What it is?

This is a new generation heating device that can be used in any room. Its installation does not require complex installation work. During operation, the biofireplace does not emit ash, soot, smoke or ash. It does not have an exhaust hood, since the flame is generated by pure organic biofuel. All that is required to install the structure is a small free space in the room, be it a corner, wall or shelf, on which a tabletop biofireplace can be placed. The heating device can also be located in the center of the room.

Installation Features

As already mentioned, a chimney is not needed for a biofireplace, so their installation is much simpler than for classic modifications. Therefore, for proper installation it is enough to remember just a couple of points.

There are two main types of biofireplaces: free-standing and wall-mounted. If you want to see a free bio-fireplace in the interior, then this is the simplest option: you simply choose the right place for the fireplace and place it there. This safe design can even stand on a wooden floor without any problems. But wall-mounted fireplaces come with brackets similar to those used to mount TVs, so this requires a little more work: you secure the bracket in the desired location, and then hang the fireplace on it.

A few words about the origin

When the biofireplace appeared, Europeans were the first to know what it was in 1977. A patent for the invention of a stove without a chimney was received by a resident of Italy, Giuseppe Lucifora, who used alcohol as a combustible material. Since that time, interest in an environmentally friendly hearth began to grow steadily. The fireplace, as a fashionable room decor, was appreciated by interior designers, because it is very convenient to use, since it is not tied to electricity and communications.

In Russia, the demand for the new invention was low, since the bio-fireplace, whose price was thousands of dollars, could not compete with traditional models with chimneys. Only a few years ago, self-contained biofuel fireplaces began to attract interest on a par with electric fireplaces. And later, models appeared at quite affordable prices for the Russian average (on average, from 30 thousand rubles for floor and wall models).

A little history

Rice. 4. Corner ecological fireplace in minimalist style

The first sample of a biofireplace was created in 1977 by Italian engineer Giuseppe Lucifora. The designer suggested using alcohol in fireplaces, which eliminated the need for a chimney supply. The inventor's idea was adequately appreciated. It took several decades before regular alcohol was replaced by biofuels.

Biofireplaces offered in stores run on liquid bioethanol or gel; models running on helium are rare. It is worth clarifying right away that fuel vapors burn in eco-hot spots. This ensures complete combustion and long operating time on a single charge.

Modern decorative biofuel fireplaces are designed taking into account fire safety requirements. Experience in operating the equipment allowed us to identify and eliminate all possible risks. Advanced models have a sensor system that monitors the operating parameters and position of the device.

Advantages, disadvantages and features

The popularity of biofireplaces is understandable; they have a number of undeniable advantages.

Pros of biofireplaces:

- they can be installed in any house, apartment or office;

- there is no need to connect to the chimney and coordinate with the fire department;

- biofireplaces are easy to use, easy to light and extinguish;

- desktop models are mobile - they can be easily rearranged and even moved to another room;

- when burning biofuel, the fireplace does not emit harmful gases, soot, soot, and does not pollute the air and household items;

- A large selection of shapes, sizes and designs allows you to choose a bio-fireplace to suit every taste.

It should be remembered that when bioethanol burns, oxygen is absorbed from the air and carbon dioxide is released, so it is necessary to ventilate the room during its operation.

Owner reviews also point out the disadvantages of biofuel fireplaces :

- Unlike wood-burning, gas and electric fireplaces, a bio-fireplace cannot be used to heat a room; it produces little heat;

- the cost of the biofireplaces themselves and the liquid used for them is quite high and not everyone can afford it;

- Open flames and flammable liquids are potential sources of fire, so care must be taken when handling and storing biofuels.

Despite the disadvantages of using a biofuel fireplace, the advantages are still more significant, so owners of stylish apartments and houses are increasingly giving preference to them, despite the high price.

When installing stoves and boilers operating on solid fuel or gas, it is necessary to correctly select and install not only the unit itself, but also the chimney. We describe in detail how to do this with your own hands in this article. Here we give recommendations for effective chimney cleaning. How to act if reverse draft occurs - read here.

Pros and cons of an interior item

The obvious advantage of such a fireplace is that it does not work on the principle of standard combustion and does not leave any traces behind. Therefore, it can be used in any room, even where installation of a standard device is impossible.

There is a long list of advantages of a biofireplace. They make it a unique building. These include:

- No installation or connection to the chimney is required.

- Can be installed in any room.

- There is a huge range of different shapes and sizes of fireplaces presented by manufacturers on the market. You can choose a device that fits perfectly into the interior.

- The risk of fire is reduced, if not to zero, then to a minimum. This is achieved through a unique fuel tank design.

- To install a bio-fireplace, you do not need to request permission or coordinate this issue with government authorities.

- Fairly simple installation process. All you need to do is bring it home and place it in the chosen location. Afterwards you can use it. But for large structures built into the wall, you will need the help of specialists.

- The product requires virtually no maintenance or care. It is enough just to wipe it from dust from time to time.

- Approximately 300-400 grams of fuel will be consumed per hour of non-stop operation. It depends on the size of the structure.

- Some may think that the cost of such an installation will be quite high. This is wrong. The price starts from 10 thousand rubles and even this is much cheaper than the simplest classical installation.

- Various aromatic oils can be used. Just one drop of such a substance can spread a pleasant smell throughout the entire room.

Classification of biofireplaces

Depending on the installation location, biofireplaces are:

Wall-mounted biofireplace – placed on the wall. Most often, its dimensions are small: no more than 1000 mm in length and 150-250 mm in depth, but with individual production of a biofireplace, the dimensions can be increased.

A tabletop (so-called “bio-candle”) is a portable, portable fireplace that can be placed anywhere on the table. It is made in various geometric shapes (rectangular, oval, bowl, cylinder). Most desktop models, for safety reasons, are protected on two or four sides by glass walls.

Floor-standing (wall-mounted, central-standing) is a bio-fireplace that is installed on the floor surface in the middle of the room or near the wall. Such models are made from various materials: metal, natural stone, glass, ceramics, wood, steel.

Built-in bio-fireplace , or hearth, is built into a niche or small opening in the wall, which is designed before the construction of the building begins or can be made locally where this is permissible. Before installation, a protective box is also built into the niche.

Corner bio-fireplace - usually installed right in the corner, at the junction of two walls. Such fireplaces are compact and take up minimal space. Corner fireplaces can also be floor- or wall-mounted.

Outdoor - fireplaces that are installed in the yard, on a green roof, etc. Such fireplaces are large in size and weight.

Depending on the mode of operation, ignition and extinguishing, biofireplaces are divided into:

- mechanical;

- semi-automatic;

- automatic.

Principle of operation

The basic principle of operation of these fireplaces is identical to traditional ones - fuel is burned in a combustion chamber or niche, which provokes the formation of fire and heat. But there is a fundamental difference. Thus, biofireplaces use exclusively “biofuel” - bioethanol or alcohol, which does not produce combustion products and smoke. At the same time, the flame in such devices is as real as it gets, it’s just of a different type – not as hot as from wood, calmer and extremely safe. Unlike wood, a flame in a biofireplace is formed due to the combustion of fuel vapors - bioethanol, mixed with oxygen, while during combustion no soot, smoke or even sparks are formed. The absence of combustion products inherent in wood is due to the fact that the burning fuel breaks down into two simple and safe components - carbon dioxide and steam. Thus, such fireplaces do not require a chimney to operate, which is a key advantage.

Design and configuration of biofuel fireplaces

The designs of biofireplaces include a special tank or container into which fuel is poured. Some models may be equipped with burners and nozzles. The design of such fires also often includes a special damper, with the help of which the supply of oxygen to combustion is abruptly stopped and the fire goes out. Ignition or extinguishing of the flame in these fireplaces occurs very quickly.

To ensure maximum safety and practicality, many models of biofoci are equipped with special technical solutions. For example, special protection for the fuel tank, which prevents fuel from spilling out in the event of an unexpected overturning of the product. Many models in a higher price category are equipped with automation and sensors that monitor all operating and combustion processes in the hearth. Automation is also capable of abruptly stopping the operation of the fireplace in the event of an accident or incorrect operation of the product systems.

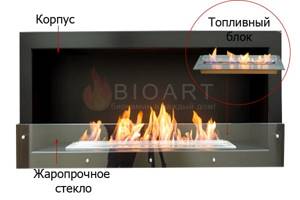

The main design of biofoci consists of:

- Fuel block (alcohol tank and burner)

- Main building

- decorative body (portal, cladding)

Depending on the model, configuration, dimensions and class, the biofireplace package may also include:

- automatic control system or unit (ignition and extinguishing, safety control, change of combustion modes, flame intensity and temperature level)

- unit and remote control at a distance

- audio module for simulating the sound of a burning fire and crackling wood

- steam generator to simulate smoke

- LED backlight to enhance the visual component of the flame

- decorative elements in the firebox (imitation firewood, etc.)

A decorative body—the lining of the fireplaces—can be considered a separate structural element. As a rule, it is this moment that is responsible for the design execution of the product, making it an independent and very advantageous participant in the interior.

Instructions for assembling a large bio-fireplace

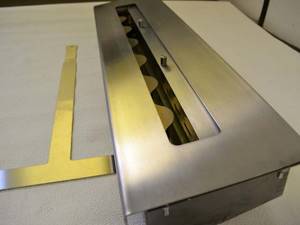

If you need to make a large bio-fireplace, the most difficult part will be making the fuel tank. The easiest way is to purchase a ready-made element in a specialized store.

If you plan to make the tank yourself, you need to take a sheet of metal more than 3 mm thick. It must be stainless steel, otherwise during combustion there may be unwanted chemical reactions and even the appearance of toxic fumes.

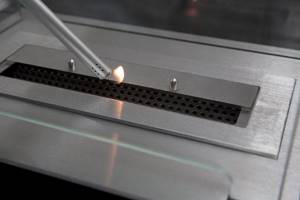

Specialized stores sell fuel tanks for biofireplaces made of stainless steel. They are equipped with convenient fire extinguishing valves

The tank itself should consist of two compartments. The lower one is for filling fuel. Vapors of flammable liquid burn in the upper compartment. Between these compartments there should be a separating plate with holes, thanks to which vapors enter the combustion zone. The shape of the tank may be different, depending on the fireplace model.

The most popular option is a parallelepiped-shaped fuel tank with a narrow upper compartment.

It is easier to make a cylindrical tank. To do this, you can take an ordinary mug and cover it with a lid cut to size from a fine-mesh metal mesh. Fuel can be poured through the mesh, which is quite convenient.

There may be several such tank mugs in the design of a biofireplace. They can be arranged in several rows or in a circle. It is important not to forget to remove the handles from the mugs. This must be done carefully so that a hole does not form.

Having decided on the fuel tank, you can start making a bio-fireplace. Let's make a floor model with two glass screens. To work, you need to prepare fire-resistant glass for screens, a fuel tank in the shape of a parallelepiped, washers, bolts and silicone gaskets for glass, plastic or metal legs.

In addition, to make the base we will need thick plywood or plasterboard, screws and 40x30 mm wood blocks.

Let's start from the foundation. We mark a sheet of plywood and carefully cut out the side parts of the base box and the top panel from it. We will not make the lower part of the box.

Firstly, its presence will significantly make the structure heavier. Secondly, it will be much more convenient to secure glass sheets without it. We are preparing two pieces of wooden block onto which the plywood will be attached.

You can make a bio-fireplace with two glass screens yourself. The design of the base can be very different - in the form of a console, table, box

On a panel cut from plywood we mark the place where the fuel tank will be fixed. Cut out the required mounting hole for the tank. Now we assemble the frame and attach the top panel to it. We process the edges of the structure well.

If we used drywall rather than plywood, its edges must be treated with putty. We decorate the resulting base in any suitable way: paint, varnish, etc.

Preparing glass panels. First, cut out two parts of the desired size. In each of them you need to drill holes for decorative fasteners. This is quite difficult, because the slightest mistake can cause the glass to crack. If you have no experience in such work, it is better to entrust the process to an experienced craftsman with a set of special tools. Holes for fasteners are also drilled on the side walls of the base.

Now we fix the glass screen to the base. To do this, we pass a bolt through the glass, do not forget to put on a silicone gasket so as not to damage the glass. We pass the bolt through the base, put on the washer and tighten the nut. This must be done extremely carefully, without applying excessive force, otherwise the glass may crack. In this way we install both glass screens.

During the assembly process, silicone gaskets must be used, otherwise the glass may not withstand the load and crack. It is wise to use a more durable option - tempered glass

You need to place legs on the bottom of the glass sheet. To do this, we put rubber gaskets into the parts and put them in place. We check the correct installation of the legs. The biofireplace should stand level and not wobble.

Using the prepared hole, we mount the fuel tank and securely fasten it. The structure is almost ready. All that remains is to decorate it with stones or ceramic logs, if necessary.

Kinds

Biofireplaces can be divided into several types, differing in location and method of installation:

Floor bio fireplaces

Particularly popular because the appearance of the models is closest to the classic look and have a high-strength body and portal.

Near-wall

Possibility to enjoy the view of the fire from only three sides. Made from natural or artificial stone. Despite the massiveness, mobility is not lost. Stable. Can be installed in open space. The peculiarity of this type is that the bottom of the bio-fireplace remains cool for safety reasons for the floor covering.

For location in the center of the room

They are made of glass with metal elements, and the fire can be seen from anywhere in the room. Installation in open space is difficult due to the uneven soil surface.

Wall mounted

Relatively small in size compared to floor-mounted ones.

There are 2 subspecies:

- Open fuel block - having the shape of a shelf, fenced with glass panels or grilles on one side or more. Perhaps the only drawback of this type is installation at a distance of at least one meter from furniture, curtains and other items prone to rapid fire.

- Closed. It is installed on the wall and looks like a painting. Produced in the form of glass blocks of different sizes. The front side is equipped with an openwork grille.

Desktop view

Compact, equipped with a small burner. It has high protection against fuel leakage in case of overturning.

Inline view

Installed exclusively in a niche. The closed top is made of fireproof tile or stone.

Outdoor bio-fireplace

The base is stable and can be installed on any type of surface. Characterized by the ability to enjoy fire from any side.

Instructions for making a compact model

Considering that the cost of such devices is quite high, many craftsmen are interested in how to make a bio-fireplace for a room on their own.

This is a fairly simple task, especially if you make a compact tabletop or floor-standing model. It can be roughly divided into two components: the fuel tank and the glass body. As a second one, you can use an old aquarium without a bottom.

For small-sized biofireplaces, you can make a fuel tank from an ordinary metal can. Its dimensions should be such that the container is hidden inside the base

For work we will need the following materials:

- a metal box that will be used as a base;

- metal reservoir for fuel tank;

- wick cord;

- a sheet of glass if there is no aquarium;

- silicone sealant;

- metal grid;

- small pebbles.

The tools you need to prepare are a glass cutter and scissors.

Let's get to work and start with the body. It will be a parallelepiped or cube without a lid or bottom. We determine the dimensions of the future structure and, accordingly, the length and width of its walls. Place the glass sheet on a flat horizontal surface, wash and degrease.

We apply a ruler to the line of the future cut and press it against the sheet. To prevent the ruler from slipping, you can stick an adhesive plaster on it.

We take a diamond glass cutter, place it on the sheet and move it away from us without strong pressure. The cutting line should be colorless and thin. If for some reason we don’t like the resulting line, we absolutely cannot circle it. You should retreat 1 mm and draw a new line. Having completed the cut, we move the glass to the edge of the base so that it coincides with the cutting line.

We carefully tap the cutting line with the head of the tool, then with a careful but precise movement we break off the glass that remains suspended. In this way we cut out all four parts of the required size.

Now they need to be glued together with silicone sealant. To do this, generously coat the side edges of the parts and connect them. Let the sealant dry. To do this, we fix the resulting structure between any fixed objects and leave it in this position for a day.

In order for the glued structure to dry while stationary, it must be fixed in any suitable way, for example, enclosed between three-dimensional objects

The dried body is cleaned of excess sealant. It will be convenient to do this with a blade. Let's start making the base of the bio-fireplace. It should be a metal box that matches the size of the glass case.

The latter should be easily and securely installed on a metal base. A metal can should also be installed inside the base, which will act as a fuel tank.

It is desirable that the volume of the tank is large enough so that you do not have to refill the bio-fireplace too often. The can is installed in the center of the structure. A part is cut out of a durable metal mesh, the size of which coincides with the base. It is placed on top of the fuel tank and secured to the edges of the base.

We make a wick from the prepared cord and lower it into a tank with fuel. Types of homemade burners for bio-fireplaces and instructions for their manufacture are discussed in our other article.

A fine-mesh metal mesh will become a reliable basis for laying decorative stones or ceramic firewood - aesthetic elements for decorating the device

We place pebbles or any other stones on top of the mesh so that they completely cover it. The stones will serve not only a decorative function. They will partially remove the heat that will be transferred from the burner to the metal mesh.

This way you can protect the glass from cracking. Now you can put the glass case in place. The compact bio-fireplace is ready for use.

Mechanical biofireplaces

Mechanical biofireplaces consist of:

- fuel block providing a living flame;

- housings;

- ignition system and lid, which allows you to extinguish the fire.

Design of a biofireplace of the hearth type

Fuel block (burner)

Only high-quality materials should be used for the biofireplace burner The best option is high-quality stainless steel. BIOART fuel blocks use high-quality heat-resistant stainless steel 5 mm thick. This material is least susceptible to oxidation and high temperatures. When heated, such steel will not deform.

All fuel blocks produced by BIOART are closed type; it is not the fuel itself that burns in them , but its vapor . This design allows you to turn the fuel block in any direction, but fuel will not spill out of it. The vapor combustion process significantly saves fuel consumption (about 1.5 times).

Advantages of BIOART biofireplaces

More information about the types of burners for bio-fireplaces can be found in our blog in the article “Types of burner designs for bio-fireplaces”.

Biofireplace body

The body of a biofireplace is its decorative part, which can be made from a variety of materials. Depending on the decorative purpose and the place where the fireplace will be placed, you can choose the following types of cases:

— panoramic housings that allow you to look at the fire from any of the 4 sides (for example, made of tempered glass or bio-fireplaces “glasses”). Biofireplaces with panoramic casings are more suitable for restaurants, pubs, bars, sofas, clubs;

- built-in - suitable for creating the illusion of a real wood-burning home fireplace. Installed in the wall. Built-in enclosures provide visibility only from the front.

Specially painted steel, metal, stones, marble, granite, veneer or fire-resistant glass can be used as decor and cladding for a biofireplace.

Preparing to make a biofireplace

To make your own fireplace, you first need to decide on its type, take the necessary measurements, and make a sketch of the future model. This will allow you to avoid errors during work.

Materials and tools

You can make a bio-fireplace at home using ordinary glass, for example, from an A4 photo frame, a glass cutter, silicone sealant, metal mesh, a mesh from a barbecue or oven, a metal box, pebbles or other heat-resistant stone, fuel and wick.

Do-it-yourself desktop biofireplace

The stages of its construction are as follows:

- We calculate the distance between the burner and the protective screen. It should exceed 15 cm to avoid damage to the glass. We measure the distance between the burners - it should be more than 16 square meters. cm.

- Preparing the fuel tank. You can use a simple square or rectangular metal box, keeping in mind the distance from the flame to the glass.

- Painting the drawer to increase its aesthetics. It is carried out only from the outside, as fire or release of toxic substances from the paint applied to the inner surface is possible.

- Creation of a protective glass casing. It can be made from ordinary three-millimeter glass or 4 glasses from a photo frame, which are adjusted to fit the metal box.

- The glass is glued together with silicone sealant, secured between supports, which can be any stationary objects, and left in this state for a day until the sealant dries.

- Excess sealant is removed with a blade.

- Biofuel preparation. Only a metal can is suitable for storing it, even if it was sold in a plastic one. The jar is placed at the bottom of the box. One standard container of fuel will support combustion for several hours, after which it will need to be replaced - you will need to remove the stones and mesh or fill in a new portion with a large syringe.

- Cutting a mesh to cover the box. This can be done in two layers. Its fastening will be more reliable if you use wire, but do not forget that the mesh must be removed to replace the can of fuel.

- Laying stones on the grid. They are needed not only as a decorative element, but also for uniform heat distribution between the grille and the screen.

- Ignition of a biofireplace with a torch lowered through a mesh into a container with fuel.

Do-it-yourself floor biofireplace

To design a floor biofireplace you need:

- Prepare materials: a sheet of drywall, 2 square meters of thermal insulation material, 2 square meters of tiles with glue, 8-9 meters of metal profile, a hundred screws and self-tapping screws, grout, stones or other decorative elements, heating unit.

- Assembling the frame using screws and a metal profile.

- Sheathing the frame with plasterboard and self-tapping screws, two layers on each wall, between which glass wool or other thermal insulation will need to be placed.

- Facing with tiles or other similar material. To do this, you need to carefully lay it out in accordance with the idea; for example, the fireplace can be made monochromatic or a pattern can be added.

- Grouting joints.

- Drying.

- Installing the heating unit in its place.

DIY bio-fireplace burner

The most reliable material for a burner is stainless steel. Its walls should be thick enough to avoid deformation when heated. You should also be very careful when assembling, since unreliable fastening or a defect will damage the bio-fireplace.

It is advisable that the burner be solid, so there is less chance that fuel will spill out. A paint can is best suited for this role, the main thing is to make sure that its size is suitable for the fireplace and that there are no cracks or holes in it.

Those who are not looking for easy ways can make the burner completely themselves; it is not difficult, since in appearance it looks like a large matchbox with an oblong hole in the top for pouring biofuel. Sheets of metal 1.5-2 mm thick are welded at the seams. You can add glass wool to it, which acts as a wick, and a damper, which will regulate the flame and extinguish it.

The burner is ignited with an ordinary wick, for example, a cord dipped into biofuel, the end of which will rise above the stones or other decorative elements.

Fuel for biofireplace

Bioethanol can be used as a fuel; it is sold in specialized stores, but can also be made at home, since it consists of gasoline, which is used to fill lighters, and ordinary medical alcohol, mixed 1 to 9. After mixing and shaking, the mixture is suitable for use.

Automatic bio fireplaces

The automatic biofireplace BIOART is a unique innovative development of our company’s specialists, which has no analogues on the biofireplace equipment market in Russia. This model is equipped with a control panel with automatic 3-level (2-level - semi-automatic) flame adjustment and a liquid crystal display that reports all changes in the operation of the device. The automatic bio-fireplace can be controlled from the remote control; it can be connected to a smartphone and WiFi; The semi-automatic bio-fireplace is equipped with push-button control.

The fireplace is equipped with a whole system of safety sensors that monitor the fuel level and temperature of the device.

Installation of a biofireplace

The installation location of the biofireplace is determined by the design features of the specific model. The installation of a bio fireplace can be done either with the help of specialists or on your own.

A fireplace with the “bio” prefix is a “highlight” of any interior, regardless of whether it is hung on the wall, suspended on mounts, placed on the floor, table or built into furniture. Some models of bio-fireplaces can be built into portals for wood-burning or coal fireplaces.

How to choose a biofireplace?

Appearance is not the only thing people pay attention to when studying the assortment in a store. The set of technical characteristics will help you choose the model that will be ideal for a particular room. When purchasing, you need to get acquainted with several important parameters. The list of properties includes:

- Biofireplace power. This is synonymous with the height of the flame, its saturation, and the heat transfer of the device. This figure for the most powerful devices can reach 7 kW. This value will make it possible to heat a room whose area is about 70 m2. However, we must take into account that in the summer it will not be very comfortable to be in a room with such a bio-fireplace: the heat will be very strong.

- Fuel tank volume. The larger the capacity, the longer the fireplace will burn after refueling the device. The maximum volume of the tank is 9 liters, but even with its smaller capacity, the main condition for filling a new portion is its emptying. We must allow the fuel to burn out completely.

- Burner: its material and thickness. There are two suitable options - ceramic element or stainless steel. The thickness of the last burner must be at least 3 mm, more is better. There are dual-circuit designs that return excess fuel to the fuel unit.

- Fuel consumption. It depends only on the operating mode chosen by the owners. If we take average numbers as an example, then we need to focus on 300-700 ml per hour.

All these characteristics cannot be considered separately, without taking into account the future room chosen for installing the fireplace. For example, if the owner’s goal is heating, then it is irrational to buy such a fireplace, since the price of biofuel is quite high. Due to the growing concentration of carbon dioxide, the room will have to be ventilated frequently, so this “duet” - a small space plus a powerful device - will require frequent opening of windows or vents.

How to make a fuel block with a burner

It is quite difficult to make a fuel tank with a burner, so it is often purchased ready-made. If the master has sufficient skills, the container can be made from a metal sheet with a thickness of at least 3 mm.

A burner for a biofireplace is most often purchased ready-made.

The tank is made of two compartments:

- Bottom - fuel is poured into it;

- The top one is used as a burner.

The tanks are separated from each other by a plate with small holes through which fuel vapors will flow.

A stainless steel mug with a mesh lid can be used as a fuel tank for a small fireplace. Placing several mugs in a decorative stand in a row or in a circle will increase the burning area.

Requirements for installation and operation of equipment

The location for the biofireplace determines the type and shape of the selected model. Even the owners themselves can install such a device. However, minimum requirements for its location still exist, since a biofireplace operates with a flame, and therefore produces heat.

- The room should be well ventilated and drafts should be avoided.

- The most powerful devices need spacious rooms. Such devices are not recommended for installation in rooms whose area is less than 25 m2.

- If the owners plan to buy a model with high thermal power, but problems arise with regular ventilation of the room, then installing high-quality supply and exhaust ventilation is no longer an advice, but a requirement.

- Fire left unattended by adults in the household is always a threat, especially for small children and furry (or hairless) curious four-legged “explorers.” Sleeping with a working fireplace is also not recommended.

- The fuel container must always be tightly closed. Fuel is stored far from the fireplace, and refueling the equipment requires turning off and completely cooling the device body.

- Replacing bioethanol with other liquids (gasoline or kerosene) is prohibited.

- When lighting a fireplace, use special long lighters.

Bio-fireplaces are allowed to be installed under or above televisions, but the distance from the line of fire to the television receiver must be at least 1 meter. The distance to other electrical appliances and any flammable objects should be similar.

Biofuel in a biofireplace

It’s not difficult to understand how a biofireplace works, but what is fuel with the prefix “bio”? Eco-friendly fireplaces were born thanks to the discovery of bioethanol. Despite such a loud name, the substance is familiar: it is industrial alcohol, which is obtained from legumes, grain crops, potatoes, sugar cane or beets.

Fuel advantage

A fireplace fueled by bioethanol promises:

- absence of unpleasant odor, soot, soot;

- light aroma due to the use of special additives;

- no burning splashes or flying sparks;

- economical fuel consumption.

The process of producing ethanol, technical alcohol includes 3 stages. This:

- preliminary preparation of raw materials - grinding;

- then - fermentation using yeast;

- its filtration is the removal of solid biomass from a liquid.

The result is weak ethanol (15%), which is then distilled and concentrated. Additives are added to the resulting ethanol after these operations, turning a simple product into a biological one - bioethanol. Alcohols obtained from organic raw materials (bioethanol, biobutanol, biomethanol), as well as dimethyl ether, are biological and environmentally friendly fuels. When burned, such products release only a small amount of carbon dioxide and distilled water vapor.

Product percentage composition

Colorless and flammable fuel consists of 95% ethyl alcohol. The percentage of other additives looks like this:

- water - 4%;

- bitrex (denatonium benzoate) - 0.01%;

- methyl ethyl ketone (solvent) - 0.5%;

- additives for odor and color - 0.5%.

In its pure form, this alcohol is completely odorless, but some manufacturers add fragrances to its composition. Burning fuel may smell like birch wood, coffee, rosemary, pine needles, etc. Flavored fuel also requires good ventilation.

Other possible (used) additives are sea salt, due to which a crackling sound appears during the combustion process, like real firewood, and special additives that give the flames an orange color.

Bioethanol consumption

What is the biofuel consumption in a biofireplace? It all depends only on the length of the fuel block. For every meter of it, approximately one liter of bioethanol is needed. This volume is enough to keep the fire burning for one hour. Each next liter of fuel will be consumed faster.

Questions and answers

What determines the price of a biofireplace?

The factors that influence it the most are design, size and management. Large devices with electronic settings will cost the most. The cheapest ones are small-sized burners without decoration.

Is fuel evaporating from the tank?

If the fireplace runs on gas, no. For ethylene-powered devices, yes. Even the damper does not completely retain alcohol vapor. But evaporation is minimal.

How hot is it in the room from a bio-fireplace?

Depends on its size and power. As a rule, large models really make you feel hot. There are no such problems with little ones.

Rules for the safe use of fireplaces

Despite the fact that biofireplaces are one of the safest fireplaces in the home , during their operation you need to follow simple rules .

- Models with an open combustion chamber must be installed at a considerable distance from combustible objects: textile interior elements, bookshelves, curtains.

- The surface on which the fireplace is installed must be level and stable, especially for models using liquid fuel.

- You should not leave the fireplace uncontrolled or trust children to light it.

- If the fireplace is not in use for a long time, drain the fuel from it. Bioethanol must be stored in a place that prevents overheating and contact with open fire.

- Fuel can only be added to a fireplace that is extinguished and has completely cooled down.

- Ignition is carried out with a special lighter for bio-fireplaces, which prevents burns.

- Bio-fireplaces can only be decorated using elements specially designed for this purpose: stones, imitation coals and logs made of heat-resistant ceramics.

- Built-in models must be installed in niches made of fire-resistant materials. Considering the numerous advantages and minor disadvantages, biofireplaces have every chance of winning a strong place among designers and owners of stylish apartments and cottages. Their installation and operation does not require extensive repair work; you just need to choose a model according to your taste and financial capabilities.

Do-it-yourself production of biofireplaces

In most cases, people decide to make a biofireplace with their own hands, having familiarized themselves with the models presented in the store and their prices. Having studied how a bio-fireplace works, you can immediately understand that there is nothing complicated in this system.

The device always consists of four basic blocks:

- frame for fastening elements;

- protective screen made of fire-resistant glass;

- fuel tank for bioethanol;

- burners.

If desired, a portal is mounted around the system, which allows you to fully integrate a biological fireplace into the interior, as usually happens with the classic version.

But despite all the simplicity, the cost of such devices is quite high, which is why in most cases it is more profitable to assemble a biofireplace with your own hands. In addition, a device you make yourself will become not only an excellent piece of furniture, but also your pride. You don’t have to make any extra efforts for this; simple skills in handling tools are enough, and all materials for a bio-fireplace can be easily purchased in suitable stores.

Hanging version of eco-fireplace

To assemble a biofireplace with your own hands, you need to prepare the following materials:

- To make a protective screen you will need glass. It is best to choose the hardened version, but in most cases the regular one will do just fine. The thickness should be chosen from 4-5 mm, this will be enough. You can buy a large piece and cut it yourself, but it is better to contact a glass shop, tell them the dimensions, and ask them to polish the edges. In this form, the glass for the bio-fireplace will look much prettier. In addition, in the workshop you can consult on methods for attaching the protective screen, because you can install it without gluing, or you can connect all the glass with sealant. The experts will tell you which heat-resistant sealant to choose.

- Metal containers and cans are usually chosen for the burner and fuel tank. In some cases, the fuel tank, frame and burner are a single unit, but it is best to provide an additional iron container that you will install inside the frame. The fuel block can be considered the main element of the system. Fuel should not leak out; the tightness must be at a high level. You can make a fuel tank for a biofireplace with your own hands by cutting out a metal tank and welding it together.

- To create a distributed fire that will occupy the space allotted to it, you will need a metal stack. The mesh is installed on the fuel tank. It is desirable that the cells in the grid be small; in extreme cases, you can fold the grid several times.

- The fire is brought to the grid using a wick, which can be an ordinary durable fabric cord. The wick for a bio-fireplace connects the fuel tank to the mesh, bringing the fire out.

- To decorate a biofireplace you will need appropriate elements. You can use stones, pebbles, ceramic imitation coals, firewood, and so on. Decorative elements are loaded inside the biofireplace, directly onto the mesh.

Good to know: Well-known foreign and domestic manufacturers of biofireplaces

For the system to fully operate, biological fuel is required. You can buy it in the relevant stores. Of course, you can make biofuel yourself, but you won’t save much from it, so it’s easier and faster to use a ready-made option.

You can find everything you need for a biofireplace in stores; there are no secret elements in its design.

Care instructions

Caring for a biofireplace is quite simple. Dust is removed from it with a regular cotton cloth. You can use a special liquid to clean glass surfaces. It is enough to rinse the heating unit with hot water. Before cleaning the fireplace, the main thing is to extinguish the fire and wait for the hearth to cool completely. Never attempt to start a fire with paper, magazine, or other flammable material. Use the special lighter included with the fireplace for these purposes. When operating the device, do not touch heating elements, logs or stones.

What are biofireplaces made of and what are they used for?

An ordinary classic brick fireplace is needed for heating the room, cooking and for interior aesthetics. The biofireplace performs the following tasks:

- serves as an interior solution;

- its power is capable of replacing an electric heater of 3000 watts;

- capable of humidifying the air;

- used in aromatherapy.

Biofireplaces consist of the following parts:

- deflector - a means of supplying hot air to the apartment;

- glass door so you can look into the fire;

- body made of wood, stone or glass;

- a heating unit, which includes a nozzle and a fuel container;

- a damper with which the height of the fire is adjusted.

In addition, the design also has auxiliary elements:

- mug;

- base;

- glass cylinder;

- plate.

Requirements for the room in which the biofireplace is installed

Due to the fact that the device does not require additional installation of special taps, it can be installed almost anywhere. The heating device can be located in a living room, in a country house, in a bar, restaurant, or in the fresh air. Decorative firewood placed in the hearth is made of ceramic stone. They create the effect of natural burning logs. However, there are some requirements for the future location of the bio-fireplace.

If this is a living space, then it must be ventilated. Infiltration during operation of the device should provide the room with a sufficient volume of air. A modern fireplace should not be installed in a cramped space of less than 25 square meters, such as a bathroom or shower room. If the room is isolated, it is recommended to open the existing doors to adjacent rooms during operation of the device. These measures will allow for air exchange and prevent excessive accumulation of carbon dioxide in the room. In a larger room, it is enough to open a window or window. The fuel used is non-toxic and safe to inhale. Any bio-fireplace, tabletop or built-in, can be used as a means of aromatherapy. There are special kits on sale containing aromatic herbs and plants.

What is biofuel

The main substance in the composition is bioethanol. This is a renewable type of fuel that is safe for the environment and humans. It is made exclusively from raw materials of plant origin, isolated from sucrose and starch-containing crops.

Stages of biofuel production:

- Preparatory work. The raw materials are crushed and cleaned.

- Fermentation. The substrate is saturated with yeast fungi, after which it is filtered to remove solid particles and fusel oils and impurities.

- Distillation and concentration. The resulting product contains 15% ethanol. By distillation, the alcohol concentration increases to 96-98%.

- Adding additives. Pure bioethanol is dangerous for human consumption, therefore, through the use of flavoring additives, it is converted into industrial alcohol. The manufacturer may add flavorings and coloring.

The cost of biofuels is explained by the complexity of the technology and deep filtration. You can find a recipe for making bioethanol with your own hands, but using it in proprietary equipment will result in breakdowns. Homemade biofuel has a different composition, which means the device will not work as the manufacturer intended. In such cases, you can forget about repairing the bio-fireplace under warranty.

Rice. 11. An example of refueling a fireplace using environmentally friendly fuel

Advantages of branded biofuels:

- complete combustion;

- absence of harmful substances;

- even fire without sparks or splashes;

- economical consumption;

- natural color;

- no odor;

- no smoke;

- the formation of an oily layer on the surface of the lesion and portal is excluded.

When burned, a mixture of air and bioethanol vapor turns into water and carbon dioxide in a small volume. A medium-sized biofireplace produces the same amount of CO2 during operation as a person does when breathing.