No heating system can work effectively in a house with poor thermal insulation. You can only dream of energy savings in winter and comfortable temperatures in summer. If you are not satisfied with this state of affairs, there can be only one way out - to buy Izovol brand insulation and carry out proper insulation of all structures.

What's good about Isobel?

Choosing insulation is not an easy question. There are many different offers on the market, but basalt wool is the leader in all respects. Although it represents an average price category on the market, its performance properties are simply excellent. And if you want to get decent quality at a minimal price, you should turn to domestic materials. For example, reviews of Izovol products note precisely these two advantages of Russian insulation materials.

The manufacturer himself, in the description of his products, emphasizes the environmental friendliness and special properties of the mineral wool he produces. Basalt fibers undergo heat treatment not in furnaces, but in hot gas chambers, as a result, the rock melts without the participation of foreign impurities. The amount of impregnation applied to the finished slabs is also reduced to a minimum. This approach has led to the fact that the technical characteristics of the insulation have changed noticeably:

1. Sound absorption rates have improved due to the random arrangement of threads. For those who are built next to a busy highway or live in a panel building with good audibility, this is a tangible plus.

2. The water absorption of the fibers themselves decreased to 0.5-1.5%. That is, almost all the moisture that gets into the Isobel thermal insulation is not retained inside, but is removed through the air pores.

3. The environmental friendliness of mineral wool has also expanded the scope of its application. And although external insulation is in any case more effective, Izovol can be safely used for interior work.

4. Very high acidity module, exceeding 2 units. This characteristic indicates the excellent resistance of basalt fibers to aggressive substances and determines their durability. For comparison, a module of at least 1.4 is considered the norm.

The few negative reviews about Izovol insulation only note the low strength of its edges. After a short time, they collapse and gaps appear at the joints, reducing the effectiveness of the thermal insulation layer. Perhaps the manufacturer should pay attention to the technologies of competitors that have gotten rid of this drawback. In the meantime, buyers can only solve this problem in one way - use a two-layer installation with offset seams.

An example of using Isobel slabs

Instructions for using this material for thermal insulation of pitched roofs are presented in the table:

| Illustration | Stage of work |

| Preparing the stingrays. When installed on the inside of slopes, Isobel thermal insulation boards must be protected from precipitation. To do this, a waterproofing, vapor-permeable membrane is mounted on top of the rafters. | |

| Laying the first row of slabs. We lay the slabs between the rafters without gaps. Fixation is carried out either using stretched nylon threads, or due to the elasticity of the edges of the panels. | |

| Laying the second row of slabs. For more effective thermal insulation, it is advisable to install the slabs in two layers. We lay the second layer of insulation on top of the first in such a way that the joints in the rows do not coincide. | |

| Vapor barrier. On the inside of the roof we cover Isobel with a vapor barrier membrane, which will protect the basalt wool from getting wet. | |

| Sheathing. On top of the vapor barrier on the rafters we fill the cross bars of the counter-lattice. We attach sheathing made of plasterboard, plywood, lining, etc. to the counter-lattice. |

This is what the roof slopes look like after installing a vapor barrier immediately before the sheathing

When thermally insulating partitions and horizontal surfaces, the material is installed according to a similar scheme. The main thing is to ensure protection from moisture and compaction!

Features of insulation

The area of use of isobel is reducing the thermal conductivity of buildings for various purposes. In the production of insulation, EcoSafe technology is used, which reduces the amount of moisture absorbed by the material. Izobel slabs are a type of basalt wool (material with the lowest thermal conductivity coefficient) and are manufactured without the use of blast furnace slag. Usually the insulation has a standard size (1000×600 mm, 1000×1000 mm, etc.).

Isobel can be produced not only from heavy basalt rocks, but also from lighter ones such as limestone or quartzite.

The resulting slabs weigh less and do not hold heat as well, but their density is higher, which affects durability. Similar izobel is used for cladding areas of the house where thermal insulation does not play a special role, but fire resistance and noise absorption are much more important (non-residential attics, ceilings, pitched roofs).

Advantages of insulation

Mineral wool would not have become so popular among consumers if it did not have a number of advantages. In relation to Izobel brand insulation, the qualities listed below are considered as such.

- Excellent thermal conductivity - coefficient from 0.03 to 0.04 - one of the smallest among insulation materials. If we add to this the thinness and elasticity of basalt fibers, we get an almost ideal material that allows us to significantly save on heating the room.

- Fire resistance - isobel belongs to group IV of fire safety materials. If there is a fire source nearby, its physical and chemical properties will remain unchanged; the slabs will also become a barrier to the spreading fire.

- Long service life - insulation made from basalt stone lasts at least 50 years if storage conditions are met. Excess liquid will not affect the material in any way - the fibrous structure will easily allow steam to pass through and condensate to evaporate.

- Weak water absorption - basalt is non-hygroscopic; only 1.5% of its volume can be filled with moisture. If water-repellent additives are used in production, the value is reduced to 1%.

- Good vapor permeability - achieved by the fibrous structure of the material and promotes the use of isobel in baths, saunas or industrial premises.

- Sound insulation - depending on the thickness of the slab, they completely or partially neutralize extraneous noise.

- Resistant to corrosion, fungi, rodents, unattractive to birds.

- Affordable price - isobel costs on average 15% cheaper than mineral wool analogues; for a slab of 1 sq. m and a thickness of 50 mm, the consumer will pay from 100 to 300 rubles.

- Environmental safety - achieved by a minimum amount of chemical components used to increase water repellency, and this is not always the case.

The above is only part of the positive aspects of izobel insulation. Other benefits are easier to feel during operation rather than described.

Production of izobel insulation

The basis for the production of fibers is basalt. Izobel insulation is produced in this way:

- The stone is crushed and melted at a temperature of 1200°C to form lava.

- Special machines blow threads out of it using directed air flows, which are collected into bundles.

- The fibers are impregnated with oil, which guarantees water resistance.

- Press to the desired thickness and cut.

- Quality checked and packaged.

The fibers have a diameter of 2 to 7 microns, they are intertwined and bonded with formaldehyde resins.

Group No. 1. General building thermal insulation

It includes many types of insulation; for the convenience of users, all technical characteristics are presented in table form.

| Name | Dimensions, LxWxT | Packaging volume, m3 | Vapor permeability, mg/M*h*Pa | Thermal conductivity, measured in W/(m*k) |

| Light | 100x60x4-25 centimeters | 0,24 | 0,3 | 0,035 |

| "Protection from noise" | 100x60x4-25 centimeters | 0,24 | 0,3 | 0,035 |

| Isobel | 100x60x5-10 centimeters | — | 0,3 | 0,036 |

| Isobel Light | 100x60x7.5-10 centimeters | 0,24-0,27 | 0,3 | 0,036 |

| L-35 | 100x60x4-25 centimeters | 0,24 | 0,3 | — |

| ST-50 | 100x60x4-25 centimeters | 0,24 | 0,3 | — |

| ST-60 | 100x60x4-25 centimeters | 0,24 | 0.3 | — |

| ST-75 | 100x60x4-25 centimeters | — | — | — |

| ST-90 | 100x60x4-25 centimeters | — | — | — |

| B-50 | 100x60x4-25 centimeters | — | 0,3 | 0,035 |

| B-75 | 100x60x4-25 centimeters | — | — | — |

| B-90 | 100x60x4-25 centimeters | — | — | — |

| F-100 | 100x60x4-25 centimeters | — | — | — |

| F-120 | 100x60x4-25 centimeters | — | — | — |

| F-150 | 100x60x3-10 centimeters | — | — | — |

| K-100 | 120x100x4-25 centimeters | — | 0,3 | — |

| K-120 | 120x100x4-20 centimeters | — | 0,3 | — |

| KV-150 | 120x100x3-18 centimeters | — | 0,3 | — |

| KV-175 | 120x100x3-12 centimeters | — | 0,3 | — |

| KV-200 | 120x100x3-10 centimeters | — | 0,3 | — |

| P-100 | 100x60x4-25 centimeters | — | 0,3 | — |

| P-175 | 100x60x3-12 centimeters | — | 0,3 | — |

Note! The above-mentioned “Noise Protection” is an insulation that also has excellent noise insulation characteristics. Izovol insulation comes in other types, let’s take a look at them

Wide range and scope of Izovol thermal insulation

To meet the needs of professional developers, the IZOVOL brand produces a wide range of universal materials and highly specialized products for insulation, sound insulation, and increasing the fire resistance of the following types of structures:

- roofs – pitched, flat, single- and multi-layer, inversion, serviceable – marking IZOVOL K, KV;

- walls - facade plaster and ventilated, internal partitions, external walls with well, layered masonry - products are designated F, V, ST;

- basements, ground floors, “floating” floors of increased acoustic comfort - insulation with the designation P;

- air ducts, chimneys, pipelines - insulation with the designation L;

- engineering and technological equipment - thermal insulation marked L, ST.

Izovol hydrophobized fiber boards ensure heat retention indoors, normalize humidity, and increase the service life of load-bearing structures.

IZOVOL insulation products are produced in various densities, with one-sided fiberglass coating, with a combined structure that combines a reinforced top layer for plaster finishing, with increased rigidity.

Features of isobel installation

Due to its ease of use, insulation is used almost everywhere. Thermal insulation with its help will be justified in the following places:

- partitions between floors;

- floor;

- roofs with a slope;

- attics;

- walls.

Like any other mineral wool, insulation requires two additional layers - hydro- and vapor barrier. The first protects the slabs from getting wet from the outside, the second - from the inside. When installing isobel on a sloping roof, it is recommended to create an air gap, the purpose of which is to remove accumulated condensate.

The key difference between isobel as mineral wool and polystyrene foam is that it is not mounted directly to the wall with glue, but is placed inside cells formed by a wooden sheathing. The advantage of this need is additional strengthening of the building frame, the disadvantage is financial investment.

Reviews about Isobel insulation

Isobel is an economical insulation material.

If the insulation is used for its intended purpose, then there are no complaints from users. So, Isobel is perfect for insulating horizontal floors. In this case, the density of the material is not of key importance, since the thermal insulation is not affected by high mechanical loads. The only thing that can be a problem is the accumulation of moisture in the thermal insulation, but this is not caused by the quality of the insulation, but by improper installation of the vapor barrier. The same problem is encountered when insulating a roof with mineral wool. If you position the vapor barrier and waterproofing incorrectly or forget to leave a ventilation gap, the insulation will be wet.

Negative reviews about Izobel thermal insulation can be found from those who have used the material to insulate walls. The complaints are caused by shrinkage, which is inevitable when soft fiber insulation is installed incorrectly. What to do to prevent Isobel from shrinking:

- install horizontal support bars every 2-3 meters;

- glue each slab to the wall;

- fasten the slabs with mushroom dowels.

And remember the requirements for insulation density for different types of work. For example, only material with a density of 55 kg/m is suitable for walls. cube or more. When using lighter materials, you need to resort to one of the above methods to prevent shrinkage during operation.

Thermal insulation IZOVOL

The Izovol company produces building materials for a comprehensive solution to problems (heat, sound, fire) insulation. Izovol brand insulation is used in systems, structures and structures for various purposes, and is also used for the reconstruction of buildings. Izovol technologies are successfully used in medicine, energy and mechanical engineering, which makes the company the absolute leader in its industry.

Izovol products are distinguished by an incomparably high level of quality. It is possible to maintain a consistently high level of production at the enterprise thanks to the availability of modern technology and experienced specialists who control the quality of goods at every stage of production.

The latest technologies, developed by the best specialists of the IZOVOL laboratory, reduce the risk of defects and defects, therefore the company gives its customers a guarantee for each product.

Another of the main principles of Izovol is the production of environmentally friendly insulation that is safe for human health. The underlying material is pure basalt fiber, so when choosing Izovol, you can be sure that you will not harm yourself.

IZOVOL is proud of its innovations and values every customer

The plant management is confident that a responsible attitude to production combined with attention to the Consumer guarantees the success of any product

Characteristics of Izovol insulation

Thermal insulation of walls is a guarantee not only of insulation of external walls, but also of sound insulation and fire resistance. Insulation for external walls is produced using environmentally friendly fiber technology - ECOSAFE, which is why Izovol thermal insulation is used in residential construction. Isovol material density helps to reliably isolate walls from external noise and drafts.

Which insulation is better - Izovol insulation

On the website of TD SSKomplekt we offer you to get acquainted with the best Izovol insulation products:

| Izovol 35; |

| Izovol 75 (Izovol st 75); |

| Izovol 50; |

| Izovol 90; |

| Izovol 100 (Izovol 120 f); |

| Izovol 150; |

| Izovol acoustic. |

It is worth noting that Izovol mineral wool is a certified and high-quality building material that does not cause harm or damage to health. The thickness of Izovol insulation guarantees protection from external influences. Thermal insulation of the facade is necessary in residential construction. Thermal insulation is suitable for insulation of interfloor ceilings, rooms with high humidity and insulation of basement floors.

Izovol insulation for the house outside has a warranty period and will not upset the owner of the house. The calculation of thermal insulation quantities for a construction site is carried out by architects and technologists when planning a building project. Thermal insulation of the roof is necessary for insulating frame walls and ceilings between floors.

Buy wall insulation Izovol

You can always buy Izovol insulation inexpensively at the StroySitiKomplekt trading house.” The official Izovol dealer is ready to provide you not only with a guarantee from the manufacturer and all the necessary documents, but also to offer a favorable price for insulation. Order insulation from StroySitiKomplekt by calling the number listed on our website and receive a free consultation and cost estimate from our managers.

Description of benefits

Isobel is positioned on the building materials market as an economy class insulation material. And indeed its price is lower than that of its competitors. According to its technical parameters, the products belong to soft insulation materials, which means a rigid frame or substrate.

The main advantages are:

- Low thermal conductivity . For example, 10 cm of Isobel retain heat as well as a brick wall 2 bricks thick;

- Long-term operation . The durability of the material is explained by the properties of basalt chips and threads included in the base;

- Non-flammability . The material is non-flammable due to the fire resistance of the constituent substance;

- Good sound insulation;

- Vapor permeability;

- Environmental friendliness of insulation;

- Does not allow moisture to pass through;

- Chemical and biological resistance ; Isobel is not susceptible to acids and other aggressive environments, as well as damage from mold and rodents.

Let's take a closer look at the most important advantages of the material.

Thermal conductivity

Various types of insulation materials

Low thermal conductivity is the main quality of this insulation. Thanks to the use of such material, it is possible to significantly lighten the structure of both walls and roofs. Due to its low thermal conductivity coefficient, the material is widely used in the insulation of frame houses.

Comparative diagram of thermal conductivity

Environmental Safety

Recently, more and more attention has been paid to the environmental component. When choosing a material today, first of all, they pay attention to the main physical and chemical indicators, then to the ecology and then to the cost.

And this is a good trend. The environmental safety of Isobel is explained by the use of natural materials in its composition, such as fibers from mineral basalt chips.

People's opinions

“I always thought Parok was the ideal insulation material until I talked to my neighbor in the country. It turns out that three years ago he mortgaged the entire house with Isobel and was pleased with the result. The temperature in the house in winter became much higher, and during this time the insulation itself did not lose any of its volume (at least where we were able to look under the cladding). I decided to buy one for myself – the material is really excellent.”

Maxim Medvedev, Moscow.

“To be honest, at first we were afraid to take Isobel - the brand is not particularly well-known, and there were no reviews about it. But the price turned out to be too attractive, so we took mineral wool for trial to insulate the outbuilding. With the onset of cold weather, the basalt thermal insulation showed itself to be excellent, the characteristics corresponded to the declared ones, and removal of the cladding after a year did not reveal any unpleasant surprises. Now we will only use Isobel.”

Andrey, Voronezh.

“I liked the new insulation in my work: it holds volume well, is easy to install, and the price, frankly speaking, is attractive. Of the minuses, I would mention the poor packaging - bulky and not very durable. It also turned out to be difficult to unravel the sheets lengthwise: even a sharp knife does not cut, but crushes the fibers. But across the blade, it cuts through basalt Isobel just perfectly.”

Grigory Miroshkin, St. Petersburg.

“I read good reviews about Isobel slabs, which supposedly do not produce allergenic dust, and bought them to insulate the ceiling. It turned out that they generated dust no worse than glass wool - although I worked in overalls, gloves and goggles, and then itched and coughed for a couple of days. Now I’ll think about how to close it from below more securely so that all this trash doesn’t fly into the rooms.”

Yuri, Belgorod.

https://youtube.com/watch?v=eTi68WouryQ

Price

| Insulation | Thickness, mm | Price, rubles |

| Isobel L-25 | 50 | 260 |

| Isobel L-35 | 100 | 295 |

| Isobel Light | 50 | 350 |

| St-50 | 100 | 460 |

| KV-150 | 100 | 680 |

| K-100 | 50 | 750 |

| P-100 | 40 | 790 |

| F-150 | 60 | 880 |

Installation

The slabs can be installed independently. As an example, consider the protection of the pitched roof of a private house. The day before you should prepare all the necessary equipment and the plates themselves. When working we will need a tape measure, a knife, a stapler, bars and plastic film

It is also important to prepare the surface itself. The roof is checked for leaks, rot and other defects

They must be eliminated before insulation work begins, otherwise the thermal insulation may be seriously damaged.

After the necessary work is completed, a lathing made of wooden blocks is nailed to the roof rafters. The recommended cross-section of the components is 4*4 cm. The lathing creates a gap between the roof surface and the heat insulator, preventing condensation from penetrating into the room.

Installation of slabs

At the next stage, the installation of insulation boards is carried out. They are placed on bars between the rafters. They are fastened together with a construction stapler. To hide the seams, cover them with double-sided tape. All that remains is to lay a layer of vapor barrier. Polyethylene or other similar material may be useful.

The process ends with finishing. The insulation is covered with the selected finishing material, for example, plasterboard.

Areas of use of Izovol heat insulator

The described type of insulation is widely used not only in private, but also in industrial construction. And it’s not surprising, because basalt wool is the best option for the following structures.

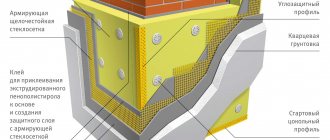

- Facades of buildings with one or several floors (including under “wet” plaster).

- Pipelines, ventilation channels.

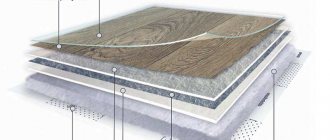

- Joists in the floor and, if the mineral wool used is characterized by increased density, under a concrete screed.

- Industrial equipment, various types of production lines.

- Pediments and attics (in this case, insulation can be done both from the inside and outside).

- Garages, verandas, agricultural facilities.

- Roofs (pitched and straight).

- Ceilings and walls (material is laid from the inside).

Characteristics and parameters

Currently, manufacturers offer isovol in mats and rolls. As mentioned above, this is basalt wool, which is made by melting and drawing threads from the molten stone mass. It is the fibrous structure that creates the possibility of the formation of air capsules between the threads, and this, in turn, is the most powerful thermal insulation.

The production of isovol is modern; high-tech equipment and high-quality raw materials are used here, so the technical characteristics of the material can be classified as “high”. Let us add that this technology is patented and has an international quality certificate ISO9001:2000 No. 41060. Domestic can be considered a leader in this area.

Heat map of Izovol insulation use

Advantages of insulation

- Isovol TechnoNIKOL mineral wool insulation made from natural materials is environmentally friendly. It is harmless to human health and life. It is distinguished by:

- High fire-fighting properties. The insulation begins to melt at a temperature of +1110C. These are irreplaceable qualities for modern construction.

- Basalt fibers inside the material are arranged randomly, which is why isovol has high sound-absorbing properties. This is another huge plus.

- High coefficient of vapor permeability. If we compare this indicator with other heat insulators, then isovol can give many a head start.

- This insulation is not spoiled by rodents, bugs and other small insects do not grow here, mold and fungi do not multiply in it. TechnoNIKOL insulation laid on a metal surface protects it from the negative effects of moisture, which means that there is no corrosion of metals under the insulation.

- During operation, mineral wool heat insulator does not lose its shape, size and quality.

- Long service life, which depends on the degree of water absorption. It makes up only 1% of the total.

- Quite high thermal performance indicators, which we will discuss below.

The material is environmentally friendly Has fire-fighting properties Durability meets standards

A table with technical characteristics will definitely be presented, but I would like to make a comparison with other building materials.

TechnoNIKOL isovol with a thickness of 100 mm and a density of 100 kg/m³ can replace:

- wood 225 mm thick;

- ordinary brickwork – 1600 mm;

- silicate brick masonry – 2000 mm.

Flaws

This thermal insulation material has one drawback - its high price. But it is compensated by a huge number of advantages. So it makes sense to take a closer look at it.

Opinions

Thus, most consumers rate Isobel highly. They confirm the above benefits. Insulation pays for itself in a few months due to reduced utility costs during the heating season. In addition, buyers are attracted by the absence of dampness and other unpleasant factors.

Isobel became popular due to its price. 1 m2 costs about 100 rubles, which is significantly lower than analogues. Moreover, it will be more durable. If, for example, ecowool retains its properties for 25 years, then the service life of Isobel by the manufacturer is at least 50 years - this is the average service life of a wooden house.

Opponents of this insulation consider covering the surface of structural elements of buildings with this type of mineral wool to be irrational due to inefficiency and lack of aesthetics. Experts explain that insulation shows poor results if the surface was not thoroughly prepared before starting work or gross violations were committed at subsequent stages.

The plant's products include the following slabs:

IZOVOL “Noise Protection” - designed for sound insulation of rooms and buildings, the slabs have a size of 1000x600 mm, thickness from 40 to 250 mm, in increments of 10 mm. Has a flammability group - NG

IZOBEL (ISOBEL) - the lightest slabs, with a density of 25 kg/m3, used for thermal insulation of non-loaded structures (partitions, floors with joists, interfloor ceilings)

IZOVOL slabs, general building thermal insulation of higher densities, the names are quite short, but it’s not difficult to understand by the name where the slab is used

Izovol L-35 - light, non-loadable structures

Insulation of external walls under ventilated facades

- Izovol St-50 - density 50

- Izovol St-60 - density 60

- Izovol St-75 - density 75

- Izovol St-90 - density 90

Mineral wool laminated with canvas, as an outer layer of insulation in ventilated facades

- Isovol B-50 - density 50

- Izovol V-75 - density 75

- Izovol V-90 - density 90

Insulation under a plaster facade (see article)

Insulation of flat roofs

- Izovol K-100

- Izovol K-120

- Izovol K-150

- Izovol K-175

The top layer of thermal insulation in flat roofs (KV - roof top)

Izovol produces the following types of insulating materials:

- General construction thermal insulation

- Soundproofing

- Technical thermal insulation

- Fire protection

- Thermal insulation for sandwich panels

Facilities where the plant's products were used. These are mainly the central regions and southern Russia, this is due to the location of the plant.

Not a single new building will last even ten years if it was built without the use of thermal insulation materials. Thanks to them, maximum heat savings are achieved, the absence of drafts and “cold bridges” inside the walls, and the service life declared by the manufacturers allows you to forget about major repairs of the building for decades.

Short description

The raw material for the manufacture of all modifications of this brand of heat-insulating material is basalt fiber. The main difference between the samples is only in density, which affects the individual characteristics of Isovol. In fact, this is a more modern analogue of the well-known and widely used mineral wool for various objects.

Products are categorized by density, product design and specific application.

1. Geometry.

- Plates. They are used, as a rule, when insulating flat surfaces in small areas, or when finishing walls with the installation of sheathing.

- Cylinders. Izovol insulation products greatly facilitate the work of thermal insulation of pipe lines.

- Rolls. It is advisable to use them for insulation where the formation of numerous joints is either undesirable or is associated with the difficulty of sealing them. Rolled Izovol is available in different densities and thicknesses, so you can buy the best option, especially since the variation in cost is insignificant.

2. Features of insulation.

Some samples have a reflective surface. It is advisable to use Izovol with foil for internal insulation of baths (saunas), as well as in cases where the building material does not have high thermal insulation properties, for example, concrete, brick.

3. Density Izovol.

This characteristic (kg/m3) varies from 20 to 100. It is indicated in the marking after the letter designations, which have their own interpretation.

For example, Izovol L 25 is a relatively lightweight insulation material and is used for finishing structures that are not intended for increased loads

If you want to buy an insulator that is both universal and at a low price, you should pay attention to Izovol (tile) L 35. But it contains synthetic additives, and this must be taken into account

Better insulation is provided by a material based on ultrafine fibers - Izovol ST-50. According to reviews from those who purchased this type of product, it is good for finishing ceilings, floors, and basement walls. Izovol with a density of 50 is excellent for thermal insulation of brickwork (so-called layered when installed between courses). There are enough application options.

Properties and technical characteristics of insulation:

- Standard dimensions (mm): length – 1000, width – 600, thickness – within 40-250.

- Density (kg/m3) – from 20 (for Isobel) and 35 (for Izovol).

- Low water absorption. Even under conditions of complete immersion, it absorbs no more than 1.5% moisture.

- Flammability class - NG.

- Thermal conductivity (W/(m*k)) – 0.035. Judging by the reviews, this is one of the most effective insulators.

- Good sound insulation (this characteristic depends on the density of the material).

- Vapor permeability (mg/m*K*Pa) – not less than 0.3.

Disadvantages of thermal insulation material

Alas, even isobel is not without its drawbacks, although there are not many of them. These include:

- the possibility of loss of thermal insulation properties in the places where the plates are joined or in the area of contact with the sheathing (the joint is not sealed with sealant or foam, like polystyrene foam);

- an additional waterproofing layer is required, since if there is direct contact with water, the slab will swell and cease to be useful;

- a sheathing of a certain size is required (according to the dimensions of the izobel insulation boards);

- the process is complicated by the use of a mask, gloves and clothing covering the skin; otherwise, small particles falling off the slab will land on the skin, causing allergies or scabies.

Despite the minor disadvantages of isobel, the material is still recommended for use in almost any room. It is available, it is easy to cover an area of the house with it, and the next replacement of insulation, if the installation technology is followed, will not have to be done earlier than in 50 years. When purchasing the material, the consumer will save a good amount, and during operation he will be convinced of the right choice.

IZOVOL L-35

IZOVOL L-35 slabs are made of mineral wool, consisting of basalt fiber and a synthetic binder, and are widely used in non-load-bearing structures: pitched roofs, attic floors, internal partitions, floors with all types of coating on load-bearing joists, ventilation and heating, technological equipment.

Insulation and soundproofing of attic rooms

The lightness and compactness of Izovol L-35 slabs attracts finishers to insulate the attic space and soundproof attic partitions. The slabs have high strength, vapor permeability (which is an important point when insulating attics) and excellent sound absorption ability.

Use for insulation of pitched roofs

The ideal ratio of size and density, as well as the convenient geometric shape of Izovol L-35 slabs are the main criteria in favor of using this material for insulating a pitched roof structure. The material does not load the sheathing, is easy to install and perfectly performs its heat and sound insulation functions.

Features of production technology

Izovol's product range includes basalt insulation materials - slabs, rolls, foil mats

Izovol insulation is made from mountain basalt rocks. Modern equipment that meets state standards is used for production. First, the rock is melted to a liquid state in gas melting furnaces, which ensures the high quality of the resulting material.

The fibers undergo a centrifugation and blowing procedure, which makes it possible to achieve the correct shape of the insulation and its uniform density over the entire area. Air gaps remain between them, so the appearance of cold bridges is excluded. Mineral wool feels soft, hard or semi-hard to the touch. The material production process is fully automated.

Characteristics of ISOROK insulation

Thermal insulation products of ISOROC are well known among construction companies. ISOROC insulation: technical characteristics are as follows:

Increased resistance to high temperatures and fire

Thermal insulation protection is provided thanks to a large number of air bubbles, which serve as an impenetrable barrier to the cold. This allows the material to minimize heat loss.

Good water-repellent properties

IZOROC products, in comparison with other materials for organizing a thermal insulation layer, which, as a rule, lose their characteristics when exposed to moisture, perfectly resist the penetration of moisture into the insulation. Even if moisture enters, the material, after drying, again resumes its properties.

Resistance to deformation and mechanical damage

The thermal insulation layer ISOROK has high stability and strength under compression and loads. Thanks to this, the material retains its thermal insulation properties for many years.

High degree of sound insulation

A very important indicator is the fact that ISOROK insulation, reviews of which can be read on our website, is a good soundproofing barrier. The structure of the material is represented by a uniform arrangement of fibers, due to which sound waves are delayed.

The insulation uses fibers of different lengths, which provides more effective absorption of sound vibrations at different latitudes. Due to this indicator, it is used as a filler in plasterboard partitions.

Environmental friendliness

ISOROC products are made from natural stone using environmentally friendly technologies and materials, which ensures indoor security.

High quality bonding elements

The granular structure of the material allows it not to trap vapors inside the insulation, so moisture does not collect and remains in it. Therefore, such walls are well ventilated, do not “bloom” and are not covered with fungus.

See more on this topic on our website:

- ISOBEL insulation technical characteristics and reviews from home owners ISOBEL insulation is a new productive material that is produced using innovative technologies using the latest foreign-made equipment. It is created on the basis of mountain basalt rocks. ISOBEL insulation,…

- Knauf insulation - technical characteristics of insulation Insulation materials are used both in the construction of private houses and in the construction of multi-story skyscrapers. Compared to the thermal conductivity of brickwork, the thermal conductivity of modern insulation is 18 times...

- URSA insulation technical characteristics of home insulation Thermal insulation material called URSA is considered to be a very good product for insulating houses. It is so popular that it is used not only for traditional wall insulation and…

- TECHNONICOL insulation - technical characteristics of sheet insulation Most owners of private houses in the winter season prefer that the room always maintain an optimally comfortable temperature, that there is no dampness and moisture, and also that…

- ISOVOL as insulation - technical characteristics and reviews ISOVOL insulation is one of the recent discoveries in the market for modern generation building materials. ISOVOL insulation, the technical characteristics of which indicate high thermal insulation performance, is intended for…

Technical characteristics of Izobel thermal insulation

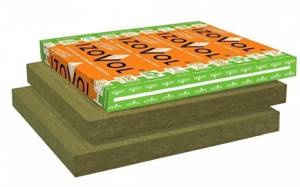

In the red package, the mineral wool density is 35 kg/m. cube

In principle, Isobel insulation is practically no different in technical characteristics from any other basalt thermal insulation. Despite the desires of each manufacturer to somehow distinguish their product from many competitors, the essence remains the same and Izobel insulation is no exception. The only thing that distinguishes it is its low price.

The cost of any stone wool depends on its density. Izobel thermal insulation in green packaging is the cheapest, as its density is only 25 kg/m. cube But Isobel P 75 has a density of 35 kg/m. cube, it comes in red packaging and is more expensive.

Isobel insulation, characteristics:

- flammability degree NG - does not burn;

- humidity of the supplied material (from its own weight) – 0.5%;

- ability to pass steam – 0.3 mg/m*h*Pa;

- thermal conductivity lambda – 0.036 W/m*K;

- moisture absorption - 1.5% per day when completely immersed in water.

The dimensions of the slabs for all Izobel thermal insulation lines are standard and are 1000x600 mm. Insulation with a density of 25 kg/m. cube (in green packaging) is available in thicknesses of 50, 75 and 100 mm, and the material has a density of 35 kg/m. cube (in red packaging) – only 50 mm.

Thermal insulation is only suitable for interior work. The lathing is needed so that Isobel does not sag under its own weight. According to the standard, when installing light basalt wool on the sheathing, horizontal strips are installed every 3 m. In this case, the laying step can be reduced to 2 m.

Despite the fact that the material is treated with water-repellent compounds during the production process, it still needs to be protected from moisture using films. For different types of work, waterproofing and vapor barrier are used. We described how to properly install waterproofing in one of the previous articles.

Conclusion

Despite the fact that the market for thermal insulation materials is rich, it is difficult to find the insulation that would fully satisfy the buyer’s requirements.

Negative reviews about Isobel brand insulation concern only the low strength of the edges of the sheets, which is why gaps may appear at the joints. To ensure that the thermal insulation is not compromised, laying in 2 layers is done with offset joints. Homes are insulated once for many years, so it is important to study market offers, calculate the required amount of materials and be able to work with them.

What types of Izovol are there?

Each type of insulation has its own characteristics and dimensions. The following describes the parameters of the most commonly used models.

Isobel

The density of such slabs is 25 kg/m3, in some models - 20 kg/m3. They are used on non-loaded inclined structures and on horizontal surfaces (floors on joists). At full immersion, volumetric water absorption is 1.5% and thermal conductivity is 0.036 W/mK.

Izovol ST

The mats are made from thin basalt fibers. They vary in their density. There are models with rates of 50, 60, 75 and 90 kg/m3. Water absorption of this material is up to 1%.

It is used for floors, sloping roofs and interior partitions. All insulation dimensions are indicated on the manufacturer’s website. This model has dimensions 100*60 cm.

Different thickness of insulation

Isovol B

This model is specially designed for insulation of ventilated facades and is finished with fiberglass. It contains a protective layer that prevents the basalt wool from being blown out and plays the role of wind protection. The density of this material is 50, 75 or 90 kg/m3. In addition to thermal insulation, it provides sound insulation and fire safety. Like all other types of Izovol, it has a flammability class of NG, that is, not flammable.

Plaster facades

Izovol F

It is used as a heat-insulating layer in façade systems with a plaster layer, and as fire-resistant cuts in structures using expanded polystyrene. The thickness of the material ranges from 4 to 25 cm. Isovol F has dimensions of 100*60 cm. The slabs are produced with a density of 100 to 150 kg/m3. They have high strength, water absorption at full immersion is 1% and thermal conductivity is 0.036-0.040 W/m K.

Izovol K

This model is used for insulating flat roofs, as a filler in reinforced concrete wall panels. One option for roof insulation is a two-layer system. If the first layer has a thickness of 10 cm or more, in this case it is best to use Isovol K. It is best to choose Izovol KV as the top layer.

A distinctive feature of this insulation is its almost square size: 100*120 cm - you can quickly cover large areas. This material has a density from 100 to 175 kg/m3. The thickness of the slabs ranges from 4 to 25 cm.

Thermal insulation of flat roofs

Izovol KV

Such slabs are used in single-layer and two-layer roof insulation systems. In the second option, a combination with Izovol K is used, it is placed on the bottom layer. If the thickness of the thermal insulation layer must be large, two layers of insulation are used. The advantage of this insulation is its increased rigidity and moisture resistance. This allows the material to be used for existing roofs. Such slabs perform not only thermal insulation, but also fire-fighting functions.

Izovol is a safe and reliable environmentally friendly non-flammable heat insulator

Izovol P

This material is used for thermal insulation of floors before concrete screeding, for flat roofs, as well as other areas with high humidity. Isovol P with a density of 175 kg/m3 can withstand a load of no more than 65 kPa, while the insulation does not deform. When using material with a density of 100 kg/m3, a load of up to 35 kPa is allowed.

When insulating the floor, the material has a soundproofing and fireproof effect. It is used to create heated or floating floors. Izovol P has standard dimensions of 100*60 cm. Other characteristics are similar to other series of material.

Izovol L

This model is used in various areas of insulation, horizontal and vertical. It is used for roofing, interior partitions, and attic floors. One of the special areas of application is the insulation of heating and ventilation systems, pipelines and refrigeration units.

Izovol Acoustic

Such materials are specifically designed to create a soundproofing layer in private (walls, ceilings, floors) construction, and in industrial (air ducts, ventilation systems) construction.

Depending on the surface or structure to be insulated, a specific type of Izovol is selected. By testing this material for yourself, you will be convinced of its excellent characteristics and high quality.

Read with this

- Interventional insulation for timber and logs

- Isover insulation

- Insulating the roof from the inside: step-by-step instructions

- Properties and structure of OSB boards: their size, quantity in a pack and application

- Basvul insulation: technical characteristics

- Glass wool

- Which insulation is best for an attic roof: 7 best options

- Do-it-yourself insulation of a sauna from the inside using different materials

- Roll insulation: soft and self-adhesive, plate or rolls, thermal insulation for walls 150 mm, types and properties of thermal insulation materials

- Technical characteristics of penofol - a universal heat insulator

How to make Isobel insulation

In green packaging, the mineral wool density is 25 kg/m. cube

Isobel is a basalt fiber insulation material. To obtain such fiber, rock (frozen magma) mined from dormant volcanoes is delivered to a processing plant where it is crushed into small pieces. Then the resulting placer is melted at a temperature of over 1 thousand degrees, resulting in a liquid mass.

To obtain fibers from molten magma, a strong air flow is directed at it. The material seems to be sprayed, and when the fibers land in a special container, they no longer stick together. To make Isobel slabs, basalt fibers are treated with an adhesive composition and sent to a molding machine, where the material is given the required dimensions. Also, the molding machine compresses the mineral wool to a set level, in our case it is 25 or 35 kg/m. cube

The last stage is checking the insulation by a technical control body for compliance with the established characteristics and packaging the thermal insulation in polyethylene. Unlike glass wool, basalt fiber is packaged in its original form, that is, not compressed. Advantages of Isobel insulation:

- produced in the Russian Federation;

- is cheap;

- does not contain blast furnace slag and coke.

It should be noted that phenol-formaldehyde is added to the adhesive composition for basalt fiber.

In its pure form it is a toxic substance, but as part of insulation it does not pose any danger. In addition, phenol-formaldehyde is contained in all plastic products, cabinet furniture and other materials that surround us in everyday life. Claims that mineral wool is dangerous to health are too exaggerated. If you want absolutely ecological thermal insulation without any impurities, then use expanded clay to insulate the floor, walls and ceiling.

To reduce heat loss, thermal insulation of pipelines with mineral wool in rolls or cylinders is necessary.

Read about which mineral wool is best for the attic in this article.