The operating costs of waste oil heating boilers are among the lowest, often even lower than the cost of gas. The process of installing heating equipment is also cheap, and boilers operating on exhaust gas are comparable in reliability to their gas or diesel counterparts.

However, they still have not gained wide popularity due to the high initial cost (usually from 100 thousand rubles), the need for constant daily care, and less functional automation and controls (with the exception of extremely expensive models). However, if you understand all the advantages and disadvantages of oil boilers, the choice may well be justified.

What is an exhaust boiler?

So, what is a waste oil boiler, which is often popularly called simply a waste oil boiler? This is a heating system that uses cheap, waste raw materials, in this case oil, for heating. Of course, the use of low-quality media has a number of disadvantages, which is why waste oil boilers are not used in private houses and apartments. However, if we are talking about a barn or other non-residential premises, then this heating method can be very useful.

Where waste oil boilers can be used:

- In the garage;

- Barn;

- Teplice;

- Livestock premises.

A waste fuel burner can operate on any type of waste oil, even synthetic. Any used liquid fuel can not only be used efficiently, but also disposed of at the same time, so some even manage to make money using such heating systems.

Some general information

Despite the fact that gas is currently the most profitable energy resource, its prices are gradually increasing, just as other alternative heat sources are becoming more expensive: electricity, coal, firewood. It is for this reason that many people are constantly actively searching for alternative inexpensive options for installing heating systems in their home.

Currently, people are increasingly giving their preference to heating using waste oil, although they use it to heat utility rooms and garages. This popularity is due to the fact that the cost of equipment of this type is practically no different from a gas heating apparatus, but at the same time, much less money is spent on servicing a boiler operating during exhaust.

Boiler with built-in burner

It is not difficult to buy a boiler that operates on waste oil. Any specialized stores sell such goods. And even if it is not in stock, in any case it can be purchased to order. Moreover, you can assemble a boiler that runs on waste oil with your own hands. Its design is quite simple, so even an inexperienced person can assemble such a unit with his own hands using detailed instructions. However, it is extremely undesirable to use a self-made boiler as the main heating equipment for heating a private residential building. In this case, it is better to give preference to liquid fuel boilers, which can also operate on waste oil, but at the same time are professional and absolutely safe equipment.

The boiler being tested for heating a house must be factory-made with an automatic control system.

Principle of operation

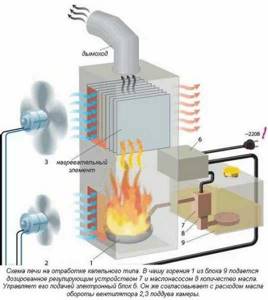

Equipment operation diagram

For the most part, waste boilers are pyrolysis, when it is not the fuel itself that burns, but the gas-air mixture released when the waste oil is heated.

Depending on the method of oil supply, there are two main types of boilers - by gravity (based on the principle of communicating vessels) or by forced injection by an oil pump and drip supply of fuel to a hot bowl.

In general, such equipment does not emit unpleasant odors due to the fact that the entire volume of fuel is burned, releasing a large amount of carbon dioxide. In fact, mining is already waste; therefore, the heating equipment and its installation literally pays off in full within a year or two.

Also reading with this article: Do-it-yourself waste oil boiler with a water circuit

Advantages and disadvantages

If we talk about the advantages of such functional equipment, they include:

- low cost of equipment, and if you assemble it yourself it will be very cheap;

- availability of fuel resources - some people prefer to buy waste from warehouses, while others get it for free;

- high efficiency;

- multifunctionality;

- ease of installation and operation.

But as for the disadvantages, to ensure efficient operation of the heating unit you will need to choose high-quality used oil without harmful impurities.

VIDEO: Review of waste oil boiler fire

Types of heaters during testing

Waste oil heating boilers are divided into three types:

- water heating;

- heating;

- household

Water heating oil boiler

As the name implies, such devices are nothing more than an alternative to modern boilers.

And the functioning scheme of such devices is platform-based: the device heats up a flat surface on which a tank filled with water is located. The outlet of the tank is equipped with a small pumping unit; it is necessary to regulate the pressure of the system. I would immediately like to say that it is extremely difficult to change the temperature of the water, so you will have to dilute it with cold water.

As a rule, in heating units of this type, tanks with a volume of no more than 140 liters are used. The water is heated in approximately two hours, which is several times faster than the operation of a modern electric boiler. And in terms of energy resources used, an oil-fired apparatus outperforms an electric heater.

Oil water heating boilers can operate in two modes:

- Fast. This mode is used to quickly warm up freshly poured or completely cooled water.

- Wick. Thanks to this function, the water is always heated. True, maintaining this regime will require a lot of fuel resources.

Operating principle of a torch burner

Water heating devices operating on waste oil are installed mainly in basements, since they are not transportable.

Heating blocks

It is not advisable to place this type of heating units in a residential area. As a rule, such equipment is installed in a special building. Despite the fact that such units are equipped with advanced filtration units, during operation they often emit the smell of machine oil.

Inside the heating block there is a special “heating” unit equipped with a water tube and a hydraulic pump. The last structural element is capable of operating both from the electrical network and from the energy generated by the unit itself. A hydraulic pump circulates the coolant in the circuit. As a rule, ordinary tap water is used as a coolant.

The operation of the equipment is simple: a mixture of waste vapors and air masses is burned, which are supplied through a ventilation compressor. The fire level is adjusted using a primitive hose equipped with a valve. The ventilation device is the only structural element of this equipment that makes any movements, so it can sooner or later become unusable.

How does the combustion process occur?

And more generally speaking, a waste oil boiler for heating premises operates for a long time without any repair and restoration work. The only thing that can cause the device to become unusable is poor maintenance and the use of low-quality fuel.

Domestic boilers

Such universal devices will be an excellent option for organizing country houses. They are, for the most part, equipped with a gas purification mechanism, thanks to which they operate practically without smoke. And the consumption of fuel such as transformer oil for the heating system, in comparison with the options discussed earlier, is minimal.

VIDEO: Ignition of a boiler using waste oil

The main advantage of such devices is mobility, due to which it can be moved from place to place without the risk of disrupting performance. Such equipment can easily fit even in the trunk of a car. And this, in turn, makes it possible to use the unit outdoors, outside the city, in the country, or while traveling. In addition, it performs several functions that are important for a full-fledged existence, in particular, it quickly and efficiently heats the room, and is multifunctional, where, along with heating, you can even warm up food.

Heating boiler under development: pros and cons

The obvious advantages of a waste oil boiler include the low cost of fuel, but the list of advantages of such a system does not end there.

Typically, the advantages include:

- Low cost not only of fuel, but also of the boiler itself. The design of the heating system is so simple that some even decide to do the work themselves and make a boiler with their own hands. It is believed that, on average, a waste oil boiler pays for itself in a year, after which heating becomes almost free, since the cost of waste oil is free.

- The boiler has no exhaust. Many may think that a waste oil boiler is extremely harmful to humans or the environment, because it burns low-quality fuel. However, in fact, no matter what is burned in the boiler, it is burned completely, even the vapors from the fuel do not evaporate, but burn. As a result, you get, oddly enough, a completely safe and environmentally friendly installation.

- Fast and complete warm-up. A boiler for treatment during the heating season will be simply irreplaceable. Fuel consumption is negligible, and the room warms up in a matter of minutes, since the firebox contains flammable oil. The temperature and burning rate of oil and vapors are very high, so the room warms up quickly and evenly.

- Simple design. If you have a couple of gas cylinders, steel pipes, sheets and a number of other standard materials in your workshop, then you can build a boiler with your own hands. In any case, even buying a boiler will not be expensive.

One of the disadvantages of exhaust boilers is that the unit exhausts air. A waste oil boiler works by burning oil and vapors, but this process requires oxygen, so the boiler literally sucks all the air out of the room. This is one of the main reasons why such boilers are not used in residential areas. For a garage or barn this is not a problem, however, in a livestock building you will have to consider an air ventilation system.

Besides this, there are some other disadvantages:

- Oil requirements. Of course, you can’t just take used oil and pour it into the boiler; it must first be filtered. True, if you give the oil time to settle thoroughly, it will filter itself and you can save on filters. If you regularly pour low-quality oil into the boiler, it will quickly break down.

- The need to frequently clean the exhaust pipe. Unfortunately, there is simply no escape from this - the pipe will have to be cleaned really often, so you should prepare in advance for regular cleaning.

Waste oil boiler

I bought this boiler two years ago, started it up, set it up for a long time, and still smokes. A few days later, the gears in the oil pump broke, they turned out to be plastic, they restored it with their own hands, and converted it from the oil pump of a Ural motorcycle. Manufacturers are not very responsive, I would even tell them about our problems. Further, after the boiler had been running for about 10 hours, there was a power outage, and then the complete breakdown came... accordingly, after the shutdown, the automation and the fan that supplied air turned off, after a minute the boiler began to fire like a cannon, throwing out flames through the hole through which air was supplied from the fan, after the first shot, a flame of 1.5-2 meters passed 20 cm from my face and it continued shooting for about 10-15 minutes until the oil burned out and the boiler went out, fortunately there was nothing flammable nearby. Can you imagine my state at that moment, because I could have remained disabled and only by a lucky chance my face was not in front of the flame, this shot could even have killed me. I call with a complaint, they tell me, probably your hood is bad, they say the pipe is low, my pipe is 1.5 meters higher than the ridge of my building, the building is two-story, approximately the height of the pipe is 14 meters, the pipe is insulated with mineral wool and sheathed with galvanized sheet, that is, everything is as it should be. At that moment, the month of December, I was doing finishing work and desperately needed heat, I heated the first floor with a diesel gun, and the second floor with two gas guns, it took a lot of gas and diesel fuel and it was expensive. It was planned to use the oil recovery boiler in parallel with the gas boiler, and there would be some savings, so a car service center was planned on the first floor, and an administrative center on the second. Conducting gas is not an easy task, and it takes a long time, and I didn’t want to curtail the finishing work, so having calmed down a little from the shots, a week later I decided to start the boiler again, but now I realized that the battery must be connected in parallel to avoid the It was after a power outage. I lit the boiler, started it up, everything worked, but then a curious plumber, who came to check the batteries and the entire heating system that they had installed, decided to look into the firebox, opened it, and a flame began to come out from there, after which the flames were drawn into the boiler and suddenly splashed everything out through the firebox along with the oil and it all caught fire on the walls and on the floor, fortunately a bucket of water and a fire extinguisher were nearby and fortunately this burning oil did not splash out on that plumber. Here’s the story... I bought a boiler for 80,000 rubles, paid about 5,000 rubles for delivery to Tatarstan, now this boiler has been standing for two years as an exhibit and reminds me that I shouldn’t mess with uncertified homemade products and such charades as “Stavpech”. They didn’t give any instructions or really explain anything, and they didn’t even hint at warning about those unpleasant situations. I wanted to sue them and contact the police, but construction was in full swing, and I wanted to finish the construction quickly. And after all this, I began to move more actively on the gas. They gave me gas, I heat up without any problems, but I accidentally remembered about this boiler and decided to write to people who are thinking about buying, don’t make mistakes. Remember “Stavpech” is bad...

Exhaust burner for a boiler - what is it and what is it used for

Some people are confused about the terms and believe that a boiler and a waste oil burner are the same thing. In fact, the burner is an additional equipment that can be installed either on the boiler itself or on its own.

Due to the exhaust emissions, this equipment can only be used outdoors or in special areas. indoors.

The burner does not play the role of heating equipment, and the task of the device is solely to heat water. The burner is easy to operate, but has a big disadvantage - exhaust emissions, so the equipment cannot be used to heat water in a living room.

Exhaust flow in the boiler

One full boiler tank is usually enough to heat an average-sized room for one day. This means that the boiler will require about 6-7 liters of waste oil per day at the height of the heating season.

During periods of warming, consumption decreases, since the boiler power can be increased.

At such moments, consumption drops to 2-3 liters per day. In any case, this is very little compared to any other heating devices, given the cost of used oil.

Waste oil boilers Teploterm

Boilers from the domestic manufacturer Teploterm are quite popular in the modern market. They are economical to operate, inexpensive, and yet highly efficient. The only serious disadvantage of boilers is the need for regular cleaning, at least once every two days. Sometimes cleaning is required daily.

Most of the manufacturer's models on the market have a power of 30 kW. Such a boiler is enough to heat a fairly large room, about 260-200 square meters. meters.

The boiler's electricity consumption is about 90 W/h, while, according to customer reviews, the efficiency is about 2-3 times higher than that of heating with wood. On average, about one scoop of ash is generated in the form of waste per day, so there is simply no escape from regular cleaning of equipment. Among the main advantages of the equipment are durability and low fuel requirements - the models accept almost any used oil with a bang. The boiler produces some waste even without filtering.

Russian-made equipment

Most Russian boilers use a different technology: the oil is first evaporated, and then its vapors are ignited. Thus, two main problems with burners are eliminated: dependence on the quality of spent fuel, multi-stage preparation, and a clogged nozzle.

Waste oil boiler for air heating

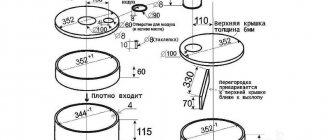

The design of such devices is simple: a plate is located at the bottom of the combustion chamber. Before starting to supply oil, it is heated, then drops of oil are applied to the hot metal. The fuel evaporates, the vapors rise higher, where they mix with air and burn out.

With a correctly configured combustion mode (temperature around 600oC), complete oxidation of all components, including heavy bituminous ones, occurs. As a result, the output is nitrogen, water vapor and carbon dioxide. When the temperature changes in one direction or another by 200oC, the “exhaust” contains a lot of harmful substances that are carcinogens, mutogens, cause poisoning and a whole range of other negative consequences. Therefore, it is worth purchasing industrial certified units. Despite their considerable price (compared to home-made units), they pay for themselves in the first year, maximum two (due to the low cost of fuel).

BELAMOS NT Series

Belamos NT hot water boilers using waste oil do not require pre-filtration of the fuel and its heating. The built-in heat exchanger allows you to achieve a fairly high efficiency. The operation is controlled by electronics, which monitor the coolant temperature, oil flow, and turn off the boiler when the flame goes out. For ease of maintenance (cleaning of the combustion chamber and bowl is required), there are service hatches. Belamos NT boilers are produced with a power from 10 kW to 70 kW.

Boilers in production BELAMOS Series NT

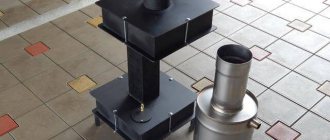

Furnaces "HEAT"

Zhar furnaces operate on waste oil, diesel fuel, and mixtures thereof. The transition from one fuel to another occurs by moving the switch to the desired position. The Zhar mining furnaces use a drip fuel supply method, that is, they do not have burners and nozzles that become clogged and require cleaning. All boilers are equipped with automation that controls the process.

Basically, “Zhar” are heat generators for heating industrial premises, but there are also hot water boilers. This is the Zhar-20 model with a power of 30 kW and fuel consumption of 3 l/hour. The boiler has a tank for diesel fuel with a volume of 20 liters, and for working off with a capacity of 60 liters.

Heating furnaces using waste oil "ZHAR"

Boilers and furnaces "Teploterm"

Teploterm boilers are produced with power from 5 kW to 50 kW, efficiency 90%. The water jacket allows you to effectively remove heat from the body and provide heating for rooms with an area of 50 m2 or more. The remote oil pump can be lowered into a canister or other container with fuel; the built-in boost fan and oil pump power supply ensure the operation of the system.

The coolant temperature is controlled. There are two modes for adjustment; switching occurs automatically (built-in thermal relay at the coolant outlet). Oil consumption from 0.6 liter/hour to 5.5 liter/hour.

Boilers and furnaces "Teploterm"

Water heating boilers TEPLAMOS series TK-603

Teplamos TK waste oil boilers operate on the evaporator principle. The oil drops onto a hot plate. There are almost no special restrictions on the quality of the fuel used; no preheating is required (if the oil is in a heated room) or other preparation. Only preliminary filtration is needed to remove foreign bodies.

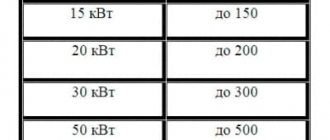

"Teplamos" are produced as single-circuit and double-circuit. Equipment power is from 15 kW to 50 kW, fuel consumption is 1.5 liters/hour - 5 liters/hour.

There are not so many Russian-made boilers in production, but people find a way out in any situation. For example, they put a burner on a regular liquid fuel and use it with this type of fuel. Buying a burner is easier and cheaper than buying a new boiler. There are these units of handicraft production, and there are industrial ones. For example, like in this video.

Similar burners are installed on KChM boilers, which can then operate during mining.

There are used boilers and home-made boilers. Read how to make such equipment with your own hands here.

There are many offers on the market, it’s not easy to navigate. When choosing, you first need to decide on the combustion system: nozzle or drip feed. Then look for manufacturers of boilers in this category. Having chosen the ones that are suitable for the price, compare the characteristics. The first is power, the second is fuel consumption per hour. Good luck!

How to make a boiler for mining with your own hands

If you have the necessary materials on hand, you can even make a boiler yourself. The first thing you need for this is a pump to supply oil from the fuel tank to the combustion chamber.

In addition, you will need:

- a tank where the fuel will be stored;

- burner;

- appropriate pump for circulating water in the heating system.

In general, this is all, although in most cases the boiler works more efficiently with a compressor that supplies air; you can do without it, but with it combustion will occur faster.

If all the elements of the future boiler are at hand, then you can begin assembly. Experts believe that assembly is the most labor-intensive process in this matter. The most important thing is the scheme, which must be correctly calculated. You can entrust the development of the scheme to a trusted specialist, and take on the actual work according to the plan yourself.

Review of popular models

If you still decide to buy a waste oil boiler, then below you can view the most popular models.

| Model | Characteristic | Price (average), rub. |

| Teplotherm GMB 5-9 kW | — Double-turn for exhaust, fuel oil, heating oil 5-9 kW with continuously adjustable coolant temperature and increased heat transfer area (efficiency 90%) — Has an oil pump power supply and a built-in boost fan. — Remote oil pump on a rod for a canister, barrel, etc. — Heating by manual ignition has two operating modes: minimum for maintaining combustion and maximum - operating mode. — Automation is implemented on the basis of a multifunctional microprocessor. — Automatic switching between modes. — Blocking from restarting after a power failure. — In case of attenuation, protection against oil overflow is provided. - The boiler is not afraid of boiling. — Oil consumption 0.6 — 1.1 l/hour. — Electrical power consumption — no more than 200 W. — The capacity of the water jacket is 12 liters. — Overall dimensions (LxWxH) 700 x 300 x 800 mm. — The diameter and height of the boiler without protruding parts are 320 x 650 mm. — Complete set: boiler, control cabinet, fuel hose, remote oil pump. — Chimney diameter 110 mm. — Weight 61 kg. | 52 000 |

| Teploterm GMB 10-15 kW | - 10-15 kW. — Blocking from restarting after a power failure. — Oil consumption 0.9 — 1.7 l/hour. — Electrical power consumption—no more than 200 W. — Water jacket capacity — 19 liters. — Overall dimensions (LxWxH) — 700 x 300 x 800 mm. — Diameter and height of the boiler without protruding parts. — 320 x 650 mm. — Chimney diameter 110 mm. — Weight 81 kg. | 58 000 |

| Teploterm GMB 10-20 kW | — Oil consumption 0.9 — 2.1 l/hour. — Water jacket capacity — 30 liters. — Power consumption — no more than 200 W. — Overall dimensions (LxWxH) — 850 x 370 x 900 mm. — The diameter and height of the boiler without protruding parts is 430 x 800 mm. — The kit includes a boiler, control cabinet, remote oil pump, fuel hose. — Chimney diameter 110 mm. — Weight 110 kg. | 68 000 |

| Teplotherm GMB 10-30 kW | — Fuel consumption 1.6 — 3 l/hour. — Electrical power consumption—no more than 200 W. — Minimum and maximum modes are adjustable. — Water jacket capacity — 44 liters. — Overall dimensions (LxWxH) — 780x370x1200 mm. — The diameter and height of the boiler without protruding parts is 430 x 1000 mm. — Chimney diameter — 159 mm. — Weight — 37 kg. | 78 000 |

| Teploterm GMB 30-50 kW | — Fuel consumption 3 — 5.5 l/hour. — Electrical power consumption—no more than 200 W. — Water jacket capacity — 57 liters. — The diameter and height of the boiler without protruding parts is 530 x 1100 mm. — Chimney diameter — 159 mm. — Weight — 271 kg. | 97 000 |

| Teplotherm GMB 30-70 kW | — Fuel consumption 3 — 7.5 l/hour. — Electrical power consumption—no more than 200 W. — Water jacket capacity — 77 liters. — The diameter and height of the boiler without protruding parts are 530 x 1400 mm. — Material — St3. — Chimney diameter — 159 mm. — Weight — 350 kg. | 117 000 |

| GeKKON 15 | — The rated power of the unit is 15000 W. — Conditional heated area — 150 m². — Working pressure (max) — 3 kg/cm². — Operating voltage — 220V. — Power consumption — 100 W. — Water temperature in the boiler (max) — 95 С. — Operating time without maintenance: 10-12 hours. — The outer diameter of the chimney is 110 mm. — Fuel consumption — 0.5-1.5 l/hour. — Weight — 100 kg. — Overall dimensions (LxWxH) - 850x560x360 mm. | 69 500 |

| GeKKON 30 | — The rated power of the unit is 30,000 W. — Conditional heated area 300 m². — Working pressure (max) - 3 kg/cm². — Operating voltage: 220V. — Power consumption - 100 W. — Water temperature in the boiler (max) - 95 C°. — Operating time without maintenance is 10-12 hours. — The outer diameter of the chimney is 115 mm. — Fuel consumption -1-3 l/hour. — Weight — 125 kg. — Overall dimensions (LxWxH) — 900x600x400 mm. | 80 200 |

| GeKKON 50 | — The rated power of the unit is 50,000 W. — Conditional heated area — 500 m². — Working pressure (max) - 3 kg/cm². — Operating voltage: 220V. — Power consumption - 100 W. — Water temperature in the boiler (max) - 95 C°. - Operating time without maintenance - 10-12 hours. — External diameter of the chimney: 135 mm. — Fuel consumption: 2-5 l/hour. — Weight — 160 kg. — Overall dimensions (LxWxH) — 950x660x460 mm. | 101 000 |

| GeKKON 100 | — Weight 250 kg. — Overall dimensions (LxWxH) — 11160x850x540 mm. — The rated power of the unit is 100,000 W. — Conditional heated area — 1000 m². — Heated area - up to 1000 m2. — Working pressure (max) - 3 kg/cm². - Operating voltage - 220 V. - Power consumption - 250 W. — Water temperature in the boiler (max) - 95 C°. — Operating time without maintenance is 10-12 hours. — The outer diameter of the chimney is 160 mm. — Fuel consumption - 3-10 l/hour. | 163 000 |

| EcoBoil-18/30 | — Types of oils that can be used for heating: used motor oils, transmission oils, hydraulic oils, kerosene. — Boiler power — 15 kW. — Oil consumption — 0.5-1 l/hour. — Weight — 57 kg. — Overall dimensions (L × W × H) — 500×500×1000 mm. — Chimney diameter — 108 mm. — Water circuit volume — 18 l. — The boiler package (single-circuit boiler) consists of a pressurization fan into the combustion chamber of the “scroll” type, a gear oil pump, a hose for connecting the oil pump with the supply to the boiler, an automatic control unit, an instruction manual, and a product data sheet. | 36 800 |

| EcoBoil-50/46 | — Boiler power — 46 kW. — Oil consumption — 2.5-3.2 l/hour. — Weight — 96 kg. — Overall dimensions (L × W × H) — 720 × 5720 × 1100 mm. — Chimney diameter — 133 mm. — Water circuit volume — 56 l. — Suitable for heating premises with a total area of up to 460 m². — Used oils of various origins are used as fuel: waste motor oils, gearbox and automatic transmission oils, oils from hydraulic equipment, diesel fuel and kerosene, various vegetable oils. — The boiler automation is connected to a 220 V network with a reduction to 12 V at the output (power supply to the oil pump motors and the inflatable furnace fan). — The boiler configuration (single-circuit boiler) is the same as the previous model. | 71 000 |

| EnergyLogic EL 340h | — Productivity — 4740 m³/hour. — Thermal power — 99.6 kW. — Fuel consumption — 8.5 l/h. — Power consumption — 2.2 kW. — Power supply — 220 V. — Chimney diameter — 285 mm. — Overall dimensions (WxDxH) — 1120x2520x560 mm. — Weight — 248 kg. — Standard equipment includes a fuel pump system, a fan, a fuel heater, a burner with a spray nozzle, a built-in air compressor, a horizontal steel heat exchanger, shutters for hot air outlet, a chimney elbow with a draft regulator, a thermostat, an hour meter, a heat exchanger, a draft meter, an hour meter , draft regulator, fuel filter. | 516 000 |

| DanVex B 30 | — DanVex boilers with high efficiency are designed for heating water in space heating systems, as well as for producing hot sanitary water (when equipped with a boiler). — This model has spark ignition. — Fuel/heat of combustion - waste oil, diesel, heating oil / 9000-10300 Kcal/kg. — Firebox type — reversible, two-pass. — Total thermal power — 35.6 kW/hour. — Useful thermal power — 31.3 kW/hour. — Electrical power consumption, max. - 1.4 kW/hour. — Mains voltage/frequency — 220/50 V/Hz. — Fuel consumption — 0.0033 m³/hour, 3.3 l/hour. — Combustion products are discharged into the chimney. — The diameter of the chimney pipe is 200 mm. — Overall dimensions (L*H*W) (without burner) — 795x625x585 mm. — The weight of the boiler without coolant is 157 kg. | 345 000 |

| Gnome 10-50 | — Thermal power 30-59 kW/h. - Min. firebox length 430 mm. — Engine power 110 W. — Engine speed 2800 rpm. — Designed for highly efficient combustion of various types of liquid fuel (any waste oils, vegetable oils, animal fats, diesel fuel, etc.). | 65 000 |

| De Dietrich 307/ii | — Power range — 180-230 kW. — Pressure drop — 0.03 (with a temperature difference of 15 degrees C) bar. — Excessive pressure in the furnace — + 1.6 mbar. — Coolant volume — 156 l. — The volume of the smoke circuit (firebox + channels) is 0.292 m3. — Fuel consumption — 379 kg/h. — Natural gas consumption — 410 m³/h. - Number of boiler sections - 7. - Firebox depth - 1101 mm. — Firebox volume — 0.174 m³. — Overall dimensions (WxDxH) — 796 x 1318 x 1297 mm. — Weight — 791 kg. | 216 000 |

You can read about the features of double-circuit boilers during testing here.

Waste oil is a good source of energy. In particular, when other heat carriers are not available or are not affordable. If everything is made with high quality, then a boiler using waste oil with your own hands will work no worse than one purchased at the factory.

Assembling a waste oil boiler (video)

In general, a waste oil boiler is an excellent alternative to conventional boilers. Such equipment has its drawbacks, so it is not recommended to use it in private homes. However, in the case of a barn, garage or cottage, a boiler can be an excellent solution. It uses little electricity and requires cheap used oil to operate. The advantages of the boiler are obvious - it is economical and affordable, while the heat transfer is at a high level. The disadvantages of the boiler are the need for regular cleaning; it is advisable to clean the exhaust pipe once a day, but in some models cleaning every other day will be sufficient. During its operation, the boiler very strongly pulls all the air out of the room, so for safety you need to either provide ventilation in the room or directly supply air directly to the firebox. You can make a boiler using waste oil with your own hands, but it is better to entrust a professional with at least the development of a plan in which mistakes cannot be made. According to the finished scheme, assembling the boiler should not cause difficulties. The consumption of waste oil in an average boiler is about 7 liters per day during the winter period and in the summer about 2 liters for heating water.

Comments

0 Dina 01/08/2018 21:57 In order for such a boiler to work, you need a lot of oil, it costs much more than regular solid fuel, so I would not recommend installing such a boiler.

There are now a huge number of analogues. Quote

Update list of comments RSS feed of comments for this entry

What is the difference

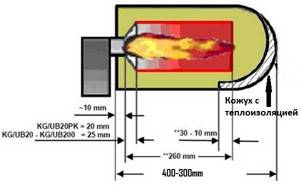

If we talk about furnaces for testing industrial production, then there are no fundamental differences. Everything is the same as in diesel fuel units: fuel is supplied under pressure to the nozzle, the resulting small drops are mixed with air and ignited by an electrode located in front of the burner.

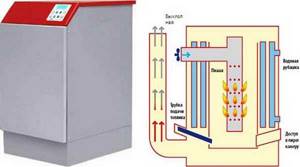

An important feature: only preheated spent fuel is sprayed (in boilers using conventional liquid fuel, this stage is not necessary). The main difference lies in the burner: it has a special structure. To completely burn out all the “heavy” bituminous components contained in the used oil, an additional afterburning chamber is attached to the burner, additionally covered with a thermally insulated casing. They do this to achieve higher temperatures, at which complete decomposition of all fuel components occurs. It’s clear: such equipment is more expensive.

The waste oil burner is equipped with an additional casing with thermal insulation for complete combustion of “heavy” components

In addition to the features of the burner, there are design changes to the boiler itself. To increase efficiency, a two- and three-pass heat exchanger is used, that is, the air passes three or twice through heated pipes in which it is heated.

The heat exchanger in boilers during production is made of two or three passes

The number, location and diameter of smoke pipes also differ. They can be located around the perimeter, can be localized above the firebox or at the top and sides. The main difference between waste oil boilers is the larger diameter of the heat exchanger pipes and the absence of turbulators in them.

For waste oil boilers, the diameter of the smoke pipes also differs

There are no differences in the material. Boilers for both waste and diesel fuel can be made of steel or cast iron. Smoke pipes can be made from the same materials. There is also a difference in the design of the doors: since more soot accumulates when working with used oil, the design of such hot water boilers provides free access both from the front to the firebox and from the rear to the chimney outlet. To be able to clean them, there is free access to the back of the smoke pipes. All this makes it possible to easily clean off soot and fumes.

If you decide to equip your liquid fuel boiler with an exhaust burner, you will have to somehow solve the problem of cleaning: the hatch in them is small, which greatly limits access.

Is it possible to pour waste into a liquid fuel boiler? In principle it is possible. But not for long: at most in a couple of days you will have to change the burner. It will be worse if the automation, or even the entire system as a whole, needs to be replaced. This occurs due to incomplete combustion of fuel. In addition, the room becomes smoky and the chimney becomes clogged. And this is not counting the harmful substances in the air, which you will breathe in plenty of. So it's better not to. If you don’t want to buy a factory boiler for testing, you can make it yourself.

You might be interested in reading about the types of solid fuel boilers.