Determining the cause

The root cause of water heater failure is rightfully considered to be unsatisfactory consumer water quality. As a result, scale forms on the outside of the heating element, and inside the tank, the walls are subject to corrosion.

In the future, such violations have the most serious consequences and lead to expensive repairs of the unit, with the involvement of specialists and the replacement of main components.

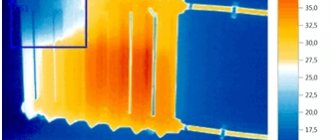

A fairly common reason is heating interruptions. Photo source: stock.adobe.com

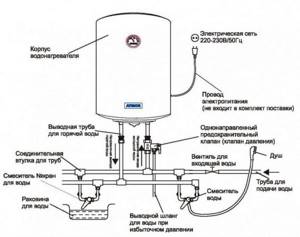

In addition to the above, the boiler may not work due to incorrect connection to the electrical network, hot and cold water systems.

Therefore, in order to protect the system from such a failure, the water heater piping is carried out according to the diagram designated by the device manufacturer, so as not to mix up the connection pipes.

Sometimes it happens that the plug heats up when the water heater is running. This can happen if the contact group is poor or the power line is low-power.

An equally common failure is when the boiler does not heat the water and the light does not light, which also indicates problems in the power supply unit.

Poor water quality

Source water with a high content of hardness salts at high temperatures creates conditions for the rapid deposition of scale on the walls of the water heater and heating element. Dense growths do not conduct heat well, and the boiler does not heat the water. With this phenomenon, there is also a disruption in the process of heat removal from the heating element, which causes it to overheat.

In addition, poor quality of source water often causes a hydrogen sulfide odor in the hot water supply coming from the boiler. It may appear due to the chemical composition of the water or the presence of bacteria in the device’s container.

The operating time depends on the water. Photo source: arouraios.gr

The first option can be detected when disassembling the heater, if the destruction of the magnesium anode is determined. The sulfides contained in water, when reacting with magnesium, form hydrogen sulfide, which destroys the protective rod.

Poor water quality is especially dangerous for instantaneous water heaters that do not have sufficient volume and have a high-speed heating mode.

Modern flow-through devices have protection against overheating, and if the indicator light comes on due to high temperature, and the output water is slightly warm and has low pressure, then this may indicate large scale deposits inside the device.

Improper use of the device

In order for the water heater to function properly during the warranty period, you must follow several mandatory operating rules:

- There is no need to set the regulator to the maximum temperature mode for heating water, since the heating element can burn out very quickly, even in six months.

- If the boiler model has 2 separate heating elements and, accordingly, two connection keys, it is recommended that only one is constantly working. Thus, you can insure the heater against burnout of one of the heating elements.

- It is very important to promptly replace a faulty safety valve.

It is made of two parts that perform different functions. The first one protects the device from excess water pressure during the heating process, and the second one performs the function of a check valve.

This is necessary to preserve water in the boiler when its pressure in the water supply network is lower than in it. Both functions are important for safe operation of the heater.

Valve malfunction can be determined quite simply. If the first function is not performed, then when the water is heated, the expanding water will not come out through the valve, and in another case, on the contrary, when the pressure in the water supply network decreases, water will begin to leave the tank.

This will cause hot water to suddenly flow from a cold tap in the mixer, or the toilet tank will fill with it.

The heating element is faulty

A particularly common type of heating element failure, when the water heater does not heat the water, is a violation of the integrity of the nichrome thread in the heating coil.

This usually happens due to overheating of the heating element, covered with scale, or when it is put into operation in a tank in which there is no water. In addition, failure can be caused by poor quality of the tube filler when the spiral moves and touches the element body.

It is best to check the heating element using a tester or multimeter. Before replacing the element, first drain the liquid and dismantle the water heater. For testing, turn on the device in the state of measuring the least resistance and touch the terminals of the element with the probes of the meters.

If the spiral has a break, the device will demonstrate that the resistance in the circuit is equal to infinity, and the multimeter will steadily display one. If the spiral is not damaged, check its displacement. One probe of the multimeter touches an arbitrary terminal of the element, and the other touches the body of the heating element. For a serviceable element, the tester shows the resistance in the circuit equals infinity, and the multimeter shows one. Otherwise, the heating element is faulty and must be replaced.

Errors during the installation process

Installation must be followed exactly according to the manufacturer's recommendations. At the same time, it is important to carry out not only proper piping with the water supply system, but also an error-free connection to the electrical network.

For units with significant electrical power, it will be necessary to carry out individual wiring from the electrical panel to the input in the subscriber's house.

If you ignore this recommendation, very soon a problem will arise that will require not only repair of the device, but also replacement of all in-house electrical wiring, which simply cannot withstand high voltage.

The most common installation defect is ignoring the installation of the safety valve. In such a case, the device will experience high pressure, which will cause:

- dangerous damage to the storage tank;

- enamel delamination on the body and exposure of the protective layer of metal walls;

- displacement of the rubber gasket.

All such problems will lead to depressurization of the container and leakage of liquid from the tank.

We repair the heater ourselves

To begin with, we establish the reason why the electrical appliance does not work. If there is no leak, there is no need to rush to drain the water heater tank. Some items can be repaired without draining the water. Moreover, 80 or 100 liters is not a trifle. Check the dryness of the casing at the bottom of the boiler. This can be done using gray toilet paper: the slightest stains literally “appear” on it. In some models (for example, in the Ariston water heater), the bottom cover can trap condensation. Then you will find leaking points only after dismantling the lower part of the case.

If the water heater does not leak, check the electrics

After dismantling the panel, first of all we “ring” the power cable using a multimeter. How to check the control module? We start with a visual inspection. All connecting tracks on the circuit board must be continuous, and there are no signs of charring or thermal darkening on the parts. If you have an electrical circuit, take the characteristics of the radio components using a multimeter

We pay special attention to power relays and powerful terminal connections. If moisture gets in, these elements can oxidize.

We check the serviceability of the heating element; many models allow access to the contact group

For example, when diagnosing a Thermex boiler with your own hands, it is not necessary to remove the heating element. However, it is necessary to disconnect all wires from the contacts. The electrical resistance of a tubular heater in most cases is about 500 kOhm (0.5 mOhm). How to check the resistance if it is not possible to accurately set the range in kOhm (mOhm)? We set the multimeter mode switch to the measurement limit as close as possible to the actual one. We connect the probes to the heater contacts without touching them with your fingers. Otherwise, you will introduce error into the measurement. If “0” is displayed on the device display, it means there is a break in the spiral of the tubular heating element. If the reading is “1”, there is a short circuit inside.

We check the tubular heater for a short circuit to the housing. This procedure is mandatory, especially if the boiler is electrocuted.

Other faults can be repaired only after draining the water. There are several ways:

- You can use a pressure relief valve, or a pre-installed additional tap. If your boiler has such shut-off valves.

- Some models have a third water drain fitting. It makes it much easier to repair the boiler yourself.

What else could break?

If the power light is on, but the water still does not heat up, the reason may be the pressure sensor (not to be confused with the mechanical safety valve, which is built into the inlet pipe). It protects the container from deformation when the water overheats, if there is a problem with the thermostats. There is a membrane inside the device.

This is the moving part of the sensor that reacts to excess pressure. If the measuring receiving hole is clogged with scale, the membrane does not return to its original position and gives a heating blocking signal. If the hole cannot be cleared, it must be replaced.

A faulty thermostat can either overestimate or underestimate readings. If in the first case, one of the protection sensors will work, then in the second, heating to the set temperature will simply not occur. This module is difficult to test.

How to change the thermostat? It is located below, on the heating element placement site.

Troubleshooting methods

Most of the defects in the operation of water heaters of various models are of the same type, so eliminating them requires a standard set of operations.

The most common boiler failure is scale formation, which can be easily identified by the device making noise during heating, as well as a characteristic sign when the water in the boiler does not heat up and the light is on on the operating panel of the device.

Cleaning the heating element from scale can be done using a variety of methods. The mechanical method involves simply removing the top layer by hand while it is still wet. Then take sandpaper and carefully remove fragments of limestone formations from the heating element. As a result, the body should become clean and shiny.

The chemical cleaning option involves the use of special reagents that soften scale. It is not recommended to use strong acids, as they can damage the metal surface of the heater.

Replacing the thermostat

A faulty thermostat leads to a violation of the temperature regime of the boiler; it either overheats the water, or does not heat it up; the indication lamp is on at this moment. If the user or specialist cannot configure its operation, then it is better to replace the regulator by purchasing a model of the same type.

The sequence of work in case of thermostat failure is:

- the pressing ring located near the heating element is dismantled;

- the sensor and control unit are removed;

- a new block and a pressure ring are installed;

- The boiler is reassembled in the reverse order.

It is not recommended to use the device immediately after changing the thermostat. First you need to make sure that there is a correct flow of tap water and that there are no leaks at the connections.

Next, open the hot water tap to release the air lock. After this, the boiler is connected to the electrical network, a preliminary start is made with a gradual increase in heating temperature.

Replacing the heating element

Despite external differences, the technological process for changing heating elements for water heating installations of different brands is the same. Regardless of the reason why the water heater cannot heat water, the following procedures are performed to replace the heating element:

- Shut off the water valve at the entrance to the boiler. Faucets on sinks are also closed.

- Completely remove water from the tank.

- Turn off the power supply.

- Remove the protective cover and use the indicator to make sure that there is no voltage.

- Remove the tank from the wall and place it on the floor.

- Unscrew the nuts and disconnect the wires, fixing the connection diagram so that during future connections, they can be connected correctly.

Protective anode

If it is necessary to replace the anode in the water heater, which protects it from corrosion, be sure to first disconnect it from the electrical network.

In mounted vertical devices, the magnesium cathodic protection rod is placed on a common area with the heating element, on the bottom of a steel container. In horizontal modifications of boilers, the heating unit is fixed to the side wall of the container.

In order to remove the heating element assembly from the housing to replace the anode, you will need:

- Unscrew the screws securing the cover and remove it.

- If the length of the wires allows, remove the thermostat and sensor, which are held on the contacts.

- In another embodiment, the electrical cable is disconnected and the thermoelement is removed.

- I unscrew the block flange with a wrench.

- The basin is placed and the block is removed.

- Use pliers to grasp the damaged anode and unscrew it from the housing.

- Then they begin to clean the heating element and wash the tank from the inside.

- The new element is simply screwed into the socket on the site.

- Next, assemble the apparatus in reverse order.

The plug gets hot when the water heater is running

Heating of the fork (slight) is allowed during operation. But if it gets too hot, you need to:

- Visually check the condition of the tees and extension cords to which the device is connected. Try to choose an extension cord with a large cross-section of wire for fire safety purposes .

- Check the condition of the outlet to ensure that the water heater plug fits tightly into the sockets. In some cases, when a plug or socket is loose, the adjacent part of the wire may become hot.

An incorrectly selected extension cord can cause a fire in a house or apartment, since water heaters are powerful and energy-intensive devices (1.2-2.6 kW).

Replacing the thermostat

To replace the thermostat, follow these steps:

- Remove the fixing ring (clamping) near the heating element.

- Remove the sensor adjustment unit and the thermostat itself.

- Install a new element.

- Secure it with a clamping ring.

- Check the condition (position) of the safety valve.

Please note that after replacing the thermostat, it is not recommended to immediately start operating the device! Check that cold water is flowing correctly inside, check that the connecting element does not hiss. The hot tap is then opened to release any air that has accumulated inside the boiler.

Only after this can a test run be carried out.

What to do if the column stops heating

If the water is too cool, turn the temperature control on the dispenser all the way to the right. Open the water tap halfway to slow down the flow through the column - this will help heat the water more.

The gas pressure on the burner may be too low. Make sure the valve on the gas line is open. If you use liquefied propane gas, invite a technician to inspect the gas pressure regulator installed on a steel cylinder.

Check the faucet for cold water. Grab the outlet hose with your hand and hold the mixer in the tap with your other hand and compare the temperature. If there is a difference in temperature, you should most likely change the mixer.

If the water temperature fluctuates and the geyser turns off. Make sure that all faucets in the house and shower heads are not clogged with mineral deposits or rust. You should also remember to promptly clean the filter elements (mesh) installed in front of the column.