Gas heating boilers made in South Korea are considered products of average quality and cost.

This is a completely fair opinion, however, there are pleasant exceptions.

Kiturami products deserve to be put on a par with the most famous and popular European-made boilers.

High quality, advanced design and other advantages of the units have made them famous and in demand both throughout the world and in Russia.

Boilers demonstrate high competitiveness, have a lot of advantages and require more careful consideration.

Benefits of Kiturami

Korean boilers, being many times more expensive than their domestic counterparts, enjoy well-deserved respect. Consumers are attracted by their reliability and thoughtful design, which frees the user from the usual troubles associated with the operation of gas equipment. Pros:

- All manufactured modifications have two circuits. A double-circuit boiler provides not only heating, but also hot water supply to the entire house. Domestic analogues have a drawback - when you turn on the water, its temperature quickly decreases. The Koreans have solved this problem - when the tap opens, the automation rebuilds the operation of the system - the water heating mode replaces the heating mode.

- Operation at different temperatures is possible thanks to two independent circulation rings. When the consumer turns off the water, the reverse transition occurs - to heating or waiting.

- Simple controls. Even a child can master it. The user's task is to select and set the temperature. For heating separately, for water – separately. Then the automation does everything without human intervention.

- A gas detection system is provided - if a leak occurs, a shutdown occurs, the flame goes out, and an accident is excluded.

- Energy saving modes. Many Kiturami modifications are equipped with a room thermostat-controller, which allows you to select modes - “absence”, “sleep”, “shower”.

- In winter, when it is frosty outside, the “Koreans” automatically maintain a stable temperature - freezing of the heating system is excluded. If the owner is away for a long time, it is not necessary to turn off the device - just set the “absence” mode.

- The equipment diagnoses problems independently, displaying the appropriate code on the screen. This function allows the user to easily identify and fix the malfunction - the instructions decipher the codes and indicate what to do.

Operating rules

The user controls the Kiturami boiler via a thermostat. Settings are made using knobs and buttons. Information about the current state of the unit is displayed by indicators on the display and lights.

Main functions:

- Room. The main mode that is used when people are in the house. To activate, press the “Presence” button and set the desired temperature using the regulator.

- Dream. Helps save fuel while on vacation. To switch, press the “Sleep” button and set the required temperature. The settings will remain in effect for five and a half hours. Then the “Indoor” mode will be restored.

- Bath. Allows you to use a large amount of hot water for two and a half hours. After the expiration date, the device switches to the previous activated mode.

- Absence from the premises. Used to prevent the heating system from freezing when the user is away. It assumes fuel savings by reducing the temperature to the minimum permissible.

- Timer. Allows you to program the boiler operating time and shutdown.

For long and uninterrupted operation of the equipment, you must strictly follow the rules of its use.

Operating rules:

- Do not store combustible or flammable objects and substances near the device;

- have a fire extinguisher in the boiler room;

- Do not repair or disassemble the unit yourself;

- prevent freezing of water in the heating system;

- carry out maintenance 1–2 times a year;

- clean the chimney and chimney of soot several times a year;

- When dirty, drain the sediment from the fuel tank and change the filter.

Installation of wall-mounted boilers

General design

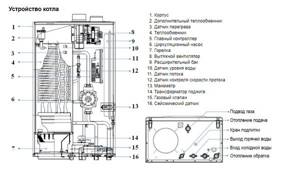

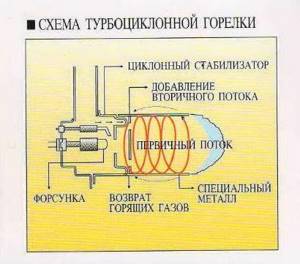

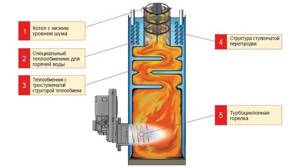

The difference and advantage of Kiturami over its competitors is its special burner. It is called a turbocyclone. Thanks to the double burning of fuel provided by such a burner, the devices operate at the lowest fuel pressure - this is especially valuable for the winter season. The manufacturer produces three lines with a similar design. Wall-mounted units consist of:

- copper heat exchanger;

- DHW tanks;

- forced smoke exhaust system;

- circulation pump;

- sensors - leakage and seismological (triggered by shocks from 4 points);

- gas valve.

The efficiency of wall-mounted devices is 91-98%. It is not recommended to independently interfere with the design of Korean-made devices - they require service.

Twin Alpha

Models of the Twin Alpha series are protected against gas leaks and water hammer. When the flame is blown out by the wind, the device does not go out - it automatically restarts. The series includes several modifications, differing in power - from 15 to 35 kW. The heat exchangers differ in design, the main one is of the flow type, and for hot water supply - the plate type. Closed combustion chamber. The device cannot function without a coaxial chimney. The energy carrier is gas. Works on natural or liquefied. The average efficiency of Twin Alpha is 92%. The coolant heats up to a maximum of 85°C. Only for systems with forced circulation. Estimated price – 30,000-37,000 rubles. Reviews from owners indicate that the devices are silent.

WorldPlus

Copper capacitive heat exchangers and internal combustion burners are used. Such solutions increase the service life of heaters, increase their corrosion resistance and ensure 100% fuel combustion. Closed version of the combustion chamber. Coaxial chimney 60/100 - it is not supplied. The line consists of 5 models, repeating the Twin Alpha power range. Everyone is energy dependent. Cost 42,000-52,000 rubles. Specifications:

- pressure 20 mbar;

- Efficiency – 92.5%;

- DHW pressure – 10 atm., system pressure – 2.5 atm.;

- The coolant heats up to 85°C.

- weight 33-39 kg.

Hi finish

A distinctive feature of the series is the double-sided combustion of the burner. The heat exchanger is capacitive. Hi fin models are capable of producing 1.5 times more water than boilers of the previous series. There are 6 modifications in total from 11,700 to 34,900 kW. Efficiency – 92.5%. The price depends on the power - 38,000-42,000 rubles.

• Alloy steel from which the heat exchanger is made prevents the appearance of scale - the operating time increases.

• Doubled frost protection.

• The flame is evenly distributed - the burner has two combustion zones.

• Multiple security modes.

All three series look favorably in comparison with their European counterparts, as they are unpretentious and, which is very valuable for Russian consumers, are capable of serving under the most unfavorable parameters:

• 0.3 Bar – pressure in gas pipes;

• 1.6 l/min – water supply.

Cost of different types of boilers

A big plus is that all the necessary elements are included in the package. Other companies often sell parts such as a thermostat and control unit separately, which increases the cost of the assembled product.

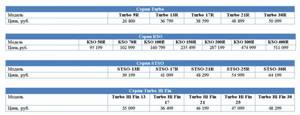

Cost of solid fuel models (in rubles):

- KF-35A - 127,199;

- KRP 20A - 270 799;

- KRP 50A - 318,499.

Bi-fuel heat generators are also represented by 3 devices.

Prices for them (in rubles):

- KRM-30 - 137,999;

- KRM-70 - 218,599;

- KRH-35A - 168,099.

Prices for diesel boilers

The cost of production directly depends on the power of the device and its efficiency. The higher these indicators are, the more expensive it will cost to purchase the unit. Other parameters influence pricing indirectly.

Other factors:

- area of the heated room;

- fuel consumption;

- materials used;

- DHW performance;

- security level: presence of sensors and safety devices.

The comparative cost of liquid fuel units is indicated in the table.

Prices for gas units

Kiturami Eco Condensing condensing units have 3 standard sizes.

Prices (in rubles):

- 16r - 52,360;

- 20r - 57,800;

- 25r - 59,440.

The TGB line includes one model: 30R. You can purchase it for 61,613 rubles.

The cost of traditional type gas appliances is presented in the table.

Model overview

KSG 100

Heating capacity 116 kW. Two circuits - heats the house and heats the water. Closed chamber. Radiator made of steel. The kit includes a control unit, a remote thermostat, instructions that contain error codes and troubleshooting, a connection diagram, etc. Capable of heating a room of 4600 sq. m. Turbocyclone burner type, characterized by minimal emissions of nitrogen oxides. The compact model easily fits into modern interiors. Compared to conventional boilers of similar power, it weighs approximately 40% less and volume is 65% less. easy to transport. Efficient operation of the heat exchanger guarantees high combustion temperatures. Innovative chimney pipe - made according to the Kiturami patent, it is 3% more efficient than models from other manufacturers. There is self-diagnosis and three modes - sleep, water heating, absence.

KSG 70

Powerful floor-standing unit with 81.4 kW. It works to heat the room and heat hot water. Heats rooms up to 650 sq. m. Chimney type - open combustion chamber. The maximum coolant temperature is 85 °C. 92% efficiency. Dimensions 128x58x89 cm.

World 5000

Wall installation. 2 circuits. They heat rooms of 400 sq. m and heat water for domestic needs without additional equipment. Maximum hot water flow 14.6 l/min. Models World-5000 13R-35R are allowed to be used on the territory of the Russian Federation - they have permission from Gostekhnadzor. There is a self-diagnosis function. Leakage protection.

World 3000 30R

Wall-mounted convection type appliance. 34.9 kW. Will heat an area of 350 sq.m. Efficiency 93%. Closed chamber. Volatile. There is auto-ignition and flame modulation.

Hi Fin 20

Mounted installation. Closed chamber. Maximum heating output 23.3 kW. Designed for heating rooms up to 230 sq. m. 85.9% efficiency. Economical gas consumption. Stainless steel radiator. Innovative burner design - there is internal and external combustion. Thanks to the interaction of the process with electronic ventilation, combustion stability is maintained regardless of weather conditions. To achieve minimum fuel consumption, fuel consumption is adjusted. There is an expansion tank and a circulation pump.

Reviews

World 5000: Vitaly M., Obninsk

I can only compare it with the antediluvian turbine-free machine that served me for 10 years. On the plus side, ten minutes are enough to warm up the entire apartment. In 2 minutes - the batteries burn out if you set it to maximum. In three years it broke down 2 times - due to debris in the pipes. All I had to do was clean it up and it worked. It is in a 2-room apartment, but the heating circuit is large - four radiators, heated floors, a heated towel rail. In 3 minutes the circuit heats up to maximum. Hot water heats up to 60 degrees in 30-40 seconds. Of the minuses. It makes a lot of noise. Parts are difficult to find.

Kiturami KRP

Kiturami KRP pellet boilers for heating and hot water supply. Pellets are used as fuel - this is a form of solid fuel in the form of granules made from compressed wood waste. Kiturami KRP pellet boilers use wood pellets of the 1st and 2nd categories Ø 6 - 8 mm and 10-30 mm long. Granules exposed to water or moisture turn into wood flour, as a result of which they lose their fuel properties. Using such wood meal as fuel can seriously reduce the efficiency of the unit, including reduced power and increased ash production. The built-in circulation pump is used when supplying hot water to distribute heat evenly in the heat exchanger. This design guarantees an efficient supply of hot water. The package includes a room thermostat. It has a number of useful functions, such as: season selection for setting the heating water temperature, turning on and off by time, the autonomous operation function maintains the minimum room temperature and prevents the boiler from bursting, the flushing function ensures the supply of a large amount of hot water and others. Some technical features of the Kiturami KRP pellet boiler

- Used for heating and water heating;

- Automatic dosing of fuel, depending on heat demand and combustion stage, into the boiler furnace via a feed auger;

- The circulation pump and expansion tank are built-in, which naturally simplifies its installation;

- The ash receptacle is in the form of a box, it is easy to empty, and cleaning the boiler, thanks to its special design, does not cause difficulties;

- The use of a specially shaped heater in the Kiturami KRP pellet boiler makes it possible to increase the ignition area;

- The design of the boiler prevents the backfire of the torch;

- For safe operation: anti-freeze function, double overheat protection, built-in overheat and water level detectors, etc.

Kiturami KRP Premium instructions and documentation:

- Kiturami KRP booklet

- Kiturami KRP User Manual

- Kiturami KRP User Manual - A (Premium)

| 1. | Operation of the Kiturami KRP-A boiler using sunflower husk pellets. To view, click on the camera. |

| 2. | Launch of the Kiturami KRP 20-A boiler. Ignition of the burner |

Device

The main elements of the boiler design are the gas burner and the heat exchanger. These are independent units, but they work in pairs and are structurally combined.

The coolant, under the action of the circulation pump, enters the heat exchanger, heats up and exits into the secondary plate heat exchanger, where it transfers part of the thermal energy to prepare hot water. After this, the coolant exits into the heating circuit.

Smoke removal and air supply for normal combustion are provided by a turbocharging fan, and the operation of the system is monitored by a control board.

A system of self-diagnosis sensors is connected to it, detecting problems and sending signals to the control board, which immediately triggers an alert on the boiler display.

Gas boilers Kiturami

The main difference and advantage over boilers from other manufacturers is the patented “turbocyclone” burner, which is installed on all gas-fueled devices without exception. The double burning of fuel that this burner provides allows the boilers to operate at low pressure, which is especially important in winter.

1. Wall-mounted boilers

presented in 3 series. They all have a similar design: • a heat exchanger made of pure copper, • a built-in hot water tank with a separate radiator heat exchanger, • a forced system for removing combustion products, • a built-in circulation pump, • a gas leak sensor, • a seismological sensor that turns off the boiler during shocks of 4-5 points, • proportional control gas valve, • closed type of coolant circulation, • high efficiency 91-98%.

There are also a number of differences • Twin Alpha. Large hot water tank, filter protecting against voltage surges in the electrical network. • World Plus. Large volume of expansion tank - 7 l, small size and weight, stylish external design • Hi Fin - the latest development. It has a number of significant differences and improvements: – Heat exchanger made of alloy capacitive steel, prevents scale and increases service life. – Burner with double combustion zone and uniform flame distribution. – Double frost protection. – Numerous programming safety modes. – The gas leak sensor on the boiler displays an alarm if the sensor on the room thermostat detects a gas leak or high levels of carbon monoxide. – Energy saving mode – consumes 1 W of electricity.

All 3 model ranges of Cuturami have a great advantage over boilers from European manufacturers - they are unpretentious and the ability to work with minimal network parameters: • Gas pressure from 0.3 bar. • Water flow from 1.6 l/min. • Built-in separator filters air from the heating system.

2. Floor-standing boilers Kuturami

are presented in 3 model ranges, all of them equipped with the latest turbocyclone burner in a closed combustion chamber and the possibility of replacing it with a diesel one: • STSG model range: – Power 15 – 34.9 kW. – Compact size. – Large hot water tank. – Heat exchange tank made of alloy steel, manufactured using a new welding technology that eliminates leaks.

• Model range TURBO. It differs from the previous one in its design, which significantly reduces noise, and in the special structure of the heat exchanger chamber through which combustion products pass several times. • Model range KSOG. In addition to significantly greater power, 58-454 kW is also distinguished by the use of special pressed heat transfer pipes, which increases efficiency. Accordingly, these boilers have substantial dimensions.

Types of Kiturami units and models

produces boilers that operate on various types of fuel, as well as hybrid options.

Gas

Kiturami gas units are produced in floor-mounted and wall-mounted versions. Models installed on a horizontal surface are represented by three lines: STSG, TGB and KSG. Wall-mounted gas boilers are produced in 4 series, differing in functionality and configuration.

The power of the installations ranges from 11.7 kW for household versions to 464 kW for industrial versions. For safety reasons, all devices are equipped with gas leak detectors.

The gas burner device with afterburning function is Kiturami’s own development. The peculiarity of the part is that it contains a plate made of a special metal that can heat up to 800 °C. In high-temperature mode, more complete combustion of fuel material is achieved and emissions into the environment are reduced.

Kiturami STSG

The STSG line includes 5 standard sizes of domestic floor-standing boilers. It features a stainless steel boiler heat exchanger with the ability to quickly heat water. Works stably even with gas pressure drops in the main line. The series devices are compact in size and can be easily placed in small spaces.

Advantages:

- space saving (boiler and boiler in a single housing);

- modes of reduced resource consumption (“absence”, “sleep” and others);

- welding of parts using our own technology;

- Built-in DHW coil for abundant supply of hot water.

Kiturami TGB Series

TGB boilers are represented by a single model 30R with a power of 34.9 kW. The device has a three-pass heat exchanger made of high-alloy steel. Allows you to heat and provide hot water in a room with a square area of up to 350 meters. Installed on the floor. In summer, you can use the water heating mode without heating.

TGB kiturami have an increased level of protection.

Safety devices:

- circulation pump fuse;

- lightning and fire protection;

- stop in case of gas leak;

- shutdown when the coolant overheats and the liquid level in the system is low.

Kiturami KSG

The series combines powerful floor-mounted industrial units in seven standard sizes. The body is protected by a load-bearing frame for safe transportation. The design includes a storage tank that can provide residents with a large amount of hot water. Due to their low weight they can be placed in attic spaces.

Equipment:

- combined double-circuit heat exchanger;

- electronic ignition;

- gas filter cartridge;

- thermostat-regulator with a choice of modes;

- gas multiblock (stabilizes gas pressure before supplying it to the burner).

Kiturami Twin alpha

The boilers of the line are mounted in a mounted design and equipped with an integrated heat exchanger. The DHW circuit is located inside the expansion tank, which ensures rapid heating of the water. Convection units are equipped with advanced automation, including a seismic sensor. The main heat exchanger, made of copper and aluminum, can last up to 12 years. The hot water temperature is conveniently adjustable in the range of 35–60 °C.

Technical features:

- automatic restart when blowing out;

- water hammer protection;

- built-in expansion tank;

- improved silent fan;

- gas valve with proportional control system (to save consumption);

- instant heating of water.

World plus line

The series was developed in 2010 specifically for work in harsh conditions. Instead of water, you can use non-freezing liquids as a coolant. The boiler features the latest development - a burner with an internal flame. It provides gas savings due to its complete combustion. If there is a malfunction, an alarm will sound.

World plus is a full-fledged boiler room in a single building.

Included:

- pump for forced water circulation;

- expansion tank;

- security group;

- electronic control unit with remote thermostat.

The series includes 5 wall-mounted models of different capacities.

Kiturami Hi fin

The units of the series are considered the safest among Kiturami gas boilers. The line includes 6 mounted models with power from 11.7 to 34.9 kW. The durable bithermic heat exchanger is made of steel with aluminum inserts. Due to the additional combustion zone, an increase in the productivity of hot water supply is achieved. The range is equipped with an advanced gas leak detection system.

The Kiturami Hi fin boiler is suitable for any type of heating system and is compatible with the “warm floor” function. The design includes a built-in circulation pump.

Unit features:

- a new double-sided burner that evenly distributes heat in the firebox;

- stable combustion at low gas pressure;

- storage heat exchanger;

- proportional gas valve;

- protection against power surges;

- circulation pump included.

Kiturami Eco Condensing

Range of 3 condensing wall-mounted boilers. To increase efficiency, they use steam cooling energy. The technology involves a significant reduction in the temperature of flue gases when passing through a four-pass heat exchanger. As it cools, the smoke loses a certain amount of energy, which is additionally transferred to the coolant.

The new design of the built-in turbofan allows the device to be used safely in areas with strong winds and on high floors.

Series differences:

- condensation heat exchanger;

- energy efficiency 1st degree - 98%;

- mixed turbofan for operation in rarefied conditions;

- the use of metal fiber for uniform burning of the flame.

Diesel

Kiturami liquid fuel heating boilers differ from diesel units from other manufacturers in their increased efficiency and manufacturability. The devices are floor-mounted.

All devices are dual-circuit and equipped with an alternative burner. If necessary, the user can easily switch to gas fuel. In summer, you can use the water heating function separately from heating.

Design elements:

- fuel tank;

- pump;

- filter;

- burner;

- heat exchange unit;

- smoke channel;

- control group: sensors, thermostat (remote control).

The boiler operates as follows. From the tank, fuel is supplied to the burner using a pump, after being filtered. Through nozzles, liquid is sprayed into the combustion zone. Inside, a mixture of fuel and forced air burns, releasing heat. Energy is transferred through heat exchange channels to the water of the heating system. Exhaust gases are drawn into the chimney.

Kiturami diesel units are presented in 4 series.

Kiturami Turbo

The basic series of Turbo domestic boilers includes devices for heating rooms ranging in size from 90 to 350 sq.m.

Peculiarities:

- three-pass heat exchanger “3-PASS” promotes more complete heat transfer;

- built-in turbulator for forced smoke removal (you can use a simplified chimney instead of a traditional bulky pipe);

- a secondary heat exchanger made of stainless steel guarantees the purity of hot water without deposits;

- reduced noise level due to a muffler;

- The large capacity of the domestic hot water circuit supports the rapid supply of heated domestic water.

Kiturami STS

STS products differ from the Turbo series by a stainless steel heat exchanger. Accordingly, their prices are slightly higher. Heat generators are designed for domestic and industrial buildings with dimensions of 150–340 sq. m.

Differences:

- stainless steel parts are corrosion resistant;

- the storage heat exchanger heats a large amount of water in a short time;

- the use of laser welding technology eliminates leakage through seams;

- For ease of installation, outlets for connecting heating pipes are available on both sides of the housing.

KSO Series

Kiturami KSO - high power industrial heating units. Used in servicing industrial and commercial facilities. Capable of heating buildings with an area of 580–4650 meters. They have the ability to heat water for domestic needs in large quantities.

Device Features:

- improved design of the turbocyclone burner with afterburning of flue gases increases efficiency and reduces emissions of harmful substances;

- the power steel frame protects against damage during transportation;

- secondary heat exchanger of capacitive type made of stainless steel;

- pressed heat transfer pipes increase the contact area, providing increased efficiency without increasing the size of the heat exchanger;

- KSO boilers can be assembled in a cascade of up to 10 pieces.

Turbo Hi Fin

Kiturami boilers of the Hi fin series differ from the basic Turbo models by an improved heat exchanger. Suitable for use in systems with forced circulation.

Design differences:

- heat exchange passages are made of pipes with special inserts to increase heat removal;

- updated burner with afterburning;

- convenient connection to the heating network (from either side);

- The DHW spiral heat exchanger ensures a continuous supply of water in large quantities.

Solid fuel

Solid fuel boilers are suitable for use in rural areas. To obtain thermal energy, the units consume biofuel: wood and coal. It is possible to use briquetted and granular materials of various origins.

Features of operation:

- availability of fuel material;

- limited time on one tab;

- the need to constantly manually service the boiler: load new portions of fuel and clean out the ash several times a day;

- the chimney and pipe periodically become clogged with soot deposits.

Solid fuel boilers come in classic and pyrolysis types. In the first case, the unit has one combustion chamber.

The second option is structurally more complicated. The firebox of such a device is divided into two parts. Fuel is placed in the upper chamber and heated until pyrolysis occurs. The wood gas generated in the process is forced through a nozzle into the lower chamber and burned there.

Pyrolysis boilers are more efficient. Another advantage is their low waste.

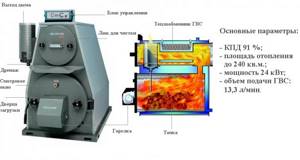

Kiturami KF

The series is represented by the KF-35 model with a power of 24 kW. A pyrolysis type boiler is capable of heating rooms up to 240 square meters. m. One full load of fuel allows continuous operation of the unit throughout the day. The heating rate of domestic water is 14.7 l/min. Efficiency - 91.5%.

Design advantages:

- spacious loading chamber for 50 kg;

- stainless heat exchanger;

- a ceramic nozzle between combustion zones 1 and 2 promotes complete combustion of fuel and pyrolysis gases;

- large loading hatch;

- the boost fan maintains a stable fireplace in the firebox;

- the secondary combustion chamber is equipped with a device for removing pyrolytic liquid;

- Ash receptacle in the form of a box.

Kiturami KRP

The KRP line includes pellet boilers that use granulated wood waste. Granule diameter: 6–8 mm, length: 1–3 cm. A full hopper allows the equipment to work without interruption for up to 5 days. The model range consists of 2 sizes: 20A and 50A.

Technical features:

- automatic fuel supply via a screw mechanism;

- built-in expansion tank and circulation pump;

- ash pan in the form of a box;

- pellet burner in the shape of a bowl with an increased ignition area;

- automatic vibration cleaning of grates.

Combined

Hybrid heating devices operate on solid and diesel fuels. Structurally, such units combine two devices in one housing. They have separate combustion zones: one for solid fuel material, the other for diesel fuel. When the resource in the first chamber runs out, the liquid fuel burner automatically starts working.

The advantage of combined type boilers is their relative independence from any one type of fuel. For the user in conditions of supply interruptions, this factor plays an important role.

Bi-fuel series KRM

The line is represented by 2 models: KRM-30 and KRM-70.

The solid fuel combustion chamber is made according to the classical design. Equipped with a grate. The ash compartment is located below. The diesel fuel combustion chamber is located above the primary firebox. A water jacket surrounds the perimeter of the body. Heat exchange pipes are located in the cavity.

The boiler works as follows. Through the loading door, fuel material is laid out on the grate and ignited. Air is sucked into the combustion zone through the ash pan door. Heat energy from the hearth is transferred to water through heat exchange. When the fire in the primary firebox goes out, the diesel burner torch automatically lights up.

Device Features:

- heating and filtration of diesel fuel;

- automatic control of air supply;

- restart when power is turned off;

- cleaning tools included.

Kiturami KRH

The line consists of a single model, the KRH-35. To burn wood, the device uses a pyrolysis method. Unlike the basic KR series, the product’s enlarged firebox accommodates 90 cm long logs and is not afraid of damp firewood. When solid fuel burns, the boiler automatically switches to diesel fuel.

Features of operation:

- It is convenient to ignite using a special button;

- when using wet fuel, you will have to clean the boiler from tar 2 times a week;

- economical consumption allows you to load the device once a day;

- automatic removal of pyrolytic liquid through a drainage device.

Diesel boilers Kiturami

Almost all models of floor-standing gas boilers from Kuturami have the ability to quickly replace the gas burner with an oil burner. This does not lead to a decrease in efficiency or other characteristics. An additional advantage is the complete interchangeability of parts for gas and liquid fuel boilers. Fuel consumption is indicated in the specifications of each model and fluctuates around 5-6 l/day for every 10 kW of power. When switching to economy mode, fuel consumption is significantly reduced. There are several ready-made modes on the programmer: sleep, absence from the room, shower and others. Depending on the mode, the temperature supply to the main circuit of the heat exchanger or to the DHW is regulated. The security system is also reconfigured for diesel fuel, liquid presence sensors automatically turn off the boiler, and the self-diagnosis system will ensure safe further start-up and operation. A fuel bunker is usually included in the delivery of boilers of a specialized liquid design.

Basic faults

Kiturami boilers are famous for their reliability and durability of parts. However, the possibility of individual problems cannot be excluded.

Most often, the components that are under maximum load fail - the heat exchanger and the gas burner..

A layer of lime deposits appears in the heat exchanger, which reduces the efficiency of heat transfer.

It is necessary to increase the combustion temperature, as a result of which the outer part of the unit gets too hot and fails.

The gas burner is susceptible to clogged nozzles and other problems that lead to the flame going out and difficulty igniting the boiler.

Often there are problems with the self-diagnosis system sensors themselves - poor contact, breakage, short circuit.

'>Solid fuel boilers

Represented by the KF and KR model ranges

Both model ranges have the same operating principle and are equipped with: • Storage heat exchanger. • Two-pass heat exchanger. • Computer control. • Remote thermostats. • Remote control. • Built-in DHW flow circuit. • Fan with proportional control. • Circulation pump. The difference is the presence of an electronic control panel and the ability to change modes (winter, summer) by redirecting all the energy in an economical mode to the hot water supply. Some KR models do not have grates.

Pellet solid fuel boilers

Represented by models of the KRP series. It is distinguished by its thoughtfulness and reliability of design. High level of efficiency and automation.

• Hopper height 120 cm with a wide loading niche of 40 cm. Designed for 150 kg. fuel, which gives autonomy for 5-7 days. • The pellets are fed using a screw auger with an electric motor, which ensures accurate and timely shipment. • Automatic cleaning of the heat exchanger surface occurs using a powerful compressor (flow force 8 kg/cm2) and a high-speed solenoid valve. • The electric drive of the ash cleaner automatically cleans the grates in the combustion chamber, preventing fuel caking. • Turbocyclone burner doses the air supply into the combustion chamber, optimizing the combustion process. • The three-pass main heat exchanger repeatedly circulates hot gases in the combustion chamber, bringing the device efficiency to 92%. • Spacious ash drawer. • Flow-through DHW heat exchanger made of stainless steel with a diameter of 15 mm, which makes the likelihood of clogging very remote. • Convenient and detailed control system. • Alert system for the presence of pellets in the hopper (there is a safety valve against spillage), water in the heat exchange system, and operation of the pellet feeding auger.

A huge advantage of pellet boilers from the Kuturami company is their versatility and unpretentiousness in relation to flammable materials; sawdust pellets, shavings, wood chips, sunflower and buckwheat husks are not a complete list of materials that can be loaded into the boiler. The moisture content of the pellets is of greater importance. As users write in their reviews, if wood pellets become damp, they can not only inevitably reduce the efficiency of the boiler, but also jam the screw feed mechanism.

Error codes, decoding and how to fix

Let's look at the most common errors of Kiturami boilers:

| Code | Decoding | Remedy |

| 01-03 | Flame ignition failed | Check the condition of the burner nozzles, the presence of gas in the line, the condition of the valves and supply tap |

| 04 | Temperature sensor malfunction | Checking the status of contacts, calling a technician |

| 05 | Boiler overheat sensor failure | Call a specialist |

| 06 | The fan operating mode is not detected | Check the condition of the contacts, call a technician |

| 07 | Incorrect fan speed | Call a specialist |

| 08 | The wire length of the room temperature controller has been exceeded | Cut the wire, check if it is in contact with the telephone line |

| 95 and 98 | Low water level in the heating circuit | Add water, check the system for leaks |

| 96 | Coolant overheating | Check the operation of the circulation pump, increase the fluid level in the system, call a technician |

| 97 | Gas leak | Turn off the boiler, open the windows, call specialists |

Combination boilers

Represented by two model ranges KRM and KRH

Bi-fuel boilers KRM series

Developed for the use of solid and liquid fuels. They are equipped with all the auxiliary devices that make up the basic set of the Cuturami company: • Heat exchanger made of alloy steel with specially reinforced, welded seams using patented Cuturami technology. • Flow-through heat exchanger of the DHW system made of purified copper. • Automated system that controls the air damper of the solid fuel part. • Turbocyclone burner in the liquid fuel section. • Fuel filter and fuel pump. • Automation system. • Circulation pump. • Remote temperature sensor. • Remote control. The boiler has undeniable advantages over products of the same class from other manufacturers, and the installation of two boilers in tandem: • Both combustion chambers are located in the same housing, which eliminates heat loss and increases heat transfer. • Automatic transfer to the use of a second type of fuel when solid fuel burns out completely. • Automated regulation of solid fuel combustion. • Both fireboxes are closed. The air is supplied by a special fan with an intake point outside the room. • Efficiency up to 92%.

Model range KRH

The models of the presented series have a 3-stage combustion system. This boiler has a gas generator (pyrolysis) type of solid fuel part. Like the previous model range, it is equipped with all the components and assemblies that increase efficiency, and an automatic switching system to diesel fuel. But there are also differences. More detailed are the safety functions: • Automatic shutdown when the diesel part overheats and blocking the air supply to the solid fuel part. • Coolant temperature sensor. • Heat exchanger temperature sensor. • Automatic re-ignition system after stopping.

The boiler has a firebox of increased volume into which firewood up to 0.9 m long is placed. A full load allows you to work on solid fuel for up to a day. It is possible to lay wet wood. The boiler provides drainage and removal of pyrogenetic waters. The included Turbo 21R liquid fuel burner (24.4 kW) with a fuel supply system based on a plunger pump can be replaced in normal mode with a more powerful one with a gear pump.

Advantages of Kuturami boilers

1. Cost.

Boilers cost much less than comparable analogues of European brands, and even some domestic ones produced under license.

2.Easy to operate.

A high level of automation, even for solid fuel boilers, is combined with a friendly, understandable interface of control systems. Many models have a self-diagnosis system that will show the corresponding trouble code. Detailed instructions on how to proceed in such cases are included in the technical data sheet of each modern model.

3. Reliability.

Simplicity of design is combined with the highest quality of assembly and materials. Repair and maintenance are elementary. Even the user of the product can carry out modular repairs. A large number of authorized sales points with a full set of repair equipment, trained personnel and replacement parts.

4. High efficiency.

Thanks to the use of the company's own patented energy-saving developments and the inclusion of all additional devices - circulation pumps, turbocharging and the like, the company's boilers have high efficiency and are very economical in fuel consumption. The automated control system also has several types of economical modes: winter - summer, heating only or DHW only, masterless mode (anti-freezing) will maintain the minimum required or set temperature, preventing freezing.

5. All company products are certified and adapted for harsh working conditions with domestic gas networks

and the quality of combustible materials. A large selection of interchangeable spare parts and additional units to improve and optimize operation - additional pumps, voltage stabilizers, additional sources of uninterrupted power supply, many pumps of various purposes and power, coaxial and classic chimneys and extension cords for them.

Feedback from users and service technicians

Many technical forums and online communities are replete with topics about technical characteristics, installation features, advantages and disadvantages of Kuturami heating equipment. Such popularity is understandable. The price/quality ratio leaves far behind competitors. But some troubles still happen.

The quality of diesel fuel in our country leaves much to be desired. This affects not only cars, but also boilers. There are several ways to fight. Filter the fuel before filling it into the boiler tank, but given that most people install high-capacity tanks of 1000-1500 liters, this is a rather labor-intensive process. Experts advise installing an upper fuel intake with a float, but you need to install an additional pump, which is not provided as standard. And if the owners forget to clean the tank and fill it on time, then the dirt that gets into the internal grooves breaks the end side of the gear in the pump.

As a result, the pressure drops from 10 atm. up to 4-6 atm. Due to the low pressure in the nozzle, soot from incompletely burned dirty fuel clogged the chimney, the combustion chamber, and settled on the heat exchanger. A drop in power of 3-5 kW led to a drop in temperature in the house. In this case, cleaning the boiler had to be carried out with partial disassembly, the stuck-on lumps of soot were knocked off with a chisel, and the cells were sanded with sandpaper so that the deflector would fall into place. The fuel pump could not be repaired and required replacement. By adhering to the rules for operating heating equipment from the Kuturami company, you will get the required temperature for little money.

Korean boilers from KITURAMI have many functions and capabilities. In terms of quality and reliability, they are not inferior to other modern manufacturers. Thanks to the latest technologies, gas boilers from this company can save gas costs by almost 30%.

About company

KITURAMI is a Korean company founded in 1962. Today it is the largest manufacturer of heating equipment in Korea. Its products are used in Russia, Europe, America and other countries. Korean heaters can operate in radically different climatic conditions - from subtropics to the Arctic. The company owns a powerful research and development center with over five hundred patents and ownership rights to its own developments. The products have ISO 9001 certificates and permission from Gosgortekhnadzor.

Gas boiler models

Korean manufacturers produce a wide range of models with different technical characteristics, power and purposes, as well as various connection methods. Any boiler can be converted to operate on reduced gas.

Before purchasing this equipment, you should familiarize yourself with the following features:

- High performance. Thanks to their technical characteristics, gas boilers from the Korean manufacturer KITURAMI can be used for heating industrial and domestic buildings. The power of such boilers is quite high; it ranges from 13 to 470 kW.

- They produce gas boilers with a closed and open combustion chamber. The type of firebox determines the quality of work, the efficiency of the boiler and the amount of gas consumed. Modern models generally have a closed combustion chamber. And also such boilers have a condensing principle of operation.

- Gas boilers can be single-circuit or double-circuit. In the first case, they are only capable of heating the room, and in the second, they heat the water and heat the room.

- Boilers vary in installation method. Depending on your wishes, you can choose a floor-standing or wall-mounted boiler. If you need to heat a large room, then it is better to choose the first option, as they have high performance. Wall-hung boilers have many functions and are small in size, so such a device can be installed in a small room.

The KITURAMI company presents several dozen models of gas boilers. The main advantage, along with other manufacturers, is the Korean assembly of the device. All components are ordered from Japanese manufacturers or manufactured at the company's plant.

Price range

The range of Kiturami gas boilers is very wide. The cost of household models (for a private home) is in the range of 30-60 thousand rubles, but there are also more powerful models that will cost 100-800 thousand.

This price difference is due to the power level and capabilities of the boiler, its purpose and design features.

As a rule, users choose units of lower power and, accordingly, cost.

Before purchasing, you should check the terms of delivery. Boilers in the basic configuration do not have a chimney, so you need to immediately decide which type is needed and order it. You should also immediately acquire filters and a voltage stabilizer .

Floor standing boilers

Floor-standing gas boilers have high efficiency, so they do an excellent job of heating large rooms.

Models of floor-standing boilers:

- Model KITURAMI KSG. This boiler has high performance and power, which can be 464 kW. This model is usually used for heating apartment buildings and industrial buildings. The coolant is heated from 41 to 75°C. Since this boiler is of a double-circuit type, it has a summer mode, in which the heating function is turned off and only the water heating function remains.

- Model KITURAMI TGB. Double-circuit gas boiler, which is used for industrial and domestic needs. Gas consumption can be significantly reduced since a turbocyclone burner is installed. At the same time, the amount of heat transfer is maintained. Hot water is heated at 20.7 liters per minute. The boiler has a built-in automatic system to prevent gas leakage, overheating of the coolant and fire extinguishing. These boilers have all the necessary modern functions and meet fire safety regulations.

Mounted boilers

The most popular are wall-mounted gas boilers from the Korean manufacturer, as they are light in weight and compact in size. Such a boiler can be installed in the kitchen or in the hallway or in another small room.

Let's look at the models of wall-mounted gas boilers KITURAMI:

- The KITURAMI World 5000 model is one of the most powerful and can heat a room of 350 m2. This boiler can use absolutely any coolant. The equipment is equipped with a built-in expansion tank and circulation pump. Thanks to the magnetic valve, gas consumption is reduced, and it is also quite convenient to use the boiler in the summer. You can control the device remotely.

- Model KITURAMI world 3000. With the additional purchase of nozzles, the boiler can be converted to operate on reduced gas. The boiler includes a separate copper heat exchanger, as well as a coaxial chimney.

- The KITURAMI world plus model was specially manufactured for Russia. This model has two built-in heat exchangers, so you can heat water without turning off the heating. In this model, fuel is completely burned and saved, thanks to a gas burner with internal combustion. Using the controller, you can set the operating mode for heating the room, taking into account individual needs. An external thermostat is installed as standard.

- The KITURAMI ECO Condensing model is a condensing boiler that receives additional thermal energy when using condensation. Thermal energy produced is about 10% of the total. This boiler is the most economical of all models produced by the Korean manufacturer. The boiler is equipped with all necessary functions. To obtain thermal energy equal to 16 kW, about 1.6 m3 of fuel will be required. Using such a condensing boiler to heat a room is very beneficial.

- Model KITURAMI twin Alpha. In such a boiler there is a forced removal of combustion products and injection of air. The design uses a heat exchanger made of copper and aluminum. Thanks to several modes, you can precisely set the operating settings. The boiler also has a system installed to protect against overheating of the coolant and the ingress of carbon dioxide.

Solid fuel

Solid fuel boilers are suitable for use in rural areas. To obtain thermal energy, the units consume biofuel: wood and coal. It is possible to use briquetted and granular materials of various origins.

Features of operation:

- availability of fuel material;

- limited time on one tab;

- the need to constantly manually service the boiler: load new portions of fuel and clean out the ash several times a day;

- the chimney and pipe periodically become clogged with soot deposits.

We recommend: Pressure testing of the heating system - the most complete information

Solid fuel boilers come in classic and pyrolysis types. In the first case, the unit has one combustion chamber.

The second option is structurally more complicated. The firebox of such a device is divided into two parts. Fuel is placed in the upper chamber and heated until pyrolysis occurs. The wood gas generated in the process is forced through a nozzle into the lower chamber and burned there.

Pyrolysis boilers are more efficient. Another advantage is their low waste.

Kiturami KF

The series is represented by the KF-35 model with a power of 24 kW. A pyrolysis type boiler is capable of heating rooms up to 240 square meters. m. One full load of fuel allows continuous operation of the unit throughout the day. The heating rate of domestic water is 14.7 l/min. Efficiency - 91.5%.

Design advantages:

- spacious loading chamber for 50 kg;

- stainless heat exchanger;

- a ceramic nozzle between combustion zones 1 and 2 promotes complete combustion of fuel and pyrolysis gases;

- large loading hatch;

- the boost fan maintains a stable fireplace in the firebox;

- the secondary combustion chamber is equipped with a device for removing pyrolytic liquid;

- Ash receptacle in the form of a box.

Kiturami KRP

The KRP line includes pellet boilers that use granulated wood waste. Granule diameter: 6–8 mm, length: 1–3 cm. A full hopper allows the equipment to work without interruption for up to 5 days. The model range consists of 2 sizes: 20A and 50A.

Technical features:

- automatic fuel supply via a screw mechanism;

- built-in expansion tank and circulation pump;

- ash pan in the form of a box;

- pellet burner in the shape of a bowl with an increased ignition area;

- automatic vibration cleaning of grates.

Installation and operation of KITURAMI gas boilers

The main requirement of the manufacturer during assembly is strict quality control. Manufacturers are also trying to create boilers that are easy to maintain and operate. Since all circulation elements are pre-built into the boiler body, the device can be installed quickly and easily.

There is no need to adjust the burner, as this happens automatically. Thanks to the control unit, you can choose the optimal mode for any building and structure. When installing a KITURAMI gas boiler, you must first install a coaxial chimney. Gas equipment piping includes connecting pipes for heating, as well as a water supply system.

Operation and setup

Kiturami boilers operate automatically.

Only a few actions are required from the user to configure it:

- Temperature adjustment carried out in working order.

- Draining and filling the system with water.

- Periodic cleaning of the boiler body from soot or dust.

All other actions occur either automatically or by invited specialists. This is especially true for initial tuning, which adjusts factory settings for greater performance and economy.

Download instructions

Download instructions for Kiturami gas boilers.

Independent intervention in the boiler design may cause its breakdown and will terminate the warranty agreement.

How to choose a KITURAMI gas boiler

When choosing a gas boiler, you need to pay attention to the weight and dimensions of the equipment, functions, water pressure in the system and performance. It is also worth considering the heating system that will be used and the characteristics of the room that will be heated.

The cost of gas boilers from the Korean company KITURAMI is low. You can choose a premium boiler at the price of a boiler with simple equipment from a European manufacturer. The quality of these boilers is very high, so they are not inferior even to German and French manufacturers, although their cost is much higher.

Advantages and disadvantages

The advantages of Kiturami gas boilers are:

- High operational capabilities of boilers, reliability, efficiency.

- Stable operation, low number of failures or failures.

- High build quality, reliability of components and parts.

- Wide selection of models to suit any need.

- An optimal set of functions, no unused features that increase the price of the boiler.

- Silent operation, simple operation.

- Relatively low cost.

- Compact, attractive appearance.

The disadvantages include:

- Energy dependence. If the power is turned off, the heating system will stop operating. In addition, Boilers are sensitive to the correct connection and stability of the power supply.

- Requires maintenance by qualified personnel.

NOTE!

These disadvantages are characteristic of any gas boilers and can be considered specific design features.