Properties of penofol

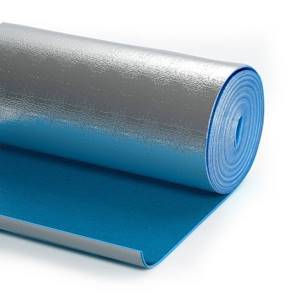

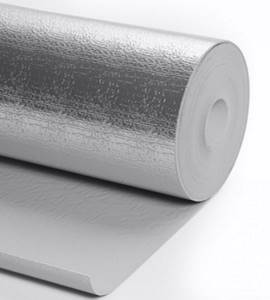

Foil penofol is an insulating material with a reflective effect, which has a multilayer structure.

The main purpose is to remove drafts or wind currents from building structures, eliminate condensation or moisture, steam that rise up the tiers. The material also isolates external noise or sounds. It is a universal type of insulator, as it increases sound insulation, vapor barrier, protects against moisture and retains heat. Such features are due to the structural organization of the material and the technology used in production. The main part of the material is foamed polyethylene . At the same time, the pores formed on it are closed and filled with air. This polyethylene foam is used in the form of skeins with different densities, thicknesses and different internal structures. Either on one or both sides, based on the purpose of the material, polyethylene is covered with aluminum foil. Before application, it is processed and polished to a shine with a maximum reflectivity coefficient (up to 97% and even more). More often, foil is applied using heat welding, which provides better adhesion of the material.

The thickness of penofol is from two to ten millimeters, the foil is only from 12 to 30 microns. The thickness of the material can be increased to 40 mm if it is necessary to create particularly powerful thermal insulation, for example, in arctic climate conditions.

The operation of penofol is based on the “Dewar vessel” principle known in physics. At the beginning of the last century, James Dewar established that every substance has a certain resistance to heat transfer. Whatever this indicator, the material can only stop or make the movement of heat slower, but not stop it altogether. At the same time, heat waves are collected in the substance and energy accumulates inside the substance; after some time, supersaturation is created, after which any material itself becomes a source of heat.

Experimenting further, Dewar isolated several substances that did not absorb thermal energy, but reflected it. Among these were all precious metals (platinum, silver and gold), as well as polished aluminum. In this case, heat rays are reflected from surfaces almost 100%. These reflectors themselves are excellent heat conductors and should be used together with heat absorbers.

A common thermos works in approximately the same way, and Dewar's research became the basis for the creation of space suits and materials for thermal insulation with a reflective effect.

The use of both double-sided and single-sided insulators reduces the cost of heating rooms in winter, and in warm summer weather they prevent the house from heating up too quickly.

Selection of materials for creating a vapor barrier layer

The main property of a vapor barrier material that you should pay attention to when choosing is the ability to transmit a minimum of steam. This criterion is calculated by the amount of steam that passes through 1 m2 per day

Some materials have an indicator of 3-5 g/m2, but most are characterized by vapor permeability of less than one. To know which vapor barrier to choose for the ceiling in your particular case, you need to study the possible options.

The first vapor barrier material was glassine, its vapor permeability was 80 g/m2. However, modern insulation in some cases has a value of about 0.02 g/m2. The appearance of the materials used to insulate the surface from steam and atmospheric moisture is almost the same

Therefore, it is very important when choosing to carefully study the information provided by the manufacturer. Otherwise, you can purchase not a vapor barrier, but a waterproofing material, the use of which will lead to damage and mandatory replacement of the thermal insulation layer.

To protect the ceiling, it is recommended to use the following types of vapor barrier for the ceiling:

- The vapor barrier polymer membrane refers to rolled materials, one side of which is completely smooth, the other is rough. When laying, the rough side should be directed downward so that a minimum amount of evaporation penetrates to the cake. The presence of roughness prevents condensation from accumulating on the surface.

- Film polypropylene and polyethylene materials can be reinforced or non-reinforced. This type of insulation requires the creation of a ventilation gap between the vapor barrier and the insulation. Ceiling vapor barrier film is used when the construction budget is limited; installation can be done by both parties.

- A foil membrane on the ceiling is recommended for use to create a barrier against moist warm air, as well as to reflect heat rays and direct them back into the room. In both cases, installation is carried out with foil towards the steam and the flow of warm air.

In most cases, vapor barrier materials have accompanying documentation, which, along with technical and operational characteristics, describes which side to attach the vapor barrier to the ceiling, and the mounting technology itself.

To avoid unpleasant moments during operation, when choosing a material, you should pay attention to the possibility of direct contact of the vapor barrier and insulation. The formation of rolls of vapor barrier polymer film is carried out in accordance with how the material will be rolled out to create a vapor barrier layer

Along the long edge of the strip there is a mark for the recommended overlap so that the insulating carpet on building structures is continuous.

The formation of rolls of vapor barrier polymer film is carried out in accordance with how the material will be rolled out to create a vapor barrier layer. Along the long edge of the strip there is a mark for the recommended overlap so that the insulating carpet on building structures is continuous.

The direction of the strips of insulating material does not play a special role; the roll can be rolled out along or across the ceiling. The main condition is to create an overlap and firmly fasten the strips into a single piece using tape.

It is recommended to choose materials for gluing and vapor barrier from the same manufacturer. Otherwise, complete tightness in the gluing areas cannot be guaranteed. Due to the features that each manufacturer endows with its products, deformation of the material and even its destruction may occur.

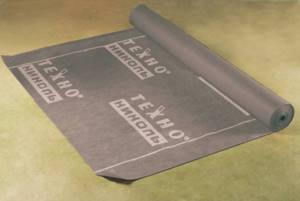

Among the large number of manufacturers of rolled roofing materials, the TechnoNikol company should be highlighted. It produces building materials for use in the CIS countries, including polymer vapor barrier membranes, polyethylene and polypropylene films.

Vapor barrier membranes are available in several innovative self-adhesive options, as well as materials that can be installed using bitumen mastic or by fusing with a gas torch.

The company's products are no less popular. Its range of materials ranges from standard vapor barrier film to foil insulation with a layer of insulation and a self-adhesive coating on the back side.

Pros and cons of penofol

When using penofol for insulation, the following advantages can be highlighted:

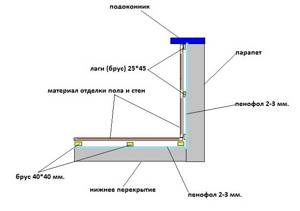

- Penofol has versatility of use - the material can be used during construction and renovation work, externally or in internal insulation of premises. For example, for balcony insulation.

- It has minimal vapor permeability on the insulation side, which makes it possible to use penofol without additional vapor barrier material.

- It provides good insulation from noise; it is often used in homes and workshops against acoustic type noise.

- Compared to other insulators, the material is quite thin. Penofol on both sides 4 mm thick can replace mineral wool laid out 8.5 cm thick, a layer of pine 1.8 cm thick or as much as 3 cm of extruded polystyrene foam.

- Penofol is easy to install . This material is lightweight, it makes it possible to install thermal insulation without outside help. For the work, no extra tools are needed, the material sheet is simply cut with a knife, it can be secured with a furniture stapler, small nails, or tape.

- Penofol is made from environmentally friendly materials that meet all sanitary requirements. The substances from which it is made are used to store food, and some of the manufacturers even warn that penofol will protect against increased radiation.

- This heat-protective material is highly flammable, which significantly increases the level of fire safety in an insulated room.

- It is too thin for rodents that like to make holes in other insulation materials to live in it.

- Penofol is convenient to transport, the canvas is collected in rolls, they can later be hidden in the trunk of a car.

Even taking into account the enormous variety and number of advantages of foil penofol, it also has a number of disadvantages:

- The material is quite soft, which limits its capabilities. It is not suitable for applying wallpaper or plaster.

- To secure it, you may need to purchase specialized glue. True, there are self-adhesive versions of the material.

- Experts recommend not using this material as insulated external insulation for buildings. It can be attached to reflect heat energy or to protect the entire structure from internal moisture with a separate layer.

Folgoizolon - foil insulation for the ceiling

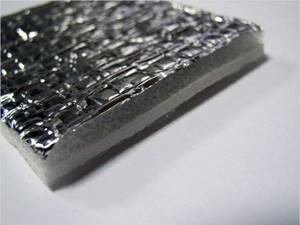

Folgoizolon is a fairly new insulation on the market, providing high-quality heat, moisture and noise insulation. The basis of the material is polypropylene or foamed polyethylene. Based on this, two types of products are distinguished, designated PPE and NPE.

- lightness of the material , which makes it possible to finish any base, provided there is no need for preliminary measures to strengthen it;

- small thickness - does not reduce the dimensions of the room, maintaining its usable area;

- elasticity - unlike some insulation materials (such as polystyrene foam boards), this foil material allows you to avoid spending time on careful preliminary leveling;

- multifunctionality , or a “3 in 1” combination, contributes to a significant reduction in the costs of purchased materials (mastics, films, fasteners, etc.) and a reduction in construction or repair time;

- ease of cutting - foil isolon can be easily cut with a sharp knife, which eliminates the need to use specialized tools;

- the absence of moisture absorption is one of the most important factors that ensures the extension of the service life of not only the foil-isolon itself, but also the structural elements it covers;

- environmental safety - does not emit harmful substances even at temperatures above 100ºС. Among other things, this material will never harbor insects or rodents.

So, is it possible to insulate the ceiling with foil insulation? Taking into account the material above, we can safely give a positive answer.

Types of penofol

Manufacturers offer different penofol options for different functionality. The generally accepted classification divides it into three varieties:

- A type – one-sided penofol (aluminum film is applied to one side of the polyethylene after foaming). This type is used more often as an additional heat insulator with foam;

Penofol type A - B type – penofol foil-coated on both sides, has universal use, including for autonomous insulation;

Penofol type B

- C type – self-adhesive. On one side there is a layer of reflector on aluminum, on the opposite side there is a moisture-resistant adhesive on polyethylene foam, which is protected by a sticker. This penofol is more convenient for finishing areas that are difficult to reach. No special installation tools are required during installation.

Penofol type C

In addition to these standardized types, the developers have also prepared modifications that occupy a separate niche in the building materials market:

- ALP type - penofol with lamination, on the foil side there is a plastic film. This type of material is used for insulation of agricultural buildings operated in a not too aggressive environment;

- M or R types – one-sided foil with a corrugated “top”;

- AIR – penofol used to prepare air exhaust structures;

- Super NET (from the word “Network”) - the main task of this type of penofol is insulation and steam protection for air vents, pipelines or heating mains.

Options for completing insulating materials

The schematic diagram of the construction of an insulated ceiling pie is applicable to all types of insulating materials. True, depending on their ability to pass steam, there may be some deviations, for example:

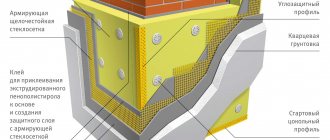

- When using extruded polystyrene, laying a vapor barrier on the ceiling located above rooms with “dry” operating conditions is not necessary. This type of insulation has almost zero vapor permeability and therefore does not require additional protection.

- When arranging the ceiling of rooms with “wet” operating conditions, a vapor barrier is installed in any case, regardless of the insulation layer used in the construction and its characteristic properties.

- When using mineral wool of all degrees of hardness and polystyrene foam, the ceiling must be protected with a vapor barrier layer.

The vapor barrier material is laid in the form of a kind of pallet, the “walls” of which should be higher than the thickness of the insulating layer. If the panel ceiling is assembled from boxes with insulation, then the vapor barrier material in exactly this form is placed in each of them. If thermal insulation is planned to be laid in the space between the joists, then they are wrapped with a vapor barrier membrane.

When using polyethylene film or glassine as a barrier, there should be a ventilation gap of 2 - 3 cm between the insulation and the vapor barrier. To do this, slats are fixed on the ceiling from the side of the premises, which at the same time serve as the basis for lining it with clapboard, decorative panels or plasterboard.

You need to think about how best to lay a vapor barrier on the ceiling when designing a house. It is at this stage that you need to choose the optimal installation option and think over the fastening scheme.

However, now there is always an opportunity to correct the shortcomings of builders and designers that appeared during the operation of the house. For example, you can correctly glue a polypropylene membrane to the ceiling. You just need to understand the characteristics and technological features of suitable materials.

Characteristics of penofol

This material has the following range of performance characteristics:

- operating temperatures range from -60°C to +100°C;

- thermal reflection on the surface reaches 95 – 97%;

- thermal conductivity indicators depend on the conditions under which the material is used and range between 0.037 and 0.052 W/m°C;

- moisture absorption per volume ranges from 0.35 to 0.7%, this value guarantees high-quality protection of the frame or ceiling from possible moisture ingress;

- if the thickness is 4 mm, then the specific weight will be 44 or up to 74 kg/m3 (this indicator greatly depends on the type of material);

- vapor permeability is no more than 0.001 mg/m h - penofol is an excellent protector against evaporation;

- ultimate compressive strength – up to 0.035 MPa;

- specific heat capacity is 1.95 J/kg°C;

- sound is absorbed - not lower than 32 dB.

More detailed technical characteristics of foil penofol can be found in the table below.

| Characteristics | Types of penofol | Units | ||

| Type A | Type B | Type C | ||

| Optimal temperature | from – 60 °C to +100 °C | °C | ||

| Surface thermal reflectance coefficient | ≥ 95-97 | % | ||

| Thermal conductivity coefficient (I) in dry condition at 20°C | ≤ 0,037-0,049 | ≤ 0,038-0,051 | W/m °C | |

| Water absorption by volume | ≤ 0,7 | ≤ 0,6 | ≤ 0,35 | % |

| Specific gravity (at 4 mm thickness) | 44 + / — 10 | 5 4 + / — 10 | 7 4 + / — 10 | kg/m3 |

| Dynamic modulus of elasticity (Eq) - under load 2 Kpa - under load 5 kPa | 0,26 0,77 | 0,39 0,72 | 0,26 0,77 | MPa |

| Relative compression (Eq) - under load 2 Kpa - under load 5 kPa | 0,09 0,20 | 0,03 0,12 | 0,09 0,20 | units |

| Heat absorption coefficient (S) at a period of 24 hours | 0,51 | 0,45 | 0,51 | W/m² °С |

| Vapor permeability | ≥ 0,001 | mg/m h Pa | ||

| Compressive strength | ≥ 0,035 | MPa | ||

| Reduced impact noise level reduction index | A3003-17 | A3005-19 | A3010-21 | dB(A) |

| Specific heat | 1,95 | J/kg °C | ||

Vapor barrier membranes

Diffuse (breathable) membranes are classified as the most effective and expensive vapor barriers. This group of products contains both single-sided and double-sided materials

The former allow steam to pass through only in one direction, so during installation it is extremely important not to confuse which side to lay the fabric towards the insulation and which to the load-bearing surface. Double-sided ones work in both directions, so there are no problems with them

Vapor barrier membranes can be single-layer or multi-layer. The first ones have an affordable price. Multilayer ones have the function of accumulating moisture inside the canvas and gradually releasing it.

A special group of products in this category are “smart” membranes. They are able not only to absorb vapors, but also to regulate the level of humidity of surrounding materials, while simultaneously acting as a water barrier. These membranes are the best choice. But their cost is beyond the means of most private home owners.

Vapor barrier membranes "TechnoNIKOL"

The undoubted leader in this category of materials is TechnoNikol membranes. For vapor barrier of wooden ceilings, the “Optima” brand is recommended for use. This hydrophobic polypropylene membrane consists of three layers:

- upper and lower polypropylene;

- medium – high-tech functional vapor-permeable film.

- weight 80 g/m2;

- thickness 0.3 mm;

- vapor permeability 5 g/m2x24 hours.

The TechnoNIKOL Optima membrane is produced in rolls. The width of the canvas (roll height) is 1.5 m. The length is 50 m. This material is optimal for vapor barrier of any type of ceiling, intended for installation indoors and on external surfaces of buildings.

Superdiffuse reinforced membrane

Diffusion membrane films "TechnoNikol"

Rules for installing a vapor barrier for a wooden ceiling

Step 1. The membrane is laid directly on the insulation so that the smooth side is directed inside the room.

Step 2. It is possible to lay the strips in different directions: parallel or perpendicular to each other.

Step 3. During installation, an overlap of at least 10 cm must be observed.

Step 4. To attach the membrane to a wooden floor without insulation, use galvanized screws with wide heads or staples with an anti-corrosion coating.

Step 5. The joints of the canvases are sealed using self-adhesive mounting tape.

Use foil tape, width 50 mm, length 30 lm.

Step 6. When laying on a floor with insulation, it is necessary to bring the edges of the panels onto the wall by 15-20 cm and secure them with suitable materials (slats or metal profiles).

Step 7. Mounting tape is glued along the perimeter of the vapor barrier layer.

Step 8. Between the membrane and the material with which the wooden floor will be lined, leave a ventilation gap 3-4 cm wide.

Step 9. Particular attention is required to the places where the vapor barrier comes into contact with the structural elements of the floor and the building: beams, chimneys, ventilation ducts.

Ceiling vapor barrier in wooden floors

During installation of the vapor barrier, it is necessary to ensure that the film is laid evenly, without folds or sagging. A guideline for correct installation can be a colored stripe, which is the center line along the entire length of the canvas.

Application of penofol

This universal type of material is well suited for insulating multi-storey buildings or a summer house in the country. The material is known and popular both in repairs and in fundamental construction.

Penofol is widely used in construction:

- For thermal insulation:

- in hangars or warehouses, heated or cold;

- residential premises;

- for refrigerators, vans or railway carriages, in cars;

- saunas or baths;

- during the construction of children's medical institutions;

- industrial buildings and administrative complexes;

- during the construction of shopping centers, shops, and so on;

- when insulating different types of pipelines;

- for chambers of refrigeration units;

- in water supply, heating or ventilation systems;

- for insulating equipment and machinery (ducts, boilers, etc.).

- To insulate parts of structures:

- when treating ceilings or floors;

- for insulation of window or door systems;

- processing of external and internal walls of buildings;

- for covering in basements and unheated types of premises;

- heat, hydro or vapor barrier of attics or roofs, roofs of various types;

- in the shielding of heating radiators.

It must be remembered that penofol not only helps to keep rooms warm in winter. If you lay it at the bottom of the roof, it will prevent the penetration of summer heat.

Selection of materials

Before you implement a vapor barrier for a wooden ceiling, you need to purchase material, taking into account the budget for the work, as well as the goals. Based on this, the following materials can be distinguished:

- polyethylene;

- films with membrane effect;

- glassine;

- varnishes;

- mastics;

- foil materials.

If we are talking about films with a membrane effect, then they will not allow moisture to pass into the premises. Among other things, they prevent it from coming out. Varnishes and mastics have the same effect. But one of the cheapest materials is glassine. Quite often, experts do not recommend using ordinary polyethylene film for installing a vapor barrier layer. It is used only in the most extreme cases. Such a coating will not allow air to pass through, turning the building into an airtight box. In this case, the rooms are not ventilated, condensation accumulates on the surface of the film. As a result, moisture settles inside the room, contributing to the formation of fungus and mold.

Let's say you decide that you need a vapor barrier for a wooden ceiling. In this case, glassine can be used only if there is not enough money for better material. It is not durable. It is most often chosen for the reason that it has a low cost. According to experts, the best solution is a vapor barrier based on liquid mastics or membrane films. With their help, you can reliably protect floors, ensuring the escape of wet vapors to the outside.

How to choose penofol

It is recommended to consider the following criteria for choosing penofol:

- The price by the thickness, as well as how many layers of aluminum were applied to the reflective surface. The standard size is from three to eight and even ten mm. Penofol with one side - a reflector with a size of 3 or 4 mm, type A - can cost approximately up to 55 rubles / m². 10 mm type B is considered much more expensive and more durable of all; the cost for it can reach from 100 to 130 rubles/m² .

- In stores you can come across the label “Penofol 2000”. We are talking about an analogue of standard material, but cheaper (it costs from 35 rubles/m² ). In terms of strength, according to experts, it is much inferior to classical insulation.

- The best ratio between the cost of the substance and the performance data is shown by penofol 5 mm thick at a cost of approximately 70 rubles / m².

- When you need to insulate the roof or basement rooms, in the basement, on the balcony, for saunas, or walls and ceilings, you can use A-type penofol. When used on wooden floors, it is better to take B-class. C-class is used for metal structures and vehicle insulation.

More about polyethylene reinforced film for vapor barrier

The main task that vapor barrier materials must cope with is combating dampness on walls, floors and ceilings. The better the material, the better the fight against high humidity. Polyethylene vapor barrier films, which are distinguished by the presence of a reinforcing layer, are excellent protection for any surface. Such films have found very wide application in agriculture. With their help, you can create greenhouses and greenhouses, thereby providing the most optimal conditions for growing vegetables, flowers and other plants. Due to the low weight of such a film, the greenhouse can be moved without preliminary disassembly. Due to the elasticity of the material, it will maintain its integrity.

But most often such a film is used to protect the thermal insulation layer. The design scheme using such a film is reminiscent of a layer cake: a waterproofing film is attached to the roof or wall, then a layer of thermal insulation is applied, followed by a vapor barrier polyethylene film, and finally finishing. With the help of such a film you can effectively get rid of excess moisture in the room, as well as protect the thermal insulation layer from getting wet. In this case, he will be able to fully perform all of his functions. In addition, polyethylene film does not allow the specific odor from the thermal insulation layer to penetrate into the room.

The minimum film thickness at which it can demonstrate its advantage is 40-50 microns. The strength of the material is increased due to the twisted thread base. The production of the material is usually carried out by heat pressing. The standard film area is 75 m2. This allows even one person to conveniently use a roll of material.

The main advantages of reinforced polyethylene vapor barrier film include the following:

- There are many methods that allow you to install film not only on flat, but also pitched roofs.

- Compliance with all quality standards, which ensures the effectiveness of using such material in construction.

- There is no process of biological decomposition of the material. This allows the film to maintain its high performance qualities regardless of exposure factors. In addition, the material is not exposed to fungus.

- Provides reliable protection of the thermal insulation layer, which allows you to maintain optimal temperature in the room.

How to lay penofol with your own hands

The best insulation effect is achieved if you adhere to the following rules:

- Between the structural element and the insulation itself, you need to leave some distance for the sake of ventilation, no more than a couple of centimeters.

- If you install one-sided penofol, the layer with foil should be directed in the direction where the heat will come from.

- It is better to connect sheets of material joint to joint, which gives uniformity in heat reflection. But if, for example, a loggia is insulated, joining using the overlapping method to a width of up to 10 cm is also acceptable.

- When sealing joints between sheets of materials, tape, also foil, should be used.

It is very important to remember that this material must be attached taking into account the fact that the reflective aluminum foil conducts current. Therefore, if there is wiring nearby, it is necessary to insulate the wires well.

An example of using penofol for insulating walls and floors

Once a material suitable for the operational requirements has been selected, additional waterproofing, protection from steam or heat can no longer be used. It will also be possible to save on the installation process and materials necessary for high-quality insulation and insulation of surfaces. You can also watch several videos on this topic.

Ceiling insulation with foil-isolon

Sheets of foil-isolon should be spread over the surface of the ceiling so that the foil “looks” into the room. After this, the insulation must be pressed with a clamp strip. The foil layer serves to reflect thermal radiation, which can be used as an additional advantage if foil isolon is used together with penoplex or polystyrene foam. In this case, the foil material will act as a vapor barrier.