The installation of gas communications in an apartment is subject to certain requirements, therefore, independent installation and connection of equipment, as well as moving the gas pipe to another place, is strictly prohibited.

All issues regarding the laying of internal and external gas pipelines are resolved by the gas service, without whose permission it is only possible to move the stove a limited distance.

We will tell you how to obtain approval for replacing a gas pipeline, and also describe the technology for moving an intra-apartment pipeline. The proposed instructions are not a guide to action; all work must be carried out by a representative of the gas service.

Reasons for moving a gas pipe

The question of moving a gas pipe may arise in the following cases:

- if you need to replace old equipment, for example, buy a gas water heater, stove or boiler, for which you need to organize more space;

- if you plan to do a major renovation in the kitchen;

- if you need to move the gas stove to another place in the kitchen, for example, move it away from the window and move it closer to the sink;

- if the owners decided to hide the gas pipe by moving it from a height downwards, for example, under the countertop;

- if you need to improve the functionality of the kitchen. For example, often in new buildings the gas pipe is installed inconveniently, for example, the gas stove is located near the window, and the hood is in another corner.

Moving the gas pipe yourself is strictly prohibited. All work related to the installation and transfer of gas pipes is decided by representatives of Gorgaz or another authorized organization.

How to perform a transfer or replacement

It is not recommended to change anything yourself, even flexible eyeliner. All the more so, cutting, extending or moving pipes should be carried out by a representative of the gas service. However, knowing the sequence and some nuances of actions when working with pipes will not hurt the homeowner.

#1: Preparing to work with pipes

Usually a team of workers (most often 2 people) arrives within the next week after approval. By this point, it is already known which sections will be dismantled or extended, and whether additional equipment will be installed, for example, a geyser. Let's look at what else is worth considering.

Taking this opportunity, you can install a gas meter or completely replace outdated equipment. If additional installation is planned, workers must be notified in advance

All equipment used in the kitchen belongs to the owner of the apartment and is purchased at his expense, therefore, it is better to immediately ask what else needs to be purchased for moving appliances and working with pipes.

If we are talking about connecting a stove or oven, you will have to buy a bellows hose of a certain length. Installers bring metal pipes with them, their cost is included in the total payment for services.

To avoid any hiccups and for the work to proceed quickly, you need to free up space from excess furniture or other items. Anything that cannot be removed must be covered with thick, non-flammable material.

#2: Dismantling the old structure

Most likely, when moving the pipe, you will need to cut off a piece of the old one and build a new one, but in a different direction. To do this, the master, using a special tool, removes unnecessary sections of pipes.

The qualifications of the craftsman authorized to move pipes are of great importance. Mechanics and electric welders undergo special training and certification, after which they receive the appropriate certificate

When dismantling the branch leading from the riser to the consumer, it is necessary to leave a small area on which the gas valve is attached. This horizontal piece of pipe cannot be removed or changed. The only exception is if the pipeline is damaged and requires complete replacement.

Sometimes residents of the top floors require the removal of a large piece of pipe that rises 1.8 m from the floor to the ceiling and then bends down 180°. It is strictly prohibited to cut the pipe and install a tap on the remaining section. The only way out is to weld the pipe so that the tap can be installed under the countertop, at a height of 0.75 m.

#3: Options for changing gas wiring

The transfer of pipes always follows the same pattern: they are moved parallel to the ceiling or walls, since diagonal and any crooked placement is prohibited. Consequently, most often the branch from the riser is lowered down, under the tabletop (rarely raised), or the vertical fragment is moved to the right/left.

A popular option for masking gas equipment: a faucet, which is easily accessible, is installed on a pipe passing below the countertop. A bellows hose is stretched from the tap to the device

When changing the direction of pipes, remember the following rules:

- internal gas distribution is an open system, all covering elements are camouflage in nature and should not be firmly fixed;

- It is prohibited to lay pipelines through ventilation ducts, as well as doors and windows;

- metal structures are predominantly used; flexible connections are allowed in equipment connection areas, but their length should not exceed 3 m;

- a rigid method of connecting pipes and hoses to pipes is used;

- Pipe transitions through walls/partitions are equipped with special adapters - sleeves.

Any work related to the transfer of pipes must begin with shutting off the gas. The organization providing the services is responsible for this.

#4: Welding metal pipes

According to SNiP standards, any changes in the position of pipes must occur by welding. Detachable connections between two sections are prohibited.

Threaded connections are used only when installing gas meters, household equipment and shut-off valves.

During the welding process, the worker must use only serviceable tools and use protective equipment: work clothes made of thick material, goggles (mask), gloves

Places burned by welding have an unpresentable appearance and also require protection against corrosion. After finishing the work, they must be treated with waterproof metal paint, matched to the color of the walls.

#5: Using Bellows Hoses

Before extending or moving a gas pipe, it is necessary to consider the option of installing a flexible transition. This is done using a bellows hose.

When choosing a flexible eyeliner, pay attention to its type. It is indicated in the technical specifications and is designated “fitting-nut”, “nut-nut”, “fitting-fitting”

Previously, rubber and rubber-fabric products were used, but the bellows turned out to be stronger than outdated materials. At its core, it is a metal or composite corrugation, but it has unique qualities.

For a long period of time, it maintains tightness and elasticity even under active mechanical stress. The structure of the shell is preserved even under high pressure of the transported medium or under constant mechanical stress.

The installation of bellows connectors is also carried out by a gas service worker. He connects boilers, columns, stoves and ovens in accordance with all the rules of the PUE and, if necessary, uses adapters and seals, for example, FUM tape.

They try to hide gas pipes in the kitchen behind decorative panels or furniture. Options for masking a pipeline are described in this article.

Step-by-step process for transferring a gas pipe

The question of how to move a gas pipe and whether it can be done at all can only be decided by gas service specialists. Without the approval of experts, no installation or dismantling work on the gas pipe can be carried out. To legally carry out a transfer, you must:

Step 1. Contact the gas service

You must contact the service at the location of the apartment. You can find the number of the gas service and consult with a specialist by phone, explain to him the situation and the reason for moving the pipe.

Step 2. Make an application

The gas service has standard application forms for the removal of gas pipes. The application must include the following information:

- name of the addressee (director, chairman of the board of the gas service),

- applicant’s details (full name, residential address, contact phone number),

- text part where the applicant should be asked to allow the transfer of the gas pipe, indicate the reason for the transfer,

- sign and date the application.

Step 3. Visit of the specialist to the site

The submitted application is usually considered quickly - within 1 day from the date of registration. The applicant is informed when and at what time a specialist will come and inspect the apartment and listen to the applicant’s wishes.

Before the specialist leaves, the owner of the apartment must contact the gas service design organization, which will help draw up a project for moving the pipe. Before the specialist arrives, this project should already be in the hands of the owner of the living space.

A gas service employee must study the pipe relocation project and assess the possibility of relocation taking into account all rules and requirements. If necessary, he can make his own adjustments or offer other options for moving the gas pipe.

Step 4. Approval of the pipe transfer scheme, drawing up an estimate

If there are any inaccuracies or errors in the project, the applicant again turns to the designers where he ordered the project (private or public service), they make the necessary adjustments and draw up an estimate.

Step 5. Payment

When all the documentation for moving the pipe is ready, the customer must pay for the company’s services according to the estimate provided . When payment is made, a gas service specialist goes to the applicant’s address and moves the pipe according to the plan.

Step 6. Transfer of the gas pipe, preparation of documentation

After approval of the project, gas service specialists carry out the pipe transfer. Before allowing gas workers to carry out work, the owner of the apartment/house must check that they have a permit/authorization to carry out such work.

The documents must not be expired; they must indicate the date of the last recertification. After carrying out measures to transfer the pipe, specialists must make all changes to the gas passport.

Obtaining approval for gas pipeline replacement

Whether a transfer is possible or not can only be decided by authorized bodies, that is, the gas service of your city (district). Only a qualified specialist has the right to carry out any dismantling and installation work. Of course, pipes cannot be moved without approval.

Even such a simple step as cutting a pipe by 10 cm must be approved, since all work related to the gas pipeline falls into the risk category

The permit is issued in the following sequence:

- Find out the contact details of the gas service at the place of registration, contact specialists, explain the situation, and consult.

- You draw up an application (using a standard form) that will “launch” the approval process.

- Based on your application, a gas service representative will arrive at your home. The time will be confirmed in advance.

- The specialist performs an inspection, listens to wishes, and answers questions. Often at this stage it is necessary to change plans, since the desired transfer does not meet safety requirements (a preliminary study of the gas pipeline installation standards will eliminate this unpleasant moment).

- Approval of the final transfer scheme, drawing up an estimate. All documents are prepared by the organization providing the services. No work will be carried out without the consent of the property owner.

- If the transfer conditions are met, pay for the service using a receipt and agree on the start time of the work.

The approval procedure usually takes several days; it can drag on for a long period for only one reason: if the property owners and representatives of the gas service have not found a compromise solution.

Any factors that violate the installation standards for gas stoves (boilers, meters, water heaters) may cause refusal to move pipes.

Preparatory activities

In order to move a gas pipe in an apartment, you must do the following before the specialist arrives:

- remove all furniture and household appliances that interfere with access to the gas pipeline or that may be damaged by the actions of a specialist;

- It is advisable to cover all items in the kitchen with plastic bags/film, since during the transfer of the pipe a welding machine will be used, which will produce a lot of smoke;

- ask in advance what tools or materials you need to buy. Typically, specialists come with their own materials, but in some cases they may ask for, for example, a hose, etc.

Rules for moving a gas pipe

To understand whether it is possible to move a gas pipe in a five-story building, you need to know the rules for installing and dismantling a gas pipe:

- It is prohibited to move the pipe into residential premises or into ventilation shafts;

- it is unacceptable for the pipe to intersect with window or door openings;

- Do not lay the pipe in hard-to-reach places. The pipe must be installed in such a way that it can be easily and quickly accessed in case of urgent need;

- the minimum permissible distance of the pipe from the floor is 2 m;

- The ceiling height for mounting a gas pipe must be at least 220 cm.

Features of using different types of gas pipes

High-pressure gas pipelines are constructed exclusively using massive pipes. If increased strength requirements are imposed on the main line, the use of steel pipes without seams will be required. You should be prepared for the fact that welding such elements is a much more complex procedure than soldering thin-walled pipes. From the point of view of optimal performance, copper pipes stand out in particular: in many respects they are preferable to thick-walled steel products. In terms of reliability, both of these varieties are almost the same, but copper weighs much less. What keeps copper tubes from being widely used in everyday life is their high cost.

When using thin-walled pipes, one should take into account their high thermal conductivity, which is why condensation often occurs on their surface. To protect against corrosion, it is recommended to coat the finished gas pipeline system with several layers of oil paint. Underground gas pipelines are organized using plastic pipes, which are characterized by flexibility, elasticity and low cost. Most often these are products made of polypropylene or polyethylene, which perfectly withstand underground conditions during the gasification of private properties. If it is necessary to equip the cottage with a low-pressure gas pipeline, black polyethylene pipes are used and have the corresponding yellow marking. It is not practiced to use polyethylene pipes under high pressure as a gas pipeline.

Gas distribution indoors is carried out using vulcanized rubber hoses that have textile reinforcement. They are not suitable for high pressure: they are usually used to connect gas stoves to cylinders or gas water heaters.

The use of flexible hoses has the following limitations:

- If the air temperature in the area exceeds +45 degrees.

- If seismic activity of more than 6 points is possible in the territory.

- At high pressure inside the gas pipeline system.

- If you need to equip any room, tunnel or collector with a gas pipeline.

All of the above situations are prohibited for using HDPE pipes as a gas pipeline. It would be safer to choose a thin-walled or seamless steel gas pipe.

Price issue

Many people are interested in the question: “How much does it cost to move a gas pipe in a private house or apartment in 2021?”

There is no specific set price; the final cost of the transfer depends on several factors:

- pipe diameter;

- installation height;

- number of joints;

- consulting;

- complexity of the work being carried out;

- gas pipeline length;

- number of connected devices;

- development of design documentation, etc.

If we talk about specific figures, the minimum price for moving a gas pipe is 2 thousand rubles . To find out the exact cost, you need to call the gas service whose services you are going to use and ask them for an estimate for the provision of services. They will quickly carry out calculations and calculate the cost of moving the pipe.

Types of gas pipelines

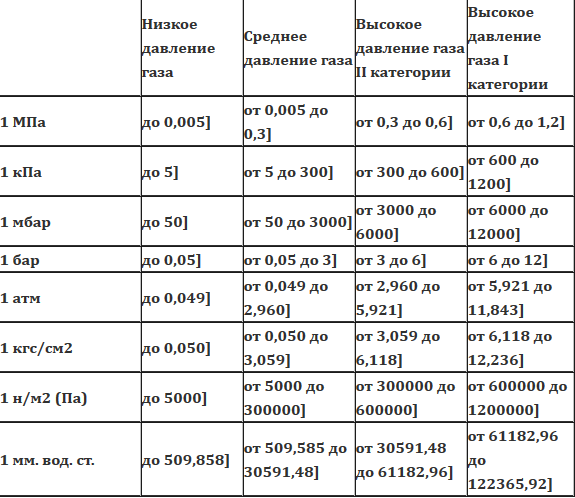

Gas pipelines are classified depending on pressure and location.

The pressure level can be:

Gas pressure in the pipe

- low pressure (up to 5 kPa);

- medium pressure (up to 0.3 MPa);

- high pressure (up to 1.2 MPa).

Gas pipelines with medium and high pressure are intended to supply gas to industrial production enterprises and gas distribution stations, so it is advisable to build them as a resource for large-scale production.

A low-pressure gas pipeline is used to supply gas directly to homes, so it is necessary to build it for populated areas, residential and public facilities.

By location they can be of the following type:

- underground;

- ground;

- external;

- internal.

Each type of installation has its own characteristics and nuances. The choice of method for laying a gas pipeline depends on many indicators, for example, the characteristic properties of the soil and climatic conditions.

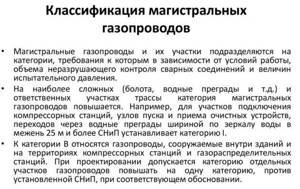

Gas pipeline communications are divided into:

- main gas pipelines;

- gas pipelines of distribution networks.

Main gas pipelines. Designed for gas delivery over long distances. At certain distances, gas compressor stations must be installed, which are designed to maintain pressure.

Gas distribution network pipelines are designed to supply gas from gas distribution stations to consumers.

Responsibility for independently moving the gas pipe in the kitchen

Some apartment/house owners, having seen the estimate for moving a gas pipe, decide to save money and not turn to the services of specialists, but to move the pipe to the right place on their own.

However, you need to understand that such actions are not only illegal, but also dangerous both for the residents themselves and for all people living in the house, since if carried incorrectly there is a risk of explosion.

For unauthorized removal of a gas pipe, the company that supplies gas to the population has the right to apply the following sanctions to the violator:

- turn off the gas line;

- charge a fee for moving the pipe yourself;

- to fine.

If, as a result of unauthorized actions of the owner of the apartment/house during or after moving a gas pipe in the kitchen, an explosion occurs or the actions of the owner resulted in the death of people, then he may face criminal liability - up to 5 years in prison.

Just shhh

My further recommendations are somewhat akin to the “bad advice” of Grigory Oster: I am going to talk about what, strictly speaking, should not be done. However, alas, we live in a real and far from perfect world.

So, what to do if you still really can’t wait to move the gas stove or shorten the gas pipe outlet?

Theory

No, no, mon ami, don’t rush to pick up the keys and hacksaw. First, a little tedious, but necessary to familiarize yourself with the regulatory requirements.

Yes, yes, I know it's ugly. Let's not rush.

The standards for gas pipes in the kitchen are set out in the document I have already mentioned - SNiP 2.04.08-87.

- Gas distribution in a residential building should be carried out mainly by welding. Threaded and other detachable connections are permissible only at connections to shut-off valves, gas meters and consumer devices;

From a practical point of view, this means for us that the internal gas pipeline in the apartment cannot be assembled from pieces. It’s really not worth climbing to a gas pipeline with welding without being able to completely turn it off. One more nuance: this paragraph of SNiP does not completely prohibit the use of dismountable connections, but only recommends refraining from them.

- All detachable connections must be made in places accessible for inspection and repair. There is no need to hide them in non-dismountable kitchen furniture;

- The gas pipe must be laid, as a rule, openly;

- If there are several gas consumers, shut-off valves must be installed in front of each of them;

- In places where people pass (for example, above a door or in a hallway), the gas pipe must pass at a height of at least 220 centimeters. What the instructions are related to - I think there is no need to explain;

- It is recommended to paint steel internal gas pipelines to protect against corrosion. At the same time, the decor of the gas pipe in the kitchen or hallway must be waterproof.

The paint must protect the gas pipeline from contact with water.

Practice

After the tap

First and foremost: in the vast majority of cases, there is no need to saw or cut anything. To move the slab, it is enough to extend the line between it and the shut-off valve. To hide an untidy steel liner, you can simply build a cabinet around it (of course, collapsible or with wide-opening doors).

How can you connect a stove or other gas appliance without violating the requirements of SNiP?

Corrugated stainless pipe. In this case, the key requirements will be met:

- The supply to the device will be rigid (a corrugated stainless pipe clearly has nothing to do with flexible hoses);

- The wiring will be done with a steel pipe. Who will say that stainless steel is not steel?

Corrugated stainless steel on the connection to the stove.

When corrugated stainless pipe had not yet appeared on the Russian market, I successfully transferred gas stoves with an oxygen or acetylene hose on steel or brass fittings. An aluminum clamp for a screwdriver was used to secure the hose to the fitting.

To transfer the slab, an oxygen hose with fittings was used.

Stainless steel connections are mounted on compression fittings: the pipe is inserted into the fitting with a loosened union nut, after which it is tightened and compresses the pipe with a silicone seal.

The threads on the connections of the fittings with the stove pipe and the tap are wound with FUM tape.

When starting up, all detachable connections must be checked for gas leaks: soap foam is applied to each of them with a shaving brush. If it bubbles, the connection needs to be rechecked.

Checking the connection with soap foam.

Do not check connections with a lit match. It's not a matter of safety: for a gas to explode, it needs to be mixed with air in sufficient concentration. The fact is that in low concentrations, with minor leaks, it simply will not ignite.

Replacing the faucet

Soviet-style gas plug valves are not particularly easy to use and require regular maintenance. In particular, the plug must be generously lubricated. The lubricant fills the grooves, preventing gas leaks, and reduces the force required to turn the plug.

Is it possible to change the faucet yourself?

Let's just say: I don't recommend doing this. But while working as a plumber, he changed gas taps, without turning off the riser. The fact is that the excess gas pressure in the pipes of a residential building is minimal:

| Consumer | Excess pressure (kgf/cm2) |

| Industrial enterprises | 6 |

| Industrial consumer service enterprises | 3 |

| Residential buildings | 0,03 |

| Public buildings | 0,05 |

It is easy to plug a gas pipe in a residential building with your finger.

If so, the rate of gas flow from the pipe will be minimal, and the pressure will not interfere with installing a new valve instead of the old one.

The replacement algorithm looks like this:

Replacement of gas tap.

All work is carried out only with the circuit breakers in the electrical panel turned off and the windows wide open. Violation of this simple and clear rule can lead to a gas explosion.

What should I replace the gas tap with? On a modern cork. Its purpose specifically for gas is indicated by the yellow markings on the handle.

Answers to questions on the topic

Question. Who can carry out work on moving a gas pipe?

Answer. Such issues should be dealt with by a special organization, which has competent employees who have been trained as a mechanic for the operation and repair of gas equipment.

Question. How safe is it to carry a gas pipe in an apartment?

Answer. If this issue is dealt with by specialists who have permission to carry out such work, then moving the pipe is a safe process that eliminates the possibility of an explosion.

Question. How to arrange a pipe transfer?

Answer. The result of completing the work done to move the gas pipe is that gas service specialists draw up a corresponding act with a note about the work done. Experts must also put a mark on the gas passport.

It is possible to move a gas pipe in the kitchen, but to do this you must first contact the gas service that services the house, write an application, wait for a specialist who will issue an opinion on whether the transfer can or cannot be carried out.

It is strictly forbidden to carry the pipe yourself . The cost of the service is calculated by specialists from the company that will handle the pipe transfer.

Upon completion of all work, the owner of the apartment/house is given a certificate, and the gas passport contains a note indicating what work was completed and when.

Basement gas inlet to the house

If you have a country house and have decided to gasify it, then you will need a basement gas pipeline entry. Its main task is to provide the shortest path from the main pipeline directly to the gas boiler.

If all communications to the house (gas pipeline, sewerage, water supply) run underground, as a rule, they try to locate them on one side of the house. In this case, according to SNiP standards, it is necessary to maintain a distance between them.

Gas Injection Definition and Applications

Let's define the concept of a basement gas inlet and its purpose. This device is a single connection of two pipes, which allows for a reliable transition from a polyethylene gas pipeline pipe to a steel pipe at home. It is protected from external damage by a steel shell, which is closed using plugs.

Installation of basement gas inlet

You can make the base entry yourself, but in this case you will need to carry out radiographic testing and clearing of the welds. To avoid unnecessary procedures, it is easier to use ready-made gas inlets to supply it to any floor of the house. They are manufactured at the enterprise in strict accordance with SNiP 42-103-2003 and in various sizes.

If the house is located in an area with a cold climate or high seismicity, then you can choose a basement input that is suitable for operation in the required conditions. This will help to avoid problems associated with work on connecting gas systems. They have a safety margin twice as high as the pressure in the gas pipeline, which will ensure safety when using a base input.

Types of base gas inlets

L-shaped plinth gas inlet

Gas inlets for the home are divided into three types.

- L-shaped base gas inlet. It is designed for bundling steel and polyethylene pipes. Its design consists of a metal pipe, protected from water ingress and having a one-piece transition, which is called “Steel-polyethylene”. The polyethylene gas pipe is resistant to low temperatures, and therefore the L-shaped entry can be used in areas with winter temperatures that drop below -20 degrees.

- Direct base entry. It is installed at the point where the gas pipe exits the surface of the earth and up to the pipe of a residential building. Its body is entirely made of special polyethylene. A feature of this type of device is the so-called “free bend”, mounted in a bendable case. The bend itself is located at the bottom of the input itself, and the permanent connection is located at the top and has a steel protective shell. It can only be used in areas where the winter temperature is no more than 15 degrees.

- I-shaped entry. It looks like a straight steel or polyethylene pipe with a corrugated metal tube (bellows) and a faucet. It is attached by welding. Placed at the exit of the gas pipe from the ground near the house. The one-piece transition is located in the vertical section of the device. The I-shaped base entry is thermally insulated and well protected from external damage. This function is performed by the case. The use of such input is acceptable in different climatic zones. It has a high safety margin.

Benefits of use

When carrying out gasification of a house, it is necessary to use a basement inlet. Watch a video of how to connect a house to an external gas pipeline system.

Base input has a number of advantages:

- Saving money due to little need for façade repairs.

- Savings on radiographic testing and illumination of welds.

- Thanks to good insulation, the base input is protected from water ingress and temperature changes. All this together allows you to significantly increase the service life.

- The system, equipped with a base entry, can be used in regions with low temperatures. This is achieved by using well-insulated cases.

- A large margin of safety allows them to be used in earthquake-prone areas.

- It is permissible to use basement input in soils that have heaving properties.

To avoid undesirable consequences caused by the explosion hazard of gas, installation work must be entrusted to experienced specialists.