When air enters the heating system, the efficiency of its operation is reduced to one degree or another, since the gas occupies a certain volume of the pipeline intended for the coolant. Thus, the air in heating pipes is a harmful factor, and it must be released as quickly as possible.

Let's take a closer look at the situation with an air lock so that, when faced with this common problem, we know how to remove air from heating pipes quickly and efficiently.

Reasons for the formation of air locks in the heating system

Air can enter the heating pipeline immediately in a fairly large volume, or it can accumulate gradually, but in both cases it forms a plug, which reduces the efficiency of heating in the apartment. There are sources of air entering the system that are independent of the consumer, but there are also those that can be prevented. Let's list them.

- Leakage of the pipeline, causing air to be drawn into it under the influence of ejection.

- Air intake during routine heating repairs.

- Faulty air vents (devices for bleeding air from the system).

- Destruction of the membrane in a membrane-type expansion tank used in closed heating circuits

- Accumulation in the system of oxygen dissolved in incoming fresh water, especially cold water.

- The water level in the expansion tank drops below the permissible limit due to evaporation.

- Filling the system with water too quickly, when the air from the radiators does not have time to be replaced by coolant.

- Significant pressure drops in the coolant in the central heating system, when water from the circuit goes into the main line, where the pressure is lower.

- Shutdowns of central heating with loss of coolant during emergency repairs of external lines.

For the formation of an air lock, in addition to the source of air supply, the following conditions are also necessary:

- incorrect pipeline slope;

- large spacing of mounting brackets on the wall with sagging span;

- malfunction of air vents or their absence.

Important! For the formation of an air lock, the presence of one of the listed ways of air entry is sufficient under the action of any of the necessary conditions.

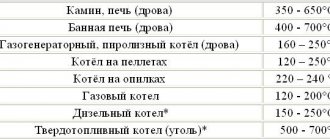

Main causes of smoke

The stove smokes due to design defects or blockages in the chimney

Owners of private houses are often faced with the fact that on windy days the stove “spits” smoke. This usually occurs due to insufficient head height. But it doesn't always need to be rebuilt. Enough to fix it, increase the visor.

There are other reasons for smoke:

- The craving weakens or disappears. It can occur due to the chimney being clogged with soot or snow, insufficient air flow, and sometimes due to structural defects in the smoke duct.

- The stove's power is increased. Smoke occurs in improved designs, for example, a bell-type stove, if they try to “heat it up” more than it is capable of.

- There is not enough air flow. If the doors and windows are tightly locked, the stove begins to “suffocate.”

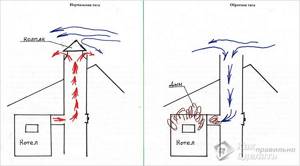

- The draft overturns. Most often, this occurs if there has been no kindling for several days. Due to idle time, the air flow does not go outside, but is drawn into the room along with the smoke.

The operating time of the furnace depends on the quality of its construction and materials. But sooner or later any structure wears out. When a stove ages, a thick layer of soot accumulates inside, reducing the clearance of the chimney, and cracks form in the brick sides, breaking the seal. These are also possible causes of smoke. This requires cleaning and restoration of the device.

The wind cap also protects the pipe from destruction

If a completely new stove has problems with smoke, it is usually due to imperfect design. You need to call a stove-maker to determine whether something can be changed with little effort. Most likely, it will be easier and cheaper to modify the structure than to destroy and rebuild the stove.

These reasons apply to almost all modifications, including the Russian stove. But with simple large heaters it is hardly possible to boost the power.

The stove in the bathhouse, sauna or garage may have special reasons for smoke. If the chimney becomes clogged with soot and dirt, she will also begin to “strain” and “snort.” The same goes for cracks in the wall that urgently need to be covered up. But there are special problems that arise when heating small buildings with stoves. There may be an obstacle located near the bathhouse. The smoke hits it and comes back. To cope with the disaster, you need to equip the sauna pipe with a windproof cap. Since the sauna is not used every day, due to temperature changes, the top of the pipe begins to collapse. It needs to be repositioned and, if necessary, increased a little.

If the stove in a bathhouse or utility room is built incorrectly, it needs to be redone.

The influence of traffic jams on the functioning of the heating system

Air, entering or accumulating in the heating pipe, forms a plug, partially or completely preventing the normal circulation of the coolant. Even if circulation through the circuit continues, a radiator that is not completely filled with water loses in heat transfer area and, accordingly, in operating efficiency.

The inner surface of the pipeline, if the pipe material is steel, at the location of the plug begins to oxidize due to contact with atmospheric oxygen. This will not lead to a significant reduction in wall thickness, but scale will flake off and settle in problem areas of the pipe, reducing its clearance and bringing the situation closer to when the system will need to be completely purged, just as a chimney is cleaned when there is excessive soot deposits.

The movement of the coolant through the airy sections of the pipe, which have less clearance, is accompanied by periodic grinding, knocking and vibration of the circuit.

In circuits with a circulation pump and a simple profile configuration, the air lock can circulate with the water and, passing through the pump, subject it to a short-term effect of “dry” operation. Such an episode once or twice will not damage the pump, but repeating it many times can lead to bearing failure.

Prevention of aeration

Follow these simple rules when replacing the cooler and you can avoid the problem of airing:

- Pour in coolant slowly, slowly, in small portions.

- When pouring coolant, compress the pipes, pumping it.

- First remove one of the hoses on the carburetor heating block or on the throttle pipe on an injection engine, as excess air will be squeezed out there. After which you can fill in coolant.

Usually, after replacing the coolant on a VAZ-2109, an air lock occurs in 90% of cases. The stove begins to not cope with its task. But you can avoid this problem by following our simple recommendations for replacing the coolant.

Diagnostics of heating circuits for air pockets.

The presence of a blockage in the heating system is usually identified when analyzing the possible reasons for the insufficient efficiency of home heating. Airy radiators can be diagnosed by feeling - cold areas will indicate the presence of air. Inspecting the pipeline is also simple if it is not equipped with thermal insulation or decorative elements, otherwise all casings must be removed.

Tapping the system in this case is not very effective - it will not show a clear boundary between air and water, and the tone of the tap depends not only on the contents of the pipe, but also on other factors - the length of the span, the thickness of the wall in a given place, etc.

Having determined the location of the air in the system, they decide how exactly to bleed air from the heating pipes.

Solution

Taking into account the fact that the reasons for the occurrence of poor traction are different, it is necessary to select a solution that is appropriate to the problem and capable of preventing it.

If the outlet overpasses are clogged with debris and soot, they should be cleaned. If the chimney is not designed correctly, the structure must be dismantled and reinstalled.

If the problem is poor exhaust of combustion products, there are various ways to improve draft. There are devices to help this process.

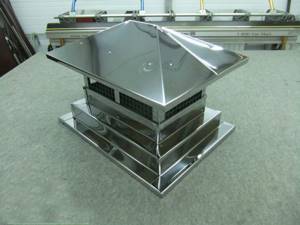

Deflector

This unique turbine is mounted on the top of the chimney and, using the power of the wind, pumps smoke from the pipeline shaft.

Deflector capabilities:

- protection of the pipeline from debris, rain and snow;

- increased traction;

- suppression of flying sparks.

The functionality of this device is developed on the basis of physical laws; it creates a forced vacuum during the passage of an air flow in its narrowing channel.

Gases enter the rarefied space in the neck of the chimney, and then are removed from the pipe by increased draft.

The use of the device has a beneficial effect on the heating system, improves heat transfer and promotes complete combustion of fuel. That is why deflectors are very popular and in demand.

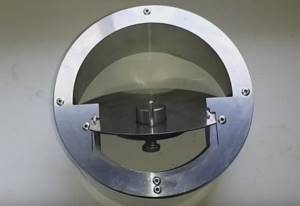

Shiber

If there are problems with heating, it is recommended to check how the damper is positioned. This is a special damper to control the traction force. Device functions:

- closing the pipe after finishing the fire to preserve heat for a long time;

- traction control;

- control of the degree of fuel combustion.

Most problems can be solved by setting the damper to the correct position.

Traction stabilizer

The device independently adds air to the system, increasing the quality of heating without human intervention. There is a safety valve to protect against overpressure.

Using a stabilizer, the effect of the burned fuel is enhanced without changing the operation of the heating equipment.

Plain paper will help remove cold air after a long break - burn a few sheets of paper and the heated air will come out. Further kindling will take place without problems.

The heating system must function without problems, without creating a threat to the life or health of people. Proper operation, timely cleaning, as well as compliance with the tips given in the article will ensure good performance of the equipment for a long time, and also guarantee the start of the heating season without unpleasant surprises.

Clean the chimney

Chimney cleaning must be carried out regularly, even if expensive firewood is used. To carry out the procedure, use a brush with a weight (no more than 2 kg) on a strong cable. A weight helps knock pieces of brick to the bottom, and a brush cleans soot from pipes and wells.

Methods for removing air from a pipeline

In modern heating systems, even at the design stage, there are standard means for bleeding air - air vents, automatic or manual, so if the heating equipment is properly installed and equipped, it is not difficult to blow out the air lock.

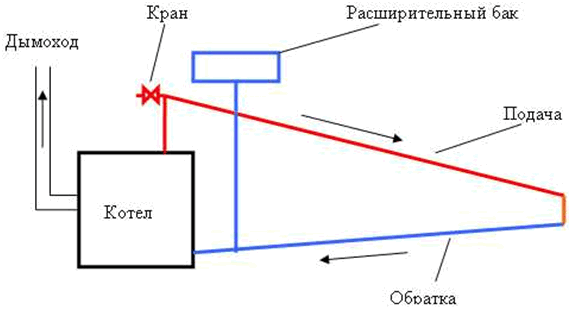

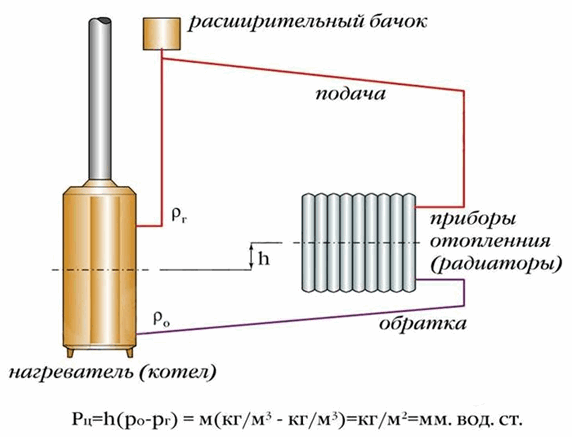

If the heating is installed in an open circuit, then the air from it can be vented through the expansion tank, which is the highest point of the system - the supply valve opens, and the gases from the pipeline will be forced out by the coolant into the tank, which will be manifested by the release of air bubbles there. After this, the water level in the tank is brought to normal.

Important! The water supply pipe is mounted towards the riser of the expansion tank with an upward slope.

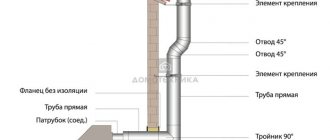

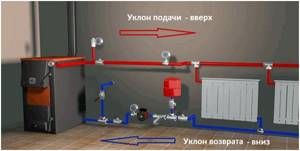

In closed circuits with forced circulation, the possibility of venting air is ensured as follows:

- hot coolant supply pipes are installed from the main riser to the remote ones with an upward slope, providing the air released from the water with a movement associated with the water;

- An air vent is mounted at the highest point of the supply pipe.

In a pipeline of this design, the ability to blow out the plug with coolant is also ensured by other air vents installed at the upper points of other sections of the network.

If repairs are necessary, the system is drained through a return pipeline arranged with a slope, the magnitude of which ensures complete drainage of water.

Air vent device

They are installed at critical points - as a rule, the highest places of pipeline spans and at the top of radiators.

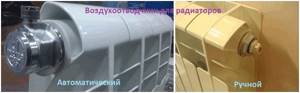

Depending on the method of operation, air vents are produced in two types:

- manual control - a shut-off valve of a needle design (in everyday life - “Mayevsky tap”);

- automatic.

Air release valves from the heating system also vary in size, design and materials, but their purpose is common - to remove gases.

Important! Air vents are required to be installed on aluminum radiators, since water in contact with this metal decomposes into components, one of which is hydrogen, which is explosive when mixed with oxygen or air in certain proportions. If the heating is gas, then the situation gets worse.

Automatic air release valves are manufactured for installation on pipelines and radiators, are simple in design and easy to operate, can be straight or angular, and are not significantly more expensive than manual devices. The price range for products from well-known manufacturers such as Danfoss, Wind or Valtec is $5-15.

Important! An automatic relief valve, regardless of design, is always installed so that its cap (outlet) points upward.

Manual air vents are a primitive design, but reliable device for releasing air from the system, installed mainly on heating radiators in their upper part. Models may differ in mounting thread size and design.

External inspection and repair

To understand why the stove smokes, you need to carefully examine the entire structure from the chimney to the ash pan.

In this case, you need to pay attention to the integrity of the structure, the absence of cracks, loose seams, traces of soot and smoke. Peeled pieces of plaster should be removed, carefully check the condition of the seams between the bricks in a cleaned area

All detected defects must be corrected.

What to do if there is a lot of damage? The best option may be to completely replace the masonry in the damaged area. When used in the upper part of a metal pipe, it can be fixed by arranging temporary fastenings to the roof and attic parts. Then you can begin dismantling the masonry. The brick must be cleaned of old mortar, soot and carbon deposits, and sorted. Then make a new laying.

If there are minor damages, you can remove defective bricks, old mortar, and lay new ones. In this case, it is necessary to ensure that the seams are filled as completely as possible. After repairs, the walls need to be plastered with clay mortar; after drying, it is advisable to whitewash them. In addition to a neat appearance, defects that may occur during further use will be more noticeable on a light surface. After completing the repair work, it is necessary to clean the pipes and chimneys.

Reasons for lack of traction

Weak traction

Draft is the movement of air that occurs due to the difference in pressure indoors and outdoors. This process is due to many reasons. But the main one is the difference in temperatures inside and outside. Most likely, you have noticed that in the warm season it is more difficult to light a stove or fireplace than in winter.

Anemometer with remote sensor

Before you take any action, you need to find out whether there is really no traction at all or whether it is just weak. The best tool to do this is an anemometer. You can ask those involved in servicing ventilation ducts or designing ventilation to take measurements.

If this is not possible, then you can do it simpler. Light a piece of paper and, after extinguishing it, bring it to the stove or fireplace and watch where the smoke goes. If it moves slowly towards the pipe, then there is thrust, but not enough. If it just spreads around the room, then there is no draft, but if it is blown out in the opposite direction, then there is a reverse draft.

Backdraft in the chimney

The main reasons for this situation may be:

- Smoke ducts clogged with soot.

- Closed damper.

- Incorrect pipe calculation or design. A square or rectangular pipe has poorer draft than a round one. This is explained by the fact that vortices are formed in sharp corners.

- Adverse weather conditions.

- Insufficient pipe extension above the roof of the house.

- A large number of sharp turns of the outlet channel.

- At the top of the pipe there is a canopy that was installed to prevent water from flowing in. It can create an air gap that becomes a traffic jam.

- There is a building nearby, the height of which exceeds the removal of the pipe.

- Poor general room ventilation. Tightly closed windows and doors reduce air flow, which creates a problem.

- The presence of a second floor and an open flight of stairs. There is a constant flow of air masses between floors, which can create problems with draft.

Reason 6 - combustion does not occur in the oven

Sometimes you can observe a phenomenon when portions of smoke and sparks fly out of the furnace in whole bursts. This is due to the fact that combustion in the furnace does not occur in the firebox itself, but in the smoke channels, and is of a pulsed nature.

Eliminating this cause depends on the specific oven. There is no universal solution. In some cases, simple traction control will help. However, many stoves will “shoot” intensely at any draft. To cope with the problem, you can try simply laying less firewood. This is better than waiting until the stove “fires” and the room is filled with smoke.

Chimney cleaning

Chimney cleaning

The traction was good up to a certain point, but over time something happened? Most likely, the channels are simply clogged. When various materials burn, soot is released. If the surface of the pipe is not smooth enough or there are many turns, then the soot will definitely settle. Accumulating over time, dross will narrow the passage, which will certainly impair passability.

Plaque has formed on the walls of the chimney

Periodically, the channels need to be cleaned; this can be done mechanically and chemically.

Traditional methods include:

- Peeling with potato skins or the potatoes themselves. In order to implement this method, you need to throw chopped potatoes or potato peelings into a well-heated oven. Usually it takes about one bucket. During the combustion process, steam is released that contains starch - it is this that softens the soot. Some of the carbon deposits fall off on its own; the remaining layer may have to be removed by mechanical means.

- Aspen firewood. They have high heat capacity. You need a few good logs. But before using this method, be sure to check the condition of the sunbed and riser. If you are not sure of their reliability, do not try to clear soot from the chimney using this method. During the process, the channels become very hot, which can lead to a fire.

- Rock salt. It is added as the wood burns. But you shouldn’t expect any special effect, because this option is more intended for prevention.

Kominichek

The most popular chemicals are Kominichek and Log Chimney Sweep. These products are placed on the coals and left for a certain time, according to the instructions. During the combustion process, compounds are released that destroy soot deposits. Manufacturers recommend that after they burn out, do not remove the coals until the next kindling, because some substances continue to act.

Chemical cleaning methods have their detractors, who say that their use can lead to the destruction of the chimney. Actually this is not true. The principle of operation is not that the reagent flares up to ultra-high temperatures, but that a chemical reaction occurs with the soot due to compounds that are released into the air. This, on the contrary, helps to avoid problems, because if soot catches fire, then a fire cannot be avoided (its combustion temperature can reach 1200˚C, only a ceramic pipe can withstand such a load).

Mechanical chimney cleaning

You can clean it mechanically.

- To do this you will need a brush. If it is not possible to purchase a special one, then you can make it yourself. To do this, you need to take two planks that will follow the shape of the chimney. Their size should be 1 cm smaller on each side. Between them it is necessary to place plates made from a plastic bottle. They should protrude by this missing centimeter. They need to be cut to form cloves.

- Cleaning should be carried out only in good weather to avoid falling from a height.

- Close all doors on the stove and fireplace. If this is not possible, then curtain them with a thick, damp cloth. It is also better to cover all the furniture in the room with oilcloth, this will protect it, because soot can damage the fabric irrevocably.

- A holder should be attached to the brush, the length of which will depend on the length of the pipe.

- You need to climb onto the roof and secure yourself using safety ropes.

- The soot is knocked downwards using forward movements. Next, it will need to be removed through special holes that are provided in the chimney channels.

It is better not to clean metal pipes this way. Using a brush can damage the walls, which will cause soot to linger and accumulate even more. If during the process you notice a serious blockage, then you will have to break through it using a special metal ball, which is suspended on a cable or chain.

Soot adhesion

The most common source of deterioration in draft is the adhesion of soot on the walls of the chimney. The internal diameter of the pipe becomes so narrow that smoke, accumulating, exits through any cracks in the unit body. The degree of soot adhesion does not depend on the location of the stove: in a bathhouse or in a house. Incorrect operation and certain types of burned wood contribute more to its formation. The first factor is insufficient, and the second is the burning of coniferous logs. The only way to repair in this case is to clean the chimney.

How to clean a chimney?

The mechanical cleaning method requires special devices:

ruff, cable, weight.

First, a weight attached to a cable is lowered into the chimney. This way you can find an obstacle or a place where the pipe has narrowed. If it is necessary to push through any object that has blocked the channel, the weight is thrown down with force. At the next stage, the pipe is cleaned with a brush. It has the shape of a square or round brush, its dimensions should be slightly larger than the pipe hole. Using down/up movements, the chimney is cleared of soot and accumulated small debris.

If cleaning doesn't help

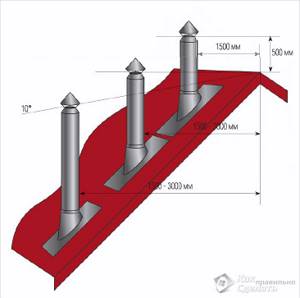

Standards for installing a chimney on the roof

In the case where actions were taken to clean the channels, but this did not give any special results, then the following points can be analyzed.

- Check at what level the top point of the pipe is. It should rise above the ridge by at least 50 cm. If there is a building nearby, you will have to raise it even higher. The fact is that due to neighboring buildings, trees or other objects, turbulence may occur, which reduces the pressure drop. In some cases, it will be enough to insert a metal pipe to extend the channel. Under normal circumstances, a total length of 5 m should be sufficient for good traction.

- In the case where the cause of poor traction is the geometry of the channels themselves, then it may be necessary to install a separate round pipe that will rise to the required height. It is important that the channel cross-section matches the power of the stove itself, otherwise excess smoke will always remain in the room.

- If you determine that the cause of poor draft is insufficient ventilation, then you will need to increase the inflow. Special elements can be installed into plastic windows that will ensure the flow of air from the street. You can also install a special valve in the room in which the stove is located. In this case, residents will not experience a lack of oxygen, and the heating device will cope well with its tasks. The ideal air movement in the channel should be 1 m/s or a little more.

- There is an option to install a deflector. This is a special umbrella-shaped tip that is mounted on the top of the pipe. When the air bends around it, a vacuum is created in the middle, which leads to a drop in pressure, which means that the flows from below immediately begin to rise upward. In some cases, a special sensor is provided that monitors the content of the exiting smoke and its temperature.

- In some situations, installing a turbine will be useful. According to the principle of operation, it resembles a deflector. But the vacuum occurs due to the fact that the wind spins it, and the blades pull air out of the pipe, which causes a pressure drop.

- Special electric fans are also available that forcefully create draft. They are installed closer to the upper edge of the channel. In some cases, it is enough for them to create a pressure difference until the pipe warms up, then everything goes on as usual.

In the evening by the fireplace

Now you have knowledge of what causes reverse thrust or its absence. Always take the necessary safety precautions before taking any action. The lives of both you and your loved ones may depend on this.

We also recommend that you read the articles:

Rules and regulations

If you do not clean the chimney for a long time, it becomes clogged with soot and creates an obstacle to the passage of smoke.

Most often, smoke occurs due to problems with the chimney. It is either clogged or initially arranged incorrectly. The most important point is the height of the chimney. SNiPs indicate the exact dimensions for different structural dimensions of roofs or the location of the pipe structure itself on the roof. For houses with flat roofs, this parameter cannot be less than 60 cm, measured from the highest point of the parapet or superstructures, for example, a terrace canopy.

If there is a garden with tall trees around the house, or neighboring houses are located nearby and higher, it is better to make the pipe larger so that the smoke does not hit obstacles, but goes freely into space.

The stove got airy (((Help

Guys, please give me some advice. Maybe someone has encountered this. The problem is this: I changed the antifreeze and after the replacement the heater started to air (the inlet pipe is hot and the exhaust pipe is cold), the engine maintains normal temperature. Camry car, 4S-FE engine. How to remove air from the stove now? It's -20 outside and it's cool to drive without a heater)) Thank you in advance for your advice.

Start the engine without closing the radiator cap, raise the speed to 1200-1400, gradually add antifreeze until the bubbles stop. In general, when driving, a working pump should push through on its own.

Toyota Gaia 2.2TD L package 1999 Mitsubishi Pajero 3 6G72 2002 Lexus LX470 2005

As an option: drive the front up a steep hill and hold the speed at 2-3 thousand until the heater return hose warms up. The fact is that in many cars the stove is located above the level of the radiator and air accumulates in it. I myself had such a trick. Good luck!

Corsa 99. 4E-FE, EL-51, 3-door hatchback

CORSA, how quickly did your stove collapse on the hill? Did you open the radiator cap or not? Today I stood on the hill with my face up for about 20 minutes and revved up the gas. It didn’t help (((Maybe not enough time has passed. At a service station like under vacuum, using some kind of machine, they change the antifreeze, but they charge 500 rubles for the work.

Posted by

JBCORSA, how quickly did your stove collapse on the hill? Did you open the radiator cap or not? Today I stood on the hill with my face up for about 20 minutes and revved up the gas. It didn’t help (((Maybe not enough time has passed. At a service station like under vacuum, using some kind of machine, they change the antifreeze, but they charge 500 rubles for the work.

Is it like under vacuum, in airless space or something? The service station won't tell you that yet. Another option: park the car with its face up, remove the heater return hose, start adding antifreeze until it comes out of the return line. Then the hose is put in place, and start. RPM 1500 minutes 2-3, turn off, check the level, top up, start again, etc. until warm air comes out of the stove. Good luck. By the way, is the air coming out of the stove completely cold or not warm enough?

Toyota Gaia 2.2TD L package 1999 Mitsubishi Pajero 3 6G72 2002 Lexus LX470 2005

Now the air is very cold. Although at first it was periodically a little warm (during different engine starts over time). Although it was twice as warm outside then. Question: face up and remove the hose from the return line - as I understand it, pour it into the radiator neck?

Yes to the radiator. The return hose must be raised above the stove.

Toyota Gaia 2.2TD L package 1999 Mitsubishi Pajero 3 6G72 2002 Lexus LX470 2005

Did you use the stove the day before the antifreeze change? There are simply some suspicions that the heater tap simply does not open. To be honest, I have never encountered a situation in the Japanese where the pump itself could not push through the stove.

Toyota Gaia 2.2TD L package 1999 Mitsubishi Pajero 3 6G72 2002 Lexus LX470 2005

Yes, I used the stove and it heated great (I already regretted a hundred times that I went to change it - it’s the first car and I haven’t played enough yet)) I also thought about the tap - but the inlet pipe is hot both before and after the heater tap. There is an idea to put it in a warm garage and then try to push through the stove with a power tool. Maybe the air there is damp and frozen)))? In any case, thanks for the idea - I’ll think about how to lift it higher in the garage at night. Because it will be tense outside in the cold...

And in the stove itself, after the inlet pipe, how is the system arranged? In the form of a coil or a branched network such as capillaries? To my shame, I have not seen it disassembled, and there is no diagram in the repair book

To be honest, I can’t tell you about the heater radiator; most likely there is an extensive network, otherwise the resistance would be too high for the antifreeze to pass through and it simply wouldn’t go there. You can see what it looks like on exist.ru

Last edited by puf; 01/03/2007 at 22:22.

Toyota Gaia 2.2TD L package 1999 Mitsubishi Pajero 3 6G72 2002 Lexus LX470 2005

Indeed, suspicions about the faucet. If it had just become airy, it would have been weak, but warm. What about cold air?...

Toyota Corolla Wagon, 1994, AE-100, 5A-FE, N. Tagil

On a gazelle, the stove is positioned very high (above the filler neck), a special drain valve is used, which is embedded in the stove pipe. The operation to remove air is as follows. We warm up the car (the radiator cap is closed), when heated, pressure is created in the cooling system, after which we turn off the engine and open the drain valve and the air comes out of it under pressure, then we close the valve. And when the engine cools, the vacuum itself will suck in the coolant from the expander. This all means that this valve can be built into any car. Maybe it will help you.

and why didn’t you change it at the service station??? After all, you don’t change the coolant so often that you get greedy, but without a headache, especially in the winter after the holidays. Of course, they don’t change it under vacuum, they pull off the upper hose going from the cylinder head to the radiator and put an adapter there, connecting this device (Vinsovsky), start your car, and your car replaces the old coolant with a new one with its pump.

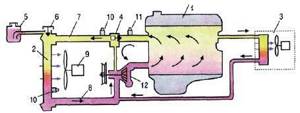

Principles of designing cooling systems

A decrease in the efficiency of the cooling system leads to an increase in the temperature of the pistons and a decrease in the gaps between the piston and the cylinder. Thermal gaps are reduced to zero. The piston touches the cylinder walls, scoring occurs, overheated oil loses its lubricating properties and the oil film breaks. This mode of operation can lead to engine seizure. Overheating is accompanied by uneven expansion of the cylinder head, mounting bolts, engine block, etc. Subsequent destruction of the engine is inevitable: cracks in the cylinder head, deformation of the joint planes of the head and the cylinder block itself, cracks in the valve seats, etc. — it’s unpleasant to even list all this, so it’s better not to let it come to that!

The engine and oil cooling system is designed to prevent such developments, but in order for the system to cope with its tasks, it is necessary to use high-quality coolant (coolant). Low-freezing coolants are called antifreeze - from the English word “antifreeze”. Previously, coolants were prepared based on aqueous solutions of monohydric alcohols, glycols, glycerin and inorganic salts.

Currently, preference is given to monoethylene glycol, a colorless syrupy liquid with a density of approximately 1.112 gcm2 and a boiling point of 198 g. The task of coolant is not only to cool the engine, but also not to boil over the entire operating temperature range of the engine and its components, to have high heat capacity and thermal conductivity, not to foam, not to have a harmful effect on pipes and seals, and to have lubricating and anti-corrosion properties.

In the 70s, antifreeze was produced based on an aqueous solution of monoethylene glycol with a crystallization temperature of 40 degrees. It did not require dilution with water when added to the cooling system. This drug was called TOSOL - after the name of the laboratory “Technology of Organic Synthesis”. Because the name is not patented, then TOSOL is a ready-to-use product, and “antifreeze” is a concentrated solution (although TOSOL is also antifreeze).

Ready-made antifreezes are colored for safety and catchy colors are chosen: blue, green, red. During operation, antifreeze loses its beneficial properties - its anti-corrosion properties decrease, and the tendency to foam increases. The service life of domestic coolants is from 2 to 5 years, imported 5-7 years.

The figure below shows a diagram of the car's cooling system. There is nothing special or complicated in the cooling system and yet...

When the engine starts, the water pump begins to rotate. The pump drive may have its own pulley driven by an accessory belt or driven by the rotation of a timing belt. The cooling system contains an impeller, which rotates and drives the coolant. To quickly warm up the engine, the system is “shorted”, i.e. The thermostat is closed and does not allow fluid to enter the radiator. As the temperature of the coolant rises, the thermostat opens, transferring the system to another state when the coolant passes along a long path - through the radiator of the cooling system (the short path is blocked by the thermostat). Thermostats have different opening characteristics. Typically the opening temperature is marked on the edge. It’s probably not worth explaining the design of the radiator. A fan switch sensor is installed at the bottom of the radiator. If the coolant temperature reaches a certain value, the sensor will close, and because If it is electrically connected to the break in the power supply circuit of the electric fan, then when it is shorted, the cooling system fan should turn on. As the coolant cools, the fan turns off and the thermostat closes the long path to a short one. It's simple, but not very...

This scheme is the basis, but life does not stand still and various manufacturers are improving cooling systems. On some cars you will not find a sensor for turning on the cooling fan, because... The fan is turned on by the engine ECU depending on the readings of the coolant temperature sensor

It is worth paying attention to the situation in which when the ignition is jammed, the cooling system fan immediately turns on. Either the temperature sensor is faulty, or its circuits are damaged, or the engine ECU itself is faulty - it “does not see” the engine temperature and, just in case, immediately turns on the fan

On some cars, special electric valves are installed on the way to the heater, allowing or blocking the path of coolant (BMW, MERCEDES). Such valves sometimes “help” the cooling system fail.

How to remove a plug from the system, the second method, detailed instructions

- We drive into a viewing hole or a flat surface, again squeeze the handbrake and engage neutral gear.

- In this case, the engine does not need to be turned off. It must be heated to a temperature of 90 degrees Celsius so that the thermostat opens and the liquid begins to circulate in a large circle.

- We do not open the expansion tank cover.

- We turn off the engine.

- Then you need to loosen the clamp in the throttle body pipe and remove the pipe. Be extremely careful and careful, wear rubber gloves when working, as the temperature is quite high (90 degrees).

- After removing the rubber hose, you need to wait a while until all the air along with the antifreeze comes out.

- Now you need to put the pipe back on and tighten the clamp.

- At the final stage, we start the engine and test the vehicle. To double-check the system in full, it is advisable to drive it at both low and high speeds.

How to bleed air

There is another method, which is most practical for a unit with a working volume of 1.6 liters. Since in this option air accumulates at a high point. Therefore, the air plug is removed from the throttle assembly.

Accordingly, you will need to use the plastic cover located on the unit itself. You will have to unscrew the cap to add oil. After completing the steps, you will need to remove all the pads, which are held in place using a special rubber seal.

Closing the lid for filling liquid, that is, oil, is quite easy and simple. Once the hose is found, you will need to carefully remove the clamp. Naturally, you should blow into the pipe so that the air comes out completely. Then, you need to quickly insert the hose to avoid air getting inside. By carrying out testing, you can verify the serviceability and functionality of the unit.