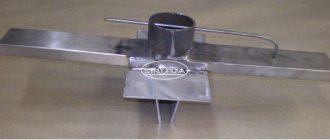

Pressure circle and cover

We take sheet steel again and mark the circle. Its diameter should be slightly smaller than the diameter of the fuel tank. This is necessary so that the pressure circle passes freely inside the firebox. In the center of the circle we cut a hole equal in diameter to the diameter of the supply pipe. But not less than ten centimeters. This will provide the necessary oxygen access and traction. We build a lid for the tank in a similar way. For convenience, it is advisable to weld handles made of a metal rod to the outer part of the lid.

Sample of a long-burning furnace

The length of the supply pipe is taken from the calculation of the length of the fuel tank and 30-50 cm is added to this value. The diameter should be about fifteen centimeters. The pipe is connected to the pressure circle by welding.

Bubafonya stove from the inside

To add mass to the pressure circle and increase its strength, 4 pieces of channel or metal corners are welded.

We weld 4 channels to the pressure circle

Recommendations for safe use

Below are simple rules to ensure safe operation of the equipment:

- It is prohibited to store flammable liquids, paper, rags, or pieces of furniture in close proximity to the stove.

- Use protective gloves when adding fuel.

- Try not to use flammable substances such as kerosene, gasoline, or acetone for ignition. If such a need still exists, we recommend doing the following: pour flammable material onto the firewood, then load it into the firebox and only then set it on fire. Be careful: watch your gloves and clothing to prevent them from catching fire.

- A long-burning stove is also used for cooking. This is possible when the structure is completely warmed up. You should wait at least 15 minutes from the moment of ignition.

- To prevent burns from contact with a working boiler, wear protective gloves.

- It is highly undesirable to use the stove to burn plastic and household waste, as this is accompanied by the release of toxic gases and the deposition of soot on the walls of the pipes.

- To shut down the furnace, you need to close the valve on the inlet pipe: this will block the air flow and combustion will stop. To urgently shut down the device, use fire safety equipment.

- It is not recommended to enamel or varnish structural elements of the stove that are exposed to heat. During operation, high temperatures are reached, which contribute to the ignition of the coating and the release of vapors that are unsafe for human health. It is allowed to use heat-resistant paint for painting.

- When choosing wood, you should focus on the size of the firebox. An important point: try not to take damp, resinous firewood, as they interfere with combustion and lead to the formation of condensation and plaque on the surface of the structure.

- The stove boiler should be placed on a solid foundation made of non-combustible material, such as iron or concrete, or a small foundation should be built for it.

Do-it-yourself Bubafonya stove

The best material for the stove is an industrial cylinder or a piece of pipe. When using a cylinder, there is no need to cook the bottom.

Since when making homemade boilers you usually have to start not from the proposed dimensions, but from what is available, the calculations will look like this:

- The diameter of the loading tank is from 30 to 80 cm. (If you make it smaller, the air will come out too quickly, but a larger diameter will lead to uneven heating).

- Diameter to height ratio 3:1 or 5:1. For example, with a diameter of 30 cm, you can take a height of 90 cm.

- To calculate the diameter of the internal heavy piston you need to know that the gap between the wall and the piston should be equal to 0.05 D. If, for example, D = 30 cm, then the gap = 15 mm on both sides. Accordingly, the diameter of the cargo pancake remains 27 cm.

- The height of the ribs for small ovens (with a diameter of 30 cm) can be approx. 4 cm, if the diameter of the boiler is 60 - 80 cm, the ribs are made approx. 6 cm.

- The thickness of the pressure piston is inversely proportional to the diameter of the furnace. For a 30 cm structure = 6-10 mm, for a 60 cm = 4-6 mm, and for an 80 cm oven, the bend thickness = 2.5 – 4 mm.

- The ribs on a piston of small diameters are made straight, but for tall stoves it would be better to bend the ribs, as if twisting them clockwise.

- The air duct should protrude from the pressure piston, its edge ending at the level with the edge of the ribs.

- The diameter of the chimney (for a 30 cm stove) is 15 cm.

- Diameter of the air duct pipe = 7.5 – 8 cm.

- The gap between the cover and the air duct is no more than 2.5 mm.

- A small collar is welded onto the furnace lid, in the place where it passes the air duct pipe. This is a very important detail in order to prevent a decrease in efficiency! Its height will depend on the resulting gap and will be 80 times larger than it.

- You also need to decide on the length of the air duct. To calculate it, it is taken into account that, at a minimum, the pipe should rise 15 cm above the collar.

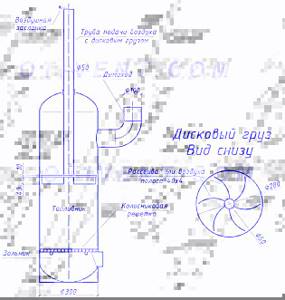

Stages of furnace assembly with dimensions of parts

The wall thickness of Bubafoni needs to be greater than that of factory models. There they are made of heat-resistant steel (thermal conductivity is higher), and the gases do not contact the wall as tightly as in a homemade model. If you make the walls 2.5 mm thick, like factory boilers, a thick layer of soot will quickly accumulate on them, and the chimney will accumulate a large amount of condensate. The wall thickness of Bubafoni should be 4-6 mm!

If you need to bend a boiler made of sheet steel, then a dilemma arises: sheet bending machines in small enterprises do not bend steel thicker than 2.5 mm.

Thin steel can still be used for low-power furnaces, but only without a water jacket!

Reliability and safety

Stropuva pellet boilers are not equipped with complex, malfunctioning automation. The boiler is controlled by a fairly simple in design and non-volatile bimetallic draft regulator. This solution gives the boiler high reliability and stability in operation.

The boiler is designed in such a way that, unlike diesel, electric or gas boilers, if the load is repeatedly exceeded, it will not explode, but will shrink inward. The manufacturer is confident in the quality of the equipment produced and provides a factory warranty of up to 5 years.

Main elements of the Bubafonya stove

- — Fuel tank (fuel is directly loaded into it, and combustion occurs here);

- — Heat removal pipeline (using a clamp and heat-insulating material, it is connected to the main pipeline of the heating system);

- — Pressure circle with weight and supply pipeline;

- — Damper;

- — Oven lid.

Tools and materials required for constructing the Bubafonya stove

- — Metal pipe 2 pcs.;

- — A metal container for the fuel tank (a metal barrel or other similar metal cylinder with a sealed bottom) with a wall thickness of at least 3 mm;

- — Grinder (grinding machine with cutting and grinding wheel);

- — Hacksaw for working with metal;

- — Sections of channel or metal corners;

- — Welding machine with electrodes;

- - Hammer, chisel;

- — Steel sheets.

A metal barrel is perfect for a furnace housing

Tools and materials

Let's talk a little about the materials used. If you want to assemble a Bubafonya stove with a water jacket with your own hands, make sure that the thickness of the walls of the combustion chamber is 4-6 mm. The jacket is made in two ways - by scalding the main body with sheet iron to form a heating circuit, or by wrapping it with a metal pipe. If the stove will heat the premises directly, then the thickness of the walls does not matter much - an old barrel will do just fine, but without through corrosion.

As for the tools and auxiliary materials needed to assemble the Bubafonya stove, we will need:

The most dangerous part of the work associated with making a stove is, of course, everything that involves an angle grinder. When using it, you need to be as careful as possible.

- Welding machine – for cutting and welding individual elements;

- Grinder (angle grinder) – for cutting and processing metal edges;

- Hacksaw for metal – for working with small elements;

- Pipes of the diameter indicated on the drawing;

- Condensate drain valve;

- Hammer;

- Sheet metal 2-3 mm thick.

We have five stages of assembling the Bubafonya stove:

- Preparing the installation site;

- Working with a barrel (gas cylinder);

- Preparation of the pressure circle;

- Chimney preparation;

- Assembly and first launch.

Let's go through these stages in more detail.

What is the essence of the top combustion principle?

In furnace and boiler equipment with top combustion, the firebox has the shape of a vertically oriented cylinder. Obviously, the fuel filler in such conditions will burn longer than with the usual method of ignition from below.

At one time, the technology was somewhat improved by Stropuva engineers, applying the following innovations:

- Air began to be supplied in doses and only to the combustion zone. To supply air, we had to install a telescopic air duct.

- In order for pyrolysis to occur in addition to combustion in the upper zone of the fuel fill, an air heating chamber was installed to 4000°C.

Afterburning of pyrolysis and flue gases occurs in the space above the fuel fill. Through the use of pyrolysis, the efficiency of the installation was significantly increased.

Rationalization from Afanasy Bubyakin: diagram of a new device

It is obvious that it is impossible to replicate the Stropuva boiler at home: in order to avoid problems, the telescopic air duct links must be manufactured with very high precision. Afanasy Bubyakin proposed a simpler method of heating air and supplying it to the combustion zone. “Bubafonya” is the nickname of this builder on one of the forums where the design was published. Later this name was assigned to the stove.

The solution is simple:

- Place a bend on the fuel filler with an air duct attached to it, extending out through the firebox cover. As the fuel burns out, the bend will lower under its own weight, and air will always flow to the top of the stack.

- On the lower side of the bend, using sections of an angle or channel, create hollow radial channels through which the air will move to the periphery. During its journey, it will heat up to the required temperature.

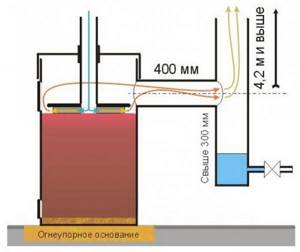

Photo 1. Diagram of the internal structure of the Bubafonya stove, indicating the dimensions of the chimney and condensate collector.

The dimensions of the bend are selected so that there is sufficient gap between it and the walls of the firebox for the escape of pyrolysis gases.

Chimney device

Any stove installed indoors needs a chimney and the Bubafonya stove is no exception. The main purpose of the chimney is to remove combustion products from the room, as well as to create the necessary draft.

To ensure good traction, you will need 2 pieces of pipe with a diameter of 110-250 mm:

- The first part, 300-400 mm long, is inserted horizontally and welded into the upper part of the body;

- The 2nd part, the “main” chimney, which connects to the 1st part, forming a 90° elbow.

Operating principle of the Bubafonya stove

It is not only residential premises that require heating in private households.

Many owners cannot imagine a single day without working, for example, in a workshop or garage, and in winter, without local heating, these buildings will be very uncomfortable.

Heating may also be necessary in homestead farming - greenhouses, premises for pets and poultry.

Conducting a heating circuit from the house into such buildings is extremely difficult and wasteful.

It is better to provide for the installation of stoves that can be heated as needed with solid fuel - firewood, sawdust, coal, etc. There are many options for such heating devices, and many of them are economical and easy to use.

Stoves can be purchased in stores, but a good owner can always make one himself. One of these common crafts is to bake a bubafonya oven with your own hands.

Long-burning stoves are becoming increasingly popular. Who doesn’t want to spend less fuel and time on heating.

Moreover, it is not at all necessary to buy expensive boilers. There are very interesting long-burning stoves that you can easily make with your own hands. For example, a very interesting and original design of such a stove is bubafonya.

The design of this miracle stove is such that the movable piston rests on the firewood stacked at the bottom of the firebox.

It divides the combustion chamber into two parts: firewood burns below it, and pyrolysis gases burn out from above. It turns out that the firewood does not burn from bottom to top, as usual, but from top to bottom.

The process is much slower, and the fuel burns with virtually no residue.

Oxygen for burning wood is supplied through a pipe, which serves as a rod for the piston.

In the upper part of the furnace, where the pyrolysis gases burn, oxygen enters through the holes in the lid (where the pipe from the piston is inserted, and where the lid is combined with the body), so there is no need to worry about tightness. This is even harmful - the stove “suffocates” if there is a lack of oxygen.

Due to this separation of the chambers, the fuel burns out completely.

The combustion intensity is controlled through a pipe to which the piston ring is welded.

For convenience, a small pin is welded to the pipe, to which a metal disk is movably attached, the diameter of which is slightly larger than this pipe. Some simply block or restrict the flow of air to any object, adjusting this gap.

The burning time of one bookmark depends to a large extent on the volume of the firebox: the larger the firebox, the more firewood, the longer the fuel burns. On average, one load of firewood from a gas cylinder burns for 4-6 hours (depending on the firewood and other “additional” fuel).

How to increase furnace efficiency?

A profile sheet around the boiler body will increase convection currents

One of the disadvantages of the homemade Bubafonya stove is its low efficiency, which can be increased in the following way:

A profile sheet is mounted on the outer part of the body, which fits tightly to the body. Thus, convective currents are formed during combustion. Cold air is drawn in through the lower part of the “waves” of the profile sheet and heats up as it passes along the body, rises to the top and exits already heated through the upper part of the “waves” of the profile sheet.

Important! To extend the service life of the heating device, you should not remove all the ash from the bottom of the stove (exactly the same recommendation applies to the Buleryan stove, in which combustion should not occur on convective pipes). The fuel should burn on ash, not on metal. This will avoid premature burning of the bottom.

Do-it-yourself bubafonya from a barrel - much easier!

So, we come to the most important point - cutting, welding and assembling Bubafoni from such waste material as a used steel barrel. It must be said that there are only two requirements for it - the absence of dents (otherwise the pressing load will hang) and the integrity of the walls

Of course, due to the small thickness of the metal, the heat capacity of the structure will, to put it mildly, not be very good, and the efficiency will not go beyond the average statistical values, but the volume will allow the homemade unit to work for up to 12 hours on one load. The advantage of a container that has expired is that if the walls burn out, you can easily find a replacement for the damaged body.

A metal barrel that has served its useful life is suitable for making Bubafoni.

Although the construction of Bubafoni is not a complex technological process, we have divided it into stages. This will allow you to follow a clear sequence of actions and avoid difficult mistakes.

1. First of all, you need to cut off the lid from the barrel. It is best to do this with an angle grinder with a not very thin cutting wheel - it is best not to cut through the metal in an arbitrary place, but to run a grinder along the weld. This method is good because the resulting cylindrical body will have smooth edges, and the cut off part with flaring can later serve as a Bubafoni lid.

When cutting off the lid you must be as careful as possible.

2. The edge of the barrel needs to be slightly bent inward, for which it is convenient to use a small sledgehammer.

This is what the top cut of the barrel should look like after processing

3. On the contrary, the lining of the lid will need to be expanded so that it fits tightly to the furnace casing.

Flared cap

4. The cork, which most barrels have, does not need to be sealed. Its presence is an excellent reason to install an additional damper to supply secondary air to the pyrolytic combustion zone.

5. A hole is cut in the center of the top hatch to the diameter of the air distributor pipe, leaving gaps for air passage.

The hole for the air distributor pipe must be cut as accurately and accurately as possible

6. A piston is made. It is best to use a steel sheet for this, the thickness of which corresponds to the design parameters, but if you do not have the necessary material, you can get by with a lid cut from another barrel. In this case, it is better not to cut it along the inner diameter of the casing, but to use the same sledgehammer, bending the edges down along the entire circumference. The fact is that a high temperature arises in the combustion zone, due to which the thin-walled piston will warp. The bends made will serve as a kind of stiffening ribs that will prevent the air distributor from deforming.

7. A hole corresponding to the diameter of the air supply pipe is cut in the center of the metal pancake.

8. Blades are welded on the lower side of the pressing weight, which will form the height of the working area and evenly distribute the air flow over it. You can simplify your work by welding sections of the channel, as shown in our photo, but it is better to spend a little time and make profiled air ducts from a metal strip. Earlier we talked about the advantages of this design.

9. A homemade washer or an old gear is mounted on the blade in the center of the piston. It will allow you to redistribute the air flow from the middle part of the working chamber to the periphery.

A piston with straight blades is much easier to make, but the benefits of turbulent mixing of air flow are lost.

10. A valve or damper is mounted on the air supply pipe, providing the device with any type of locking element - even a simple wing nut. After this, it is inserted into the “pancake” and scalded with a continuous seam.

The air supply pipe is equipped with a valve

11. The upper part of the casing is marked according to the diameter of the pipe for connecting the chimney.

Marking the housing for the chimney pipe

12. The pipe is welded with a continuous seam, checking its tightness.

The pipe is installed using a continuous seam to ensure the tightness of the structure.

13. Supports made of metal corners or pipes are mounted to the lower part of the body.

14. The top hatch is equipped with comfortable handles, after which the piston is installed and the unit is closed with a lid - that’s it, Bubafonya is ready.

This is what Bubafonya can be made from an old metal barrel

After assembly, the stove is installed in place, the chimney is connected and a test run is performed.

Design and principle of operation of Stropuva boilers

Loading fuel into the Stropuva furnace is possible only from above. For better ignition, the main fuel is mixed with sawdust; you can add flammable liquid. Ignition also occurs through the top door, which must be closed tightly after all actions.

The chimney will form a draft, the fire will flare up from the top of the fuel. Quickly igniting the firewood will ensure good air flow. Fire and smoke rush through the inner housing structure to the smoke hole. Some of the hot gases also rush upward, simultaneously heating the metal and water.

The internal chamber of the air duct increases as the fuel burns. An afterburning chamber is formed in the increased space, which has a positive effect on efficiency. In this case, the fire will not flare up too much, the protection will work in the device. Thanks to the device, the air damper either opens or closes, increasing or decreasing the draft or combustion temperature.

Advantages and disadvantages

Bubafonya solid fuel stoves are distinguished by their simplicity and good characteristics. They relieve users from unnecessary hassle with firewood, providing long-term heat supply to the premises. Let's take a look at their main advantages:

The fuel in Bubafon burns for quite a long time, warming up the room well, however, as soon as the combustion stops, the stove cools down very quickly.

- Long burning - from 6 to 20-24 hours (and even more). It all depends on the size of the unit used and the quality of the fuel used;

- The simplest design allows you to easily assemble the Bubafonya stove with your own hands, using available tools;

- Minimum adjustments - the only regulator is a small slide valve in the air supply pipe;

- Does not require electricity - the Bubafonya stove can operate in buildings without electrification;

- Reliability - if we look at the diagram of this stove, we will find that there is practically nothing to break in it;

- Possibility of working on any type of solid fuel - up to anthracite, characterized by maximum heat release.

There are also some disadvantages:

- Rapid loss of temperature when the firewood is extinguished - there is simply nowhere for heat to accumulate;

- Not the most beautiful design - this applies most of all to homemade units, which are often assembled from old gas cylinders and barrels;

- Difficulty in maintenance - loading firewood requires removing the pressure plate and thoroughly cleaning the bottom of the stove from ash and coals;

- It is necessary to take care to remove soot and condensate - soot is most often formed when burning coal;

- Too intense combustion of the Bubafonya stove can lead to overheating of the air or coolant (when using a water jacket) - therefore, the most minimal control is still necessary;

- The possibility of smoke entering the room - this happens due to the backdraft effect when the smoke exits through the air supply pipe.

Some disadvantages are quite serious, but you have to put up with them. For example, to remove condensate more easily, it is recommended to work on the chimney, and in order to give the draft the right direction, you should install a blower fan with variable speed control in the system.

The easiest way to collect condensate is to make a chimney with a vertical outlet downwards. The smoke will go to the upper part, and the condensate will collect in the lower part, equipped with a drain valve.

This is interesting: Impregnated wood

Features of a potbelly stove - pros and cons

A good master can easily make a Bubafonya stove in one day, this is a significant plus. The maximum you have to buy is a cylinder and pipes from scrap metal. Other advantages of a potbelly stove:

- burning duration on 1 load is 6…10 hours;

- omnivory - waste wood, garbage, sawdust, freshly cut branches are placed in the firebox;

- ease of repair, any burnt part can be easily replaced.

Note. It is better to load garbage, small waste and coal mixed. To heat with sawdust alone, you need to weld a metal heel from below to the diffusers, otherwise the shavings will block the path of air. The stove operates mediocrely on pure coal and requires forced pressurization.

disadvantages of Bubafoni are much more unpleasant:

- The stove is difficult to regulate. When working with high-quality dry wood, the damper helps you choose the optimal mode. If you burn with garbage and damp wood, the air duct must be opened completely.

- The potbelly stove's omnivorous nature is a double-edged sword. From burning low-quality fuel, the chimney becomes clogged with soot literally within a day.

- Without good draft, the stove will begin to smoke into the room. Hence the requirement for the height of the chimney - at least 4 m, counting from the grate, pipe turns 90° - no more than two.

- You can’t throw logs “on the go”, unless you pour a handful of sawdust through the air channel. This means we learn to dose the amount of fuel correctly.

- A potbelly stove made from a 200 liter iron barrel is very bulky and inconvenient to use. The piston is too large and heavy, the thin metal quickly burns out. Fortunately, the housing is easy to replace.

Why is “Bubafonya” dangerous: a well-heated firebox cannot be extinguished using a damper. Air seeps through the cracks, and the wood continues to smolder. The heater should not be left unattended or act radically - lift the lid and pour out a bucket of water. There is a smoke screen in the room.

Top combustion furnace structure

The design of this type of heater is very different from traditional wood-burning stoves. The vertical stove “Bubafonya” consists of the following elements (see drawing):

- a cylindrical firebox with an ash pan door and a removable top cover;

- disk weight with air distributors welded to the end of the air pipe;

- grate;

- chimney connection pipe.

Drawing of a stove made from a standard 50 l gas cylinder

The cylindrical shape of the walls of the combustion chamber is due to 3 reasons:

- From an aerodynamic point of view, a round pipe is always better than a profile one. Rising along the walls, combustion products evenly heat the body of the potbelly stove.

- There are no fillet welds - the weak point of any steel furnace or boiler.

- During the combustion process, fuel residues do not “hang” in the corners, which is observed even in some long-burning boilers.

The upper end of the air pipe is equipped with a damper for manually regulating the air supply to the firebox. A disk-shaped weight is attached to the bottom (other popular names are pancake, piston). Straight or curved air flow distributors are welded to the bottom of the disk. The pipe itself passes through the firebox cover with a minimum gap of 2-4 mm.

The furnace is ignited from above (photo on the left), combustion continues under the piston (on the right)

How the Bubafonya long-burning stove works:

- We fill the chamber to the top with solid fuel - firewood, coal, sawdust. We ignite the fuel directly from above, as shown in the photo. Then insert the piston into the firebox and close the lid.

- Open the damper at the end of the air duct. When the stove lights up, close the air supply about halfway.

- Combustion occurs in the upper zone of the fuel fill, under the pancake. It is there that air from the pipe enters under the influence of the natural draft of the chimney. Distributors promote better flow dispersion.

- Hot gases pass through the gap between the disk and the body, give off heat to the walls of the chamber and rush into the chimney.

- As the wood burns, the load lowers under its own weight until it rests on the grate.

An important feature of Bubafoni. Since fuel combustion occurs from top to bottom, the combustion zone gradually moves behind the piston. The walls around the flaming layer of firewood are heated to the maximum (sometimes red-hot), the temperature of the rest of the body is much lower.

The zone of greatest heating is clearly visible from the outside when the potbelly stove heats up red hot

History of creation

The creator of the stove is Afanasy Bubyakin from the city of Kolyma, known under the nickname “bubafonja”. It was from his pseudonym that the name of the stove came from. The prototype was the Lithuanian-made Stropuva boiler, which has a more complex design.

Bubafonya is a long-burning stove, this is its main difference from ordinary potbelly stoves, where the entire stack lights up at once. In Bubafoni, due to a lack of oxygen in the combustion chamber, combustion occurs gradually.

Guide to self-assembly of a Stropuva boiler

Before starting work, prepare the necessary equipment for this.

You won’t need any extremely difficult to use tools or hard-to-find materials. However, it is better to collect everything in advance so as not to be distracted by searching for missing elements in the future.

Stropuva boiler assembly kit

- Metal barrel. Use a large container with a capacity of 200 liters or more.

- Welding machine.

- Thick-walled metal pipe.

- Fiberglass.

- Metal channels.

- Asbestos.

- Chisel.

The function of the body of the heating unit in question will be performed by a large metal barrel. You can use either new or old container. The main thing is that the barrel does not have through holes and signs of severe corrosion damage.

The function of the body of the heating unit in question will be performed by a large metal barrel

If possible, it is best to use a Soviet-made barrel. Such products are much more durable and high quality compared to their modern counterparts.

If you have access to a rolling machine, you can purchase a large sheet of metal and use it to assemble the boiler body. The recommended sheet thickness is 2.5-3 mm. The optimal dimensions are 125*250 cm. At the end you should get 2 cylinders with a diameter of 50 and 45 cm.

Furnace assembly

The work of making a sling boiler is carried out in a few simple steps.

First step. Clean the barrel from all sorts of contaminants, and then cut a hole in its top. That is, you simply need to “knock out” the top of the container to gain free access to its interior.

Sheet metal housing

Second step. Cut a small piece from a metal pipe with a diameter of about 15 cm. From it you will make a pipe for connecting the chimney.