- DIY pellet burner: quick assembly and process automation

- Why do you need a pellet burner: features of the device

- Pellets: what is it? Detailed fuel characteristics

- Design features of pellet burners

- DIY pellet burner: varieties

- Gravity pellet burner: design features

- How to draw a drawing of a pellet burner?

- DIY pellet burner: preparatory stage

- How to make a homemade pellet burner: basic recommendations

- Making a hopper for a pellet burner with your own hands

- Further arrangement of a pellet boiler with your own hands

- How to automate the process and configure a pellet burner yourself?

- Pellet burner Zota Fox 25: reliable and efficient model with wide functionality

- Automatic pellet burner Teplodar APG-25

- Video: DIY pellet burner

DIY pellet burner: quick assembly and process automation

A pellet burner is installed on a solid fuel boiler and is used to organize space heating. It can be purchased ready-made, but it is quite expensive. If necessary, such a device can be made independently. A DIY pellet burner can be made from different materials and have both a simplified and a more complex design.

Burner for testing: varieties, device, how to make it yourself (read more)

The pellet burner is installed on a solid fuel boiler and can be made by hand.

Why do you need a pellet burner: features of the device

Pellets are a fuel that is of high quality and can compete with conventional firewood. To produce such raw materials, wood and agricultural waste, as well as peat, are used. Pellets are small granules.

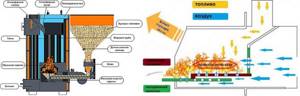

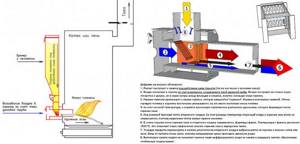

The operating principle of a pellet burner installed in a boiler.

What is the advantage of such pellets over standard types of fuel? First of all, it is necessary to note the high efficiency of raw materials. Ordinary firewood, after burning, releases from 40 to 80% of its energy. The remaining material is recycled, so the economic feasibility of such heating is questionable.

A boiler with a pellet burner allows you to increase material recycling up to 90%. This is one of the highest combustion rates among all types of fuel. It is worth noting that granulated raw materials are not recommended for use for some types of boilers. For example, such fuel can harm equipment whose operating principle is based on pyrolysis.

On a note! When choosing a burner, you need to pay attention to its power. Today you can purchase models that automatically adjust this indicator. An example is the Zota pellet burner.

During fuel processing, the temperature inside the burner can reach 1000 °C. It follows that extreme caution must be exercised when using such a device. This is especially true for do-it-yourself designs. Errors in assembly or improper use may result in a fire.

During operation of a pellet burner, the temperature inside it can reach 1000º.

Pellets: what is it? Detailed fuel characteristics

This raw material is characterized by high energy intensity. It is thanks to this that it has become widespread. When processed, one kilogram of granulated pellets releases approximately 5 kW/h of heat. It follows from this that to organize the heating of a standard private house with average dimensions, you will need about 2 kg of material per hour.

Pellets for the burner are loaded into the device approximately 1-2 times a day. When loading a new portion of raw materials, it is recommended to clean the ash pan from combustion products. Store-bought burners require weekly cleaning, and homemade devices get dirty even faster. It is recommended to clean a home-made device approximately once every 3 days. Otherwise, it will fail quite quickly.

Some burner models do not require loading for 5 days. An example is the APG-42 pellet burner. This model is compatible with Teplodar-Cooper boilers.

The disadvantage of pellet burners is reverse combustion, which is accompanied by the penetration of the pyrolysis zone into the bunker intended for storing and supplying fuel. This entails smoke in the room in which the heating equipment is located, and there is also the possibility of a fire.

Pellets are small granules that are made from wood and used as fuel.

Pellets made from sawdust or any other processed waste can be blown away if there is excess air in the structure, which will lead to the generation of a large amount of waste (ash). The air supply must be clearly regulated, otherwise not only its excess, but also its deficiency can lead to ineffective operation and rapid clogging of the device.

The need for granular fuel in air is determined primarily by the combustion mode. Selecting the right regimen is a primary and very important task. The burner enters operating mode in 5 stages. Before starting to operate the device, you must become familiar with each phase in more detail.

The first step is to ignite. The burner for a pellet boiler is ignited using a special ceramic lighter rod, which, when turned on, heats up to a very high temperature (900-1100 °C). Devices made by yourself can be ignited with an ordinary torch.

On a note! Under no circumstances should flammable liquids be used to ignite the burner. In this case, the combustion process will immediately go into the bunker, resulting in a fire.

When burned, 1 kg of pellets releases approximately 5 kW/h of heat.

The second stage of preparing equipment for operation is startup. It is very important to adjust the correct air supply to adjust the burner flame. Next, the device is overclocked. At this stage the burner enters normal operating mode.

After acceleration, it is necessary to adjust the air so that the correct temperature of the coolant in the return is set inside the device. Then you need to stop the supply of granular fuel and set the required air intensity.

Using pellets

In areas where there is no centralized gas supply, pellets are the most effective and relatively inexpensive fuel. When 1 kg of pellets is burned, thermal energy is released, which is equal to what will be produced after burning half a liter of diesel fuel. The total output power is 5 kW/h. To heat a one-story house in an area where winters are not too severe, it will take approximately 50 kg of pellets per day. The advantage is that they can be filled once every few days, depending on the boiler model. Pellets are placed in a special hopper, from which they are automatically fed into the burner. You will have to service your homemade pellet burner twice a week.

One of the disadvantages of using pellets and pellet burners is the possibility of backdraft. In this case, fire may break out into the bunker. The consequences of such a process will not be the most pleasant, because it will be a good fire. The second nuance that requires special attention in relation to a pellet burner is the amount and intensity of air supply. Pellets are quite light, so an excessive flow can simply blow them off the device, and they will remain unburnt. With less air supply, the pellets also do not burn completely, which leads to the need to clean the burner. For the entire pellet combustion process to be correct, it must have a certain sequence.

To ignite, you must use a special lighter, which is a ceramic rod. It does not affect the pellets with direct fire, but heats up to a temperature of over a thousand degrees. This approach is necessary so that when igniting pellets, the flame does not go into the fuel bunker. The next step is to supply the required amount of air, which is necessary to ensure that the combustion flame is even and stable. Next comes the exit to operating mode. This occurs due to the larger amount of air supplied to the pellet burner. The important factor here is fire without smoke. The stop occurs due to the complete cessation of air supply to the pellet burner.

This is interesting: Laying heated floors under tiles - system installation technology

Design features of pellet burners

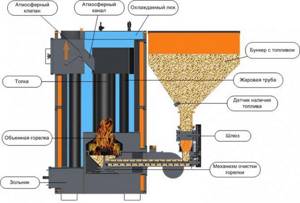

The main task of any burner is to ensure uniform heating of the boiler. This goal is achieved through the processing of granular fuel. From a structural point of view, the burner is a combustion chamber, which most often resembles a pipe in shape. Combustion inside such a device occurs due to the continuous supply of air.

Fuel delivery is carried out by a special device - an auger. To pump air into the structure, a fan is provided, the operation of which does not allow the flame to go out. The burner can have a variety of shapes, which does not significantly affect the efficiency of the device. Chambers that have a round cross-section are the most common. This is due to the fact that they are the easiest to make. However, rectangular options are also quite common.

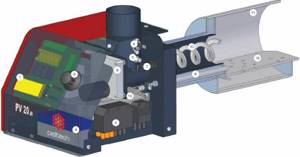

The device of a pellet burner, where 1 – LCD display, 2 – control knob, 3 – backup battery, 4 – connecting connector, 5 – fuel level sensor, 6 – safety thermal relay, 7 – photosensor, 8 – internal auger motor, 9 – igniter , 10 – internal auger, firebox, 11 – combustion grate, 13 – fan.

Round burners used for pellet processing have a flat base. It is used to accommodate fuel and is mounted externally to the front surface. It is worth noting that some burners have the ability to connect a GSM module. An example is the Terminator 15 pellet burner. Its cost is approximately 75 thousand rubles.

The operating principle of these devices is quite simple. First, the sawdust is loaded into the hopper, after which it is delivered through the channel to the burner. A fan blows air to maintain the required flame level inside the device. Combustion products accumulate in the ash pan. It is recommended to clean this compartment at least once a week.

Product structure

Let's look at what main parts a homemade pellet burner consists of. Its task is to ensure uniform combustion of fuel and stability of the flame, due to which the water jacket of the boiler unit is heated

Particular attention is paid to the possibility of adjusting the combustion intensity

The pellet burner consists of the following elements

:

- combustion chamber (in the form of a round or rectangular pipe);

- loading hopper for fuel;

- screw conveyor for supplying bulk fuel;

- fan for forcing air into the combustion chamber.

The volume of the loading hopper determines how often the boiler operating in automatic mode will have to be serviced. The operation of the blower fan is regulated by an electronic control unit - the intensity of the air supply affects the rate of fuel combustion.

Electricity is required to operate the electronic unit, fan and screw conveyor, so this burner device is energy dependent.

Principle of operation

The pellet stove is equipped with a burner that works according to the following principle

:

- The first portion of fuel entering the combustion chamber is ignited with minimal air supply.

- During the combustion of the first portion of fuel, the air supply increases, the flame intensifies and warms up the combustion chamber.

- The fuel supply begins in small portions, the air pressure stabilizes, and the flame becomes even.

- Operation of the burner in a stable mode allows for economical fuel consumption and efficient heating of the water jacket of the boiler unit.

Design Features

The combustion chamber, made of a round or square pipe, has a tray inside for burning fuel, and on top there is a pipe with a screw conveyor for dosed supply of sawdust, granules or other fine-grained energy carriers. The chamber is attached to a flange plate, which is adjacent from the outside to the front plane of the boiler unit.

The natural flow of air does not make it possible to burn fuel in a suitable mode, so a fan is installed, turning the combustion chamber into a wind tunnel.

Dry bulk fuel with optimal air supply burns with virtually no residue. The flow of forced air carries a small amount of ash into the ash pan - that is, the combustion chamber cleans itself during operation. It is necessary to remove ashes from the ash pit once every 7-10 days - the frequency depends on the intensity of the accumulation of unburned residues. If the fuel moisture content is high, the ash pan must be cleaned more often.

Organizing the supply of bulk fuel to a homemade pellet burner is carried out in two ways

:

- A large hopper is installed in the room, into which fuel is loaded for 7-10 days of continuous operation of the boiler (it is with this frequency that the burner ash pan needs to be cleaned). To supply fuel to the burner nozzle, it is necessary to install a screw conveyor, the length of which depends on the distance between the hopper and the boiler.

- The hopper is mounted directly on the pellet burner so that bulk fuel enters the burner auger under its own weight. A gravity pellet burner is simpler and cheaper to manufacture, but it will have to be serviced more often - usually a hopper is used, the volume of which is enough for 1-3 days of boiler operation.

Positive Features

A do-it-yourself sawdust burner is a device that helps expand the functionality of a conventional solid fuel boiler. Its installation allows you to save firewood and coal if inexpensive or free waste from wood processing or crop production is available. This approach will significantly reduce the overall heating costs of a private house, cottage or garage.

Pellet burners have a number of advantages, including

:

- economical fuel consumption;

- minimum amount of ash and harmful emissions into the atmosphere due to optimization of the combustion mode - fuel and combustible gases burn almost completely;

- little need for maintenance - fuel is added no more than once a day, the ash pan is cleaned no more than once a week, the operation of the unit is automated.

Pellet burner device

DIY pellet burner: varieties

Devices that are used for processing granular raw materials are divided into two types depending on the principle of operation - with forced intake and gravitational. The choice of one type of equipment or another depends primarily on individual operating conditions.

On a note! The most common burner option requires the presence of electricity. In this case, electricity is necessary to operate the mechanism that ensures an uninterrupted supply of granular fuel. Automatic pellet burners (with forced intake) are considered the optimal solution for organizing heating of a building.

At the moment, pneumatic pellet burners from Obshchemmash are popular.

Devices of this type include several mechanisms through which granules are delivered. The first of them operates using a pneumatic system. The second mechanism is equipped with a special tool - a screw. Safety in the system is ensured by the design of the channel, installed from the bottom up, through which the granules are supplied.

Automatic devices have one serious advantage - fire safety. Such devices are used in equipment from different manufacturers. For example, they are integrated into Teplodar boilers. Pellet burners, reviews of which are mostly positive, are quite expensive. The price of some models exceeds 150 thousand rubles. More budget options can be purchased for 60-80 thousand rubles.

The pneumatic type design is characterized by maximum safety. This is because the pellet delivery system delivers fuel in small portions. Thus, it is not delayed in the communication channel. For such a burner, it is possible to install a large hopper that does not require frequent loading. If desired, a device of this type can be purchased. Currently, pneumatic pellet burners from Obshchemmash are very popular.

Screw-type feed mechanisms include two main units. Using the first auger, granulated fuel is taken from the bunker. The operation of this device allows you to transport pellets to another receiver. After this, the second screw sends the raw material directly to the burner.

Automatic pellet burners are characterized by high fire safety.

The disadvantage of devices in which fuel supply is forced is their dependence on energy. In the event of a power outage, the burner stops operating.

Advantages and disadvantages

The equipment has a number of advantages:

- Pellets are a safe fuel compared to gas and electricity;

- Allows you to significantly reduce space heating costs compared to using electric boilers. At the same time, pellet installations are more expensive than gas equipment, but do not forget that it is not always possible to supply gas and purchase gas cylinders;

- Homemade installations guarantee high efficiency - 95%. Some store installations are over 97%;

- They are used not only for heating the room, but also for producing hot water;

- There are no rules for transporting and storing fuel. When near a person, pellets do not cause allergic reactions, and there are no toxic fumes when burning;

- Fuel is available for purchase. Equipment owners complained about the lack of fuel and the need to prepare a supply of pellets from the winter when the devices appeared; now there is no need to store a large volume of pellets at home; if necessary, they can be bought everywhere;

- The price of pellets is on average at the same level, unlike gas and electricity, the tariffs for which periodically experience seasonal fluctuations;

- Installation of the device does not require special skills, and there is no need to coordinate the installation with authorized bodies;

- After combustion of pellets, natural mineral ash is formed, which does not require special rules for disposal.

Along with the advantages of such equipment, there are also a number of disadvantages:

- High cost of ready-made store equipment. Despite the popularization of devices in recent years and some reduction in prices, pellet boilers are still more expensive than gas or electric equipment of similar power;

- The equipment requires constant maintenance (especially outdated models). The user will have to clean the ash pan and heat exchanger from accumulated ash once a week. In modern models, cleaning is provided at an automatic level;

- In the absence of automatic fuel supply, the user has to load pellets into the bunker manually;

- It is necessary to ensure minimum humidity conditions in the rooms in which pellets will be stored awaiting use;

- Imported equipment is practically not designed for the conditions of the harsh domestic winter, as a result of which breakdowns and malfunctions often occur;

- In remote areas, fuel for the winter still has to be stored due to the instability of supplies.

Gravity pellet burner: design features

Devices of this type, operating on pellet fuel, have a different operating principle for supplying pellets. It should be said right away that such units are more convenient to use. The main advantage of the gravitational mechanism is that it does not require a connection to the electrical network.

In this case, the pellets are located in a bunker and can enter the connected channel under the influence of their own weight. There are several popular domestic companies producing such units (Pelletron, Behemoth). A pellet burner of this type is started very simply - by changing the position of the damper. It is important to remember that the chimney has a draft regulator, which can also be adjusted.

On a note! The main disadvantage of all gravity structures is that they do not provide as much safety during operation as their counterparts. During operation, there is a possibility of ignition of granulated fuel in the bunker. An increased risk of ignition exists due to the design of the hopper, which is directly connected to the opening through which the fuel is supplied.

Gravity pellet burners can be used without an electrical connection.

The efficiency of gravitational devices is slightly lower than that of analogues that operate through the forced supply of granular fuel. Installing this type of pellet burner is not a difficult task. Its complete connection can be completed in just a few hours.

In order to increase the fire safety performance of this device, many manufacturers install special dampers on it. They are equipped with thermal sensors, which, if a flame enters the channel connecting to the bunker, are activated and block the passage.

Frequent malfunctions

Pellet boilers are solid fuel boilers, so during operation they may have similar faults.

In order to avoid them, even before installing a pellet burner for a solid fuel boiler, you need to fulfill all safety requirements, in particular: preparing a room with triple air circulation and a solid base for placing the boiler and auxiliary equipment.

The boiler must be wired exactly according to the diagram provided by the boiler equipment manufacturer or according to an individual project, when producing a pellet burner yourself.

When operating a pellet boiler, malfunctions quite often arise that can be eliminated yourself:

- The release of sparks from the chimney due to high draft or contamination of the ash pans.

- Black smoke from the chimney is a lack of air supply to the firebox.

- White smoke from the chimney is excess air in the firebox.

- Increased fuel consumption due to the use of low-quality pellets.

- The occurrence of popping noises and the emission of smoke into the furnace room when the boiler door is opened means contamination of the smoke ventilation systems of the unit.

How to draw a drawing of a pellet burner?

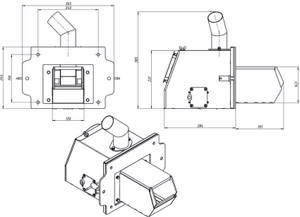

Before starting to independently design a burner intended for processing pellet fuel, it is recommended to complete its individual drawing. The diagram must necessarily contain information about all components and parts. The drawing requires you to indicate the main elements:

- camera;

- fuel bunker;

- screw;

- fan.

The diagram must contain all the necessary dimensions of these products. When making a drawing of a pellet burner with your own hands, you should remember that the detail of its execution determines how reliable the device for processing fuel pellets will be.

Manufacturing drawing of a pellet fuel burner.

Before starting to draw up the diagram, it is recommended to calculate in advance the required dimensions of the bunker. When performing calculations, you should take into account how much area the structure will heat. It is also worth noting that the parameters of the bunker have a direct impact on the frequency of its cleaning.

The fan operation is controlled by an electronic unit. When drawing up a diagram, you need to remember that the performance of the main components of the device depends on the availability of electricity.

Thus, making a drawing of a pellet burner with dimensions with your own hands is not so difficult. If necessary, you can use a ready-made scheme, of which there are many on the Internet. But in such a situation, it is necessary to select a drawing that will meet specific conditions.

DIY pellet burner: preparatory stage

Before you begin assembling a burner that processes granular fuel, you need to do some preparatory work. First of all, you need to calculate the area that will be heated using this device. Knowing this indicator, it will not be difficult to calculate the required power of the heating device. When calculating the power indicator of a pellet unit, the following factors are taken into account:

- average annual temperature in a particular region;

- building area;

- ceiling height in the building;

- number of door and window openings;

- building materials from which walls, floors and ceilings are made.

Then you should prepare all the tools that will be used when assembling the pellet burner with your own hands. Video and photographic materials help to get an idea of this process, so it is recommended to study them in detail.

It is necessary to determine the thermal transfer resistance of the materials used. This coefficient will be required in the future to calculate heat loss. The power of heating equipment must be at least 10% higher than heat loss.

On a note! There are special online calculators that allow you to determine the power of the boiler. They can be easily found on the Internet using the search bar of your browser.

Experts recommend purchasing ready-made pellet burners. The price of these devices varies from 50 to 200 thousand rubles. Making such a device is quite difficult, since many operational nuances need to be taken into account. Purchased models are also equipped with the necessary thermal sensors, which makes their operation convenient and safe.

Making a pellet burner is a complex and labor-intensive process.

How to choose a combi boiler

The selection criteria are almost the same as when choosing a TT model. You definitely need to decide on:

- Number of contours . Single-circuit models are more common; they heat only the heating circuit. Double-circuit models are also capable of heating sanitary water (it does not mix with process water from the heating circuit). Double-circuit models are 10-40% more expensive, but this is still the cheapest way to organize hot water supply in a house.

- Burnt fuel . Basically, combined boilers are designed to burn both coal and charcoal, firewood, pellets, and peat. Models with a cast iron heat exchanger are capable of burning anthracite. But some boilers are designed only for firewood. Types of fuel are always described in the technical specifications or boiler passport.

- Heat exchanger material . There are two options: steel or cast iron. Steel heat exchangers are inexpensive to produce, lightweight, resistant to temperature changes and mechanical damage, but have thin walls and are not resistant to corrosion; their service life is on average 12-15 years. Cast iron heat exchangers are heavy, have thick walls, are not subject to corrosion and last more than 30 years, but are used in more expensive models.

- Working pressure . Some models are designed for an operating pressure in the system of no higher than 1 bar, which means that they cannot be used in closed heating systems with forced circulation, where the operating pressure is usually 1.5-2 bar.

- Efficiency . It is not the most informative indicator when burning solid fuel, since it strongly depends on its quality (dryness and type of wood, ash content and calorific value of coal). However, when using a gas burner, 4-5% efficiency can pay for the higher cost in one heating season. The optimal efficiency indicator is 80% and above.

Minimum required power

For an average uninsulated or poorly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% reserve) = 13 kW. Boilers of this power are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

Also, when purchasing a double-circuit boiler, it is recommended to add another 10-15% to the result, since when heating hot water, the heating circuit is not heated. Total 13 kW * 1.1 (10% reserve) = 14.3 kW. If the house is located in the extreme southern or northern point of the country, is well insulated, has high ceilings or a large glazing area, correction factors are taken into account, changing the result by 5-30% up or down.

How to make a homemade pellet burner: basic recommendations

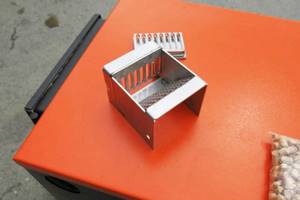

The most important structural element that is part of a pellet burner is the basket. When making such an element yourself, you should remember that there is one common problem - granules getting stuck in the back wall, which is located at an angle and has slots. To solve the problem, you need to make the cracks differently. The standard version takes into account continuous slots, but it is recommended to make a more cellular structure.

The ideal size of the rear wall slots should be 2 mm smaller than the size of the secondary fuel pellets. The gap between the back wall and the bottom of the basket must be at least 6 mm. The front wall also has slots, but in this case they must be solid.

Before work, it is recommended to study videos demonstrating the assembly of a pellet burner. Reviews of various home-made devices will also help you choose the right device option.

There is a channel located under the bottom of the basket that is part of the burner. It is necessary for secondary air. The height of the channel should be approximately 29 mm. A deviation of 1 mm is allowed here. The back wall itself is not perpendicular, but at an angle. The tilt angle is 45°.

It is recommended to make the size of the slots in the rear wall of the basket 2 mm smaller than the size of the pellet fuel granules.

The price of a pellet burner purchased ready-made is several times higher than the cost of a prefabricated version. Thus, self-manufacturing of this device allows you to significantly save money.

The size of the basket with tray is selected taking into account individual needs. In this case, it is necessary to focus on the indicator that determines how much fuel will be processed per 1 hour of burner operation. The best option is considered to be a device with dimensions of 13x13 cm. The depth of such a basket should be approximately 10-12 cm. Such a device allows you to burn about 2-3 kg of granular fuel in 1 hour.

Gravity burners

The gravity pellet burner can be made non-volatile, because the fuel in it is poured directly into the pyrolysis chamber, and pressurization can be provided by draft in the chimney. It is also possible to enter the gravity burner into operating mode manually, manipulating only the damper on the burner and the damper (draft regulator in the chimney). However, this costs a slightly lower boiler efficiency and a greater fire hazard. Therefore, any gravity burner requires qualified maintenance. Let's hope that this article will help the reader with this too.

Pellet burners with gravity feed

Non-volatile gravity burners with manual control are not produced by industry: if used incorrectly, they are extremely dangerous. Semi-automatic burners with self-feeding fuel are sold under the name gravity burners. To prevent fire from entering the bunker, either install a gateway (on the left in the figure) made of thermosetting, i.e. elements that expand when heated, or use a double-grid scheme on the right. The movable grate periodically moves back, takes a portion of fuel and transfers it to the combustion zone, while simultaneously pushing the ash into the ash pan of the boiler. In this case, a complex burner with a screw is not needed, but this design is bad in that the gap between the grates quickly becomes clogged with ash residue. If the movable grate gets stuck in the rear position, fire penetration into the hopper is almost inevitable, so a fire sluice in a burner with a double grate is also necessary.

Without electricity

A homemade pellet burner can be made non-volatile if it is made according to the basket-flare scheme:

- The fuel is poured directly into the pyrolysis chamber, which is a perforated steel basket. The basket is made removable, because For each caliber (diameter) of pellets you need a separate basket.

- The immediate penetration of fire into the bunker prevents, to a certain extent, “tertiary” air being sucked in through the holes in the feeder.

- Primary air provides pyrolysis of fuel in the basket.

- Pyrolysis gases and secondary air enter the combustion chamber, where the main combustion occurs.

- A torch of hot gases erupts from the combustion chamber, heating the boiler.

Note: some factory burners are also built according to the described scheme, incl. well-proven Pelletrons. But they are by no means energy independent, because... equipped with built-in automation. A UPS (uninterruptible power supply) for Pelletrons can be purchased optionally or use a computer one.

Looking at Pelletrons

The operating diagram of a non-volatile pellet burner with a boiler is given on the left in the figure, and the diagram of its device and description of the principle of operation is on the right in the same place:

The device of a gravity pellet burner

An indispensable condition for successful operation is a damper in the chimney with obviously excess draft. This burner is put into operation quite simply:

- Fully open the burner damper and air damper.

- Open the fuel supply valve on the bunker (it must be there!)

- Light the pellet and immediately close the damper on the burner.

- Observing through the inspection window of the boiler (also mandatory), smoothly and slowly open the burner damper until the torch flares up and a cloud of ash appears. Do not blow out pellets!

- Using a damper on the boiler temperature sensor (or according to the type of torch), the burner is brought into operating mode.

Stopping the burner is also easy:

- At the end of the cycle, the furnaces shut off the fuel supply to the bunker.

- The gate is opened completely.

- Immediately upon opening the gate (preferably simultaneously with it), the burner damper is closed for approx. at 3/4.

- Preventative work on the burner (if necessary) begins no earlier than 10 minutes after the last signs of combustion disappear.

Details and dimensions

The most important part of the burner is the basket. The Achilles heel of homemade baskets is the pellets getting stuck and coked in the inclined back wall, which disrupts the pyrolysis process and causes the fire to go into the bunker. To avoid this, the slots in the rear wall should not be made solid, but as shown in the inset at the top right in Fig. The dimensions of the slots are 2-3 mm smaller than the size of the pellets in plan. The gap between the back wall and the bottom of the basket is 2 mm less than the caliber of the pellet, but not less than 6 mm. But the slots in the front wall separating the pyrolysis part from the combustion chamber need to be solid. It’s even better if they are open at the bottom. The height of the secondary air channel under the bottom of the basket for a 15 kW burner is 28-30 mm. The back wall is tilted 45 degrees. Such a basket with a tray measuring 130x130 mm in plan and 100-120 mm deep will burn 2-3 kg of pellets per hour.

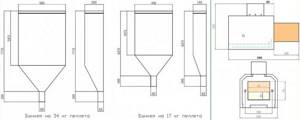

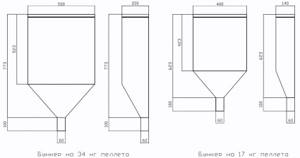

Drawings of a gravity pellet burner and a hopper for it

An equally important part is the bunker. It is precisely into bunkers of arbitrary design that fire most often breaks through. Fortunately, there is no need to be clever here: the bunkers from Pelletrons, the drawings of which are given on the left in the figure, have shown themselves to be excellent. With a 15 kW burner, a 34 kg bunker in an average winter in the middle zone provides daily heating, and 17 kg semi-daily.

The dimensions of the combustion chamber can be taken from Pelletron 15 (highlighted in color on the right in the figure. It is better to make the secondary air channel L-shaped with an upward bend, this will ensure its active mixing with pyrolysis gases and a slightly higher boiler efficiency.

The combustion chamber must be made of heat-resistant steel with a thickness of 2 mm. Since hot steel is difficult to weld, you need to draw a chamber profile, roll it up and rivet the joints or spot weld them. By the way, you can also make a tabletop spot welding machine with your own hands at home.

Note: for another version of a homemade gravity pellet burner, see next. video clip:

Video: DIY gravity pellet burner

Method for adjusting pellet burner pressure

Possible improvements

It will greatly simplify starting the burner and make it safer due to less reaction to the draft in the chimney. For a 15 kW burner, a 20 W fan is sufficient. The easiest way to adjust the boost is from a scroll fan, as shown in Fig. on right.

Note: on pellet heating forums, e.g. American: donkey32.proboards.com, you can find ideas to put Peltier elements in the boiler and run a 12 V computer fan from them to supercharge. Firstly, the Peltier elements will instantly burn out in the chimney. Secondly, the computer fan power is an order of magnitude less than required. Thirdly, without control electronics powered by a thermocouple in the furnace, the system will go into overdrive, because It will turn out - it flared up more, the pressure was stronger, but it should be the other way around.

You can also carry buckets of pellets not once or twice a day, but weekly or even monthly. An indispensable condition, according to fire safety rules, is that the boiler must be located in a separate fireproof boiler room. Then we put a large hopper with a long-term fuel supply, an auger and free fall of pellets (see above), but not in the burner feeder, but in the supply hopper. The latter has 2 fuel level sensors, upper and lower (preferably optocouplers). There is little fuel - the engine turned the auger and sprinkled. The consumables are full - stop! Well, if the electricity goes out, you’ll have to carry it in buckets.

Making a hopper for a pellet burner with your own hands

The second necessary element of any burner installed on heating equipment is a hopper. The most common problem that arises during the operation of homemade devices is related to the penetration of flame into this structure. In order to assemble a reliable bunker, it is recommended to use ready-made drawings of popular bunkers from Teplodar or Pelletron. A pellet burner can be made of any power, but it is best to take standard 15 kW devices as an example.

Drawings of a hopper for a 34 kg and 17 kg pellet burner.

The volume of the bunker is also selected individually. You can make a box that will hold 17 or 34 kg of granular fuel. For the manufacture of the combustion chamber, a material such as stainless steel is traditionally used. Moreover, its thickness should be at least 2 mm.

On a note! Steel walls are joined using welding equipment.

The dimensions of the bunker are borrowed from any suitable model (for example, Pelletron 15). The pellet burner includes a secondary air channel, which is best made in the shape of the letter “L”. This will significantly increase the efficiency of the operating device.

In addition, the burner should be provided with air supply. This will make it possible to simplify its launch, since the reaction to draft in the chimney structure will be reduced. For a device with a power of 15 kW, 20 W fans are suitable. Experts recommend purchasing a fan, which is called a snail. This is due to the fact that the operation of such a device is easiest to regulate.

The fan is an important part of the pellet fuel burner, as it simplifies its operation.

Further arrangement of a pellet boiler with your own hands

Assembly of the device body is carried out in several stages. You can handle this task yourself, but you need to clearly understand the nuances of the work. The body is best constructed in a horizontal plane. This is because this arrangement allows for maximum equipment efficiency.

It is recommended to use brick (fireclay) as a material for the manufacture of the body. The process looks pretty simple. It is necessary to assemble the box and place the heat exchanger inside it. It is worth noting that the brick body is made without a top cover. The heat exchanger must have outlets for connecting heat supply pipes.

Do not forget that the burner should be equipped with a special controller. Pellet burners can be completely mechanical, but in this case it is much more difficult to set them up. Regulation is made taking into account the individual characteristics of the device and the area of the heated room.

The use of brick for the installation of the housing is recommended because it has good insulating qualities and is able to accumulate heat to a greater extent than other common materials such as steel and cast iron. Photos of burners and other heating equipment can be easily found on the Internet.

To make a heat exchanger, you need to cut pipes with a rectangular cross-section and connect them together.

First of all, the heat exchanger is manufactured. To do this, you need to prepare pipes with a rectangular cross-section. Then they need to be cut (in accordance with the drawing) into pieces of the required length. After this, the individual segments are connected to each other using welding. It is necessary to provide pipe supply to the heat exchanger. Then a chimney with an ash pan is installed.

How to automate the process and configure a pellet burner yourself?

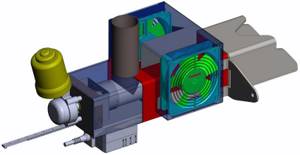

Homemade pellet boilers have one feature - the absence in the design of a device that provides an influx of natural draft. Without draft, as you know, it is impossible to maintain a flame inside the device, so you will need to install a fan. To ensure uninterrupted operation of the boiler, an auger is also used, which is responsible for delivering fuel from the bunker to the combustion chamber.

In order to fully automate the workflow and, if necessary, achieve its adjustment, you need to integrate a controller into the design. Its role is played by the pellet burner control unit.

On a note! Mechanical control is carried out using a simple regulator.

Using the control unit, you can fully automate the operation of the pellet burner.

The main task to ensure the normal operation of heating equipment is to achieve a balance between two main indicators. The first of them is the volume of granular fuel, and the second is the air intake rate. If you can correctly adjust these indicators, then the flame will evenly heat the heat exchanger.

All necessary indicators can be set using the burner control module. What it is? The control unit provides complete control over the operation of the heating unit. Of course, the best option is to purchase a new device.

Purchased models have the ability to quickly connect to the main working elements of a pellet boiler. As a result, the controller will regulate the supply rate of granular fuel, as well as the fan speed. The display located on the control unit allows you to configure the pellet burner.

It is worth noting that the auger must have a sensor that monitors the need to supply granular fuel. It works as follows: it detects when the auger is full and sends a signal to the equipment. After this, the supply of pellets is suspended.

Using the controller, the speed and volume of pellet fuel supply is adjusted.

The principle of operation of the pellet device

As a rule, a standard pellet-type burner is sold by manufacturers already equipped with additional devices:

- screw device for fuel supply;

- controller for automatic regulation of the functioning process;

- bunker box for fuel;

- lambda probe that measures the residual amount of oxygen and automatically regulates combustion.

Construction of a pellet boiler

In the area from the burner to the auger, a plastic corrugation is sometimes installed, which allows, when a reverse draft is formed, to prevent the spread of fire.

The main elements of a pellet burner also include:

- an air supply fan located at the bottom of the device or behind the burner and controlled by a special controller;

- thermoelectric heating element involved in automatic ignition of pellets.

The fuel supply is carried out through an electrically driven auger, and is also checked by a controller with temperature sensors and indicators that reflect the operation of the pellet burner.

The control scheme for the temperature regime of the coolant in the heating system is very simple.

When certain temperature values are reached, the burner is switched by the controller to the “standby” mode with prolonged smoldering of the fuel. After the coolant cools to the required level, the sensor sends a signal to turn on the burner fan, which causes the pellets to ignite and transfer the equipment to standard operating mode. A heating element can be used for ignition.

The performance of a pellet burner depends on the rate of fuel supply to the firebox and its quantity, therefore only proper adjustment of these parameters helps ensure optimal operating efficiency of the equipment.

Pellet burner Zota Fox 25: reliable and efficient model with wide functionality

This type of pellet burner is used in Zota Fox series boilers. It is used in heating units, the design of which does not include a plate made of cast iron material. To date, such a burner has proven itself only from the best side. It is characterized by efficiency and reliability, as well as a long service life.

The Zota Fox pellet burner processes granular fuel. The size of each pellet used in this case ranges from 6 to 8 mm. The power of this unit is regulated by an automatic system. This indicator may vary (from 5 to 25 kW).

Installing a Zota pellet burner on a solid fuel heating boiler allows you to automate its working process. Equipment equipped with a granule processing unit has certain advantages:

- reduction of heating costs for residential buildings;

- increase in operating time when loading one portion of granulated fuel;

- maintaining the required temperature in the room.

On a note! The power of the burner used for processing pellets is determined depending on the area of the heated room. It is worth noting that a 1 kW device can provide heat to a room of 10 m².

The Zota Fox 25 pellet burner is an efficient and reliable unit.

The burner power is adjusted automatically. For this purpose, the design provides a special control module. Zota Fox pellet burners (5-25 kW) have many additional functions that are easy to activate and configure on the control panel. These include automatic ignition of granular fuel, quick start and stop, automatic cleaning of the burner and other modes.

Safety in such a device is realized by a sensor that regulates the combustion temperature of the fuel. This device can also be connected to a GSM module or thermostat installed in a heated room. The cost of such a burner is approximately 75 thousand rubles.

Areas of application of solid fuel burners

Most often, solid fuel burners are used in areas where there are problems with energy and gas supply. In Russia, very often in the fall and winter, dacha villages are left without power supply; in 90% of such garden cooperatives there is no gas at all, so burners running on wood, peat coke and coal are simply irreplaceable in such situations. They are easy to use and, with sufficient fuel, can operate without interruption for months. That is why solid fuel burners are often purchased by summer residents to heat their homes in the winter. Such equipment is often used in cottages and private houses within the city.

Automatic pellet burner Teplodar APG-25

This device is automatic. It has many advantages. The products of this company are of high quality and have a long service life. A burner of this type is sold together with a hopper, which is delivered disassembled. In addition to the bunker, the kit includes an auger that delivers pellets, as well as a control panel.

This model has many advantages. One of them is ease of installation. If you wish and have certain skills, connecting such a model can be done in just 30 minutes. Teplodar pellet burners require preliminary settings, which are made according to needs. The hopper should not be filled too often (twice a week is sufficient).

Pellet burners Teplodar APG-25 are a high-quality product with a long service life.

In this case, cleaning the ash pan from combustion products is done no more than 2 times a week. As a rule, only once is enough. It is worth noting that, in addition to the APG-25, there are also more powerful modifications produced by this manufacturer. For example, the APG-42 model has become widespread.

These devices are installed on Cooper brand heating equipment. Pellet burners of this type are equipped with an improved auger, thereby increasing the overall reliability of the design and its service life. The control panel has a convenient and clear display, which indicates all the necessary operating parameters of the heating equipment.

Thus, in order to make a burner that processes pellet granules, you must first calculate the power and prepare a drawing. During work, you must be careful, since any mistakes made during assembly of the structure can lead to a fire of the pellets in the bunker.