- Clean the pipe from any contamination.

- Degrease the joint with gasoline or solvent.

- Allow time for the surface to dry.

- Apply sealant.

- Join the sockets.

- Once dry, remove excess sealant.

If you follow these simple steps, the joint will be reliably sealed and will last for a long time.

Liquid sealants

Available in suspension form. They are not used independently, only in conjunction with fiber materials. It will simply be forced out of the connection, this is especially noticeable in pipelines operating under high pressure. Used as a lubricant for connections of water supply elements. When choosing a drying agent, you need to pay attention to the fact that when it dries, it shrinks.

Anaerobic sealant is an exception.

This plumbing sealant for pipe connections dries in the absence of air without changing volume, protecting metal connections from corrosion and the water supply itself from leaks in the connections. High-quality fixation occurs with minimal sealant consumption.

Advantages of anaerobic sealant

- Hardening occurs as a result of polymerization. Excess is easily removed, as it does not harden in air.

- Good adhesion allowing the connection of plastic and metal pipelines

- The ability to use not only for sealing water pipes, but also pipelines with aggressive agents due to the inertness of the sealant.

- Successful application for sealing pressure pipelines.

- Automation of the sealing process is possible.

Flaws

To disassemble threaded connections sealed with anaerobic sealant, a special tool or preheating of the connection is required.

Features of using anaerobic sealant

When carrying out work below the required level, pre-heating of the elements is necessary for high-quality sealing. The sealant must be applied as evenly as possible, distributing it over the entire surface of the thread. Sealant can be applied to both external and internal threads. Before performing sealing work, clean and degrease threaded connections.

Typically, anaerobic sealant is produced in tubes with droppers, which ensures its accurate and quick application and high-quality filling of thread gaps.

Anaerobic sealants differ in the composition of their components. Therefore, when choosing an anaerobic sealant, you need to be guided by its technical characteristics and operating conditions of the elements being sealed.

Peculiarities

The sealant is used to ensure the smooth operation of sewer and water pipes. To prevent the pipes of plumbing accessories from leaking and spoiling the mood of their owners with constant dripping. But this is only a small fraction of what this material is capable of.

The miracle product is made on the basis of silicon. Since this is a hard stone, at least 4 more components are added to it, which bring the sealant into a paste form. The plumbing option also contains fungicides - components that protect against bacteria and mold, which are a good antiseptic. Organic additives in the sealant are responsible for reducing viscosity, and mechanical additives improve the adhesion of the product to the surface being treated.

Today, one of the most fashionable trends is to renovate a room in the same style, color, and design. The sealant has a wide range of colors, which is achieved by adding special dyes to the initial composition.

Another nice thing about using this putty is that once opened it can be stored for quite a long time. To prevent it from drying out prematurely in the tube, you need to cover the hole with something.

What the sealant does not want to interact with under any conditions is:

- polypropylene and polyethylene;

- PVC;

- polycarbonate;

- acrylic.

That is, not a single smooth surface in combination with a sealant will provide the very powerful adhesion that is necessary to prevent moisture from entering where it is not needed. And the use of silicone with copper, zinc or lead can lead to intoxication of the body. Because this explosive mixture emits toxic fumes.

To understand which sealant is best to purchase for a given situation, let’s try to determine their main types.

Getting rid of fistulas

Before you fix a leak in a sewer pipe, you should understand how to fix it.

You can use the first method:

- wrap the damaged area with a rubber gasket;

- tighten with a clamp.

There is an alternative method:

- if a large fistula occurs, you will need to use a repair coupling;

- cut a piece of rubber to the size of the coupling;

- Tighten it well and the leak should stop.

It is worth noting that special plugs can be found on sale. They are installed in cleaning areas. You can additionally put a rubber gasket on the plug. The solution to sealing a cast iron sewer pipe if the leak continues is to additionally seal the plug with silicone.

If a leak has formed at a joint, then the joint is additionally filled with liquid glass, that is, silicate glue, on top of the sealing layer.

Main types of sealing materials

A variety of materials can be used to seal butt joints:

- self-adhesive sealing tapes;

- sealants based on modified silicone;

- technical sulfur;

- linen or jute rope;

- asphalt bitumen;

- Portland cement solution;

- epoxy resin.

Each of these materials has its own tasks, features and scope of application.

Scotch tape

Scotch tape is made on an acrylic or bitumen-rubber base, it contains a copper or aluminum layer and a protective film, which is removed during the installation process. This is a simple and effective product with a long service life (over 10 years).

It provides high connection strength, protects pipes from corrosion and is a good dielectric. The scope of application is the sealing of inserts, functional plugs, pipeline rotation angles, and bends.

Silicone sealants

The composition of such sealants includes rubber, so they are distinguished by increased elasticity and good adhesion to the surface. There are one and two-component formulations.

The first, depending on the components, are of two types:

- Acidic. The polymerization process is accompanied by the release of acetic acid, but after hardening the odor disappears. The elasticity of the material is maintained at temperatures ranging from -50 to +200 °C. They are not used to seal metal elements, as they strongly oxidize the metal and can cause corrosion.

- Neutral. Suitable for all types of connections.

In two-component compositions, along with the base, there is a catalyst that accelerates polymerization, and the solidification process does not depend on the thickness of the layer. But the cost of such sealants is higher.

Technical sulfur

Most often, technical sulfur is used to seal cast iron pipes. Lumpy sulfur or a substance in powder form is sold in the retail chain.

Before use, the material must be crushed and heated to the melting temperature (130°C), after which it is filled with the joint surface.

We recommend that you read: Sealing a chimney using heat-resistant sealant

After 10-15 minutes, a dense waterproof surface is obtained.

Low elasticity is the main disadvantage of this sealant. To increase it, add white clay (10-15%).

Linen or jute strands

This type of material is characterized by low cost and ease of use, but their technical and operational characteristics are inferior to modern types of sealants.

To create a strong connection, a 6-50 mm rope is used, which is an ordinary twine or twine impregnated with bitumen or resin, which makes this material unusually strong and impenetrable. Previously, before the advent of modern sealants, this was the most popular method for strengthening and sealing pipe joints.

Mastic and bitumen

To seal the joints of ceramic pipes and fill sockets, compositions are used whose main components are asphalt mastic or petroleum bitumen. Rubber-bitumen, asbestos-polymer-bitumen, talc-bitumen mastics performed well.

Based on the type of application, the mixtures are divided into cold and hot. The former are easier and safer to work with, they contain 50-70% bitumen and are more expensive.

When using hot applied mastics, they are heated to the required temperature at which the solution becomes plastic. The result is a quick-setting, seamless surface. When hardened, it does not shrink and is cheaper than cold applied mastic.

Portland cement solution

Portland cement consists of gypsum, clinker and calcium silicate. The working solution is prepared by mixing the dry mixture with water. It sets quickly and forms a durable water-repellent surface. To increase elasticity, special additives are used. The material is resistant to sudden temperature changes and can be used for outdoor use.

Epoxy adhesive

To obtain a sealing composition, universal adhesive is mixed with a hardener in a ratio depending on the grade of pipeline material.

All standards are contained in the instructions for the epoxy resin; they must be observed; violation of the proportions will lead to a decrease in the performance characteristics of the finished coating and will affect the hardening time.

Popular brands of sealants (brief product characteristics)

The modern market offers simply a huge selection of different sealing materials. The Ceresit and Moment brands are rightfully considered the highest quality and most popular. It is the compositions from these manufacturers that are recommended to be purchased and used, if possible. But besides them, there are other brands.

Ciki Fix

A brand of sealants that are great for ceramic and metal sewer pipes. The composition is colorless, so the owner does not have to worry about the design being damaged. After drying, this mixture hardens and becomes resistant to various solvents and detergents. It has excellent adhesive properties, thanks to which it is able to firmly adhere to various surfaces. This waterproof and elastic mixture does not deteriorate over time, even if it was used outdoors and not indoors.

Ciki Fix sealant for sewer pipes

By the way, the products of this brand do not have sanitary properties, so they are not recommended for use in rooms with poor ventilation, in order to avoid the appearance of rot and mold on sewer pipes.

Belinka

Compositions consisting of one component - silicone rubber. The sealants of this brand are similar to a thick paste that can harden from moisture in the external environment. Used to repair or strengthen seams and joints of the sewerage system. They have good elasticity and high strength. Also, the products of this brand, after drying, are able to resist the adverse effects of the external environment, such as snow, rain, too bright sun or sea water. And, in addition, it is practically not susceptible to the harmful effects of various chemical solutions.

When strengthening vertical joints, this type of sealant does not slip, which greatly simplifies working with them. The drying time of the composition varies depending on the applied layer, ambient temperature and humidity. Until the composition has hardened, it can be removed somehow with a solvent or detergent. If the mixture has dried, then only a mechanical removal method is suitable.

Tytan

Specializes in the production of sanitary-type silicone sealants. In each type of product of this brand you can find various additives that prevent the appearance of fungus and mold. To give the joints particularly high strength, it is recommended to use a compound marked Professional. After drying, the composition is practically unaffected by various detergents and cleaning agents. It is also important that the color of the applied composition does not change over time.

Dow Corning

Their products can often be used as glue. Dow Corning brand products have a thick consistency and are also able to penetrate deeply into even the smallest gaps, while simultaneously strengthening seams and joints. The compositions of this brand can easily withstand temperature changes, since their normal operation range starts from -65 degrees and ends at 260 (usually this indicator for sealants is limited to 180 degrees). However, the substance can withstand short-term loads and temperatures up to 315 degrees. This type will be useful if you need to create something elastic and heat-resistant.

Dow Corning Sealant for Sewer Pipe

Dow Corning sealants have a paste consistency. They do not drip when applied, are resistant to gasoline and oil, and are often used as glue. Most often, such compositions are used for industrial needs.

Krass

This brand produces sealing substances consisting of one component. After hardening of this composition, high-strength seams are obtained that do not change color and do not shrink over time. The substance is universal and is considered the most resistant to fire among all those described above. Krass brand products are well suited for sealing plastic or ceramic pipes (but not cast iron), dry quickly, and when dry form strong but elastic joints. Thanks to this, the entire structure can easily withstand even too large seam deformations. Sealing agents of this brand can be used both indoors and outdoors.

Using glue for sewer pipes

Sewage equipment that is significantly worn out, with numerous damages, is repaired using epoxy resin. The material is necessary to eliminate leaks when repairing a pipe.

Through cracks discovered after inspection of the equipment are sealed using a two-component adhesive composition. The mixture is prepared immediately before use, following the manufacturer's recommendations.

A detailed inspection shows that it is quite easy to fix the leak if you use epoxy resin to seal it. The composition is used in combination with a hardener, and the ratio of components to form the working mixture is 1:2 or 1:1. The polymerization reaction proceeds much faster when the temperature increases by 10˚ C. The sealing of the resulting cracks is quite strong, since the epoxy composition has minimal shrinkage, high resistance to adverse factors, and stable physical and mechanical characteristics.

Epoxy adhesive is obtained by mixing resin and hardener in a ratio of 1:10, and distilled water is used to form a composition with water-borne resin.

Thus, by following the rules for connecting sewer pipes, it is possible to carry out high-quality work related to the repair and planned replacement of equipment.

Replacing a defective pipe

Often, due to serious damage, it is necessary to completely replace the entire pipe. To do this, you will need to stock up on tools and parts: a hacksaw for metal, flax, pipe wrenches, a sealant, a union nut and a coupling.

The sequence of work will be as follows:

- Using a metal hacksaw, the defective section of the pipe is cut out, plus 30 cm.

- We unscrew all the connections, clean the threads, and remove the cut piece of pipe.

- We make a new thread on the old pipe. To hold it, we use plumbing wrenches.

- We screw the coupling onto the pipe, after which we determine the length of the pipe to be replaced, taking into account the thread.

- We fix the pipe in a vice and cut off the required section.

- Using a die we cut a thread on it.

- We wrap flax around the thread and lubricate it with a sealant.

- Using a coupling, we connect the new piece of pipe to the old one.

- At the other end we join the new and old pipe with a union nut.

If emergency repair of a pipe is necessary, it can be wrapped in rubber from a bicycle inner tube and then secured with couplings.

How to choose a sealant for sewer pipelines

It is necessary to build on the type and structure of the engineering communications themselves. Polymer sealants are ideal for treating joints in an apartment, office, or cottage because they:

- are inexpensive;

- available to a wide range of consumers;

- presented in a wide range;

- easy to use;

- do not require special training.

For large volumes of work, it is recommended to combine materials with each other. Alternatively: sealing tape + mastic/epoxy resin/sealant.

An important factor is the material used to make the pipes. You need to make sure that the chosen product has good adhesion to metal, cast iron, polypropylene and PVC products, since the quality of the seam and its durability depend on this.

In some cases, other means of sealing drain lines are also suitable:

- rope soaked in resin - for cast iron/ceramic drains;

- technical sulfur - for sealing small joints;

- sealing cuffs - made of rubber and suitable for various types of pipelines.

What is pipe sealant?

Pipe sealant

Various insulating materials are used to seal threaded connections on pipelines.

Liquid silicone sealant

Plumbing silicone sealant for sealing pipe joints is a synthetic glue that, after drying, forms a plastic joint. It is better to use it in conjunction with a fiber seal; such a connection can withstand high pressure in the pipeline.

Anaerobic sealant

Used to seal metal fittings. It is applied inside the threaded joint where there is no air. It has high thermal and chemical resistance, withstands pressure up to 16 atm. Its adhesion to metal forms a strong connection. It does not harden in air; remove excess with a rag.

FUM tape

Synthetic smooth tape for sealing pipes. It stretches when wound and tightly covers the thread, convenient to use. Protects threads from corrosion.

Dry flax

Natural organic matter. One of the first materials used in plumbing. Hygroscopic, absorbs moisture, rots or dries out and crumbles into fibers. Previously, flax was used together with paint. Now pastes are used to protect it from moisture and drying out.

Plumbing thread

A thin synthetic thread is wound into each turn of the thread, while stretching and forming a tight connection. Experienced plumbers use unilock thread, which results in a neat and durable connection. The disadvantage of this sealant is its high price.

Sealants for sewer pipes

Sealant for sewer pipes is presented in the following types:

- sealing tapes;

- polymer compositions;

- ropes made of natural materials - jute or hemp;

- epoxy resin;

- Portland cement;

- rubber cuffs.

A good sealant for polypropylene sewer pipes is a special tape. This is foil tape that, when screwed onto pipes, sticks to them and serves as good protection against water leaks. There may be summer or winter versions, as indicated in the labeling. The summer option is used for sewerage inside the apartment. The external pipeline will require winter design.

The sealant for PVC sewer pipes can be polyurethane glue. It is used to connect individual parts of the pipeline. We get a tight, permanent joint. It is selected taking into account the operation and chemical composition.

Ways to solve the problem

The method by which the breakdown will be repaired is selected based on the cause of the problem. Therefore, you need to determine exactly why the crack formed, and only then begin repairs. If a leak occurs in a cast iron sewer pipe, it can be eliminated in the following ways:

- install a clamp with a rubber gasket. To use this method, the pipe must be located at a distance of more than 50 mm from the wall; in other cases, installing a clamp is impossible;

- installation of cement bandage. Gauze impregnated with cement is applied to the accident site, a standard and universal method for eliminating problems and cracks;

- use of chemicals. You need to mix copper oxide powder and phosphoric acid, put the resulting solution on the damaged area and wrap it with a thick cloth.

When choosing a method, you should pay attention to the installation conditions of the cast iron pipe itself and the cause of the problem. If you use the wrong method, you can only worsen the situation, which will lead to the formation of new cracks

Basic requirements for compositions

To choose a truly high-quality sealant, you need to evaluate its compliance with the most important criteria:

- Suitability for a particular material. Some sealants are designed for use on plastic, while others are suitable for metal substrates. There are also universal compositions that are suitable for any plumbing task. The information the user needs is always on the packaging.

- Resistance to adverse effects. A good sealant must withstand the influence of household chemicals, alkalis, ultraviolet radiation, high and low temperatures.

- Long service life. The product must last for at least 5 years when it comes to sealing pipes, and up to 3–5 years when sealing seams between a wall and a bathtub or other plumbing fixtures.

- Elasticity. The sealant must not crack from vibration or temperature changes, which cause expansion and contraction of materials. If elasticity is poor, the seam will quickly deteriorate.

- Polymerization time. If your bathroom renovation is urgent, you need to choose the fastest-drying compounds.