Date of publication: September 17, 2018

Bath ceremonies in Russia have always been respected, and remain so today, despite any political and economic processes. To relax after a difficult day at work in the sauna, warm up, relieve stress and tension, get rid of thoughts, and at the same time carry out health prevention - every owner of a bathhouse or sauna has this opportunity.

Equipping your steam room with a good sauna stove is not at all difficult, the main thing is to decide what kind of stove you need - for example, a closed or open type of heater? Which is better? How does one type differ from another? In this article we will try to reveal the basic concepts and differences between the two types of heaters, their advantages and features.

To begin with, you need to define the heater itself. What it is? From the name it becomes clear that stones play a key role here. A sufficient volume of heat-conducting stones is placed in a special casing, in which they are heated and transfer heat to the steam room. This is the heater.

The first sauna stove in history with an open heater

This simple, essentially device was invented by people thousands of years ago. The very first baths, discovered by archaeologists in the sites of ancient people, were a hole in the ground, which was lined with straw and brushwood and a pile of stones was thrown on top. Burning brushwood heated the stones, the heat from which the first people used for heating. A little later, inventive humanity came up with a unique innovation of this design: a homemade tent made of branches and skins was erected over a pit with brushwood and stones. Thus, it was possible to keep the heat from the heated stones within one space in which people warmed themselves, were treated and, in fact, steamed. By the essence of its design and operation, this first device can be called an open heater.

Type of heating oil

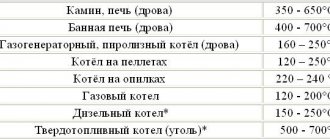

According to the type of fuel, heating structures are divided into:

Wood burning

This option is primarily for those whose bathhouse is located in an autonomous area, cut off from the power supply mains. Power outages are also a reason to think about a stove that is independent of the mains.

- firewood is fuel that you can stock up on without any problems; store-bought logs are relatively inexpensive, and if the site is located in a forest area, the fuel will be completely free;

- financial savings on connecting to the central power grid;

- the pleasant atmosphere created by burning logs;

- wide variety of models.

- longer heating time compared to options running on other fuels;

- the need for regular tossing of logs;

- the need for regular cleaning of the ash chamber.

Electrical

This is the most common option. The main disadvantage is dependence on the main power supply. Or relative high cost if electricity is “produced” autonomously. In addition, using an electric generator is not very convenient.

A secondary disadvantage is the lack of atmosphere inherent in wood heating. If the aesthetic component is not of great importance, this minus can be omitted.

- accessibility – there are models of different price categories;

- prompt and uniform heating of the room;

- a fairly high degree of fire safety;

- small sizes;

- no need for connecting pipes, cleaning chimney channels and other manipulations inherent in other options.

Gas

The fuel used is gas (cylinder or mains). The equipment includes a fuse and a thermostat.

On a note! Gas ovens are dangerous. It is recommended to purchase them at branded retail outlets. It is mandatory to check the technical passport - the heating unit must meet all necessary standards. By purchasing a stove externally, the buyer runs the risk of installing a low-quality product that could lead to trouble.

Advantages of gas equipment:

- financial savings;

- quick heating of the steam room;

- no need to monitor the condition of the fuel (which is important, for example, for wood-burning sauna stoves);

- small sizes; in other options there is a firebox and an ash pan that take up space; here these elements are not present - gas equipment can be installed even in a modest-sized steam room;

- possibility of comfortable temperature regulation.

- danger - you need to constantly monitor the technical condition of both the stove itself and the cylinders (if there is a cylinder version);

- the need to connect to the main gas pipeline or regularly purchase cylinders.

Combined

Such modifications are designed for two types of fuel. One of the popular combined options is a device that runs on wood and gas. Unlike a gas unit, it has a firebox for logs. At the same time, it is possible to connect to gas equipment.

What to choose - closed or open oven?

Today, the level of comfort of bath procedures is, of course, incomparable to what ancient people could afford. And this is for the better. However, the question of whether to buy a cast iron sauna stove with a closed heater, or, for example, a metal one with an open one, should be asked before making the final choice. To do this, let’s take a closer look at the features of this or that type.

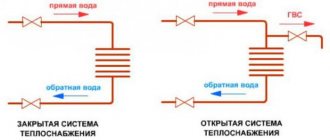

As you might guess, the main difference between the two types of stoves is in the design and location of the container with stones. In closed oven models, the stones are placed in a closed casing, which only has a door to view the stones and throw water on them to generate steam. And in open ovens, the mass of heat-accumulating stones is open to view, they are easily accessible and you can conveniently pour water on them to produce saturated steam. True, precaution is important here - too much water can harm both the bath procedure and the equipment itself. But there are other differences.

Steam source

Yes, no matter how strange it may sound, but stoves have different sources of steam, so stoves are divided into two types: conventional and with a separate steam generator. A steam generator is used when the oven does not produce enough dry steam, which is considered traditional bath steam, or you want to obtain finely dispersed steam.

Features of room heating

Your sauna stove can be cold or hot. It is generally accepted that cold ones are those whose walls do not heat up above 45°C, and hot ones are ovens with a wall heating temperature above 100°C. This is an important parameter, because the heat of your bathhouse is transferred through the walls.

Regardless of the type of fuel or material of your stove, all stoves are divided into two main classes - “cold” and “hot”. Let's find out the advantages and disadvantages of "cold" and "hot" ovens.

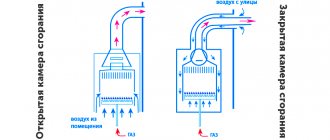

Let's start with "hot" ovens. Stoves of this type are installed in bath buildings that do not have any other heating option. In a hot stove, the outer surface heats up to 100o C. The main disadvantage is the risk of overheating the room. You can quickly change the temperature in the steam room only with the help of ventilation.

In a “cold” stove, the outer lining does not heat up to significant temperatures, so in winter such a design cannot sufficiently warm up the steam room. This is a model for baths that are heated in some other way.

The outer surfaces of a “cold” furnace are heated to a temperature of 40 - 50 C, which is the lower limit for producing steam. Any “cold” stove warms up the room for a very long time; the air is heated due to the fact that the stove “takes” cold air from the floor of the room, passes it through itself and comes out already warm.

Mistakes you shouldn't make.

- Haste, as you know, is good only for catching fleas. But when choosing a sauna stove, there is no need to rush. Select several models, and from them already one.

- It often happens that consultants do not talk about the stove, but advertise it. It may be that a criterion that the seller did not mention is important to you.

- Do not neglect consulting a specialist.

- If you require specialist advice, please contact us by phone... or in any of our stores. Our specialists will answer all your questions.

- It is necessary to decide on the type of fuel used. This is important because it is the type of fuel that determines the power of the stove, and stoves with different types of fuel require different conditions and additional design elements.

Optimal conditions inside a steam room for a Russian-style steam room

A metal or cast iron stove with a closed heater is mainly used in classic Russian steam rooms, where the air temperature should not exceed 70-80 degrees Celsius, while the air humidity should be quite high - at least 65%, and better yet, more. Unlike a Finnish sauna with dry air, in a Russian bath humidity plays a decisive role - it is she who “guides” the bath procedures and has a positive effect on the human body. Steam saturated with moisture helps the pores open, promotes the release of sweat, while “smoothing out” the heat, allowing you to perceive it with comfort.

The humidity and temperature parameters described above are achieved precisely thanks to the closed design of the stove heater. So, the entire volume of stones in it heats up quite strongly, to a temperature level of about 300-750 C⁰. At the same time, excessive heat should not enter the steam room, so as not to overheat it. To “retain” the heat inside the furnace, a casing was invented - made of brick, cast iron, iron and other materials. The stones located inside the casing have direct or indirect (depending on the internal structure of the furnace elements) contact with the fire - they heat up, as expected, but the heat from them is retained by the casing and the amount of heat that is needed directly enters the steam room itself - without excess .

EasyStim ovens

These units are made from stainless steel 4-6 millimeters thick, the chromium content in them is 17%. In order to reduce the number of welds, the firebox and container for stones are formed by stamping and bending. To strengthen the walls of the firebox, special stiffening ribs are used, and to improve the heating of the stones and reduce the load on the bottom, it is made round in shape.

To prevent flames from entering the chimney, a flame breaker is installed in the firebox. The chimney channel is curved in order to more efficiently use the energy obtained during the combustion process. As a result, the flue gases go around the container filled with stones from all sides, which leads to their high-quality heating.

In order to regulate the operation, there is a handle at the top of the unit that changes the location of the thermostat damper. When the gap is open, intense heating of the room occurs, and if it is closed, the stones are heated.

Such closed-type sauna stoves have steam generators installed inside, namely systems consisting of tubes with holes that are located in the heater. The water that enters there falls on highly heated stones, and is then distributed over a large area due to the presence of a system of holes.

The water begins to evaporate, falling on the hot stones. The steam that is formed rushes up, bypassing the stones towards the outlet located above. As a result, the steam is broken into small particles, heats up more and becomes almost transparent.

Features and advantages of stoves with a closed heater

The closed design of the heater has the following features, which, in fact, are advantages:

- the steam room heats up more slowly, but with better quality: the heat is distributed evenly, promoting a comfortable microclimate and favorable conditions for steaming

- Strong heating of the stones contributes to the process of heat accumulation in them for a very long time: the bathhouse cools down for a long time, allowing you to both increase the time of bathing procedures and warm up in the steam room even the next morning

- the steam room does not overheat, and the temperature level in it is at a level comfortable for the human body

- quite high, but comfortable temperature in the steam room is maintained for a record long time without the need for reheating

- a closed heater, namely its walls, retains the required volume of steam without “splashing” it into idle conditions: the steam infuses, becomes light and rich

- the heating speed of the steam room can be easily adjusted using the door of the closed heater - just open it and the heat will flow into the room

- high level of fire safety

Sauna stoves with a closed casing for stones are made of various materials, which, of course, also affect the heating and thermal parameters of the equipment. So, for example, a metal stove for a Russian bath with a closed heater will heat up faster than a cast iron one, but the cooling process will also be fast - metal does not store heat for a long time. But a cast iron stove will retain and release accumulated heat for a long time, but it may take hours to heat it up. A brick stove also retains heat for a long time, but this type of equipment is rarely used anymore - why assemble a stove brick by brick when you can buy a ready-made one for the same money?

We build a stove with our own hands

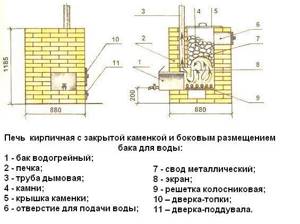

Of course, you can buy a factory-made stove with a closed heater at an affordable price and of good quality, but for many true connoisseurs of the Russian bath it is important to make it yourself. Homemade stoves are made from red brick or sheet steel (pipes).

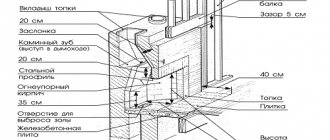

Laying a brick heater always starts from the base. The foundation is installed 50 cm below ground level. It is raised to floor level using a mortar of cement and sand in a ratio of 1:3 (hereinafter clay-sand mortar is used). After a day or two, the base of the stove needs to be protected from the effects of temperature changes by placing roofing felt on it. The first row of bricks is laid on it, and another piece of insulation is placed on top of it. This way, condensation will not penetrate into the brickwork, which means it will not destroy the stove.

It is important to ensure that the rows lie strictly horizontally. For greater strength of the stove, it is necessary that each vertical seam between the bricks, the thickness of which should not exceed 0.5 cm, be covered with bricks of the next row. The verticality of the masonry is determined using a plumb line, horizontality - using a level. Even with the slightest inaccuracies, any brick oven will collapse or tilt.

During the masonry process, a damper, grate bars, doors, and a water tank are installed. The firebox is laid out at an angle so that the non-combustible residues resulting from the combustion of firewood pour out through the grate into the ash pan. The grate is installed in the lower part of the firebox (from the door inward), leaving a gap of 0.5 cm on all sides in case of thermal expansion. To install the blower and combustion doors, pieces of wire with a diameter of 2 mm are placed in the masonry seams. The heater is installed 55 cm above the firebox. This will ensure intense heating of the stones.

When installing a water tank, the space around it must be filled with clay-asbestos mixture. This will allow the container to expand freely when heated. If this is not taken into account, there will be a risk of cracks forming in the masonry.

After laying out the stove, you need to think about the chimney. The pipe must rise above the roof surface by at least 0.5 m. Where it passes through the ceiling and roof, a layer of thermal insulation is laid, for example, mineral wool covered with foil or tin. Among other things, the structure needs to be sanded down and whitewashed. Thanks to such manipulations, you can determine how tightly the brick sauna stove is built. Soot on the whitewash will indicate this. To protect the chimney from precipitation, a tin cap is installed above it. You can also route the pipe through the wall. You just need to secure the passage through it. This method is more reliable in terms of fire safety.

It is not recommended to start using the stove immediately after its construction, since it must first be dried. This may take 3-4 days. All doors and dampers must be open during drying. First, the stove-stove is heated with wood chips several times a day for 15 minutes until moisture stops appearing on the surface of the damper. This will indicate that the stove is completely dry.

Homemade brick heater

What stones to take

The quantity and quality of steam depends on their correct choice. For 1 cubic meter of steam room, 35–45 kg of cobblestones are needed. It is best to use gray and black stones collected near water, as they are stronger than others. It is not recommended to give preference to spicy options. When water gets on them, they can start to “shoot.” The cobblestones should be oval or round in shape, approximately the size of an adult’s fist. The rounded shape allows smoke and fire to easily penetrate between them, heating them evenly.

It is impossible to say for sure which option is better: metal or brick. But a sauna stove that you made yourself will completely coincide with your desires and create the most favorable atmosphere for sauna procedures. A properly constructed structure will provide not only good heat in the steam room, but also high-quality steam.

Pros and features of ovens with an open casing

Sauna stoves with open heaters are also very popular today. Especially when arranging a Finnish sauna. Open stones allow the steam room to heat up faster, but it also cools down quite quickly. At the same time, the open casing helps heat the steam room to very high temperatures, and if you are a fan of hot, dry air, then this is definitely your option. The Finns, for example, only recognize such steam rooms; they prefer dry and extremely hot air than moist steam and moderate temperature - like in a Russian bath. Therefore, it is not customary for the Finns to throw water on open stones: firstly, steam immediately eliminates excess heat and dryness, making the air humid, and secondly, strong steam at such high air temperatures as they like in Finland can severely burn a person and cause serious injury. damage to his health.

The oven must be used for its intended purpose so as not to harm either the equipment or your health. So it is best to choose an open or closed type of heater based on personal preferences for the level of temperature and humidity during bathing procedures. For lovers of moist, healthy steam and moderate temperatures, a closed stove is suitable, and for those who prefer dry air in a steam room at high temperatures, an open heater is suitable.

Types of furnaces by materials

The structures are made of brick and metal. Both materials have pros and cons.

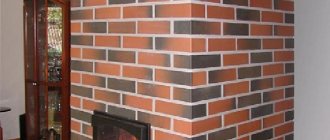

Brick

Brick sauna stoves are a traditional solution. Many owners of private baths are now more inclined towards factory-made products - it’s easier and faster. But professional stove makers recommend not to deviate from traditions.

Such structures are massive. Weight can reach a ton or more. A full-fledged unit of this type cannot be placed in a small steam room. But mini-structures, although they are less powerful, are quite accessible to owners of small buildings.

Advantages of brick options:

- good and long-lasting heat transfer – a heated structure can transfer heat for up to 8 hours;

- high degree of fire safety - you can steam in the bathhouse without fear for your health and life;

- soft heat - a brick stove for a small steam room perfectly warms the room and users, but the high temperature does not cause discomfort;

- possibility of heating a large area;

- Excellent decorative effect - design variations are endless.

Flaws:

- the need to construct a foundation is a consequence of considerable weight; small stoves do not need a powerful base;

- the need for a highly qualified stove maker - the technology for laying stoves is much more complex than conventional masonry;

- stove buildings eat up bath space; but there are options designed for vertical laying - the usable area is preserved;

- thermal inertia - such units melt within several hours; therefore, you need to prepare for bath procedures in advance;

- considerable cost – professional services are expensive; but, if you put it in with your own hands, the monetary disadvantage will turn into a temporary one - you can save money, but spend a lot of time.

Metal

Those for whom brick sauna stoves are not suitable can choose from a variety of metal variations. Such structures are divided into cast iron and steel.

Figure 3. Stylish cast iron heating design

* Advantages of cast iron options:

- high heat transfer;

- anti-corrosion effect;

- no problems during long periods of downtime;

- a huge selection of models - powerful and beautiful.

Disadvantages of cast iron:

- heavy weight; in this case, a foundation may also be required; the base does not have to be as strong as in the case of masonry, but the presence of a pedestal is recommended;

- poor amenability to processing - if there is a need to modify the unit, without certain tools it will be problematic or impossible to do this;

- intolerance to sudden temperature fluctuations;

- considerable cost.

Now about the features of steel models.

Figure 4. Homemade steel model for a bathhouse

Pros:

- ease of installation;

- no need for a foundation;

- the possibility of producing handicraft options;

- fast heating;

- simplicity of the firebox;

- space saving;

- availability;

- a large number of factory models.

Minuses:

- shorter service life than cast iron modifications;

- relatively fast cooling;

- low degree of fire safety;

- low power; one medium unit is enough to heat a small steam room, but for heating large saunas it is recommended to install several stoves;

- poor protection against thermal shock - shielding is required to protect against the negative effects of infrared rays.

Among steel models, products made of chrome steel are very popular. Their main advantage is that the burning of oxygen in the steam room is minimized.

The simplest version of a metal structure is a potbelly stove. If you have the funds and/or the desire to build a better unit, it is better to ignore the potbelly stove. But with a modest budget and lack of qualifications, this is an excellent option.

Which stove is best for a private bath? The answer depends on capabilities and needs. The brick option will be preferable if there is no need for prompt kindling. The metal solution is suitable for those who do not want to deal with the hassle of construction or want to quickly prepare a steam room.

Advice! When choosing a stove, you need to evaluate and analyze a large number of parameters. Only in this way will the use of the bathhouse bring the greatest benefit and pleasure.

*