The column or flow heater is becoming an increasingly popular product. A small device can fit compactly in the kitchen and provide hot water to several points of intake. In addition, heating with gas is cheaper than heating with electricity. But what to do if the gas water heater is leaking? Should I call a professional or figure out the problem myself? Possible options are indicated in the article.

The first signs of a pipeline leak

In most cases, leaks in utility lines are immediately noticeable. After all, puddles appear on the floor and other structural elements of the building. However, minor leaks are not always so obvious.

Heating pipe is leaking

If the leak is small, it can be determined by the following signs:

- PP pipes become wet;

- drops that look like dew appear in the area of the fittings;

- the pressure in the pipeline system drops sharply.

If any of the above situations occurs, the owner of an apartment or house needs to pay attention to the water supply network. Maybe it's time for a renovation

A leak that is not eliminated, even in the form of a small trickle of water, will cause irreparable harm. Moisture can get on electrical appliances, penetrate electrical cables, or ruin just-completed renovations for neighbors on lower floors.

Conclusions and useful video on the topic

The following video will introduce you to the consequences of unsuccessful unauthorized reinstallation of a water heater with water entering the gas pipeline:

Sometimes identifying the source of a leak is not so easy. And the consequences of water getting into a gas pipe can be fatal, since in the absence of gas, household appliances do not always automatically turn off. The characters in the following video talk about this:

Obviously, if water accidentally gets into the gas system, the person responsible for the accident faces serious trouble. Even if it is possible to avoid or reduce administrative liability, the moral and material costs will be significant.

It turns out that it is cheaper not to break the Rules and seek help from a specialized organization than to cause trouble for yourself and your neighbors.

Would you like to share your own experience in eliminating problems when water gets into the gas supply system? Do you have useful information on the topic of the article? Please write comments in the block form below, ask questions and post photographs.

Variety of geysers used

The principle does not differ significantly from different manufacturers. Specifications vary.

By what indicators do the models differ:

- Performance;

- Type of burner;

- Degree of security;

- Ignition method;

- Flue gas removal method.

Classification by ignition type:

- Manual. Found on older models. Most modern manufacturers prefer not to use this type of ignition. To turn it on, you need to light the burner yourself with a match.

- Piezo ignition. To turn on the heater, just press a button. Within a few seconds the water from the tap will be hot.

- Electronic ignition. Allows you to save gas, as the automation turns off and turns on its supply.

Based on the type of burners installed, there are two types of heaters. At constant power, manual temperature adjustment is required. With a variable, automatic adjustment occurs. Modulating burners supply water at a uniform temperature.

Speaker power is one of the main selection criteria. Minimum value -16-19 kW. Maximum – 28-32 kW. A heater with low power will heat up to 10 liters of water per minute. This is not enough for a large family. You can only wash the dishes. Average indicators increase the volume to 20.

In order not to encounter the fact that there is no water pressure in, you should choose trusted manufacturers. The German and Italian companies have gained trust in the market. But there are domestic popular brands. The Neva geyser combines proven quality and an affordable price.

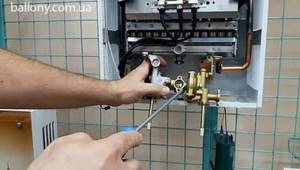

Leakage of threaded connections

Sometimes water drips from the gas water heater due to leaking threaded connections. In the places where they are located, manufacturers use American nuts (flare nuts).

To seal them, rubber gaskets are used, which, when exposed to high temperatures, lose their elasticity, become hard and allow water to pass through.

To troubleshoot you will need:

- Turn off the water (there is a special tap on the tube through which cold water is supplied to the column);

- Unscrew the threaded connection with an adjustable wrench (it will be easier to unscrew if the connection is slightly heated);

- Take out the old rubber gasket and carefully inspect the threads.

If the thread is not damaged, then you just need to replace the gasket with a new one and tighten the connection with a wrench. If there are defects on the American thread, the union nut will need to be replaced.

The best option would be modern silicone gaskets. They are more durable than rubber seals and provide better sealing. Instead of one gasket, you can use two in one place of the threaded connection.

Ways to fix sewer problems

In order to try to remove a blockage in the sewer drain of an apartment or house, you must first determine the location of the blockage.

So, if a problem with water outflow is observed in the kitchen sink, and all other drain points are working normally, it means that the garbage plug has formed specifically in the siphon under the sink. In the same way, you can identify blockages under the sink in the bathtub or under the bathtub/shower stall itself. Depending on the location of the plug, chemicals such as “Mole”, etc., can be poured into the drain hole in accordance with the instructions and eliminate the problem of deposits on the pipes.

- As an aggressive anti-clog agent, you can use simple soda mixed with hot water. That is, first pour soda into the hole in the bathtub or sink, then fill it with hot water. After this, vinegar is poured into the hole. The reaction of the components should push the plug or simply liquefy it.

- You can also use a standard plunger to remove a blockage in your home drain. Cleaning is easy with it. You need to fill the plumbing fixture with water and tightly cover the drain hole with a plunger. Now you should make rhythmic movements up and down with the plunger, creating a vacuum in the manifold. Under its influence, the plug should either come out (most often it is hair) or go into the waste system. You can clean the sink and toilet in a similar way.

Main types of faults

You can fix a malfunction in a gas water heater by turning to specialists for help or doing it yourself. But still, when working with such equipment, it is necessary to know the safety measures, as well as their strict adherence.

IMPORTANT! Otherwise, independent repair of a gas water heater is fraught with HUMAN SACRIFICES.

List of breakdowns found in geysers:

- The igniter does not light;

- The pilot light goes out;

- There is a pipe leaking in the radiator;

- Water is leaking at the connections.

There are two main reasons why a gas water heater leaks. Failure is determined by elimination. Where exactly the fault is located is indicated by the localization of the liquid. The fact that the gearbox has failed will be indicated by water flowing from below. If condensation appears in the column, the heat exchanger (gas column radiator) is faulty.

The most common breakdowns:

- A reducer or water block is a device that sends a signal to open the gas valve and then to ignite. From the inside, the gearbox looks like a hollow structure, divided in two by a membrane. When water is supplied to the reducer, pressure arises, from which the membrane wears out over time, leading to malfunctions. When liquid drips from the column's safety valve, this means that the membrane is blocking water access, but due to wear, the barrier disappears.

- Another sign of a problem with the membrane is a leaking water unit. Such a breakdown can also be caused by failure of the rod sealing gasket.

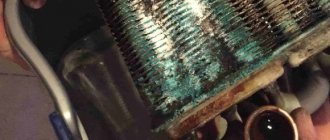

At first, during operation, only a few drops of water are released; over time, the flow in the gas water heater becomes more and more intense. Microcracks or corrosion in the radiator appear due to constant exposure to fire. As a result, the copper or steel pipes of the coil burn out. In this case, condensation first accumulates on the internal components and the housing. Leak points are indicated by a change in the color of the copper - it turns green.

First of all, if water is flowing from a gas water heater, you need to check the places to which the pipes are connected. This will prevent leaks due to failure of gaskets and loose threaded connections.

Review of manufacturers

The main difference from other analogues is the affordable price and the lack of electricity required for operation.

Keber boilers are also popular; they are equipped with an automatic safety and regulation system, which ensures precise gas supply and temperature stabilization.

(Termotechnik) presents a large selection of boilers and offers floor-mounted, parapet-type, gas and solid fuel units. Many years of experience ensures excellent quality and guarantees product reliability and long service life.

Eliminating problems associated with blowing out the boiler requires special care and responsibility. It is necessary to check all components of the boiler to determine and eliminate the cause of the malfunction. If the recommendations presented do not bring results, it is worth calling the gas service specialists. Remember that quickly getting rid of problems will prevent additional breakdowns and protect not only the entire system, but also the residents of the house.

Watch the video in which a specialist examines one of the most common reasons: why a gas boiler goes out in the wind, what needs to be done, what work needs to be done to improve draft in the boiler:

Professional repair

It is not recommended to carry out any repair work related to gas yourself due to its danger. Use the services of a service technician.

- The company works seven days a week from 7:00 to 23:00, the master will arrive on a day convenient for you, even on the day of your request, if you submit your application before noon.

- All company specialists have specialized education and approvals for gas work.

- The quality of the repair is confirmed by an official guarantee.

- We use only original spare parts.

To ensure the stove lasts a long time, do not leave it unattended while cooking. Take proper care of it in a timely manner. This will extend the life of the equipment and protect you from unforeseen situations.

How to protect the column from freezing?

Is your gas water heater freezing through your chimney pipe and you don’t know what to do to avoid this problem? Let's take a closer look at this issue.

The instructions for the equipment specify the temperature conditions at which the equipment functions normally. When the outside temperature drops, individual components of the water heater may fail. Just because a device is under warranty does not mean there is absolutely nothing to worry about. The manufacturing company clearly defines operating standards, violation of which may result in loss of warranty.

If the location of the column is an unheated room, and the equipment itself is equipped with a chimney, the problem is solved by installing a check valve that prevents frosty air from passing through the chimney directly to the body of the device

You can avoid freezing if you drain the water in a timely manner. This applies not only to country speakers, but also to devices that are located in private houses or apartments.

It is necessary to drain the water in the following cases:

- abnormally frosty weather;

- frequent power outages;

- unheated room.

This measure will not hurt if you are leaving for a week or more, which means the gas water heater will not be in use.

To drain the water, turn off the gas valve and the incoming water supply tap. Then turn on the hot water on the mixer and wait until the water is completely drained.

You can avoid costly repairs by using the “Winter-Summer” mode, if, of course, the speaker is equipped with it. By increasing the heating temperature, you save equipment from freezing

Another case is possible when the column is in a warm room and still freezes. The part of the pipe located indoors remains warm. And that part of it into which the “street” air enters goes into minus. The condensation formed in the pipe turns into ice, which, in turn, binds the check valve. The removal of gases from the column will thus be blocked - the fan will not be able to open the valve. It will be impossible to turn on the column in such a situation.

The solution to the problem is quite simple. You can use a regular household or construction hair dryer. The device must be turned on in maximum heating mode. Now all that remains is to heat the pipe. The ice will quickly melt and the valve will be released. Now you can turn on the column and let it run for 10 minutes so that the smoke exhaust line completely warms up and dries out.

Sometimes the cause of freezing is problems with ventilation or defects in the manufacture of the housing. If the device is under warranty, you should contact a service center. If the warranty period has passed, sealing the case helps.

Possible consequences and ways to eliminate them

As a rule, it is not the person who caused the accident who shows the first signs of concern about the current situation. One can only assume that he is in a state of shock, because it is simply impossible not to notice that something has gone wrong.

Complaints are starting to come from other residents whose gas stoves and heating appliances suddenly stopped functioning, and water began to stream from the burners.

Such an impromptu fountain of water from a gas burner cannot please the neighbor, because she was left without gas during the entire emergency work.

Emergency services have to shut off the gas supply and begin carrying out repair work of varying levels of complexity. Water will need to be removed from the gas pipe along its entire length.

If the culprit of the accident lives on the top floor of a multi-storey building, gas workers will have to check the gas appliances of all his neighbors, who, in turn, are obliged to provide access to their apartments.

It would be a mistake to think that this kind of accident occurs only in apartment buildings: in individual buildings there are also craftsmen who can organize such a water extravaganza

Frosty weather can further complicate the emergency situation. After all, draining the water is easier than breaking through the ice plugs that have formed in the gas pipeline. If the pipeline runs along the facade of a building, it is heated using gas burners. This is dangerous and painstaking work.

In winter, the pipe running along the facade of the house should be heated, a puncture should be made in it, the water should be drained, and only then the drain hole should be welded

If the water is in pipes located underground, you will have to dig them up and then drill drain holes into them.

The ice plugs are pierced with special cables, after which all the resulting crumbs are carefully removed. Sometimes it is easier to cut out entire sections of the route and replace them with new ones rather than risk leaving some of the frozen water inside.

Before freeing gas pipes located in the ground from water, they need to be dug up, and then drain the water through technical holes or replace part of the pipe if there is irremovable ice in it

Now you can weld the holes, check the gas pipeline for leaks, and only then bury the trench.

Causes and solutions to leaks

It is important to monitor the refrigerant level in the system. There are special marks in the expansion tank for this purpose.

If the level constantly drops and you have to add fluid, then the system is leaking. We need to look for the cause and eliminate it quickly. Let's look at the main reasons for leakage and ways to solve the problem:

- If the radiator has a neck, then you need to check the cap. The coolant is heated to 120 degrees Celsius and circulates through the system under high pressure. If the cap is not able to hold pressure, then the antifreeze evaporates from the heat exchanger and the level drops. This problem is solved by replacing the cover with a new one.

- The second reason for antifreeze leakage is wear of the rubber pipes. Check the connections to the radiator. If there are traces of coolant leakage, replace the pipes and clamps.

- The most unpleasant failure is the appearance of a leak in the radiator itself. It occurs as a result of mechanical shock, physical wear, or due to the use of low quality antifreeze.

Finding a large hole will not be difficult - hot steam will pour out of it. It is difficult to eliminate such a defect on the road. Get to the nearest service station quickly and have the heat exchanger repaired or replaced. In any case, the old radiator will have to be dismantled and inspected. Some craftsmen know how to weld holes. If the radiator is made of copper or brass, then it can be soldered. Aluminum is repaired using argon welding.

Experience shows that such repairs can rarely be carried out efficiently, and after just a few months the car owner is forced to replace the radiator with a new one.

It is more difficult to detect a small leak, but the antifreeze itself will help in the search. Its chemical composition contains a dye that is illuminated under ultraviolet light. Just shine a special lamp on the radiator and you will see where the coolant is leaking.

A defect discovered in a garage is eliminated using cold welding. This is a two-component epoxy resin. The prepared composition is similar to plasticine and is applied to the detected defect. Pre-clean the surface: remove dirt, oil and dust. After 15-30 minutes, the weld hardens and the leak is eliminated.

There is an opinion that you can eliminate a small leak using folk methods, for example, using dry mustard. This product is added to the radiator; under the influence of temperature, the particles increase in size, spread throughout the system and, where there is a leak, close the hole. Remember that once the defect is eliminated, foreign substances clog the entire system: engine channels, radiator honeycombs. Do not use traditional methods. Find another option to get to a service station or use radiator sealant.

What to do if the column does not light up?

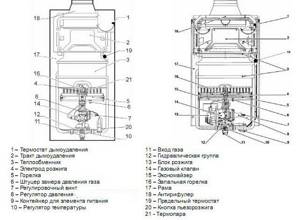

Internal structure of the gas water heater -

This is the most common question that arises among owners of gas equipment. Wait to panic - let's understand the situation. In fact, there can be a great many reasons for this - from the simplest and most banal, which can be eliminated in 5 seconds, to very serious ones, for which you will need a specialist.

Place the receiving flask under the funnel, remove the stopper from the top and open the stopcock and allow the bottom layer to flow out of the funnel. Close the tap and you have now separated the two layers. Both layers should always be maintained until the desired connection is isolated, and the layers they separate should also be carefully marked. In general, you will have to "dry" the organic layer by placing it on magnesium sulfate or sodium sulfate.

Thin layer chromatography is a powerful method for separating compounds based on their polarity and interaction with silica and assessing sample purification. Now place them in the developing chamber. The developing chamber should have some developing solvent, but the level of this solvent should not be higher than the pencil mark on your plate. Mark the distance relative to where the solvent passed. Now visualize your plate by first noticing the spots that you can visually see, then the spots that you can see with an ultraviolet light source, and then finally adding your plate to the iodine chamber.

The very first thing you need to do

– see if the pilot light is on. If it doesn’t even think about igniting, then you can’t do without a gas service specialist. He will competently clean the igniter nozzle, or maybe replace the igniter itself with a new one.

The second probable reason is that you simultaneously opened a tap with cold and hot water, and the flow of cold water was much greater

. This is what led to the extinguishing of the flame in the igniter.

This procedure is shown below. The white matte surface depicts the solid phase of this chromatography procedure. This is the line on which the pattern is applied. If the sample is immersed in a solvent, it will damage the results. A piece of filter paper is placed in the chamber to draw the solvent into the top of the chamber. Finally, it is important to close the chamber to ensure that the solvent does not evaporate.

The column heats the water incorrectly

To draw a sample in a tube, heat one end of the tube on a hot plate and then lower the cool end into the sample. This will bring the sample into the tube. Once all samples have been loaded, the plate can be placed in the chamber. Make sure the solvent is below the sample line and that the plate is not touching the filter paper. Also keep an eye on the plate. It only takes a few minutes for the solvent to dissolve. When the solvent reaches approximately one centimeter below the end of the plate, remove it from the chamber.

There is no draft in the chimney

You try to light the gas, but it just won't light. Why? First check the draft in the chimney

.

It is likely that it is clogged with various debris, and combustion products simply will not be discharged outside, but will remain in the room. In this case, the built-in automatic safety device of the device simply does not allow it to ignite and does the right thing - it is life-threatening!

Make sure the plate does not touch the filter paper. Once the slab is removed from the chamber, mark the solvent front for later calculations. Once the wafer has dried, two methods can be used to visualize the location of the sample on the wafer. Ultraviolet light can be used. Another way to visualize the sample is to use an iodine chamber. Placing several pieces of iodine in a covered container and then adding a plate will cause some samples to turn brown.

Prevention of geyser problems

Either way, using a pencil outline, locate the sample for subsequent calculations. These calculations are shown below. Melting point is used to evaluate the purity of a product. In the picture on the right, note: at the top, the positions of the melt water pipe, the viewing area and the heat control.

Your actions in this case are simple

: open a window or window. Light a match and bring it to the chimney. If the flame does not even attempt to deflect, then the chimney is not working. Just call a professional to clean the pipe and everything will be fine.

Pre-inspect the chimney outlet. Perhaps one of the neighbors installed an antenna above it, so the draft disappeared. By the way, this is prohibited, as it is a potential cause of carbon monoxide poisoning.

Column chromatography is often used by organic chemists to purify liquids. The impure sample is loaded onto a column containing an adsorbent such as silica gel or alumina. An organic solvent or mixture of solvents flows through the column. The sample components are separated from each other by separation between a stationary packaging material and a mobile eluent. Molecules with different polarities are separated to different degrees and therefore pass through the column at different rates.

If there is a leak in the connecting elements

The eluent is collected into fractions. Fractions are usually analyzed by thin layer chromatography to ensure that separation of the components has been successful. The success of your split will depend on how well you pack and load the column. Cracks will form in the silica column if it dries, and the compounds can break the cracks instead of separating between the mobile and stationary phases. The connections pass quickly through the sand and do not stick to it. Sand is used at the bottom of the column to ensure a smooth silica gel line. The bottom of the column is usually cone-shaped. If there was no sand at the bottom of the column, molecules moving down the center of the column would encounter less silica gel than molecules moving along the edge, closer to the glass. As a result, the particular component elutes as a wider band, which is undesirable. Sand is used at the top of the column to promote uniform loading of the sample. The sample is dispersed evenly through the sand. After removing the clamp from the bottom of the column, the sample is evenly distributed onto the silica. Without sand, the sample would be added directly to the silica and would stick where it was added, not evenly across the surface of the silica.

- It is important to have smooth sand and silica.

- It is also important to add the sample thoroughly and evenly to the packed column.

- Do not allow the silica to dry out while heating the column.

The rotary evaporator is a new addition to the organic chemistry laboratories here at Wake Fore.

Another possible reason for the lack of draft is tightly closed windows in the room.

. Simply put, the urge has nowhere to come from. This is especially true if you have plastic windows and it’s cold outside. Of course, you will try to close it as tightly as possible, completely blocking access to air. If after opening the window the column lights up, then the problem is obviously solved.

Although the tool looks quite complicated, it is actually quite simple. The purpose of rotorap is to remove low-boiling organic chemicals, usually solvents, from a mixture of compounds. The rotary evaporator is the method of choice for solvent removal in the modern organic laboratory. Solvents or low boiling compounds are removed by simple distillation. Rotawap is designed to operate under vacuum and simultaneously heat the sample. A cold finger is used to condense liquid vapors, which fall into a separate flask.

The batteries are low (battery)

Batteries for the speaker with automatic ignition

If your unit has an automatic ignition system, then do not miss this reason, even if you bought the column a few months ago. Enterprising manufacturers promise a year or more of work on a single charge, but in reality this is not at all the case - the cells “die” much faster.

Below is a photo of a rotary evaporator. The lower red arrow points to the bath temperature regulator. The middle arrow indicates the attachment point of the bulb. The top arrow points to the rotation speed control knob. Infrared light or radiation has the right energy to enhance the stretching and bending of bonds, which are vibrational transitions. Because molecules have many possible vibrational states, each with a slightly different energy and therefore a different emission frequency required to amplify the vibration, many absorption bands appear throughout the infrared spectrum of even the simplest molecules.

What to do in this case

: Replace the batteries with new ones and try the power button again. If the column lights up, the problem is fixed.

How long do you hold the ignition button? For the speaker to function properly, you need to press the button for at least 20 seconds

! If you hold it less, the speaker will go out after some time.

Today, infrared spectroscopy is commonly used to identify the presence of functional groups. Our organic students typically only analyze liquid samples. The department owns two Fourier transform infrared spectrometers located in Salem.

If the software is already open, close all existing program windows. Use the drop-down menus to perform the following tasks. For the Galaxy: - Collection: Background collection. Make sure the light path is transparent when getting the background. Otherwise your data will be discarded.

Weak water pressure

The column can only operate at a certain water pressure in the pipes. If the pressure is low, then she won’t even think about turning on.

What to do in this case

: Open cold water in another room. If the water flows there also “sluggishly,” then the problem is in the water supply system. All you have to do is wait. If the water flows very quickly, then the problem is already in the unit itself.

The selected spectrum and its name will be displayed in red. Once you've selected the spectrum you want to delete, use Edit:Delete to delete it permanently. Analysis: Finding Peaks If too many peaks have been flagged, you can move the threshold line down by sliding the bar on the left side of the screen.

The line may not appear, but you will notice fewer and fewer peaks being labeled as you lower the threshold lower and lower. Although this is not usually necessary for organic labs, you can save your spectrum if you wish. Clean your plates with acetone or ethanol and place them back in the desiccators. Throw away any used Kimvips and place disposable pipettes in a broken glass container.

Filters or membrane?

If the device goes out after turning it on, then the problem is most likely in the temperature sensor, which is responsible for overheating of the column. In this case, there are 2 possible scenarios:

- The column lit up, worked for 10-15 minutes, after which it went out, and all attempts to relight it lead to nothing. After some time, it can be turned on again, and after 10-15 minutes the story repeats itself in a circle. The reason is that the overheat sensor is too sensitive. It detects that the temperature around the column is too high and turns it off. In general, this is a manufacturing defect, so if you wish, you can send it in for service.

Remember that this problem can only appear in the height of summer, when it is hot, or in winter, when all the windows are closed. You'll be lucky if your purchase warranty hasn't expired by then. Otherwise, you will have to pay for the repairs out of your own pocket.

Gas chromatography is used to separate the volatile components of a mixture. A small amount of the sample to be analyzed is drawn up into a syringe. The syringe needle is placed into the hot injector port of the gas chromatograph and the sample is injected. The injector is set to a temperature higher than the boiling points of the components. Thus, the components of the mixture evaporate in the gas phase inside the injector. Within the column, the components are separated.

Ideally, the components of the mixture will arrive at the detector at different times due to differences in separation between the mobile and stationary phases. The detector sends a signal to the chart recorder, which results in a peak on the chart paper. The peak area is proportional to the number of molecules generating the signal.

- Unit shutdowns do not have a pattern - it may not turn on, then work properly, and then turn off again. If this situation is familiar to you, then the cause may be a frayed sensor conductor sheath. The exposed part closes to the body and the safety valve turns on. Who should I contact in this case?

To a service center or to the model manufacturer. Gas workers will not help you here, since this is not their area of expertise. And you can hardly fix anything with your own hands.

When and where can I file a complaint?

ABOUT US A úþüÿðýøàøÃÂúûÃÂÃÂà¸ãâââlas ”ã] ã] ãâ² ã¿¿¿ããlaceãââãããâ ]Turey paper ã] ã²ããããulate. ÃÂÃÂõÃÂõý÷øàÿþ ÃÂûðñþüàýðÿþààòþôàò úòðÃÂÃÂøÃÂõ ÃÂûõôÃÂõàÃÂþà VALUE °ÃÂ, þôøý â ÿõÃÂõôðÃÂàò ãÃÂ, ð òÃÂþ ÃÂþù àòÃÂþôÃÂÃÂõù þÃÂüõÃÂúþù â þ ÃÂÃÂðòøÃÂàÃÂõñÃÂ. 59 Chapter 59 ÷ðÃÂòûõýøàóÃÂðöôðý ÃÂðÃÂÃÂüðÃÂÃÂà ¸Ã²Ã°ÃÂÃÂÃÂàôþÔ A A ÿþôðÃÂø ò þÃÂóðýø÷ð ÃÂøÃÂ.

Types of threaded connections used in instantaneous water heaters

The following types of fittings can be used in internal cold or hot water supply lines:

Sgony

- this is one of the old types of threaded connections used for laying cold, hot water or gas pipelines. In fact, these are two threaded pipes connected to each other by a coupling with a lock nut.

These types of joints can still be found in old houses. In instantaneous water heaters they are definitely not present, but they may be in front of the column. To seal threaded fittings in squeegees, flax tow or a special synthetic tape is used. It is on the slopes that water begins to drip.

Tips: Before unscrewing the threaded connections, drain the water by first turning off the water tap on the water supply when entering the apartment.

Their difference from other fittings is that one end of the fitting is welded to the pipe.

Threaded fittings

can definitely be encountered when disassembling an instantaneous water heater. These are standard connecting elements for pipelines. To ensure tightness, a special tape or linen tow is wound onto the threads. The coupling then tightens the connection and ensures a tight seal. The advantage of such a connection is its low cost and simplicity. However, novice craftsmen are unlikely to be able to make a high-quality seal the first time.

Unlike threaded connections, the one called “American coupling” is better and more convenient to install. Here the role of seal is played by a rubber, paronite or propylene gasket. In order to repair an American one, you need to replace the old worn gasket with a new one and tighten the union nut.

Compression fittings

can be used when switching from polyethylene pipes to metal ones. In the geyser itself, exclusively metal pipes are used.

Compression fittings can be used to supply water to a gas water heater when switching from metal-plastic pipes to metal ones.

If water drips on the fitting, it must be disassembled, the gasket or sealant replaced and reconnected. Water leaks on a threaded connection can be dealt with using an adjustable wrench.

Main characteristics

A water seal is a pipe that is bent and constantly contains water. As a rule, water serves as a kind of barrier to gases; therefore, what is located on the other side of the drain hole should not penetrate into the room. A water seal is practically the same as a water seal and a siphon. If the water seal breaks, the siphon is without water. It can disappear slowly when the sewer system has not been used for a long time.

To prevent this from happening, in the event of a long absence, many recommend putting two drops of sunflower oil into the drain. It will create a kind of film, which will prevent evaporation.

What will the person responsible for the accident have to pay for?

On average, work to eliminate the consequences of incorrectly connecting a instantaneous gas water heater can take 2-3 days. All this time, the neighbors of the craftsman may remain completely or partially without gas. One can only imagine how their gratitude will know no bounds.

Don’t even try to correct or aggravate the emergency situation on your own in some way: you have already worked hard - rest and trust the professionals

In addition to the popular anger that fell on his head, the troublemaker will also feel financial losses.

He will have to pay the cost, voluntarily or through the court:

- emergency work using construction equipment;

- gas lost during pipe opening;

- gas pipes that have to be replaced in case of ice blockages.

The total amount of these costs can reach several tens of thousands of rubles. To avoid getting into a similar situation, it is necessary to follow the Rules approved by the Government of the Russian Federation No. 410 dated May 14, 2013, and involve specialists for the safe installation of instantaneous gas water heaters.

Repair of polypropylene pipes in hard-to-reach places

It is not always convenient to carry out repair work directly at the accident site. The difficulty lies in using a soldering iron, since the process is carried out in a limited space.

Plumbers work

In this case, to perform welding, perform the following steps:

- The tool is prepared and checked.

- Burrs, dust, dirt and grease are removed from the surfaces being welded. Degreasing is performed with wipes soaked in solvent or white spirit. The substance used must be completely dry.

- The soldering iron heats up to 260 °C.

- The hot pipe nozzle is removed using a gas wrench and quickly put on the pipe in a hard-to-reach place. At the same time, the fitting is heated on the soldering iron.

- The nozzle is removed from the pipeline element in a limited space, and the connecting part is removed from the tool.

- The heated PP parts of the pipeline system are joined.

The repair process in difficult places can also be carried out using a classic fitting with a union nut - an American one. It can be easily installed and removed. This fitting allows you to quickly remove the system assembly for repair or complete replacement. American provides a high level of tightness.

Manufacturers produce American fittings with internal, external threads and mixed types. They are made from various alloys, including steel and brass. American ones are produced in the form of plugs, crosses, tees and adapter couplings.

Radiator clogged

You can find out complete information on the selection, operation and maintenance of gas water heaters (instantaneous water heaters) from all manufacturers if you go.

In addition to specific information on the site, you can also study specific problems from other people on this topic who have already purchased a gas water heater or instantaneous water heater and thus avoid them. You will find a regularly updated list of such problems and their solutions.

The heat exchanger radiator consists of pipes and metal plates located close to each other. The plates are in direct contact with the flame, so soot accumulates on them over time.

You can determine that this is a problem by the following indicators:

- Yellow color of flame.

- The fire tends not upward, but to the side, heating the body.

- When operating at full power, the water heats up slightly.

- Soot is pouring out from under the column.

In order to clean it, you need to remove the heat exchanger. To do this, remove the casing and unscrew all the elements that hold it. During disassembly, cover the burner with a rag to prevent soot from getting into it.

After removal, the knot is carried to the bathroom and washed there. It is best to leave it in a container with high sides for several hours to allow the soot to soften. Next, the space between the fins of the heat exchanger is cleaned under running water using a long-hair brush and detergents. At the end, drying and installation is carried out in the reverse order.

The essence of the cold welding method

The idea proposed by the inventors of this method of connecting parts is quite simple. The composite material is thoroughly mixed, after which complex chemical reactions are launched, imparting new properties to the mixture. Over time, the soft composition hardens, penetrates the structure of the materials being bonded and becomes comparable in strength to metal surfaces.

Excellent performance characteristics make it possible to use cold welding to solve a wide range of household problems:

- Elimination of leaks in metal and polymer water-pressure structures.

- Sealing cracks in heating radiators.

- Sealing places of damage to metal elements of the car body.

- Strengthening problem areas of pipeline networks.

The material can become indispensable in situations where the problem section of the pipeline is in a hard-to-reach place, where, even if you wanted to, it would not be possible to use a welding machine or other bulky device.

Leaking pipes

You can find out the whole truth about the conspiracy associated with the selection, operation and maintenance of gas water heaters (instantaneous water heaters) of all manufacturers and models.

If water begins to drip from the column, perhaps the reason is that fistulas have formed on the copper pipes. In order to find the location of the leak, you need to carefully inspect the heat exchanger with the water turned off. Some fistulas are easy to find; you will see water coming out of these places. Small holes can be seen by the green spots and rust around them.

There are three ways to fix a leak:

- Install a clamp with a rubber gasket. If space allows and the pipe does not fit tightly to the casing, the simplest, fastest and most effective way is to install a metal clamp with a rubber gasket. Despite its simplicity, this method allows you to eliminate the leak without damaging the structure.

- Solder the fistula.

Having previously cleaned and degreased, the leak area is covered with flux. After this, using a powerful soldering iron or a torch with a gas cylinder, the fistula is soldered. In this case, it is necessary to ensure that the solder covers the desired section of the pipe with a layer of 1-2 mm. If several holes are nearby, it will be effective to solder a piece of copper plate. It is not recommended to solder cheap Chinese heat exchangers. They are usually painted on top to hide the uneven color of copper with impurities. In such columns, the pipes are too thin and will burn through during soldering. - Use cold welding. It is important to carefully look at the instructions and make sure that it can withstand high temperatures. A piece of cold welding is taken out of the packaging and kneaded with gloved hands until it begins to harden. After this, it is applied to the pipe and smoothed until it hardens completely.

After soldering is completed, water is turned on to the water heater to check it. It is advisable to additionally clean and solder all areas with a greenish tint. Perhaps, over time, new fistulas will appear there.

A leak can also form due to worn gaskets. If water leaks from the pipe joints, you should simply replace the gaskets there with new ones.

Why are the first signs possible?

The reasons that can cause a leak in an apartment can be divided into professional mistakes or shortcomings, and everyday accidents. The first includes errors when installing gas equipment, including faulty pipes, cylinders, columns, as well as too loose fastening of the gas hose. Such causes of household gas leaks may not be detected immediately.

Gas shut off

Partial or loose closing of the tap, or the extinguishing of the fire on the gas burner of the stove due to a draft or other reasons, can also cause a leak. The fact that the gas is partially burned can be seen by the color of the fire. During normal operation of gas equipment, it has an even blue color. If you see that the flame has turned yellow or acquired reddish tints, then this indicates a malfunction and you should contact a specialist.

The main danger of natural gas is that it is completely neutral in odor and color. But for timely detection of its leakage, a special substance is added to the gas used in everyday life, which has a sharp and strong specific odor.

Therefore, the very first sign will be the appearance of an unpleasant sour gas smell in the house. If the leak was not detected immediately, the person will experience gas poisoning. Its symptoms include headache, dizziness, dry mouth, general weakness, nausea, red eyes and watery eyes, pale skin, sleep and appetite disturbances. If you find them in yourself, you should consult a doctor who will determine gas vapor poisoning.

Where does the water in the column come from?

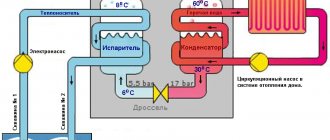

To understand the causes of the problem, you need to understand the device. The basis of the design is a metal body, to which two pipes are connected. A flow of water passes through one for heating, and gas is supplied through the other.

Water pressure acts on the membrane, the igniter and burner are activated. It heats the heat exchanger through which cold water moves. You open the faucet and get a hot stream.

Most dispensers operate automatically as soon as the tap opens. Manual and piezoelectric ignition is also found.

Why did the column leak?

There can be several reasons for a leak.

- Gaskets between connections are worn out. Rubber gaskets are installed between the pipes and pipes for tightness. Over time, they tear, become deformed, become damaged and require replacement. If a leak is noticed in the area of the connecting elements, you need to remove the old ones and install new gaskets.

- The heat exchanger (radiator) is leaking. Most often, water drips from the connections between the pipes and the radiator. Due to temperature and moisture changes, supply pipes wear out and corrode, so water flows from below. It is necessary to seal or replace faulty parts.

- Prevention has not been carried out for a long time. Gas equipment requires periodic inspection and maintenance to prevent breakdowns.

Repairing a plastic pipeline

Such networks rarely leak; if this happens, then, as a rule, the culprit of the accident is the fitting. Sometimes it is enough to tighten it, and this can be done without turning off the water - directly under pressure. However, do not overtighten the part, otherwise the plastic will burst, and you will be guaranteed trouble.

If a pipe does burst, you will have to work hard, but even in this case you can do everything yourself, although you will have to run around looking for tools and equipment.

So, you have to replace a fragment of a plastic structure that has leaked. If the pipes are polypropylene, then classical soldering will be sufficient, which can be done using a polyfuse (a special model of soldering iron). Is your network made of metal-plastic? Then you will have to make inserts on the threads. However, sometimes - with minor damage, sometimes wrapping with insulating tape is enough (just choose fresh one so that the material stretches and does not tear) or treatment with a special glue (polyurethane, epoxy, thermal compound).

Worth paying attention! Couldn't find a soldering iron? Use the so-called “handicraft welding”. The technology involves sealing the crack with the material of the pipeline itself.

To do this, apply a hot nail to the hole (with proper skill, you can heat the leak using a regular lighter). The material will become pliable, so filling the hole will not be difficult.

Regular electrical tape can save your home from flooding

If there is a leak in the pipe

If you want to know about which geysers (instantaneous water heaters) you should not choose, about the subtleties and nuances of their installation and connection, as well as hidden information on their proper maintenance for all manufacturers and models, then go here -.

But we also have information on this problem and more, which you will not find anywhere, first of all, because it is asked by specific people who could not get more support and advice anywhere (which they themselves tell us). And secondly, their problems are so complex that sometimes our expert Alexander Kholodov takes 10 days or more to deal with people.

And now EVERY question from the user and the answer to it, in order to avoid financial costs as a result of improper operation or repair of the flow-through heater. And here it doesn’t matter which manufacturer’s device is involved in the issue. All that matters is the unique situation as a result of which the issue arose, because as one good saying goes: “forewarned is forearmed.”

First aid for a leaking radiator

This article will be useful not only for those who are faced with the question of how to fix a leaking heating radiator. Since the situation is everyday, and plumbing equipment tends to wear out (especially in old houses), everyone needs to know the strategy of action in case of detection of a leak. The battery is leaking, what should I do? – the answer to this question will be exhaustive.

It is important to understand that leaks vary in complexity and location, and in the event of a real hot flood, you should immediately call the emergency service by calling the control room

Before you begin to clean up the accident, you need to know about safety precautions

Health is more important than property

When the battery leaks, what to do is just as important to know as what not to do!

- If hot water is gushing in all directions, forget about your property and, first of all, take safety measures to protect yourself and your loved ones from thermal burns. Repairs, things, equipment are not the most important thing.

- Throw a blanket, preferably a cotton one, over the leak. Or something that can absorb water for a while and prevent it from splashing.

- Do not get carried away with safety nets in the form of buckets, basins and rags - this temporary measure may cease to be effective at any time, especially if emergency flooding begins. The amount of water in a cast iron battery is quite large.

- Do not rely on the myth that a leak can go away on its own, become stuck and become overgrown with rust.

- A leak in a heating battery discovered before going to bed or before work, even if it is minimal, should under no circumstances be ignored. The average person is unlikely to be able to visually assess the scale of the accident and destruction of the mechanism: the leak may not expand for weeks, or it may turn into a flood in a couple of hours

- Try to shut off the coolant supply to the batteries. The valve for this procedure is usually located in the basement of the house.

- In the event of emergency flooding, after shutting off the water in the riser, nothing better can be thought of than draining the water from the batteries. In this case, repairing the breakdown will be quick and safe.

Administrative responsibility and its size

Of course, the direct damage resulting from the accident will have to be paid by the identified culprit. But will he be fined for water found in a gas pipe?

And if so, to what extent and on what basis? In answering this question, we will proceed from the assumption that the result of an error when connecting the column was only the entry of water into the gas pipeline.

In this case, most often we are talking about the sanctions provided for in Article 7.19 of the Code of Administrative Offenses of the Russian Federation “Unauthorized connection and use of electrical, thermal energy, oil or gas.”

This article provides for the following fines:

- 10,000 – 15,000 rubles for citizens;

- 30,000 – 80,000 rubles for officials;

- 100,000 – 200,000 rubles for legal entities.

For officials, the fine may be replaced by disqualification for a period of 1-2 years. Repeated violation aggravates guilt and increases financial liability.

This could be the end of the discussion of the topic of fines, if not for one nuance: lawyers disagree on whether Article 7.19 of the Code of Administrative Offenses of the Russian Federation can be applied in the situation we are considering. Since such a discrepancy exists, let us consider the arguments of both sides.

Unauthorized connection is a tie-in

There is an opinion, which is usually expressed by defenders of those responsible for the accident, that an unauthorized connection is made for selfish reasons, the purpose of which is to steal gas. It is carried out in addition to metering devices for the unaccounted consumption of this resource.

This connection can be made using one of two possible methods:

- insertion into a main line located underground or on the street;

- connection to a household line that was previously functioning, but was disconnected by the resource supplying organization for non-payment or upon termination of the contract for other reasons.

Obviously, both of these connection methods require insertion, that is, connection in a place where there is no corresponding technical branch to which, for example, a flexible rod could be screwed.

The connection of the gas water heater was carried out in a place that was technically provided for in the household scheme of the current contract with the gas supplier. That is, such a connection cannot be considered an insert; such a connection is not unauthorized, and Article 7.19 of the Code of Administrative Offenses of the Russian Federation, in this case, cannot be applied.

There was a violation of the Rules for the Use of Fuel, the punishment for which is provided for in Article 9.11 of the Code of Administrative Offenses of the Russian Federation. Penalties in this case (in rubles):

- 1000-2000 for citizens;

- 2000-4000 for individual entrepreneurs or officials;

- 20,000 – 40,000 for legal entities.

For entrepreneurs and legal entities, administrative suspension of activities is possible.

Any arbitrariness is unauthorized

There is also an opposite opinion, based on different interpretations of the concept of “unauthorized connection”. Supporters of this decision believe that not only the insertion, but also the replacement of one household appliance with another in violation of the existing Rules for the use of gas is unauthorized.

Clause 10 of these Rules (approved by Resolution No. 410 of May 14, 2013) provides grounds for replacing gas equipment and the fact that only a specialized organization can carry out this type of work. Consequently, work carried out independently is considered unauthorized.

It should be noted once again that civil liability in accordance with Art. 1064 of the Civil Code of the Russian Federation, as well as compensation for costs associated with calling emergency services, the violator faces regardless of administrative punishment.

Emergency measures to eliminate leaks

You can quickly eliminate a leak using clamps, sealants, bandages and cementing the defect site. If water drips from the joint, you can try tightening the nut before disassembling.

Bandage and clamps

A plumbing clamp is a crimped metal ring that wraps around the damaged area of the pipe and is tightened with screws. The diameter of the part must match the pipe.

To stop the leak, you need to compress the defect area with a rubber seal (bandage), put on a clamp, adjust its position and firmly tighten the fasteners on the sides.

If there is no clamp, you can tighten the seal using wire; instead of a special plumbing bandage, use a piece of a bicycle inner tube or any soft rubber.

Folk method: self-tapping screw

It is recommended to use self-tapping screws only for holes and cracks whose size does not exceed 1-4 mm. It allows you to eliminate leaks under pressure if it is not possible to completely turn off the water supply.

For repairs, you will need a galvanized fastener and a press washer. Using a hand drill, a self-tapping screw is screwed into the leak site, wedging it in and tightly fixing it in the hole. To increase efficiency, you can place a thin elastic spacer under the washer.

The method is suitable for temporary repairs of cold water and sewage systems. The presence of an obstacle inside can lead to clogging of the pipe, so you need to replace the damaged section as quickly as possible.

Cold Welding Tools

Cold Weld adhesive contains epoxy resins, a hardener and reinforcing particles that consist of metal or ceramic. The composition is used to repair water supply systems with pitting corrosion or a crack in a straight section.

How to use Cold Welding:

- turn off the water supply to the apartment and wait until it dries;

- put on gloves;

- carefully remove rust and paint from the pipe (processing with sandpaper should be local, since removing a large layer of oxides can lead to the appearance of new fistulas);

- Apply glue thickly to the damaged area, wait for it to dry according to the instructions (to speed up polymerization, you can warm it up with a hair dryer).

To repair sewer plastic pipes, you can use the patch method. An additional section with a margin covers the damage, and is attached with polyurethane sealant or “Cold Welding”.

To repair, you need to cut a patch from a pipe of the same diameter, apply glue to both surfaces, press tightly and wrap it with tape or a bandage. After polymerization, the additional screed is removed.

Sealant thread

Sealing threads and tapes help with pitting and leaking joints. The material is wrapped tightly around the dry pipe or placed over the threads.

Cementing the leak

Cementing a leak is effective only in cases where it is possible to shut off the water supply until the mixture has completely dried.

How to repair:

- Dilute the cement with water so that you get a saturated solution, but not a paste.

- Cut the wide bandage into 25-30 cm strips. Soak them in the resulting mixture.

- Mix separately a thicker cement mortar (as for finishing). To increase efficiency and speed up setting, you can add Liquid Glass glue to it.

- Wrap pieces of soaked bandage over the damage, covering each layer with a thick paste.

- Wait until completely dry.

Using improvised means

In addition to plumbing compounds, improvised means can also be used as a sealant:

- Salt and bandage. The damaged section of the pipeline is wrapped in a bandage, each layer of which is thickly sprinkled with salt. When moisture gets in, the reagent dissolves, covering the hole with a reinforcing layer. The method is only suitable for repairing cold water systems with low water pressure.

- Fabric and automotive sealant. The elastic material is impregnated with liquid waterproof glue and applied to the leak in several layers. Polymerization takes from 6 to 24 hours. When repairing joints, nitro enamel can be used instead of sealant.

- Baking soda and Moment glue. Small holes can be sealed with sodium bicarbonate. Rub baking soda into the slightly dampened damaged area, filling cracks and areas of corrosion. After drying, superglue is poured on top. The hardened cyanoacrylate and soda powder form a strong stopper.

How does a heat exchanger work?

A heat exchanger, or radiator, is designed to heat water from the burner. The flow flows through the coil tubes, instantly warming up from the burning fuel. Most often the block is steel or copper. How much does the device weigh? Copper device - from 3 to 3.5 kg. The steel apparatus is much heavier, for this reason it has lower efficiency.

Features of steel product:

- Lower cost compared to copper.

- Due to the plasticity of the material, heating does not harm the surface.

- It is resistant to corrosion.

Copper device:

- It has high efficiency and fast heating.

- Products that contain additional impurities are cheaper.

- Corrosion resistance.

- Light weight if it is pure copper.

Trying to reduce the cost of production, manufacturing companies add impurities to copper. Because of this, the radiator heats up unevenly, which leads to burnout of individual parts. Some people coat the surface with heat-resistant paint, but this brings little results. The service life does not exceed 2-3 years.

Copper is more resistant to corrosion than steel. Most manufacturers do not indicate how much copper is used to produce the product, convincing them that the heat exchanger is made of a thick layer.

To extend the life of the device, install water filters. They soften and clean the liquid from impurities that settle on parts in the form of scale.

How much does it cost to replace a gas boiler radiator? If you take into account the purchase of a new device, delivery and installation, it will be cheaper to repair the heat exchanger.

Man-made emergency

It is enough to read the news to be convinced that water penetration into the gas pipe of the water heater is not such a rare occurrence. So that we ourselves do not end up in a similar situation, let’s figure out how others get into it.

Let's say an old gas water heater has broken down or simply stopped being pleasing to the eye. Of course, it needs to be changed so as not to be without hot water.

Today, in the era of shortage-free trade, it is not difficult to buy a new gas heater, if only you had the money. But it’s not enough to just purchase a new household appliance; it also needs to be properly installed in the apartment’s gas circuit.

The average home craftsman does not see any problem in such a situation. After all, he has just successfully dismantled the old equipment and is ready to install a new column in its place.

He does not want to turn to gas specialists for help due to a number of reasons:

- it is necessary to clarify which organizations in the city carry out this type of work legally - they have the appropriate license;

- it is necessary to provide the selected contractor with a set of documents;

- you will have to wait for the approval of technical conditions;

- You need to pay for the connection service.

People have just bought an expensive gas water heater; they don’t want to pay for the services of representatives of the gas company, and even wait for some time for their arrival. After all, the old device is usually already turned off. The prospect of living for several days without hot water drives you crazy and pushes you to decide to do everything yourself and “quickly.”

And here, when the new column is almost installed, it is so easy to make a fatal mistake: confuse the water and gas connections. So, the connection was made, the water was open, and the master went to call the household members so that they could appreciate the improvement in the quality of life that had overtaken their family.

However, it is not necessary to be distracted for a long time for water to enter the gas pipe in this situation. While the craftsman froze in anticipation of warm water from the tap, it streamed into the gas pipeline, since the pressure in it is lower than in the water supply.

What to do after a flood?

If water gets into a gas stove, how to dry it? You must proceed as follows:

- if the gas was opened, immediately turn off the burner and shut off the gas supply;

- if there is a specific smell, open the windows and organize intensive ventilation;

- remove all liquid;

- Wipe all parts dry and let them dry.

If you have thoroughly removed the moisture, and the electric ignition clicks and sparks, but the burner does not light, do not touch it for several days to allow it to dry completely.

If there is severe flooding and it is impossible to blow out the filled parts yourself, contact experienced engineers.

Bleeding air in radiators

So, first of all, you should focus on bleeding air from heating devices - radiators. In this case, you should use the already proven option: bleed the air through the Mayevsky valve. This tap is usually installed instead of blind plugs on the radiator, at the highest point. This arrangement implies the accumulation of excess air directly under the valve. In other words, when it opens, the first thing that will come out is air, and then water will come out, which will indicate that the plug in the heating system has been completely eliminated.

To do this, you just need to place a container into which a small amount of liquid will be poured out along with the air. Open the tap and wait until only water comes out, without the characteristic sounds of air bubbles.

Radiator leak

Hot water appears thanks to the existing heat exchanger. The heat exchanger radiator consists of metal pipes and plates located close to each other. The plates come into direct contact with the fire, due to which soot appears on them during operation.

Signs of soot accumulation include:

- The flame is yellow;

- When burning, the fire deviates to the side and heats the body (the flame should tend upward);

- Soot falls off the gas water heater;

- Even when operating at full power, the water heats up weakly.

To remove soot, you will need to remove the casing by unscrewing the bolts (latches) that secure it.

Important! To prevent soot from entering during disassembly of the column, it is necessary to cover the burner with a rag.

After the assembly is removed, it must be washed by placing it in a container with water for several hours to loosen the soot. This will make it easier to clean the space between the heat exchanger plates. For quality cleaning, it is recommended to use running water, a long-bristled brush and detergents. After drying, the radiator is put in place.

Green spots on the heat exchanger indicate existing cracks and holes.

If the geyser is leaking due to a failure of the heat exchanger radiator, then the actions should be as follows:

- The water supply pipes must be shut off to prevent water from entering the gas water heater. After which the hoses are disconnected and the remaining water is drained. The remaining liquid in the coil is removed with a pump or vacuum cleaner; you can try blowing the water out with your mouth using a hose. This must be done, since the remaining moisture absorbs heat during the soldering process, and it will not be possible to heat the metal to the desired temperature.

- Damaged areas (they are green) will need to be cleaned with sandpaper and degreased with a solvent, and then wiped dry.

- Crushed rosin or an aspirin tablet should be sprinkled on the work surface. Rosin and aspirin will serve as solder here.

- Using a soldering iron with a power of at least 100 W (since they will have to work at temperatures above 180 degrees), it is necessary to increase the solder to a height of approximately two millimeters. If the soldering is loose, this means that the working surface is not heated enough. You can additionally heat the soldering area with an iron or another soldering iron.

- Each through-hole fault will need to be soldered in a similar manner.

- After the soldering work is completed, you need to wait until the working surface has completely cooled and assemble the gas water heater.

- Before full operation, the equipment is started in test mode.

If the geyser is leaking, but no leaks are visible on the radiator, then perhaps they are located where it is turned towards the body. In this case, you will need to remove the heat exchanger from the housing, which will require disassembling the entire column. Before starting the procedure, it is advisable to familiarize yourself with the diagram in the passport, since this is a rather labor-intensive process and knowledge of the structure of a specific model will simplify the work.

Important! The liquid that flows down the coils of the heat exchanger can cause a change in the color of all the coil pipes (they will be completely green due to oxidation). If there are no locally oxidized areas, then you need to connect a hose and run water. Damaged areas can be detected by leaking drops.

Soldering damage to pipes can only be used as a temporary measure to eliminate the reason why the geyser is leaking, since the repaired surface remains vulnerable. The best option for troubleshooting problems that result in water dripping from the column is to replace worn elements with new ones.

Water dripping from water gas group

If water drips from a gas water heater in the area of a water-gas unit, then there may be two options for a leak:

- A crack has appeared in the membrane.

- The seal around the gas valve stem is worn out.

In both cases, the Frog - water-gas block will have to be disassembled.

Tips: Don't forget to drain the water from the system. To do this, shut off the water supply at the inlet and unscrew any threaded connection. If air enters the system, water will begin to pour out.

To disassemble the water-gas group, you need to unscrew from 4 to 8 screws securing the two halves of the plates. The following will open in front of you: membrane, plate, rod, spring. After disassembling the assembly, inspect the diaphragm and gas valve stem seal.

The oil seal is a small rubber ring that serves as a seal. Clean the areas of rubbing steam from lime deposits. If calcium salts are deposited abundantly on internal parts, there is a reason to install a filter at the water supply to the apartment to purify the water from salts. Replace worn parts, reassemble the unit in reverse order and reinstall.

What to do if a gas water heater is leaking: causes of malfunctions and features of their elimination

Using a gas water heater is one of the best options for heating water in a house when there is no centralized water supply or the ability to obtain hot water. The technology is very useful and independent of public utilities. It provides residents with uninterrupted hot water. However, these devices also fail for unknown reasons.