Features of the furnace during mining

Boiler furnaces for waste are most often installed in places where there is an abundance of used engine oil: in garages, car service centers, and on farms with their own fleet of vehicles. The process of recycling used oil is not easy, since it cannot be poured into the ground or sewer. Using it as fuel can solve the problem.

If you install an ordinary potbelly stove for this purpose, it will warm up the air quite quickly, but as soon as the burning of the fuel stops, it will immediately become cold. Therefore, it is impossible to stably heat a garage or workshop in this way. If you make an exhaust furnace with a water jacket, the energy efficiency of the heating unit will increase significantly.

Do-it-yourself stove: drawings, videos and design features

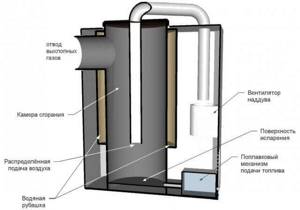

Before you make a waste oil stove with your own hands, you need to study its structure. The device consists of two tanks, which are connected by a perforated pipe. The lower compartment is a firebox. There is a pipe element with holes in the middle, and a heated element on top. There are holes in the firebox that regulate draft and increase the intensity of fuel combustion.

The diagram shows the operation of such a device

Fuel is supplied to the lower compartment, which is ignited using matches, rags and paper. After a few minutes, the top layer begins to boil. At this time, the vapors pass into the burner, where they are saturated with oxygen and completely evaporate. Then the smoke masses move to the chimney and are removed. Engine, transmission, diesel and industrial oils are used for fuel. Such devices are distinguished by their simplicity, low cost and high efficiency.

Helpful information! Do not use any solvents for the firebox.

How the oven works and works

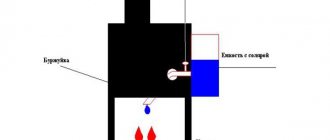

The design of an exhaust furnace with a water circuit is not complicated: two chambers that are connected by a perforated metal pipe. The lower chamber is equipped with a special container where the fuel (working off) is located. It can enter the waste oil boiler with a water circuit automatically or manually. Light the stove using a small amount of gasoline, which is poured onto the oil on top. The gasoline begins to burn, the oil underneath it heats up and begins to boil. Oil vapor enriched with oxygen in the perforated pipe begins to actively burn in the pipe and the upper chamber. At the same time, in the lower chamber the temperature is 350 degrees, and in the top it reaches 900.

If the stove has a manual fuel supply, the fuel flow and ignition in the lower chamber occurs through a special hole at the bottom of the chamber. With an automated fuel system, a pipe leads into the chamber, which is connected to a container filled with used oil.

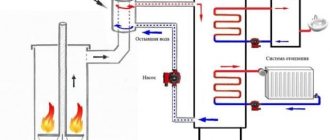

The lower chamber must be additionally equipped with a special hole with a damper so that the draft and combustion temperature can be controlled. To organize a water circuit, a tank is installed above the upper chamber or around the chimney duct with fittings welded to it for the supply and exit of coolant.

Important. To control the temperature and pressure of the coolant, you need to install a pressure gauge and thermometer on the heating unit.

Operating rules

A waste oil furnace has exposed surfaces and poses a risk of fire. The floor must be covered with heat-resistant materials - ceramic tiles, concrete or metal. The wooden flooring is sheathed with iron sheets. Adjacent walls and flammable structures near the stove are also covered with steel. The unit is not installed in drafts; fuel supplies, rags and rubber items are stored separately. Do not add new oil to a running device. A powder-based fire extinguisher must be stored in the building.

The microclimate and heat distribution in the room can be improved using a water circuit on a homemade stove. Using waste oil instead of fuel allows you to economically and efficiently heat a building.

In this video you will learn more about the design of the mining furnace:

The advantages of such a stove, and what disadvantages need to be taken into account

Waste oil furnaces with a water circuit come to the rescue in many cases and have their own advantages:

- This is a universal heating unit that is ideal for utility rooms, greenhouses, home workshops, garages;

- construction of a furnace is inexpensive (it can be assembled from scrap metal);

- warms up the room very quickly in any frost;

- compact design;

- can be adapted for heating and cooking;

- allows waste to be disposed of.

But there are also disadvantages that need to be kept in mind when operating the stove:

- requires regular cleaning of the chimney and combustion chambers, as during operation it is intensively covered with soot;

- it operates “loudly” and produces a hum when the fuel is actively burning;

- you need containers and a place to store used oil (it will freeze outside at sub-zero temperatures);

- the furnace is a fire hazard, since the body heats up to very high temperatures and the requirements for installation and operation must be strictly observed.

But all these disadvantages are not significant compared to fuel savings, especially if used engine oil is obtained free of charge. If all requirements are met, the stove will serve for a long time and safely.

Oil furnaces with a water circuit can have any configuration and size, it depends on what materials the home craftsman has at his disposal, and on what power the unit plans to obtain.

Pros and cons of the design

The advantages of a device operating during testing include the following points:

- ease of installation and operation;

- does not smoke during operation;

- fire safety: it is not the oil that burns, but only its vapor;

- economical to operate, independent of gas and electricity;

- it is easy to regulate the temperature in the room and control the amount of waste in the unit;

- In addition to heating, the stove is also used for cooking.

Among the disadvantages the following are noted:

- A chimney with a length of at least 4 m is required.

- The pipe must be positioned strictly vertically, without horizontal or inclined sections.

- The oven and duct require regular cleaning.

- Used oil must be purified, otherwise structural parts may explode. A substance containing alcohols and water can burst into flames even in a heating container. Oil purification includes the stages of settling and filtering. Carrying out such a procedure at home is not possible, therefore owners of such stoves with a water circuit are recommended to buy ready-made purified fuel. A liter of prepared waste substance with delivery costs an average of 15-20 rubles.

- Oil should not be kept in the cold. It is better to store it in a place where the air temperature is above 0 °C.

What are the fuel requirements?

Any oil that has exhausted its service life is suitable as fuel: industrial, transmission and motor oil.

There are certain requirements and precautions that you need to be aware of before you start operating the unit:

- the mining should not contain impurities, even minor ones, as this may cause an explosion of the heating unit;

- A fire can be caused by ordinary water getting into the oil, which boils much faster than oil, and the splashes can ignite.

Important. Before pouring waste into the fuel container, it must be filtered. It is prohibited to use other flammable liquids as fuel. Gasoline for ignition is taken in very small quantities.

What stoves can you build yourself using drawings?

A waste oil stove with a water circuit can have a different design:

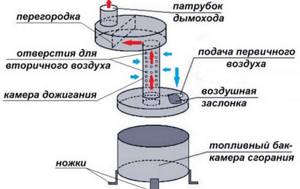

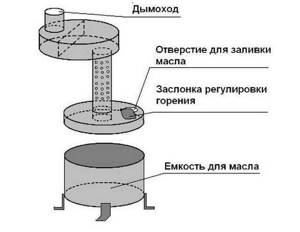

- The stove is round in shape, welded from steel sheet. The fuel tank is combined with the combustion chamber. The afterburning chamber is a perforated pipe and an upper chamber equipped with a dividing partition that cuts the flame. A hole is cut in the lid of the lower chamber into which the waste is poured, and air will also flow there. The principle is this: the wider the damper is open, the better the oil will burn.

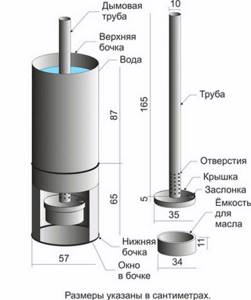

- Two barrel oven. In one (bottom) there is a fuel tank, there is a hole for loading it. The upper combustion chamber consists of a pipe that passes through an upper barrel filled with water. It has fittings for supplying coolant water. Externally, the model is very similar to a samovar. Its body gets quite hot, so you need to handle the stove with care. Such a “samovar” is installed only in those rooms where accidental contact with the body of people or animals is excluded. This design has a big advantage: the large tank acts as a heat accumulator.

- Compact mini-oven made of square profiled pipes 18x18 cm and 10x10 cm. Simple in design, it is very easy and quick to assemble. You can cook food on it.

- A practical model of an exhaust boiler with a water circuit from a gas cylinder with a cut off upper part. Here you can provide an automated feed of mining. The oil line is located in the combustion chamber. The water circuit has the form of a boiler, through which a chimney channel is passed. Or it could be a copper heat exchanger coil that is used to wrap the furnace body.

Sizes may vary. But the location of the main nodes is unchanged.

General principles of operation of a furnace for a garage or summer cottage

The essence of the process is simple: since the oil itself does not burn so much as it smokes, it must be heated to boiling point and the released vapors must be ignited.

Accordingly, you need a container for heating the oil, air supply points and an afterburner chamber. And, of course, the chimney. The diagram below shows the principle of the simplest stove with a square fuel tank.

So:

- approximately ½…2/3 of the volume is filled with waste into the fuel tank, also known as the firebox. This is no longer possible - either during the boiling process the oil will splash out, or simply not enough flammable vapors are formed;

- after the fuel has settled a little in the tank and gives off a certain amount of evaporation, the contents are set on fire. This is done with the help of a “torch” - a burning splinter, a rag (preferably also oiled), paper. Next, the filling hole is closed and not opened again until the fuel burns out;

- when heated, the oil begins to produce more and more vapors; they rise to the afterburning zone, mixing along the way with secondary air. Since the heated vapors are much higher in temperature than the air surrounding the pipe, oxygen is drawn into the holes very actively, contributing to an increase in the combustion temperature. The draft can be adjusted using dampers, thereby increasing or decreasing the intensity of vapor combustion;

- heating of the surrounding room occurs due to heat exchange between the hot combustion chamber, pipes, afterburning chamber and air. To ensure that the device releases heat longer, a damper is placed between the afterburning chamber and the chimney, reducing the rate of removal of heated and burning vapors.

To ensure uniformity of the process, the afterburning chamber and the firebox are made of approximately the same size (volume).

If the stove is made correctly, the flame has a white-blue color. Accordingly, the combustion temperature is 1000 degrees Celsius and higher. If the flame has golden-orange, reddish tones, the combustion temperature is clearly insufficient - weak draft, low heating of the exhaust, design problems in general. With a blue-white flame, the soot formed during the combustion process partially burns out before reaching the chimney, which significantly reduces the necessary frequency of cleaning the smoke ducts.

Regardless of how correctly the structure is designed and executed, soot and soot will certainly form in it, and non-combustible sediment will accumulate at the bottom of the fuel container. Therefore, it is necessary to make the oven as collapsible as possible - this will make cleaning it much easier.

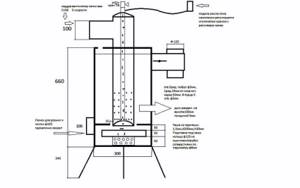

Features of the chimney device

The length of the chimney in these furnaces is taken to be at least 4 m. This is necessary both to create proper draft and for high-quality removal of combustion waste

It is also important to install high-quality ventilation in a heated room, since some of the combustion products somehow end up not in the chimney, but inside the room

The diameter of the chimney is assumed to be at least 100 mm, and the presence of elbows, turns, and complex shapes is extremely undesirable - cleaning the chimney is necessary much more often than with conventional stoves, since the fuel produces a large amount of soot.

The best option for installing a potbelly stove is strictly under the hole in the roof through which the chimney will be led out. In this case, the vertical position of the chimney will ensure stable draft and easy cleaning. The outer part of the pipe must be insulated. If this is not done, condensation mixed with unburnt soot will settle on the inner walls, quickly narrowing the passage for smoke.

How to make a waste oil stove: step-by-step instructions

The most common furnace model used for mining is made from pipe sections with a diameter of 352 mm and steel sheets 4 mm and 6 mm thick. You need to prepare a small piece of thick-walled pipe with a diameter of 100 mm and a metal steel corner for supports. This model can cope with heating an area of 80 square meters. meters.

Tools you will need for work:

- welding equipment;

- grinder with a circle for cutting metals and a grinding disc;

- drill;

- roulette.

You also need to purchase heat-resistant paint and solvent.

Stages of manufacturing a stove for mining with a water circuit according to the drawings:

- The necessary parts are cut out, and burrs are removed from the cut areas;

- The lower tank is welded from a pipe 115 mm high and 344 mm in diameter. The bottom is made of steel sheet. The legs can be welded from a metal corner or from pipe scraps.

- A pipe section with a diameter of 100 mm and a height of 360 mm is perforated.

- The lid of the lower tank is assembled together by welding: a pipe with a diameter of 352 mm, a height of 60 mm, a lid with two holes and a perforated pipe. The damper is secured to the air supply hole with rivets.

- Parts of the upper compartment are welded from a pipe with a diameter of 352 mm and a height of 100 mm. The bottom is welded from a steel sheet, in which there is a hole for a perforated pipe.

- Weld a chimney pipe with a diameter of 100 mm and a height of 130 mm. On the inside of the lid, closer to the chimney, a partition made of steel sheet is attached.

- The upper chamber is welded to the lid on which the chimney is installed. The upper chamber is connected to a perforated pipe. You can strengthen the structure by tightening it with an iron rod.

- The upper compartment of the boiler is tightly placed on the lower one.

- In order to increase the service life of the unit, it is painted with heat-resistant silicone paint. Before applying paint, the metal is cleaned of rust, and the seams after welding are cleaned of scale.

- Install the stove and connect it to the chimney duct.

Important. The chimney pipe of a welded stove for mining with a water circuit must be straight, at least four meters long and without bends.

Using the same principle, you can make a rectangular oven.

Materials

When making a stove during testing, you can use your imagination and, depending on the availability of available materials, think through the design. Another advantage of the device is the absence of expenses for the purchase of metal products - they can be replaced by scrap metal, which lies in excess quantities in any garage or warehouse.

- The oil reservoir can be a metal body without holes that can withstand the burning temperature of the oil. The oil chamber is often made from empty, unwanted gas cylinders.

- To connect the chambers you will need a pipe 4 - 5 millimeters thick. It is possible to make a pipe from a metal sheet of the required thickness.

- Another pipe for the chimney may be less thick, but it must be without holes or significant rust spots that weaken the metal. The length of the chimney should allow it to be removed at least a meter from the building envelope.

- Leg material. These can be corners, channels or short pieces of metal pipes.

Connecting the water circuit to the furnace

The water circuit is connected to the upper chamber. You can weld a water container directly to the surface of the furnace, but it is better to make a separate structure so that when the bottom burns out, water does not get into the combustion chamber. This will cause the oil to splash and ignite.

The tank can be made to any size. For maximum heating, it should fit tightly to the upper chamber and the chimney. Fittings for the coolant supply and return are welded to the tank.

Be sure to attach a thermometer and pressure gauge. The pump and expansion tank are installed on the return line, closer to the boiler.

Fire safety requirements

During testing, the furnace becomes hot and becomes a fire hazard, so you must comply with the requirements for its installation and operation:

- The floor surface must be fireproof. Concrete, ceramic tile, and metal surfaces are allowed. The wooden floor near the stove is covered with metal.

- If the wall next to which the stove is located is made of wood or other non-fire-resistant material, then it must be covered with an asbestos sheet.

- Do not allow drafts in the room where the stove is installed. Flames from a perforated pipe can spread to surrounding objects.

- Storing any flammable materials near the stove is prohibited.

- Mining reserves are stored in another room.

- Do not add fuel while the stove is operating.

- You should keep powder or salt fire extinguishers in a convenient place indoors.

Important. Burning used oil must not be extinguished with water. The fire will only get worse.

A waste stove is an economical and convenient heating unit, which, with proper operation and installation of the water circuit, will significantly improve the indoor microclimate and will be an indispensable source of heat in a garage or workshop.

Fire precautions and operating rules

A furnace using waste oil is an increased source of fire hazard. It has open surfaces that heat up to high temperatures during operation.

There are special requirements for the room where the stove is installed and for its operation:

- Floors must be made of fireproof materials: concrete, tiles, metal. Wooden floors in the area where the stove is installed must be covered with sheet metal.

- If the stove is installed in close proximity to wooden or other non-fire-resistant walls, they also need to be sheathed with metal or covered with asbestos sheets.

- It is forbidden to place the stove in places where strong drafts are possible: the wind can blow the flame through the perforation in the pipe.

- Easily combustible materials, flammable liquids, and oily rags should not be stored in close proximity. Used oil should be stored separately.

- Do not add oil to a working oven.

- There must be a powder or salt chemical fire extinguisher in the room.

It is strictly forbidden to extinguish burning oil with water!

This will lead to the spread of the combustion area. A self-made stove is an economical and efficient heating device, and connecting a water circuit to it improves heat distribution and improves the microclimate in the heated room. When used correctly, the stove is safe and takes up minimal space - a real boon for garages, workshops and industrial premises.