The central element of a gas boiler should be considered the burner. All other components are built around it.

A lot depends on how this unit is designed, and first of all, the efficiency of the boiler, so the owner of an autonomous heating system should have a good understanding of this issue.

Our material will serve as a good assistant in this important matter. At the same time, let's see how to make a gas burner for a boiler with your own hands.

Types of gas burners

Before studying the classification of gas burners, their function should be clearly understood. Contrary to popular belief, a burner is not just a nozzle through which gaseous fuel is supplied.

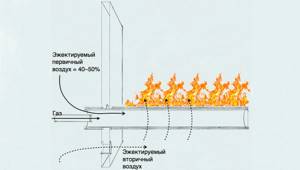

Its task is to mix air into this fuel, and the design of the product must be such that the combustion of the resulting gas-air mixture is stable. According to the method of pumping air into the gas flow, gas burners for heating boilers are divided into several types:

- atmospheric;

- supercharged (fan and turbocharged);

- diffusion-kinetic.

In addition, burners can be:

- Single-stage: such a device operates with constant power. Maintaining the temperature of the coolant (or air in the rooms) at a given level is ensured by timely ignition or shutdown of the burner. At the same time, the temperature constantly fluctuates within a certain range, and the burner and other boiler elements have a relatively short service life.

- Two-stage: can operate in two modes - nominal and half. When there is a slight load on the heating system (during warming periods), the half mode is activated, ensuring smoother operation of the boiler and less wear on all its components, including the burner itself.

- Modulated: the power of the device can be adjusted smoothly from zero to nominal. Thanks to this, the boiler operates constantly and in the most optimal mode, as a result of which its wear is minimal.

The temperature of the air or coolant (depending on the type of thermostat) in modulated burners is kept strictly at a given level without any fluctuations, while fuel consumption is reduced by 20% compared to a single-stage burner.

Primary requirements

We list the signs of a high-quality gas burner:

- The fuel burns completely: this requirement is very important, since incomplete combustion of gas not only reduces the efficiency of the heater, but also pollutes the atmosphere with nitrogen oxide and carbon monoxide.

- The device has a fairly long service life.

- The design is extremely simple, installation is not difficult.

- The noise emitted by the burner does not exceed the values permitted by sanitary standards.

If the burner is a combination burner, that is, it is capable of working with different types of fuel, then it should be quickly and easily switched to one or another type of fuel.

Installation and safety requirements

During the installation process, it is recommended to consider the following points:

- the boiler should be installed as low as possible in relation to the heating pipes;

- the pipeline is attached at a slight angle;

- the number of turns of the pipeline should be minimal;

- the boiler must be installed in a separate fireproof room;

- the unit is installed on a concrete or brick floor, or on a metal sheet;

- A thick steel sheet is laid in front of the combustion doors;

- the distance from the walls to the unit must be at least 20 cm;

- Careful thermal insulation of the chimney is required to avoid heat loss and the formation of acidic condensation, which can corrode the internal surface of the chimney.

You can determine the efficiency of the boiler during operation - if the smoke coming out of the chimney does not smell of carbon monoxide, then your device has a high indicator.

Atmospheric burners

A burner of this type sucks in air according to the principle of a jet pump: gas is passed through an ejector, where, due to the high speed of movement, its pressure drops (Bernoulli’s law); air is sucked into the gas flow due to the pressure difference. The strengths of this device include the following:

- Simplicity of design.

- Compactness.

- Energy independence.

- Low noise level.

- Low cost.

- Possibility of simple conversion of a solid fuel boiler to use gas fuel: the atmospheric burner just needs to be installed in the ash pan chamber.

However, it is impossible to “load” too much air into the gas flow only due to the jet effect, therefore burners with high power cannot be atmospheric.

The power limit for atmospheric burners is on average 9 kW (approximate value of the maximum heated area is 90 sq. m).

Tools and materials

Before you begin installing a coal boiler with your own hands, you need to decide on its design, i.e. you must clearly understand where it will be located, what power it should be, etc. Based on this, you need to draw up a drawing of the future device or find it on the Internet.

To assemble a coal boiler with your own hands, you will need the following materials and tools:

- fireclay brick, sand, clay;

- pipes with rectangular or round cross-section;

- sheet steel with a thickness of at least 5 mm. Having a drawing, you can cut steel into the required pieces at specialized bases;

- metal corners;

- doors for fireboxes and for ash collection;

- grate bars, you can purchase ready-made ones;

- chimney damper;

- stainless steel;

- welding unit and electrodes for welding;

- Bulgarian;

- drill, drill bits.

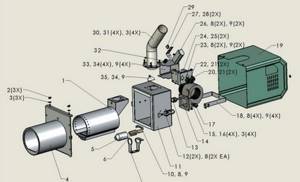

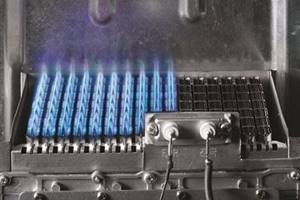

Fan

In such devices, air is pumped by a fan in the amount required. Thanks to the forced supply of oxygen, the following can be achieved:

- The power is not limited in any way - with the help of a fan, any amount of gas fuel can be provided with a sufficient volume of air for complete combustion.

- The combustion chamber can be made closed, that is, isolated from the boiler room. Air enters such a chamber from the outside - through a special air duct. Accordingly, the danger of flue gases entering the house due to reverse draft is eliminated, and the requirements for supply ventilation of the boiler room are reduced. In a boiler with an atmospheric burner, a closed chamber would be impossible, since the force of natural draft would not be able to overcome the aerodynamic resistance of the air duct and deliver a sufficient amount of air to the burner. It should be emphasized that for the operation of a boiler with a closed chamber it is not necessary to install a separate air duct: the so-called. coaxial chimneys, which are a pipe in a pipe. Flue gases are discharged through the inner pipe, and fresh air is supplied through a cylindrical channel between the walls of the pipes - internal and external.

- Devices with forced air supply “know how” to perform self-tuning, due to which user participation is reduced to a minimum.

Pressurized gas burner

Fan burners are more expensive than atmospheric burners and are noisier in operation. In addition, they cannot work without electricity, so they have to be equipped with uninterruptible power supplies.

There is another type of burners - diffusion-kinetic. Such devices are usually seen in high-power industrial-grade heaters. They combine the principles of atmospheric and forced-air burners.

If you need to heat a utility room or cottage, it is not necessary to buy a heating device. You can make a simple heater with your own hands, saving a decent amount.

Read about the characteristics and types of combination boilers here.

And here https://microklimat.pro/otopitelnoe-oborudovanie/kotly/gazovyj-konord-otzyvy.html you can read reviews from people about the use of Conord gas boilers.

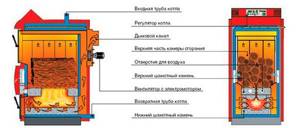

Description of operating modes

The very principle of operation of a pellet burner is as follows: a portion of fuel enters the chamber, it is ignited and the minimum air supply is turned on. As the fuel burns and the chamber warms up, more air is forced in. As a result, a stable, even flame appears, heating the heat exchanger with water. In factory burner devices, the process is fully automated, ignition is provided by an electric incandescent element, and its operation is controlled by a photosensor. The amount of air and pellets supplied to the chamber is regulated by an electronic unit, receiving signals from temperature and pressure sensors. A diagram of a pellet burner will help you understand how the device works.

Fuel in the form of wood pellets or seed husks can be supplied to the pellet burner auger in various ways:

- The traditional method is to supply pellets from a separate large hopper so that its capacity is enough for at least 7 days of operation of the boiler, which needs to be cleaned once a week. From the bunker, the fuel is moved to the burner device by an additional screw conveyor of the required length.

- A DIY gravity pellet burner can be equipped with a simpler fuel supply. In it, husks and granules are poured under their own weight into an auger from a hopper installed directly above the burner device, which delivers the required amount into the combustion chamber. Then the power reserve of the boiler will be from 1 to 3 days, depending on the intensity of work.

It is not difficult to select materials for making the device. Considering the temperature regime of the combustion chamber, it is better to take a pipe made of heat-resistant steel with a wall thickness of at least 4 mm. The flange plate, with which a homemade pellet burner is attached to the body of the boiler installation, can be made of ordinary quality steel with a thickness of 3 mm. The feed conveyor can be purchased assembled, or you can make it yourself from an ordinary pipe by placing a screw in it. For rotation, a low-speed electric motor, gearbox and bearings are selected. The fan must be purchased and fixed to the plate, preparing a seat for it. The plate itself must be made by studying the drawings of the pellet burner, and depending on the design of the boiler door.

Pellet burner parts

What to look for when choosing?

If the purchase of a device is due to the desire to convert a solid fuel boiler to gas fuel, its power should significantly exceed the power of the firebox.

It is also necessary to take into account the compatibility of the boiler and burner.

So, for example, not every “solid fuel” can be converted to install a fan burner, and in boilers such as, for example, “DON”, it is impractical to install them due to insufficient thermal insulation of the boiler tank.

The nature of the movement of the gas-air mixture has an important influence on the operation of the burner. Based on this feature, these devices are divided into straight-flow and twisted. The latter are characterized by a more powerful air flow.

DIY gas burner

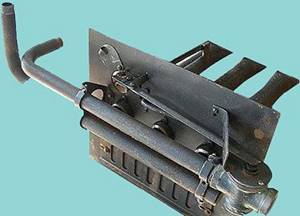

So, let's look at how to make gas burners for heating boilers with your own hands. A homemade gas burner for a solid fuel boiler can be assembled based on a valve from an oxygen cylinder, for example, VK-74. Its outlet pipe should be equipped with a homemade fitting, which can be connected to the gearbox using a rubber-fabric hose.

On the inlet pipe intended for screwing into the cylinder, you need to install a cap with a hole for connecting the nozzle. The latter can be borrowed from a gas stove or blowtorch.

It is necessary to weld a nozzle to the cap - a piece of steel pipe 100 mm long, the wall thickness of which is 2 mm.

There should be a gap of 15 mm between the cap and the nozzle, through which air will be drawn in, so first you need to weld three pieces of thick wire to the cap, and then a nozzle pipe to them.

The homemade burner is ignited in three steps:

- We open the tap on the gas supply line or on the cylinder (in the case of using liquefied gas).

- We bring a match, a lighter or a burning paper wick to the nozzle.

- Open the valve.

The power of this device can be adjusted by closing or opening the valve. The green-blue part of the flame is the hottest.

The nozzle setting is to position the torch in its center. To do this, the wire holders are slightly bent.

If the burner is needed for operation, a tip bent at an angle of 45 degrees should be welded to its nozzle.

A steel cylinder valve can also serve as the basis for a homemade gas burner. A plug with a hole made in it for the nozzle is screwed onto its pipe. In this case, the “donor” of the jet is a blowtorch, the nozzle of which has a diameter of 0.8 mm. The nozzle of the burner itself should have a diameter of 30 mm. By changing its length using attachments, you can adjust the size of the torch. A valve can play the role of a regulator.

How to achieve safety

Here the matter is in the so-called. Reynolds number Re, showing the relationship between flow speed, density, viscosity of the flowing medium and the characteristic size of the region in which it moves, for example. cross-sectional diameter of the pipe. From Re one can judge the presence of turbulence in the flow and its nature. If, for example, the pipe is not round and both of its characteristic sizes are greater than a certain critical value, then vortices of the 2nd and higher orders will appear.

Not all homemade gas burners are accurately calculated according to the laws of gas dynamics. But, if you arbitrarily change the dimensions of the parts of a successful design, then the Re of fuel or sucked air may jump beyond the limits that it adhered to in the author’s product, and the burner will become, at best, smoky and voracious, and, quite possibly, dangerous.

Injector diameter

The determining parameter for the quality of a gas burner is the cross-sectional diameter of its fuel injector (gas nozzle, nozzle, nozzle - synonyms). For propane-butane burners at normal temperatures (1000-1300 degrees), it can be approximately taken as follows:

- For thermal power up to 100 W – 0.15-0.2 mm.

- For a power of 100-300 W - 0.25-0.35 mm.

- For a power of 300-500 W - 0.35-0.45 mm.

- For a power of 500-1000 W - 0.45-0.6 mm.

- For a power of 1-3 kW - 0.6-0.7 mm.

- For a power of 3-7 kW - 0.7-0.9 mm.

- For power 7-10 kW – 0.9-1.1 mm.

In high-temperature burners, the injectors are made narrower, 0.06-0.15 mm. An excellent material for the injector would be a piece of needle for a medical syringe or dropper; from them you can select a nozzle for any of the indicated diameters. Needles for inflating balls are worse; they are not heat resistant. They are used more like air ducts in supercharged microburners, see below. It is sealed into the injector cage (capsule) with hard solder or glued with heat-resistant glue (cold welding).

Power

Under no circumstances should you make a gas burner with a power exceeding 10 kW. Why? Let's say the burner efficiency is 95%; for an amateur design this is a very good indicator. If the burner power is 1 kW, then it will take 50 W to self-heat the burner. A 50 W soldering iron can get burned, but it does not threaten an accident. But if you make a 20 kW burner, then 1 kW will be superfluous; this is an iron or electric stove left unattended.

Armature

The third factor that determines the safety of the burner is the composition of its fittings and the procedure for using it. In general the scheme is as follows:

- Under no circumstances should the burner be extinguished using the control valve; the fuel supply is stopped using the valve on the cylinder;

- For burners with a power of up to 500-700 W and high-temperature ones (with a narrow injector, excluding the transition of Re gas flow beyond the critical value), powered by propane or isobutane from a cylinder up to 5 liters at an external temperature of up to 30 degrees, it is permissible to combine control and shut-off valves in one - standard on the cylinder;

- In burners with a power of more than 3 kW (with a wide injector), or powered from a cylinder of more than 5 liters, the probability of “overshooting” Re beyond 2000 is very high. Therefore, in such burners, between the shut-off and control valves, a reducer is required to maintain the pressure in the supply gas pipeline within certain limits.

Note! Preparation for igniting the burners should be carried out during the period of scheduled maintenance of gas devices. Most often, such work is carried out before the heating season. Without preliminary checking of the burners, their operation is prohibited.

Service Features

Servicing a gas burner involves only one operation - cleaning it.

This should be done annually. Users are not recommended to carry out this procedure on their own, since it requires disassembling the boiler and, accordingly, its correct assembly. Typically, service centers clean burners.

Accumulated dirt is removed by blowing with compressed air. Setting its pressure should be approached with caution: some of the modern burners can be damaged by a pressure of 8 - 10 atm.

To reduce the need for cleaning the burner, a filter should be installed on the gas supply pipe. This can only be done by a specialist from the gas industry, where you need to apply.

Did you know that a modest voltage of 12 volts can also serve as a heat source? Assemble a 12 Volt heater with your own hands and check it yourself - instructions are included in the article.

Why you need an inverter for a heating boiler and how to connect it, you will find out by reading this information.

Conclusions and useful video on the topic

As you can see, building a gas stove will not be difficult even for a novice home craftsman and such a device will cost much less than a purchased option. This will require a minimum set of tools and materials, as well as some free time.

But, do not forget that homemade gas equipment is fraught with a hidden threat, so it is important to handle it very carefully and do not forget to turn off the gas supply when you are finished using the device.

If you had to assemble a gas stove yourself, please tell our readers about it. You can attach photos of the assembled device to the article and share the secrets of the assembly.

For heating small, remote non-residential premises, a homemade heater made from a gas burner and a heater made from a gas stove are suitable. To provide sufficient heat to medium-sized rooms, you should consider installing a gas heat gun or gas fireplace.

All devices considered can operate both from gas pipes connected to the room and from gas cylinders. It is worth remembering that when connecting to a gas pipe, it is necessary to install a meter and officially register the procedure with the gas control authorities. When installing a self-made structure, this procedure will become much more complicated.

If you use gas cylinders, you can effectively heat your room in the winter. It is important to remember that following safety precautions is the key to successful work with any gas devices.

Tags: gas, burner, hand, own, economical

« Previous entry