Most dachas in Russia are rarely used in winter, since they were originally built for summer holidays and, due to their characteristics (wall materials, insulation), are unsuitable for living at sub-zero temperatures. At this time, most summer residents move back to the city, leaving their country houses without light and heating.

However, before leaving an unheated dacha face to face with frost, it is necessary to carry out a number of preparatory measures, because the water in the pipeline can simply freeze. If you do not prepare the water supply system for frost, then in the spring you may be in for a surprise, because frozen water during a new start-up can severely damage the pipeline.

That is why it is so important to remove all water from the pipeline, irrigation systems, pumps, etc. before winter at the dacha. In this article we will tell you in detail about how to properly preserve the water supply in the country.

Why blow out water pipes before frost?

The main problem of all country water pipes is freezing of water at subzero temperatures. Such a decrease in temperature negatively affects not only the pipeline, but also other equipment. An air compressor can help avoid such consequences; it can be used to clear water from the pipeline so that it does not freeze in it in winter.

This process removes water from:

- Water pipelines unprotected from frost (usually they run between nearby buildings);

- Automatic watering systems;

- Drinkers for animals operating in automatic mode;

- Structures for supplying water to swimming pools.

During the purging process, you need to understand that a pressure of more than 10 atmospheres cannot be supplied to the country pipeline. Otherwise, the pipeline may rupture or leaks will appear over time.

Why shouldn't you add antifreeze to pipes?

Antifreeze can corrode seals. The glycols it contains are quite aggressive and can damage them, and over time they can leak.

Have you ever left your dacha or country house for the winter, moving to the city, where it is much more convenient? Surely yes. At least in our area there are few people who like to freeze at their dachas in winter, especially considering the average temperature in January.

The problems faced by owners of unheated premises in winter are always the same and relate mostly to water supply systems.

For any pipeline, it doesn’t have to be a water supply, dropping the ambient temperature to below zero is a big problem. If you do not prepare the system before winter, then on sunny spring days you will be in for a not very pleasant surprise.

Blowing heating pipes with a compressor

How and why to prepare pipelines before winter? In this article you will receive a comprehensive answer.

Preparing the country water supply for winter

The process of preparing a pipeline at the dacha itself is simple. However, it is important to do all the steps in a certain order, otherwise you may make mistakes and not drain all the remaining water.

First of all, prepare buckets and other containers before starting work. Blowing with a compressor is carried out as follows:

- Turn off the water completely and then drain the system. At this stage, some of the water will flow out of the pipes by gravity, and the rest will have to be blown out;

- Disconnect other pipeline branches from the central one, so you can isolate them for further purging. Don't forget to install plugs, otherwise a lot of water will spill out;

- Connect the inlet pipe to part of the pipeline, and then plug in the air compressor. When the water stops flowing, the water cleaning is complete and you can turn off the air blower;

- Additionally, the pipes should be mechanically cleaned to remove accumulated deposits (usually minerals and salts).

It is better to carry out the preparatory work on purging the pipeline with a partner, so you can do it faster.

The process of preparing household appliances for the winter period

After cooling, the water is removed from the device using a drain tap, and if it is not available, do this using a drain hose, having first unscrewed the screw on the safety valve. Then you need to loosen the nut on the outlet hose, which will allow air to enter and remove water from the boiler. Remaining water from dishwashers, as well as washing machines, is removed from the drain hole, most often located on the front panel at the bottom of the equipment. For this purpose, place a container under the drain, open it and remove the water.

Have you ever left your dacha or country house for the winter, moving to the city, where it is much more convenient? Surely yes. At least in our area there are few people who like to freeze at their dachas in winter, especially considering the average temperature in January.

The problems faced by owners of unheated premises in winter are always the same and relate mostly to water supply systems.

For any pipeline, it doesn’t have to be a water supply, dropping the ambient temperature to below zero is a big problem. If you do not prepare the system before winter, then on sunny spring days you will be in for a not very pleasant surprise.

Blowing heating pipes with a compressor

How and why to prepare pipelines before winter? In this article you will receive a comprehensive answer.

What equipment is needed to blow out pipes?

Plumbing compressors come in a variety of varieties, and their use is not limited to purging pipelines. Below we will tell you in detail about existing compressors, and then you can make the right choice.

Scroll compressors

These devices are primarily characterized by their high reliability and long service life. They are so called because the main element of the installation is a special spiral, which is perfectly balanced, so vibrations are practically not felt during operation.

There are few moving elements in the installation of a scroll compressor, so no extraneous pulsations are observed when the pressure increases. This compressor differs from the piston compressor in its increased volume.

Diaphragm compressors

In such devices, air compression occurs under the influence of a membrane. In this installation, it performs a reciprocating motion, and thus performs the same functions as a piston.

Diaphragm compressors differ:

- stable long-term work;

- long service life;

- ease of use;

- corrosion resistance;

- safety to use.

Inside such a compressor there is a dense rubber chamber; it plays the role of the main air storage device. Therefore, a membrane-type compressor does not rust, which is why it lasts much longer.

Piston compressors

The operating principle of this compressor can be compared to the combustion chamber of an engine in a car. After all, air is also compressed here as in cylinders. Although the design of a piston compressor is quite simple, therefore these models are inexpensive and anyone can purchase them.

Negative aspects of the unit: short operation, high noise level.

Screw compressors

A pressure screw is installed in the design of this device. Almost all models are sheathed on the outside with sound-insulating material, so screw compressors operate almost silently.

The screw compressor needs to be lubricated once every 3 months, but this is only in case of active use. It is this feature that makes this compressor an indispensable assistant in the country when blowing pipes.

Air purging technique

Air has high compressibility, unlike liquid, in which this property is much less pronounced. Thanks to this characteristic, it is successfully used in shock absorbers. Excellent compressibility indicators also explain the fact that effective blowing requires a powerful compressor, which cannot be said about the machine version. When blowing out a long pipe, there is a rapid drop in air flow pressure, which makes it impossible to blow out the remaining volume of water.

Purge of the water supply system must be carried out taking into account the permissible pressure and air consumption. You should not use too strong compressors, since the pipes with which the internal wiring is equipped can withstand a maximum pressure of 8-10 atmospheres. The process of purging a complex and long plumbing system, which is equipped with multi-story buildings, can require a very large air flow.

What are the pros and cons of using a compressor to blow out pipes?

Any devices used by humans have advantages and disadvantages, compressors are no exception. The positive aspects of using a compressor for blowing pipes include:

- Affordable price. In any city you can purchase inexpensive piston and screw compressors. Some services also sell used equipment. Such services include Yula and Avito. If you decide to buy a used compressor, be sure to pay attention to the accumulator, as they may be rusty;

- High performance . Many models have a coaxial drive, so you can increase the operating speed several times;

- Mobility . Small compressors are easy to maintain and use, as they can be easily dragged from place to place;

- Unpretentiousness . All compressors are already filled with the required amount of lubricant at the factory, so there is no need for constant maintenance.

The disadvantages of using compressors to blow out pipes in a dacha include the likelihood of leaks in the future. This is due to the fact that some pipeline branches are often long. Therefore, it is necessary to create high pressure in the pipeline to expel water, otherwise some connections may begin to leak water in the spring.

Important! Conventional household compressors cannot be used for purging water pipes, as they are not designed for this purpose. In this case, the water supply system of the dacha will not be completely cleaned, and there is a high probability that water will remain in it. Only powerful specialized compressors can create the necessary pressure in order to completely remove water from the pipes.

Compressors and their variants

In order to blow out country pipes, you will need special equipment of varying power. It all depends on the complexity of the pipeline and its length.

Let us consider in more detail the possible options for this equipment, which differ in individual characteristics.

Piston compressor

Here, air is compressed in piston cylinders according to the operating principle of an internal combustion engine. The advantage of this type is the simplicity of the design, its maintainability and low cost. The disadvantage is the limited operating time and noise of this process.

Scroll compressor

This type is distinguished by its small dimensions and low productivity. Its work occurs as a result of the interaction of two helices. Such equipment is suitable for blowing short-length pipes with small diameters.

Screw compressor

The operating principle of such a device is based on the parallel rotation of two special screws. Due to low friction, this process requires little electricity and is characterized by low noise.

On the other hand, it should be noted the high productivity of this design. He is able to create sufficient pressure. Due to the complexity of the design, such products are very expensive and difficult to repair.

Diaphragm compressor

This type is similar to the piston design. A membrane is used instead of a piston. Its features are low efficiency and low pressure. To increase power, a small receiver is used in which compressed air is stored.

As a result of the combined work of these two elements, low-power equipment is capable of creating high pressure. This way you can significantly save your family budget. After all, to purify the water supply of a private house or cottage, there is no need to buy powerful equipment.

Be careful with the pressure you use.

Methods for blowing pipes in a country house without a compressor

If you don’t have a powerful compressor, you can easily make one yourself. For this purpose you will need a minimum amount of necessary equipment and additional things:

- Durable polypropylene or Teflon canister;

- Drill;

- Step drill;

- FUM tape;

- Unnecessary bicycle or car camera;

- A pressure gauge for checking tire pressure (costs no more than 100 rubles in car and bicycle stores);

- Ball valve (required to shut off the air supply);

- Several flexible hoses for water supply;

- Fittings with threaded connections for connection to the canister.

The process of creating a simple compressor for blowing pipes

- Drill three holes in the side of the canister. Their diameter should be slightly larger than the fittings;

- Insert the fittings into the canister, make gaskets from the old chamber. And then tighten them securely with the bolts;

- To one fitting you need to connect a simple foot pump for inflating wheels or a small car compressor;

- Connect the hose securely to the second fitting, then screw in the ball valve, and then again the flexible connection. Do not forget to seal all connections with FUM tape;

- A pressure gauge is screwed into the third fitting to monitor the pressure in the canister.

Heating on a water-lifting column

Such a decision was encountered only once. One of the clients organized the heating of a pipe from a summer tap along its entire length using a thermal cable. The disadvantages of the solution are obvious:

- The system works as long as there is electricity. When there is a power outage, we end up with enlarged pipes.

- Constant energy consumption, and therefore costs.

Our specialists will definitely not recommend such a solution to their clients and implement it. It is presented rather as an example of an unsuccessful approach to solving a problem.

I want another option

Discuss with an expert

Specialist consultations

How to blow out pipes in a dacha using a compressor?

- Connect the flexible line from the canister to the vented part of the pipeline (do not forget to remove one plug or open the tap before doing this, since the water will need to come out somewhere);

- Close the ball valve;

- Pump up pressure into the canister with a compressor (this is done with a manual or electric compressor);

- Then it is necessary to increase the pressure in the canister to 4-5 atmospheres;

- After this, you need to stop pumping air into the canister;

- Now you need to gradually open the tap, and the air pressure will displace all the water from the system being purged.

How to drain water from the water supply system for the winter - stages of work

Many users solve the problem of how to properly drain water from a water supply system for the winter in different ways; if the procedure was not previously structurally provided for, its implementation becomes more complicated. Some “Internet experts” recommend using a compressor to blow out the entire system to pump out water.

This advice raises serious doubts about its effectiveness due to the fact that water can be at the bottom of pipes and other components, and air can pass over it without touching the surface, and few people understand where and in what direction to blow the system. In addition, not every owner has a free compressor at his disposal, and the task of freeing pipes from water residues can be successfully solved without it.

Similar “useful” advice can be heard regarding household appliances regarding turning washing machines upside down, disassembling shower heads, etc.

Rice. 4 Winter valve in caissons for wells

Summer cottage water supply system

Removing water from the external system of a summer cottage or country house consists of the following stages:

- For the winter, the submersible pump is usually removed from the pipes of the well or well, and the surface pumping station is also dismantled. At the same time, the submersible electric pump, external pump and hydraulic accumulator of the station are freed from water residues, dried and stored in the house, utility room, barn.

- If the owner is absent from the house for a short period of time in winter and does not dismantle the equipment, the following methods are used to drain water from the external pipeline (it is assumed that the underground water supply is laid with a slope towards the source):

- A surface tee with a ball valve built into the pressure pipeline is used. To drain the water, the tap is turned and it flows into a caisson or well; in the first case, the presence of water masses in a closed chamber is undesirable, so it is collected in a convenient container and poured out. In a deep well, if it is not possible to go down into it, the ball valve is turned with the help of a long stick, a rod, or a rope tied to the handles.

The industry produces a similar type of device with a built-in rod for opening the shut-off valve.

Rice. 5 Operating principle of the automatic drain valve

- There are manual shut-off valves on sale, which are a coupling with a hole, put on a pressure pipeline, in the side wall of which a hole is pre-drilled. The drain is closed with a valve to which a strong cord is attached; when it is pulled out, the plate rises, clears the hole, and the water pours out from the side of the pressure pipeline.

Another variation of this design is a check valve paired with a drain valve, installed in a section of the pressure pipeline or after an electric pump that does not have an internal valve.

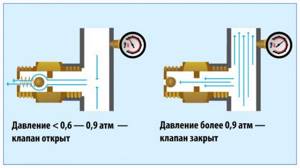

- The automatic shut-off valve design consists of a spring-loaded ball in a seat that shuts off the outlet when the high pressure system is in operation. As soon as the pressure weakens when the automatic control of the pumping equipment is turned off, the spring pushes the ball away from the outlet fitting and water flows out through the vacated hole.

Rice. 6 Automatic winter drain valves Debe G15 and an example of their placement

- Instead of a regular check valve, you can use an electric valve to drain water from a water supply system in a country house - it is installed at the inlet of the pressure pipeline or the outlet of a submersible electric pump, connected to the power supply and opened by pressing a button.

- The most cost-effective drainage method is to punch a small hole in the wall of the pressure pipeline, wrap it with electrical tape (due to small water losses, this can not be done), and if it is necessary to dewater the pipeline, clear it of the obstacle.

Rice. 7 Manual winter valve for a well with a control rod - design, location

Central and autonomous water supply

The internal water supply of the house is designed in such a way that the slopes towards its lowest point are observed, and to drain into the sewer, two taps are used separately for cold and hot water.

Operations to remove water from pipes, electrical and plumbing equipment are carried out in the following sequence:

- Disconnect all automation from the power supply.

- Open all the valve taps on the faucets in the bathroom, shower, and kitchen, setting them to the middle position - thus freeing the hydraulic accumulator (its position should be strictly vertical) from accumulated water.

- If there are any, open the drain valves under the sink; if the hydraulic tank is installed on legs, turn on the valve under it.

- Then open the common taps for draining cold and hot water into the sewer.

- Drain the water from the water heater using a bypass bypass, a special pressure relief valve (raise its flag), or various shut-off valves.

Rice. 8 Winter valve with movable damper Gilex Focus 32

- To free the water seal of the toilet from water, take a large rag with good absorbency, and after eliminating the water masses, plug the hole with dry cloth. To create a frost-free water seal, you can use antifreeze or a salt water solution and pour it down the drain.

- The shower head is lowered down the cabin or bathtub, freeing it from water residues.

- Unscrew the caps of the coarse and fine filters and remove the cartridges, leaving them untouched or washing them if they are heavily soiled.

- Empty the siphons of the kitchen sink, bathtub or shower stall from water by unscrewing the drain caps at the bottom; if unpleasant odors appear in the room, the drain holes are closed with plugs or rags in plastic bags. As with the toilet, you can pour antifreeze into the drains or a glass of water with two tablespoons of salt mixed in it.

- In the washing machine, unscrew the plug at the bottom of the front side to drain the water and place a container with low sides under it to collect liquid, and open the doors for better drying.

- With a dishwasher the situation is more complicated; you may need to unscrew the water supply and drain into the sewer, lay them horizontally on the floor and absorb the leaking liquid with a rag.

Stages of preservation of home water supply

Next, we will talk about the procedure for preserving the water supply system at the dacha for the winter. The whole process is done in several stages:

- Turn off the water at the entrance to the house;

- Open all plugs in the home branch of the pipeline;

- Prepare cans, rags and containers. Since water can escape from all open parts of the pipeline;

- Connect the compressor to the vented part of the pipeline;

- Turn on the compressor; when air comes out, it means the water supply system is preserved and therefore will not be damaged by frost.

Making your own compressor

The canister is equipped with a bicycle nipple and a water hose that has a fitting. One of the taps, which has a male thread, is connected to the female fitting. In this case, the foot pump is snapped onto the nipple. After turning off the main main tap, be sure to open all the taps to spontaneously remove some of the water. At the end, all taps are closed (titanium shut-off, as well as taps in the house and summer kitchen, outdoor tap for watering). Then the pump and receiver are connected to a street tap and pumped, followed by opening the adjacent tap to completely eliminate any remaining water.

Then the water supply network is filled again, the common tap is closed and similar actions are performed with the remaining taps open. The result is identical to the above.

In general, such a receiver is suitable for removing residual water from a water supply system even if the water supply system is not disassembled.

Stages of conservation of street water supply and automatic watering systems

Street water supply in dachas is often located above the ground or at a depth of up to 0.5 m. Therefore, such systems must be emptied before winter frosts, otherwise the resulting ice will break all the pipes.

It is especially important to blow out all metal pipes, since threaded connections quickly burst in the cold. PVC pipes are not so afraid of frost, but the water still needs to be removed from them; a compressor will also do an excellent job with this task.

Do not forget to remove water from storage tanks for irrigation, outdoor showers and other containers. All ball valves must be left open, then they will easily survive the winter and can be used in the future.

Do-it-yourself septic tank conservation

In year-round country houses, the septic tank does not freeze, but when the owners leave for the whole winter, work on its insulation cannot be neglected.

To preserve a septic tank for the winter, you need to:

- disconnect it from electricity;

- disconnect pumps and air compressors;

- pump out the liquid from the septic tank by ¾ (or add water, but the septic tank should be a quarter full!).

- pour bacteria into the septic tank (this will get rid of unpleasant odors after re-opening)

- insulate the septic tank lid and pipeline with any insulation.

This is the neck liner for insulating a septic tank made by our participant with the nickname Ice9avalon.

If there are still concerns that the walls of the septic tank may freeze, throw a five-liter bottle half filled with water into each section.

Eugene2012 Member

Then the ice, expanding, will compress the plastic of the bottle, and not the plastic of the septic tank.

Having completed all this work, you can leave the dacha with a clear conscience until spring - in spring the autonomous water supply and sewerage systems will work like new.

You can learn more about how to prepare your water supply for winter, how to insulate a well, and how to properly drain water from a heater. Read our article on how to prepare your country house for the cold. Find out how to properly mothball a construction site. Watch a video on how to properly prepare your garden for winter.

Source

Stages of conservation of wells and wells

In addition to preserving pipes in the country, it is also important to take care of preparing water sources for frost. Below we will tell you how to do it correctly.

Well

The water in the wells always has a positive temperature, so it does not need special conservation. If the well is shallow (up to 4 meters), then it is recommended to make a heat-insulating cover that will protect the well from freezing. It can be made from sheets of polystyrene foam or penoplex.

Well

Preservation of a well for the winter is done in several stages:

- First of all, remove all equipment from the well (they need to be stored in a heated room);

- Then you should blow out the pipes that go into the house;

- After checking the casing, you can fill it with a neutral composition (crushed stone with fine sand is perfect for this purpose);

- An antifreeze liquid must be applied to the top of the structure.

Is it necessary to pump a well in winter?

Prolonged inactivity negatively affects the condition of the well. It begins to silt and the water quality deteriorates. For example, filter sand wells are very dependent on the intensity of operation (they silt up and fail quickly if they are not used in winter). It is recommended to pump them at least once a month for 20 – 30 minutes.

After the end of the winter period, it is important to properly restore the operation of the water intake, that is, pump up the well. The task is to lift layers of silt and sand from the bottom and squeeze them out of the pipe.

- We use the vibration method. We lower the vibration pump into the well and alternately, lowering and raising the apparatus, loosen the deposits at the bottom. We repeat the procedure until clean liquid arrives. We periodically clean the pump from dirt. We make sure that it does not sink to the bottom.

- Another version of rocking is carried out by pressing and throwing small particles of silt and sand that have accumulated at the bottom onto the surface. We use the method used in brine production wells, operating on the principle of “squeezing out brine.” We lower a smaller diameter pipe into the well until it stops at the bottom. We connect a hose to it from above, and let water through it with high pressure. The water jet squeezes out sediments and sand particles come to the surface. When gravel particles appear, we stop the process and remove the narrow pipe. We lower the pump and pump the water intake in the usual way. The disadvantage of this method is that the mesh filter may not withstand the pressure and break.

Periodic pumping of your own well extends the life of the water intake structure.

How to mothball a well

The well is preserved for the winter so that in the spring it is completely ready for use. This means that throughout the winter we will not be able to use it; access to water will be completely blocked. We have already done the main work: we drained the water from the pipeline, heater and plumbing fixtures, and removed the pump.

Now the well is not in danger, the main thing is to close the wellhead correctly: screw on the head, which will protect sheets, etc. from rain, snow, and seal it tightly with film.

In a water supply system arranged according to all the rules, a caisson is made - it deepens the well below the freezing point, protecting it from rain and groundwater. A well with a caisson will survive any frost, the only thing is that this device is not cheap.

A FORUMHOUSE user with the nickname Lesha-Samurai has a fairly standard situation: there is a well 75 meters deep (self-flowing 10-15 m3 per hour), which will not be used in winter, and a categorical reluctance to install an expensive caisson.

According to FORUMHOUSE administrator Andrey 203, a caisson is the only reliable option in a leshy case.

A caisson is needed to move the wellhead below the freezing depth of the soil.

However, a successful method of caisson-free well conservation has yet been found. Using this technology, Lesha-Samurai and his friend have been preparing their well for winter for several years now.

- Take 6-7 soda bottles (there should be some drink left in each bottle), shake each bottle to create pressure in them.

- Remove the head of the well and insert bottles into it.

- Put the head back.

- Pump air into the well using a car compressor through the nipple (pump for about 10 minutes). This will ensure that the water level in the well is reduced to the level of soil freezing.

- Shut off the air outlet from the well with a ball valve.

You can take a plug for 1, use a drill to make a hole of a suitable diameter in it and insert a nipple into it with oil.

Even if air leaves the well through elements of such a structure and the water level rises, the bottles will prevent its expansion.