Composition and structure of warm linoleum

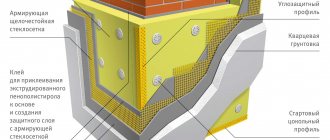

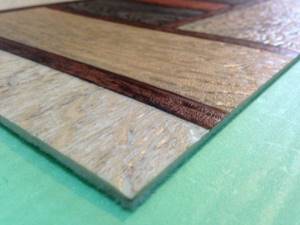

The structure of insulated linoleum is slightly different from standard floor linoleum, with a large number of layers and thickness. The standard number of layers is 5 or more.

- The first layer is a thin transparent film that protects the decorative coating and lower layers of material from damage. The durability of the coating depends on this layer; it accounts for all static and mechanical loads.

- The second layer is decorative, also made in the form of a film, with a certain color scheme, pattern or pattern imitating natural materials.

- The third layer is made of polyvinyl chloride, it is necessary to give comfort and practicality to the material, provides softness, elasticity, creates additional water resistance, as well as noise insulation.

- The fourth layer is necessary to create strength for the canvas; it is made of special fiberglass.

- The fifth layer is the insulating material itself. It is the most massive and thick layer. The main materials of the fifth layer are foamed PVC, felt or jute, which we will discuss in the next section of this article.

approximate structure of insulated linoleum

Advantages of insulated linoleum

Easy to install

For flooring rolled linoleum, a specialist with experience will not be superfluous, but in conditions of economy, even a beginner can perform such work, having first watched the training materials and knows how to handle a knife, adhesive materials and a measuring tape. The main difficulty of installation may be cutting the canvas to the required size. Some varieties do not even need to be glued to the subfloor, since the linoleum adheres well to it and it is enough to press it with baseboards against the walls.

Hides floor defects

To lay thick, insulated linoleum, you do not need a perfectly flat concrete screed; it is enough that it is level with the horizon. Massive insulation will hide small cracks, depressions and some protrusions.

ease of installation

Additional insulation

This property cannot be called the main one for linoleum; first of all, it is a protective and decorative coating for finishing. However, increasing the thickness of the back layer of the roll creates a noticeable effect. It allows you to significantly reduce heat loss through the floor, retain the heat of artificial heating longer, and also ensure a comfortable surface temperature for your feet. Unlike porcelain stoneware coverings, linoleum does not instantly cool down, but can prevent heat loss for another 30 to 60 minutes, depending on temperature conditions.

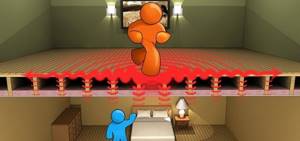

Noise insulation and “quiet” coating

A thick layer of insulation can absorb airborne sounds, and also does not create structural noise when walking on its surface. Impact sounds are softened but not absorbed. Read more about soundproofing methods in the article: “Soundproofing an apartment. Materials for soundproofing walls"

can enhance sound insulation

Affordable cost and aesthetics

One of the best alternatives to expensive floor coverings. For relatively budget funds, you can create a beautiful and functional floor finish. Most types of linoleum are difficult to distinguish in appearance and sometimes even by touch from natural boards or laminate.

Comfortable cleaning and practicality

The outer surface of linoleum, unlike the back, is not afraid of moisture and any liquid. It washes well from almost any contaminant and does not absorb water. You can clean linoleum either with plain water or with the addition of any detergent, except chemical solvents.

Durability

The service life of insulated linoleum is longer than conventional rolled material and ranges from 10 years. A longer service life depends on the amount of load to which the coating is exposed. Moreover, unlike natural materials such as parquet boards, linoleum does not need to be coated with protective impregnations every 2-3 years. Read more about parquet boards in the article: “Parquet boards - their properties and structure”

Conclusion

High quality product!

The heterogeneous structure and the presence of a heat-insulating layer significantly improve the quality of the coating, extend its service life and add comfort to the operation of the material. At the same time, the cost and installation of such linoleum are not fundamentally different from the usual brands and varieties of roll-type floor coverings. The video in this article presents some nuances on the topic, watch it!

Disadvantages of insulated linoleum

Along with practical advantages, insulated types have specific limitations in operation. The existing shortcomings are not critical and can be ignored, but nevertheless, it is advisable to take them into account when choosing and installing them.

Difficulties in repair

The damaged coating can be glued to the floor, but it will no longer be possible to achieve a solid surface as it was originally. Traces of damage will remain visible and in this case it is impossible to do without a complete renewal of the coating.

linoleum repair

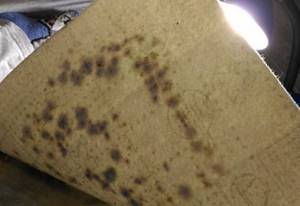

Afraid of humidity

All varieties, except linoleum on a foamed PVC base, absorb moisture. The layer creates a damp environment, favorable for mold and mildew. If an unpleasant damp smell begins to appear in the room, this may serve as a signal to renew the linoleum.

Not suitable for rooms with high humidity levels

Instability to a humid environment limits the space for installing insulated coverings. It is recommended to lay linoleum only in consistently dry rooms where the subfloor is always dry. It is not recommended to use such linoleum in kitchens, areas in front of entrance doors, dressing rooms and similar rooms.

fungus on the back of linoleum

Surface abrasion

Both insulated and regular thin linoleum are equally unsuitable for high-traffic areas. Under prolonged loads, the top layer of material quickly wears off, completely loses its visual appeal, and holes and abrasions appear. This coating is for residential use and is not suitable for offices.

Easily damaged by sharp objects

Stepping on sharp heels or pointed furniture legs can easily damage the decorative layer or, with prolonged exposure, leave deep dents. Linoleum can be cut well with sharp objects.

damaged linoleum

Afraid of chemical solvents

Conventional floor cleaning products are not harmful to the top layer, but when interacting with highly concentrated alcohol-based or gasoline-based solvents, such as building spirit or acetone, damage will occur. This property should be taken into account when cleaning and repairing work in the house.

Fire hazardous

Does not self-ignite. But when exposed to open fire, it supports combustion and releases toxic substances.

linoleum is not fire resistant

Types of warm linoleum

All insulated linoleum differs in the type of insulation layer material:

Linoleum based on PVC insulation

According to many characteristics, it is one of the best bases for insulating flooring materials.

Polyvinyl chloride is a foamed plastic with a cellular structure, to which plasticizers and additives can be added, depending on the purpose of the material. This is the basis of a large number of modern building materials and is used primarily to enhance thermal insulation properties.

- A distinctive feature of the material is its absolute resistance to moisture.

- Elasticity and resilience. A high-quality coating that can restore its flatness after prolonged exposure to heavy pieces of furniture.

- Thickness ranges from 1.5 to 3.5 mm

- Durability, subject to operating rules, is 10 years

- Maximum temperature before deformation 27-30℃

- The fragility of the coating increases greatly when the air temperature decreases from 0℃ and below.

- Affordable price.

foamed linoleum

Felt warm linoleum

Felt is a natural textile material made from felted wool. A dense layer of felt, as an insulating material, is glued to a standard linoleum pie made from upper protective and base layers. This linoleum has a standard structure of 5-7 layers, depending on the class of material.

- Felt is an environmentally friendly material and is therefore suitable for use in residential areas.

- It is afraid of liquid because it absorbs it and, as a result, loses its rigidity. This instability to humidity contributes to the formation of fungus in the structure of the insulation, which, on the one hand, is covered with a water-repellent layer of linoleum, and on the other hand, is in direct contact with the subfloor, through which dampness can accumulate.

- Not suitable for rooms and floors with high levels of humidity, due to its instability. Such premises include kitchens, floors in front of entrance doors from the street, some floors of the first floors, the percentage of humidity of which can vary greatly.

- Soft when walking, can hide many uneven floors. Softness, on the one hand, ensures comfortable use, and on the other hand, it causes the appearance of dented areas and dents.

- Affordable cost. Unlike PVC-based materials, there is no fiberglass, which reduces the cost of felt linoleum.

- Average durability. In greenhouse conditions it will last up to 10 years without replacement.

- Thickness can be up to 5 mm

felt-based linoleum

Jute insulated linoleum

This variety received its name based on the base material, which is natural jute. Thickness can be up to 5mm, usually costing no more than 4 layers, using PVC only for the protective top film. It serves as both insulation and the basis for the rigidity of linoleum, therefore the central layer of PVC is not built into the structure of the coating.

The advantages of the type include:

- Better environmental friendliness. Unlike foamed PVC, which is a completely artificial material.

- Comfortable softness.

- A high level of thermal insulation of jute, which allows you to prevent the warm air temperature from cooling through the cold concrete of the floor for a long time, as well as retain heat from additional floor heating, if any.

- Can be mounted on any surface, except surfaces prone to accumulation of moisture and dampness.

The main disadvantage of jute linoleum is its tendency to absorb moisture and, as a result, the occurrence of bending and mold, therefore the material cannot be used in wet spots, such as the kitchen, hallways and similar locations where there is a risk of contact with dampness.

Read more about the types and structure of linoleum in the article "Linoleum." Pros and cons of linoleum. Structure and composition"

jute base

jute linoleum

How to choose warm and regular linoleum

The many varieties of linoleum can cause certain difficulties in choosing it. The difficulty lies not only in the risk of purchasing low-quality material, but also in ensuring that the selected coating matches the specific room according to key parameters. Let's look at what main points you should pay attention to.

Choosing linoleum according to the technical characteristics of the room

These parameters for linoleum include:

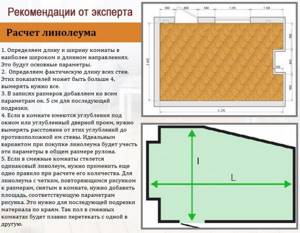

Room floor dimensions

The easiest and most beautiful way to install linoleum is as a single layer, without creating seams. The very presence of a seam is labor-intensive to work with and creates an unattractive appearance. In addition, if the surface has a specific pattern, then it becomes difficult to select the pattern at the joints. Manufacturers produce rolls with a width of 1.5 to 5 meters, so it is possible to choose the appropriate size for the average room. Before you go shopping for material, measure the perimeter of the room in overall size, length and width, along each edge of the room, taking into account the protrusions. It is recommended to add 5-10 cm to the resulting dimensions as a margin for possible measurement errors. Thus, it is possible to avoid the appearance of seams in those places where there was not enough material due to inaccurate measurements, and also to minimize the presence of waste material that will appear after trimming, shrinking and installation.

Indoor humidity and the risk of its occurrence

As noted above, it is not advisable to use insulated linoleum in areas with high humidity. If you need to use linoleum in the kitchen, hallway or bathroom, then it is better to choose a material with a foamed PVC base, without the use of natural additives such as jute and felt. PVC is the ideal solution for wet spots.

linoleum on a foamed PVC base is well suited for wet spots

Estimated load level or class of linoleum

In rooms where the traffic and load on the protective coating is insignificant, almost any class of linoleum from 22 to 32 classes is suitable. But in order to save money, it is more advisable to purchase classes from 22 -31. In areas with high traffic, it is recommended to use materials with an increased wear resistance class from 31 to 44 classes, depending on the expected load.

to avoid abrasions, it is necessary to choose a more durable class of linoleum

Properties of subfloor material and room temperature

The type and predominant base material is linoleum, and should be selected based on the floor surface with which it will interact. So, for example, if the installation will be carried out on a bare concrete screed of the first floor, with an unstable level of humidity at different times of the year, then only a moisture-resistant PVC base will be suitable. If the subfloor is always in dry conditions, with a built-in “warm floor” system, or it is a dry interfloor ceiling, then you can safely use insulated types of linoleum based on felt and jute.

The frequency of heating and the temperature range that can be in the room are also very important. For country houses where stable heating is not expected during the cold season, where the temperature level can drop to -10 ℃, it is not recommended to lay linoleum. Similarly, if the “warm floor” system is used as the main source of heating and its heating may exceed the recommended + 27, then this creates fire hazardous conditions in the house.

linoleum on heated floor

Selection according to material characteristics

All from the same batch

If you plan to lay linoleum of the same color and texture in all rooms, then it is advisable to purchase the material from one batch at once. Already in the next production line, of the same brand, the shade and even part of the pattern may differ.

Upper layer

The top layer of coating can create certain difficulties in operation. For places with a high level of pollution, especially in the kitchen, where grease can settle on the coating, in hallways at the entrance and similar places, it is better to use linoleum with a smooth surface that can be easily washed off from deposits. In such rooms, a corrugated surface can become a real problem for the owners. The corrugated texture, with a minimal level of slipping, is suitable for bedrooms and living rooms, bathrooms and toilets. It will not accumulate as much dirt and require frequent cleaning.

corrugated linoleum is not suitable for places with high pollution

Selection by thickness

To use the coating as additional insulation, you need to choose insulated varieties up to 5 mm thick, which we talk about above in the article. For protective and decorative purposes, the best option would be ordinary thin PVC linoleum.

Linoleum color

To ensure that the new flooring always pleases the owners, fits naturally into the interior, and generally suits the renovation, both in color and pattern, experiment with the material. Take a sample of the material from the store for fitting and apply it on the spot to the walls, furniture and other interior objects in the room, so you will see for sure whether the selected type of linoleum is suitable specifically for your room. On computer projects that can be offered to you for viewing in hardware stores, color, shades and patterns are rarely perceived objectively, since the level of natural light in the room and the color of the room are not taken into account.

Determining the quality of linoleum

A high-quality material should restore its shape after mechanical compression and bending, and also retain its color. However, prolonged compression may cause damage. To check the strength and quality, when choosing, bend the edge of the canvas with your fingers and release. Linoleum of satisfactory quality should regain its shape and there should be no dents left on it. In addition, there should be no white streaks that occur when stretched; the color should be restored to its original state. If the material has passed such a simple test, then you can be sure that during use there will be no dents left on it from the soles and furniture.

good quality linoleum should not leave marks after short-term compression

Docking options

Thickened commercial linoleum is laid in industrial and public buildings.

To seal the joints, a welding machine and a low-fusible connecting cord are required.

Responsible work is performed by qualified builders.

Preparation for installation

The main condition for good quality is a flat and clean base plane. On elastic polyvinyl chloride, even small roughnesses quickly appear; ruptures often occur on large convexities.

The base is leveled, primed, vacuumed

It is important to ensure that no water gets into the area.

According to the room plan, pieces of a certain shape are cut out. Then the canvases should rest and straighten.

Threshold

The length of the strip is adjusted to the width of the doorway.

Products are available in various colors. The element is placed at the joint and secured to the base with screws.

Scotch tape instead of glue

In everyday life, gluing linoleum is often done with double-sided tape.

The canvases are spread out and placed end to end. Double-sided tape is glued to the area of the floor under the joint.

After removing the protective layer, the edges are joined.

Invisible seam

This practical option is indispensable for gluing linoleum with your own hands. There are differences in how to join used linoleum and new material.

Old canvas, cut by hand, cannot always boast of neat edges. To make the seam invisible, the strips are laid overlapping each other; a joint 5-6 cm wide is formed. The patterns are carefully adjusted until they completely match.

The marking of the future seam is applied along the center line. Both elements are cut through. It is advisable to make the incision in one movement; A ruler and a utility knife will help with this.

For protection, the surface should be sealed with wide masking tape; An incision is made along the seam line. Through a needle nozzle, the adhesive is gradually squeezed into a narrow gap. To prevent the mixture from dripping, keep a swab under the tip. The height of the roller should not exceed 4 mm. For a detailed description of the process, watch this video:

The joint dries within 10-15 minutes. Removing the hardened excess completes the process. The transparent, almost invisible joint is flawless - the canvas looks like a continuous carpet.

Sometimes seams decorate the interior. Talented craftsmen manage to emphasize the elegant patterns on the floor with contrasting shades. There is a composition that can glow at night.

How to choose linoleum for heated floors

To correctly select the types of linoleum suitable for any underfloor heating system, the recommendations below can help, which are based on the beneficial combination of the properties of linoleum and the heating system itself.

Warm floor heating temperature

For any floor covering, the heating temperature of the TP system should not exceed 30 ℃. The temperature limits of the material should always be indicated on the packaging. When heated above the recommended temperature, toxic substances may be released that are harmful to health. In addition, floor temperatures above 30℃ may cause discomfort to people indoors and are therefore set by international standards.

The underfloor heating system must be recessed into the screed to a depth in accordance with the installation technology.

Often, unskilled specialists or employees of one-day construction companies neglect the requirements of GOST, due to saving material or as a result of ordinary negligence. As a result, the heating temperature is not evenly distributed over the finishing floor covering (in our case it is linoleum), overheating, deformation and damage to the material occurs, such errors increase the fire hazard in the room.

the underfloor heating system must be built into the screed

Linoleum thickness

Thin linoleum, up to 2 mm thick, is recommended to be installed if the TP system will be used as the main and constant source of heating. In this case, the thermal conductivity of the material will allow the room to heat up faster and better allow warm air to pass into the room. At the same time, heating costs are reduced.

It should be noted that the manufacturer defines the underfloor heating system as an additional, auxiliary heating source to create a comfortable floor temperature, but not for operation as the main heating.

Thick linoleum, plus or minus 5 mm thick, is more suitable for rooms where the heated floor system is rarely used, as an additional source of heating in severe frosts. Such linoleum will take longer to heat up, but will also retain heat better. The disadvantage of this solution is the increased heating costs, since the thickened linoleum takes longer to warm up the room. However, in conditions of not constant use of TP, such consumption is effective.

installation of linoleum on IR heated floor

Linoleum insulation material

The material used in linoleum as insulation is not particularly important. You need to focus on humidity, subflooring and others. The main criterion for choosing a fabric for installation on top of a warm floor is its thickness, since linoleum is made from any material, both thick and thin.

Installation on a water heated floor

In practice, linoleum can be used on all types of TP construction, but it only fits well with a water-based system. In this case, the floor gradually heats up and also cools down slowly; the flooring material has time to adapt to smooth temperature changes and is least susceptible to deformation. When installed on an electric TP, the linoleum heats up unevenly and there is a high risk of delamination and swelling. Only porcelain tiles are suitable for any TP. Read more about the properties of porcelain tiles in the article “Porcelain tiles in repair. Types of porcelain tiles, pros and cons »

linoleum is best suited for water TP

The choice of the type of insulated linoleum directly depends on the properties of the room, the characteristics of the subfloor (floor), the presence or absence of heating systems built into the screed, the level of humidity in the room, the frequency of heating and, in general, the purpose of the room. Therefore, before you start choosing a floor covering, you should determine exactly what efficiency you want to get from the material and what technical properties of the room the linoleum should be combined with.

Linoleum in the nursery

About the need for vapor barrier

Many people do not know why a vapor barrier is needed when installing floor coverings with insulation. The fact is that water vapor, which is released during wet cleaning or cooking, tries to seep through the walls and floors of rooms, while it negatively affects various wooden structures, such as joists. Due to temperature differences in adjacent rooms or inside and outside the building, steam turns into condensation. Subsequently, water seeps into the wood structure and causes its destruction.

The walls of a wooden house, as well as the roof, are protected from moisture by antiseptic or waterproofing impregnation, which cannot be said about the floor elements. To protect the logs, a vapor barrier film is used, which protects not only the wood, but also the insulation, for example, mineral wool, from destruction. In this case, the vapor barrier allows the building to breathe. That is, air saturated with water will freely pass through thermal insulation and wood products.