What is zonolite

The mineral vermiculite is actually just a raw material for the production of expanded vermiculite - zonolite, which is occasionally found in deposits. Natural vermiculite is a product of natural erosion of mica biotite from the phlogopite series of hydromicas. When they say or write that windows were made from these micas in the old days, this is not true - phlogopite micas are opaque. Before the mass production of silicate glass, windows were glazed with the almost transparent mica muscovite, which began another mineralogical series of mica. Over 90% of the world's production of top-quality muscovite came from Russia, which in the West was called Muscovy; hence the name muscovite.

Natural and expanded vermiculite (zonolite)

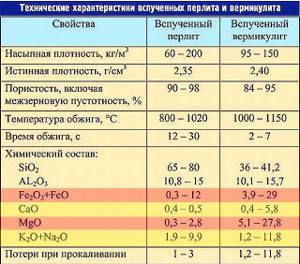

Vermiculite in natural deposits is a layered mineral of color from dirty yellow to almost black with green. During firing at 400-1000 degrees, it loses crystallization water, swells across the layers 15-20 times and changes color - this is already zonolite. For agricultural technology, medium-burnt expanded vermiculite is used, see fig. or highly burnt; after firing, it is crushed into granules according to its intended purpose, see below.

Vermiculite and perlite

One of the main tasks of vermiculite in plant culture is to absorb excess soil moisture and release it back into the soil as needed. In the range of moisture sorbents, vermiculite ranks after hydrogel and zeolites. Compared to gels, the exchangeable moisture capacity of vermiculite is small (up to 400 ml of water per 100 g of dry matter), but it does not disturb the soil structure and does not worsen, but on the contrary, increases its permeability. Compared to zeolites, vermiculite is cheaper, but has less moisture absorption and does not have ion-exchange properties. The closest competitor to vermiculite in all respects is expanded perlite. It lacks some of the disadvantages of vermiculite (see below), but is much less stable in the ground (2-5 years). For more information about the comparative qualities of vermiculite and perlite, see the video:

Advantages and disadvantages

Vermiculite fertilizer has a number of advantages, including:

- improving soil quality;

- reducing the amount of salts, metals, chemical elements in the soil;

- vermiculite reduces acidity levels;

- sufficient soil aeration;

- water balance adjustment;

- enhancing the properties of other fertilizers;

- protection of the root system from drought and frost;

- perfectly drains the soil;

- increase in productivity;

- reducing the likelihood of soil and planting diseases;

- no expiration dates.

Growth stimulator:

Heteroauxin

Disadvantages of vermiculite:

- interferes with the identification of pests in the soil;

- adjustment of the amount of watering is required.

Vermiculite: scope, pros and cons, installation features

When solving the pressing issue of thermal insulation of a home, one has to face the problem of choosing a thermal insulation material.

The range on the market is quite wide, but almost every option has significant drawbacks. In one case, the flammability deters, in the other, the high hygroscopicity rate.

The article discusses the characteristics and advantages of vermiculite, which is the golden mean of price and quality.

Description and scope of vermiculite

Vermiculite is a natural crystalline mineral with a layered structure. Belongs to the group of hydromicas. It contains: silicon, iron, magnesium, calcium and other mineral components.

The main advantages due to which the material is used in construction are resistance to aggressive influences, high acidity, retains its integrity for a long time, and does not decompose.

Many gardeners are familiar with vermiculite; it is often used as a mulching material, a substrate component, and an aerator. It is not used so often in construction work, although its properties and physical characteristics are of great interest for this field of activity. Among the developed areas:

• production of paint and varnish products, soft roofing;

• when installing a “warm floor” system;

• as a filler for heat-insulating and decorative plaster mixtures;

• for insulation of individual areas in the house (chimney, floor, roof, etc.);

• as a component of a screed mixture.

Vermiculite has good insulating characteristics, due to which it is used in regions with warm climates as backfill in three-layer walls to prevent overheating of the house, and in northern regions - for thermal protection of housing.

Insulation is produced in the form of backfill, compressed slabs, blocks, pipe segments, and liners.

Pros and cons of vermiculite

To appreciate the material, you need to familiarize yourself with its advantages and disadvantages.

Among the main advantages of vermiculite:

• environmental friendliness, during operation no toxic substances are released during heating;

• low thermal conductivity (0.055–0.098 W/m•°C);

• fire resistance (operating temperature range from minus 260° to plus 1200°);

• does not shrink over time;

• has good vapor permeability, which eliminates the formation of condensation in the room;

• resistance to microbiological processes, rodents and insects do not show interest in the material;

• during long-term transportation it retains its integrity and properties;

• when performing installation work, the use of special equipment and additional equipment is not required;

• a room with a vermiculite layer in the walls receives additional sound insulation.

Flaws:

• high price;

• natural material is highly hygroscopic, therefore, before sale it must be processed to create water protection (when purchasing, it is recommended to read the quality certificate);

• the need to leave ventilation gaps during the installation of insulation to remove moisture.

Efficiency

The effectiveness of vermiculite wall backfill can be assessed using proven indicators. A 20 cm thick layer of natural insulation replaces a one and a half meter wide brick wall and a two meter wide concrete wall. An embankment in the attic with a layer of 5 cm reduces the heat loss of the room by 75%, and a thickness of 10 cm - by 92%.

Undeniable thermal insulation qualities are also present in plaster mixtures that include vermiculite. Lined facades reduce heat loss by up to 30-45%.

Vermiculite is often compared to expanded clay, but the characteristics of the materials are significantly different. For example, vermiculite insulation is lighter in weight, which means the load on the load-bearing walls and foundation is minimal. When filling cavities, a tighter fit of mineral fragments is achieved than in the case of expanded clay.

Features of installation of interfloor ceilings and roofing

Installation work is carried out using technology corresponding to the type of insulation (bulk or slab material)

It is worth paying attention to the presence of water protection, otherwise the mineral will attract moisture from everywhere

What is vermiculite and its types

The mineral vermiculite belongs to the category of hydromicas. It is formed in the earth's crust and is an organic substance. This remedy is often used when growing crops. After extraction, it is processed under the influence of elevated temperatures. This helps dry the material and make it more free-flowing, giving it a flake structure.

Since the substance contains many natural growth elements, it is excellent for growing plants. Valuable ingredients that are suitable for flowers and other crops include the following:

- calcium;

- magnesium;

- silicon;

- iron;

- aluminum;

- potassium.

Vermiculite has a scaly structure that helps retain a lot of air. This substance is very important for the normal development of the plant. The substrate helps to increase aeration parameters in the soil. This means that it stops caking and becoming covered with a hard crust.

The main characteristics of the substrate are the absorption and release of moisture at the moment when the roots require it. The exchange of moisture and air accelerates the growth of crops and facilitates their survival.

Vermiculite has different places of origin. Taking into account its variety, the composition also differs:

- Altai material contains a lot of potassium , magnesium, and iron. It is characterized by a dark bronze tint. The composition is suitable for germination of seed material and cuttings.

- Rala vermiculite includes a standard set of minerals. It is gray in color and has a universal purpose.

- Kazakh material contains less iron. At the same time, it helps make the soil more alkaline. Therefore, it is mainly used for acidic soil. This material has an almost white tint.

- Kola vermiculite has a variegated color and contains a lot of sodium, magnesium, and calcium. It is mainly used in areas with acidic soil. It helps to normalize the pH.

- American, African and Australian varieties of the material make the soil more alkaline, but do not absorb water as actively. They have a reddish or brown color.

Read more: Instructions for using Yantarina, how to dilute growth regulator and analogues

Mixing with other materials

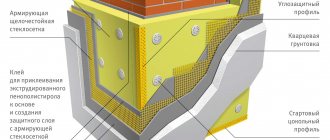

Despite the relatively affordable price, vermiculite slabs laid in their “pure” form will end up being quite expensive. Therefore, insulation is more often used in construction for the production of various solutions. In particular, it allows the production of so-called “warm plaster”.

This combination has many advantages compared to traditional methods of finishing external and internal walls. The specific gravity of plaster with vermiculite is lower than that of other compositions.

At the same time, it surpasses other materials in terms of thermal resistance. A 25 mm layer of plaster mixed with vermiculite provides the same performance as a 100-150 mm layer of cement and sand.

In addition to increasing the thermal insulation properties of the wall, the use of this combination can improve the noise absorption rate.

Vermiculite plaster can be applied to almost any surface, including concrete slabs and brick. It has sufficient adhesion. Cement-vermiculite mortar tolerates low temperatures well.

“Warm plasters” have another important quality: they have a golden or silver color, obtained due to their inclusion in the rock. Under the influence of sunlight, this feature will be most noticeable.

Price

The cost of the product varies, depending on the manufacturer, the fractions contained in the elements. The Russian drug 50 liters costs approximately 800 rubles. The price of Vermiculite per kg is approximately from 50 to 100 rubles.

Vermiculite is a good organic fertilizer that can be used equally successfully in both open and closed ground. It is used at different stages of plant development from seed planting to adult plants.

Specifications

The parameters of vermiculite depend on the size of the fraction; in addition, its exact composition has an impact. Key characteristics of expanded vermiculite:

- thermal conductivity;

- hygroscopicity;

- sound absorption;

- heat resistance.

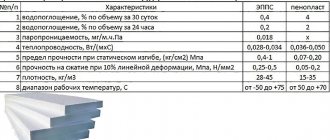

Fractions smaller than 4 mm are mainly used in construction. The coarse fraction is used as a filler for refractory concrete. The fine fraction of 0.5-1 mm is used as a bulk heat insulator, which is used to fill voids in walls or as a fill for insulating floors. The characteristics are presented in the table.

More details on properties.

Thermal conductivity.

The layered structure of the material after swelling under the influence of temperature has a dominant role on this parameter. The individual plates remain firmly connected, but the direct contact between them is broken and filled with air. The material itself has a thermal conductivity of the order of 2-2.7 W/m*K; due to the breaking of bonds between the crystalline plates, this figure is reduced to 0.03-0.12 W/m*K, which puts it on a par with mineral cotton wool and extruded polystyrene foam. At the same time, it is used in bulk, from which the material is able to fill all the irregularities and niches.

Hygroscopicity.

A property that explains the demand for vermiculite in agriculture and even hydroponics. The gaps between the crystallized plates are filled with equal ease by air and water. The material is highly hygroscopic. For example, 100 grams of vermiculite can hold up to 500 ml of water. More importantly, water and moisture enter and exit the material with equal ease. When using vermiculite as insulation for building envelopes, this must be taken into account and it is advisable to use it as an advantage, and not as a disadvantage.

Sound absorption.

Vermiculite has proven to be an excellent material for creating soundproof barriers. High absorption, lack of settling in the material during compression and increased elasticity allow reverberation to be controlled over a wide range. Simply put, vermiculite is able to absorb sound waves without producing secondary waves or extraneous sounds under the influence of friction or deformation. When vermiculite is compressed and pressed by approximately 10-20%, maximum absorption of sound waves is achieved.

Heat resistance.

The melting point of vermiculite exceeds 1300 degrees. After swelling, the material no longer undergoes modifications and is not subject to decomposition, changes in composition, etc. This makes it a heat-resistant material that can be used to insulate stoves, fireplaces, pipes and chimneys.

In addition to these characteristics, vermiculite can be described by a number of useful properties:

Environmentally friendly, without harmful emissions in the entire range of permissible operating conditions. Prevents condensation. It quickly absorbs moisture and then just as easily releases it as steam.

It is important to create optimal conditions for removing excess moisture. High turnover. Easily fills voids, niches and surfaces of complex shapes. Does not attract rodents

It is not an attractive food for them and, due to its high hygroscopicity, quickly absorbs the odors of rodent marks, which makes them quickly lose interest in the space filled with vermiculite. Does not cause allergies. It is not radioactive and reflects part of the radiation spectrum, has a neutral pH.

Expanded vermiculite is sold as insulation in bags of 50 liters. This is enough so that with a layer thickness of 10 cm, two bags are enough to fill 1 m2.

Material with a fraction of 0.5-1 mm for insulating floors is supplied to the installation site via air ducts, just like, for example, ecowool. Otherwise, it is filled directly from the bags. There is no need for additional fluffing for filling.

How to improve soil quality

Quite often, the main problem when growing plants is poor quality soil. And vermiculite is simply irreplaceable here. How to properly use vermiculite for these purposes and how much to add to the soil?

To make the soil moist, breathe better and become loose, vermiculite is added together with organic fertilizers. 25 kg of organic matter requires a bucket of vermiculite.

The mineral is also added when sowing seeds, spreading the fraction along the entire bed. For 1 m2 of planting you will need approximately 10 spoons of vermiculite. When planting seedlings, add 3 additional spoons into each hole.

Attention:

Vermiculite also cleanses the soil, absorbing all the products of gas exchange, as well as heavy metal salts.

For clay soil, vermiculite is simply irreplaceable. It should be applied after rain, otherwise a dense crust will form on the surface of the earth, and the soil will not allow air and moisture to pass through. For 1 m2 take 2 liters of product.

Highly acidic soil is also not suitable for all crops. And here vermiculite can help, neutralizing acidity. Can be used in conjunction with perlite. 2.5 liters is enough to make the soil suitable for each plant.

Description and scope of vermiculite

Vermiculite is a natural crystalline mineral with a layered structure. Belongs to the group of hydromicas. It contains: silicon, iron, magnesium, calcium and other mineral components.

The main advantages due to which the material is used in construction are resistance to aggressive influences, high acidity, retains its integrity for a long time, and does not decompose.

Many gardeners are familiar with vermiculite; it is often used as a mulching material, a substrate component, and an aerator. It is not used so often in construction work, although its properties and physical characteristics are of great interest for this field of activity. Among the developed areas:

• production of paint and varnish products, soft roofing;

• when installing a “warm floor” system;

• as a filler for heat-insulating and decorative plaster mixtures;

• for insulation of individual areas in the house (chimney, floor, roof, etc.);

• as a component of a screed mixture.

Vermiculite has good insulating characteristics, due to which it is used in regions with warm climates as backfill in three-layer walls to prevent overheating of the house, and in northern regions - for thermal protection of housing.

The ground in the regions of the middle zone and the Urals freezes strongly in winter, which often causes cracks to form in the concrete bowls of swimming pools. Vermiculite helps correct the situation. It is poured to the bottom, as well as into the cavity between the bowl and the edge of the trench during the construction process.

Insulation is produced in the form of backfill, compressed slabs, blocks, pipe segments, and liners.

Application for plants

Vermiculite absorbs water in large quantities and releases it gradually. The water absorption coefficient is 400–500%, that is, every 100 g of mineral binds and stores more than 400 ml of water in its structure. An important property of vermiculite for plants is the creation of an optimally moist soil environment.

The material has earned the honorable name of “agronomic” rock.

Let's list why plants need vermiculite and in what situations it is most useful:

- Added to earthen mixtures to improve aeration (air permeability) and water absorption.

- Crushed expanded crystals are used in agriculture as a substrate for hydroponic culture (growing without soil).

- To mulch the soil, a mineral with different particle sizes is used - from dust-like to the diameter of small coins.

- Saturates the soil with substances beneficial to plants.

The mineral supplement prevents the growth of bacteria and fungi. In addition, vermiculite is a fertilizer, as it contains potassium, magnesium, and iron. Adding material to the soil helps grow healthier, stronger seedlings. The following uses exist.

Germinating seeds, growing seedlings and rooting cuttings

The mineral additive ensures a uniform supply of moisture to the seeds during germination. The inert material protects against rotting and the spread of mold.

How to use vermiculite to germinate seeds:

- the material is pre-moistened with water;

- fill containers for germination;

- sowing seeds;

- placed in a warm place.

Planting material can be sprinkled with the finest fraction of the mineral when sowing in the beds. This helps distribute the seeds evenly and protects against evaporation. Sprouts, and then seedlings, receive moisture evenly, the roots are protected from temperature changes.

Drainage

Vermiculite is less often poured as a drainage material at the bottom of the pot. Expanded clay is most often used for this purpose. However, large fractions of layered mineral are also good drainage.

Perlite for plants

Pour a layer of mineral additive 1–2 cm high at the bottom of the container for planting. Drainage absorbs excess water, waterlogging of the soil substrate is excluded. At the same time, the soil is enriched with macro- and microelements.

Soil improvement

This is one of the main uses of vermiculite, for which this material is used in agriculture. The mineral additive is mixed with the soil in different proportions depending on the type of plant.

The enriched substrate does not cake, does not undergo calcification (formation of white plaque on the surface), and does not acidify.

Mulching

Used as mulch to protect the soil from excessive evaporation. A layer of mineral additive creates a microclimate on the soil surface that is favorable for roots. One method of application: water the plants and sprinkle the damp substrate with mulch. You can loosen the soil, cover it with a thin layer of vermiculite and dig it up.

In the greenhouse

Sow the seeds and plant the seedlings in soil mixed with vermiculite. Less watering will be required, replanting will become less stressful, and plant adaptation to new conditions will be easier. Thanks to the additive, fertilizing is better absorbed.

Storing bulbs and tubers

The mineral additive is used for winter storage of planting material. In the fall, dig up tubers, bulbs, corms and rhizomes of plants that cannot overwinter in the soil due to low temperatures. Place the planting material in boxes and cover with vermiculite.

Mineral in the garden

Mulch the ground around fruit and ornamental trees and shrubs with vermiculite. This treatment is useful when the area becomes waterlogged in the event of heavy rainfall. Mulch also prevents roots from freezing in winter.

Advantages of the backfill method

Working with bulk material simplifies the installation process compared to molded heat insulators. The slabs must be cut and fixed using fasteners. Also, such insulation contains joints that can form cold bridges, which leads to the loss of the heat-insulating qualities of the material.

Mineral slabs tend to cake. Expanded granules do not cake and do not shrink. They also provide a high degree of sound insulation due to their porosity.

The use of vermiculite as an insulator solves a number of problems that are not available to other types of thermal insulation materials. In addition to very low thermal conductivity, the insulator provides fire resistance, chemical inertness, and reflectivity. A wall with loose insulation will become a good fireproof barrier during a fire. Also, the use of such thermal insulation material will reduce your financial costs of insulating your home.

Flaws

The main disadvantage of vermiculite is its ability to absorb moisture 3-4 times its own volume. However, it gives it away with the same ease, unlike natural materials (cellulose, wood) or polymer insulation.

When using vermiculite, it is especially important to ensure good ventilation to remove excess moisture. Since this is a natural requirement when arranging a roof and roofing when using absolutely any insulation material, strong water absorption is considered a disadvantage among the features that should be remembered and taken into account when designing a house.

Specific gravity of building materials - Sergey Chervach

Material specific weight, kg/m3 Concrete Reinforced concrete 2500 Concrete on gravel or crushed stone from natural stone 2400 Tufobeton 1200-1600* Pumice concrete 800-1600* Concrete on volcanic slag 800-1600* Expanded clay concrete on expanded clay sand and expanded clay foam concrete 500-1800* Ceram zito concrete on quartz sand with porosity 800-1200* Expanded clay concrete on perlite sand 800-1000* Shungizite concrete 100-1400* Perlite concrete 600-1200* Slag pumice concrete (thermozit concrete) 1000-1800* Slag pumice foam and slag pumice gas concrete 800-1600* Concrete on granulated blast furnace slag 1200-1800* Agloporite concrete on fuel (boiler) slags 1000-1800* Concrete on ash gravel 1000-1400* Vermiculite concrete 300-800* Gas and foam concrete gas and foam silicate 300-1000* Gas and foam ash concrete 800-1200* Mortars Cement-sand 1800 Complex (sand , lime, cement) 1700 Lime-sand 1600 Cement-slag 1400 Cement-perlite 1000 Gypsum-perlite 600 Porous gypsum-perlite 500 Gypsum slabs 1000-1200* Gypsum cladding sheets (dry plaster) (plasterboard) 800 Brickwork Clay ordinary (GOST 530-80) on cement-sand mortar 1800 Clay ordinary on cement-slag mortar 1700 Clay ordinary on cement-perlite mortar 1600 Silicate (GOST 379-79) on cement-sand mortar 1800 Trepelny (GOST 648-73) on cement-sand mortar 1200 Slag on cement-sand mortar 1500 Ceramic with a density of 1400 kg/m3 ( gross) on cement-sand mortar 1600 Ceramic hollow with a density of 1300 kg/m3 (gross) on a cement-sand mortar 1400 Ceramic hollow with a density of 1000 kg/m3 (gross) on a cement-sand mortar 1200 Silicate eleven-hollow on a cement-sand mortar 1500 Silicate fourteen-hollow on a cement-sand mortar 1400 Stone Gra nit, gneiss and basalt 2800 Marble 2800 Limestone 1400-2000 Tuff 1000-2000 Wood and other natural Pine and spruce 500 Oak 700 Plywood (GOST 3916-69) 600 Facing cardboard 1000 Multilayer construction cardboard (GOST 4408-75*) 650 Wood-fiber and particle boards (GOST 4598 -74 *, GOST 10632-77*) 200-1000* Fiberboard slabs (GOST 8928-81) and wood concrete (GOST 19222-84) on Portland cement 300-800* Reed slabs 200-300* Peat thermal insulation slabs (GOST 4861-74) 200 -300 Tow 150 Thermal insulation Mineral wool mats stitched (GOST 21880-76) and with a synthetic binder (GOST 9573-82) 50-125* Soft, semi-rigid and hard mineral wool slabs with synthetic and bitumen binders (GOST 9573-82, GOST 10140-80 , GOST 12394-66) 50-350* High-hardness mineral wool slabs with an organophosphate binder (TU 21-RSFSR-37276) 200 Semi-rigid mineral wool slabs with a starch binder (TU 400-1- 61-74 of the Moscow City Executive Committee) 200 Glass staple slabs fiber on synthetic binder (GOST 10499-78) 50 Stitched glass fiber mats and strips (TU 21-237275) 150 Expanded polystyrene (TU 6-05-117878) 100-150* Expanded polystyrene (GOST 15588-70*) 40 PVC-1 foam ( TU 6-05-117975) and PV-1 (TU 6-05-1158-78) 100-125* Polyurethane foam (TU V-56-70, TU 67-98-75, TU 67-87-75) 40- 80* Plates made of resole-formaldehyde foam (GOST 20916-75) 40-100* Perlite plastic concrete (TU 480-114574) 100-200* Backfill Expanded clay gravel (GOST 9759-83) 200-800 Shungizite gravel (GOST 19345-83) 400-800 Crushed stone made of domain slag (GOST 557876), slag pumice (GOST 9760-75) and Agloporite (GOST 11991-83) 400-800 gravel and sand from perlite switched (GOST 10832-83) 200-600 Vermiculit Vooked (GOST 12865-67 ) 100-200* Sand for construction work (GOST 8736-77*) 1600 Other Foam glass or gas glass (TU 21BSSR8673) 200-400* Flat asbestos-cement sheets (GOST 18124-75*) 1600-1800* Petroleum construction and roofing bitumen (GOST 6617-76*, GOST 9548-74*) 100-1400* Asphalt concrete (GOST 9128-84) 2100 Products made of expanded perlite with a bitumen binder (GOST 16136-80) 300-400 Ruberoid (GOST 10923-82), glassine (GOST 2697-83), roofing felt (GOST 10999-76*) 600 Polyvinyl chloride multilayer linoleum (GOST 14632-79) 1600-1800 Polyvinyl chloride linoleum on a fabric base (GOST 7251-77) 1400-1800 Reinforcing rod steel (GOST 1088 4-81) 7850 Cast iron 7200 Aluminum (GOST 22233-83) 2600 Copper (GOST 859-78*) 8500 Window glass (GOST 111-78) 2500

Properties of expanded clay

- high strength

- fire resistant

- frost-resistant

- does not contain harmful impurities;

- does not absorb water;

- durable

- does not lose its properties and is not destroyed when frozen

- not subject to rotting

Absolutely safe for humans and the environment.

Expanded clay is a product of rapid firing of low-melting clays. From Greek, the word “expanded clay” is translated as “burnt clay,” which is absolutely true. Despite heat treatment, it not only does not lose the properties inherent in the clay itself, but also acquires additional ones, becoming porous.

Photo: Properties of expanded clay material. Application area

On their basis, expanded clay concrete blocks are made, the thermal insulation and mechanical properties of which allow them to be used for the thermal insulation construction of floors, walls, ceilings, foundations and basements. Thanks to the expanded clay filler, these blocks also acquire its properties. They are lightweight, durable, fireproof, acid resistant, etc.

Application

Skamol V-1100 and VIP-12 slabs are used both for lining and for thermal insulation of all fire-resistant structures. They will not decompose even when directly exposed to flame. Due to the resistance of V-1100 and VIP-12 boards to carbon monoxide CO and hydrocarbons, they can be used in furnaces with a reducing atmosphere. They are virtually sulfur-free and are therefore an ideal choice for furnaces that produce nickel alloys or other sulfur-critical alloys. Due to their higher density, VIP-12 slabs have greater wear resistance than V-1100 slabs.

Basic properties

Hydromica is not used in its natural form. The mineral serves as a raw material for the production of expanded vermiculite, widely used in many industries. To implement the swelling process, a temperature of 400–1000 °C is required. Heating promotes delamination of the mineral, which occurs due to the presence of water in the composition. Gradually turning into steam, the liquid causes the mica to delaminate.

The volume of material can increase 20 times. When exposed to high temperatures, cooling down, it retains its scaly structure. Then it is crushed to obtain a fraction of 5–20 mm.

Technologies for laying vermiculite building materials

Vermiculite belongs to the group of mineral insulation materials, therefore work using it is regulated by the Interstate Standard “GOST 12.1.007-76 System of Occupational Safety Standards (SSBT). Harmful substances. Classification and general safety requirements (with Amendments No. 1, 2).”

Insulation of roofs and interfloor ceilings

When insulating interfloor ceilings and roofs using vermiculite in granular form, the work is performed in the following sequence:

- A vapor barrier is placed on the insulated surface, preventing moisture from penetrating from inside the room.

- The frame of the insulated structure is mounted into which vermiculite is poured.

- Waterproofing is installed to provide protection against water penetration from the outside.

- An air gap is left between the waterproofing layer and the insulation, ensuring air circulation in the insulated plane, facilitating the weathering of excess moisture.

- The counter lathing is installed and the finishing or roofing covering is laid.

To reduce costs, when using vermiculite as insulation, you can mix it with sawdust in a 1:1 ratio.

Insulation of walls and partitions

Insulation of walls and partitions is carried out during their construction; this applies to frame and well technologies. In this case, vermiculite is filled in as the structures are erected, with slight compaction being performed. When installing internal walls and partitions, vapor and waterproofing are not installed, and there is also no need to create any air gap between the insulation and the enclosing structure.

When insulating walls from the outside, the work is performed in the same way as when insulating the roof and interfloor ceilings.

Another way to insulate a camp using vermiculite is to pour insulation into the interior of hollow walls made of brick or concrete blocks.

Preparation of solutions and building mixtures

Due to the fact that vermiculite is a fairly expensive building material, it is often used not in its pure form, but as part of a mortar, plaster mixture or as a concrete filler. In this case, the positive properties of this material are partially transferred to the prepared mixture, its heat-retaining abilities are improved.

When preparing plaster mortars for exterior use, fine or medium fraction vermiculite, cement and water are used. For plaster used indoors, sand, or clay and lime are added to the above listed components, which is determined by the presence of a particular material and the parameters of the solution that will be obtained as a result of its preparation (strength, tensile strength, etc.).

Vermiculite boards

Vermiculite boards - PVTN boards, are a popular building material, used in the same way as granulated vermiculite. PVTN slabs are made by pressing fine foamed vermiculite, and all the positive properties of the material are inherent in products made from it.

Plates are used for:

- protection of stoves of various designs installed indoors from the danger of burns and other negative phenomena of operating personnel and users;

- thermal insulation of metal structures, in places where there is such a need;

- performing thermal insulation work of various types, as an alternative material in relation to other sheet types of insulation (foam plastic, mineral wool, etc.);

- construction of fire-resistant partitions and suspended ceilings;

- enhancing the fire safety of premises for various purposes made of flammable materials.

Vermiculite boards have an attractive appearance and can be easily processed with hand cutting and other tools.

The use of vermiculite in the construction of buildings and structures makes it possible to achieve a double positive effect both in terms of thermal insulation properties and in terms of fire safety of structural elements. In addition, having good sound-absorbing properties, vermiculite has proven itself as a sound-absorbing material used in noise-absorbing structures.

Why the problem?

Some plant growers consider vermiculite almost a poison for plants. Like, 2-3 months, and the plants on the vermiculite substrate die, see for example. video clip:

Video: an example of plant death due to the thoughtless use of vermiculite

Such stories cause heated controversy, and the evidence is quite convincing on both sides. What's the matter? If you look into the audience comments, it turns out: a) supporters of “for” use vermiculite first. for young plants (seedlings, seedlings) and cuttings, or in open ground; b) opponents of vermiculite mostly use it indiscriminately (see below) in potted plants of certain species. From here it is clear that the use of vermiculite must be made taking into account both the properties of the substance itself and the conditions of its use.

Chemical composition

In mineralogy, micas are classified as complex aluminosilicates of unstable composition. Technical characteristics of expanded vermiculite and perlite are given in table. in Fig. below. The content of the components indicated in it is standardized by the technical specifications for the finished product, but besides them, vermiculite contains nickel, titanium, manganese, etc. compounds in negligible quantities. Of these, only manganese is a micronutrient for plants; Occasionally, traces of molybdenum and boron, also needed by plants, are found in vermiculite. The rest of the microimpurities are ballast, not always useful.

Chemical composition of expanded vermiculite and perlite

But it’s not only and not so much about ballast. Let's pay attention to the lines highlighted in red. Iron is also a microelement necessary for plants, but only in the 2-valent form Fe(II); Trivalent iron Fe(III) is useless, and its excess is harmful. Fe(II) is present in vermiculite in the form of oxide FeO; Fe(III) as oxide Fe2O3. The proportions of both vary greatly even in samples from the same deposit and therefore their ratio is not standardized.

Magnesium is a vital meso-element (part of chlorophyll), but in vermiculite it can be in large excess. In open ground this is not a problem: magnesium salts are easily leached and in direct light plants often lack it. But in a pot, magnesium will alkalize the soil, and with a lack of light, plants can deplete themselves by synthesizing excess chlorophyll.

Calcium is also a mesoelement; potassium is the main nutritional element. But their oxides, like sodium oxide, form alkalis in the presence of moisture. On open ground, this is again not a problem: vermiculite is a persistent mineral, leaches very slowly, and alkalis are mobile. But in general they have nowhere to go from the pot, and 2-3 months. the period is just sufficient for plants that love acidic soil to wither in alkaline soil: Saintpaulia violets, azaleas, dieffenbachias.

Granule fractions

Vermiculite is waterproof, insoluble in water, and leaches from the surface. The rate of release of alkalis from vermiculite into the substrate depends on the size of the granules according to a quadratic law: when the particle size decreases, say, 10 times, the alkalization of the soil accelerates 100 times.

Vermiculite granule fractions

Vermiculite for agricultural technology is produced mainly in 2 fractions: granules about 1 cm in size (about the size of a fingernail) and finely ground, see fig. Coarse-grained vermiculite is used in all cases except one - germination of seeds, cuttings and growing seedlings on a mixed neutral substrate, see below. If finely ground vermiculite is used in potted adult plants, the result will most likely be failure due to alkalization of the soil.

Alkalis are not always bad

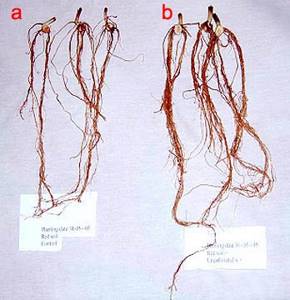

Results of rooting cuttings in a substrate with vermiculite (b) compared with control (a)

As we see, there can be more potassium in vermiculite than in perlite. Potassium is known to promote root growth. Seeds, seedlings and young parts of adult plants (cuttings) that are on the brink of survival are much less sensitive to the composition and chemical reaction of the soil, but they need to take root as soon as possible. The main obstacles in this case are a lack of air for the developing roots and spores of pathogenic fungi, but they need an acidic environment for development. Using nutritious but soil-acidifying peat with finely crushed vermiculite alkalizing it as a substrate for germination and rooting (see below) gives impressive results: in Fig. on the right are the roots of the control group of cuttings a, treated with heteroauxin and rooted in the usual way, and group b was rooted in a mixture of vermiculite and peat with and without a growth stimulator.

Note: when is it better to use vermiculite for seedlings, seedlings and cuttings, and when to use perlite, see video:

Video: vermiculite and perlite, pros and cons

How to choose vermiculite for plants

The composition of vermiculite within the limits indicated above and the content of ballast microimpurities in it vary greatly depending on the origin of the raw material. The deposit where the original mineral was mined, its quality and suitability for various agricultural purposes, in some cases, can be determined by the type of product on sale.

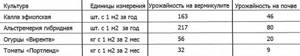

Results of growing flower and vegetable crops on vermiculite

The best vermiculite for agricultural technology is light, slightly yellowish Ural (item 1 in the figure below). The ancient Ural mountains are reborn. Together with the temperate continental climate, the erosion conditions of vermiculite there are such that it contains predominantly iron. in the form of Fe(II), and magnesium is just enough for plants. Growing flower and vegetable crops in dry hydroponics with Ural vermiculite gives results comparable to those when using expensive growth stimulants that require regular use, see table. on right. The alkalization of Ural vermiculite is insignificant and can easily be compensated by adding peat infusion to the nutrient solution.

Types of vermiculite for agricultural technology

Kazakhstan vermiculite from deposits in the young mountains of the Alpine uplift is very similar to the Ural vermiculite, but a little paler, pos. 2, because It contains less Fe(II). But Fe(III) is also less, so this variety is well suited for dwarf and potted plants. It has virtually not undergone natural leaching, and therefore in dry hydroponics and pot culture it is suitable for plants that love or tolerate slightly alkaline soil. Application on open ground and for seeds, seedlings, seedlings - without restrictions.

Pinkish vermiculite from Altai and the old mountains of Europe (item 3) contains a lot of Fe(II), potassium and magnesium. This is the best substrate for germinating seeds and rooting cuttings. On vermiculite of this composition, nightshade seedlings grow best: tomatoes, vegetable (sweet) peppers (see video at the link: //www.youtube.com/watch?v=Stx-yDRxXKo).

Variegated vermiculite from the Kola Peninsula and Scandinavia (item 4) is similar in composition to the Ural and Kazakhstan, but contains a lot of potassium, sodium, calcium, magnesium and microimpurities. Good finely crushed for germination and rooting in a mixture with peat. Brown of subtropical origin (item 5) and red (“red”, item 6) tropical vermiculite are a less expensive alternative in substrates for the same purpose. They are not very suitable for open ground due to low moisture absorption, and are not very suitable for potted crops due to the high content of Fe(III) and alkali-producing components.

Expanded clay

Expanded clay is fired clay balls, they are used as drainage and are also suitable as a soil additive. The porous structure provides greater moisture capacity, and the irregular shape of the balls ensures good air and moisture exchange.

Expanded clay "Peter Peat", 2 l.

It is used as a loosening additive to soils, creates good drainage, and promotes better aeration of the substrate. When mulching the surface of the substrate, expanded clay prevents the development of mold and fungal diseases.

Due to natural alkalinity, it prevents acidification of the substrate

.

Used for rooting cuttings and growing plants using the hydroponics method.

Expanded clay is a reusable material (rinse with water before reuse).

Vermiculite consumption

The method of application and the required amount of material depends on the purpose of its use.

- Add 10–15% of the volume to the substrate for growing decorative potted plants.

- To root cuttings, prepare a mixture of peat and vermiculite in a 1:1 ratio.

- When planting potatoes, place ½ tbsp in each hole. l. mineral supplement.

- For tree trunk circles, use 6–8 kg of mulch for each square meter of area.

- To improve heavy soils, add 2 liters of vermiculite per square meter of plot area.

- Add 10 kg of mineral per 100 liters of organic matter to the compost.

Greenhouse frame for polycarbonate: secrets of selection

For items 1–3, it is recommended to use small fractions of the mineral. This is necessary to protect the tender roots of young plants from damage. In other cases, particle sizes are not critical.

Main advantages

So, we found out that vermiculite consists of crystals connected in certain groups. The material is durable, does not compress and does not collapse over time, which cannot be said about the same mineral wool. Thanks to all its advantages, the material is significantly superior to its competitors - perlite or expanded clay.

In terms of thermal conductivity, the material is similar to mineral wool, and its resistance to flame and aggressive environmental influences is approximately the same. But the sound insulation properties are an order of magnitude higher than those of any other insulation. But the main advantage of vermiculite is its low price and availability (more on prices a little later).

Using vermiculite for mixtures and solutions

Mixtures for masonry and plaster are produced from fine-grained vermiculite. They are sold ready-made. Another option is to make the raw materials yourself. You will need cement, sand and insulation. The ratios are: 1:0.5:2 or 1:1.25:1.75. At the output, the plaster will have a thermal conductivity coefficient of 0.24–0.4 W/m*K.

Reinforced concrete floors can be insulated with a screed containing vermiculite. In addition to thermal insulation, the layer will protect the rooms from noise. The technology for forming the screed does not change.

However, since the insulation is hygroscopic, it is not recommended to use it for very damp rooms, basements, or foundations.

Otherwise, vermiculite is a universal, environmentally friendly and practical material, used both in the process of building a house and in the finished building. It is easy to work with, and its long service life will allow you not to think about changing the insulation for many years.

Properties of vermiculite insulation

Vermiculite insulation is a material that is widely used in construction and finishing work during the construction of new buildings, and carrying out major and ongoing repairs of old buildings. It is used in the form of pressed slabs, as a filler and as an additive to plaster mixtures. It is used for insulating walls, floors, attics and ceilings. Insulation with vermiculite is carried out during the construction of pipeline systems and highways for various purposes, which significantly extends their service life. This has a positive effect on the operation of equipment and pipeline fittings installed for the smooth functioning of the entire system.

Technological features

Vermiculite in the form of slabs and in bulk.

Vermiculite is an environmentally friendly material created by nature. Belongs to the minerals of the hydromica group. It has a crystalline form of golden brown, yellowish or bronze color. It was found that when vermiculite plates are heated, they transform into threads or worm-like columns. Actually, this property made it possible to give the material such a name, because vermiculite means worm in Latin. After examining its physicochemical properties obtained after heating, vermiculite insulation began to be used in various industries, agriculture and construction. Also read: “Choosing the best insulation for the roof.”

The main advantages of the material include:

- fire resistance (1350 0 C);

- density (not higher than 150 kg/m3);

- low thermal conductivity (no more than 0.12 W/m*K);

- resistance to aggressive environments, bacteria and does not form mold on the surface;

- hygroscopicity;

- ability to absorb sound (sound absorption coefficient up to 0.8);

- environmental friendliness;

- service life (60 years).

Before pouring antifreeze into the heating system of your home, you need to clean the pipes and radiators from all kinds of contaminants.

Here you can read what equipment is needed to pump the heating system with antifreeze (antifreeze liquid).

Methods for insulating walls with vermiculite

View of a wall plastered with mortar containing vermiculite.

Vermiculite insulation of walls is carried out during the construction of new buildings and old buildings constructed from different materials. Thermal insulation in bulk form can serve as a filler in the manufacture of heat-resistant concrete and is used for plastering surfaces. It is produced in different fractions (from 0.5 to 12 mm) and is sold in retail chains in paper bags, most often weighing 25 kg.

Granular vermiculite can be poured into inter-wall voids. The pressed slabs are secured using special fasteners and can be cut before installation. The slabs can serve as good insulation when lining fireplaces, stoves, chimneys and pipes. Vermiculite for ceiling insulation additionally performs soundproofing functions in multi-story buildings.

Vermiculite insulation, the properties of which remain unchanged regardless of its type, is also used for plastering vertical surfaces. To do this, it is added to concrete mixtures in certain proportions. You can make them yourself or buy ready-made ones. Comprehensive home insulation with vermiculite (walls, floors, attic) will save on heating bills.

The method for installing an electric heating boiler consists of two parts: inserting the circuit and connecting to the network.

Vermiculite insulation of floors and attics

The technology for insulating floors and attics with vermiculite is the same. In this case, the thermal insulation is protected with special films. A vapor barrier should be installed on the side of the warm room, and waterproofing on the side of the street or unheated attic.

When performing thermal insulation with vermiculite, the presence of waterproofing and vapor barrier is mandatory

It is extremely important to place these protective layers correctly

Insulation of a pitched roof

When insulating the floor, waterproofing is placed under the vermiculite.

With such insulation, it is important to correctly select the thickness of the vermiculite poured. It depends on temperature conditions and ranges from 10 to 20 cm

The technology for insulating a pitched roof is as follows:

- a vapor barrier film is laid on the rafters;

- granular vermiculite is poured in;

- covered with a layer of waterproofing and a counter-lattice;

- the roof is spreading;

- Internal lining is carried out with any material.

Vermiculite insulation, the properties of which have been well studied, is a modern material that has a wide range of applications.