Mass gasification, which began in the USSR in the mid-60s of the last century, made it possible for owners of private farmsteads to change the way they heat their homes. For this purpose, the country's industry produced gas boilers, which had a common designation for all models - AGV - a gas water heating apparatus (according to another version, “unit”). Particularly popular were gas boilers from Zhukovsky, a city near Moscow closely associated with the aviation and space industries. AGV gas boilers for private homes are still produced there, their design has undergone virtually no changes, and the letter “O” has appeared in the name - AOGV.

Gas boiler AGV-80

What is the difference between AGV and AOGV

AGV boilers from the city of Zhukovsky can be considered the same technical rarity as UAZ cars. Moreover, they are similar in reliability and ease of operation.

Initially, gas boilers AGV-120 and AGV-80 were produced. The number in the abbreviation is the volume of water in liters. It characterizes the power of the boiler, which is convenient for the average user, since the number coincides with the maximum possible heated area.

Modern gas boilers AOGV (the abbreviation stands for “Gas Water Heating Unit”) are more efficient devices, the power of which ranges from 11.6 to 29 kW. The number in their model index indicates precisely this parameter, and to determine the possible heated area it must be multiplied by 10. Their design has undergone slight changes. For example, the flame tube is made cone-shaped and divided into three sections (number 3 in the index), which made it possible to increase the efficiency of the device from 0.8 to 0.9. In addition, some models are equipped with an additional water circuit (water heater) used for hot water supply. Its presence is indicated by the letter “K” in the index - AKGV.

For user convenience and expanded choice, boilers are available in three types of equipment:

- Economy - all fittings and automation are made in Russia.

- Station wagon - imported automation is used in the most critical units.

- Comfort - all fittings and automatic devices are made in Italy.

Table. Technical characteristics of AOGV boilers produced by Zhukovsky Machine-Building Plant

| Characteristic | Model | ||||||

| AOGV-11.6-3 | AOGV-17.4-3 | AOGV-23.3-3 | AOGV-29-3 | ||||

| Burner power (kW) | 11,6 | 17,4 | 23,3 | 29 | |||

| Heated Smax (m 2 ) | 116 | 174 | 233 | 290 | |||

| Fuel | Natural or liquefied gas | ||||||

| Working gas pressure (Pa) | 1274 - natural 2940 - liquefied | ||||||

| Heating efficiency (%) | 86 | 88 | 88 | 89 | |||

| Operating pressure in the boiler (kPa) | 100 | ||||||

| Dimensions (mm) | 850×310×412 | 1050×420×480 | |||||

| Weight (kg) | 30 | 49 | 52 | 55 | |||

| type of instalation | Floor | ||||||

| Gas outlet diameter (mm) | 117 | 135 | 140 | ||||

| Diameter of lines (gas-heating) in inches | ½ — ½ | ¾ — 2 | |||||

Technical characteristics of the heating device "Taiga":

| Overall dimensions, mm depth width height | 785 560 750 |

| Working surface of the plate, mm length width | 530 370 |

| Heat exchanger surface, sq.m. | 1,87 |

| Volume of combustion space, cubic meters | 0,06 |

| Grate area, sq.m. | 0,10 |

| Volume of the water chamber of the device, l | 94 |

| Rated thermal power, kW | 23,2 |

| Efficiency of the device on anthracite, %, not less | 71 |

| Weight, kg, no more | 132 |

| Hydraulic pressure during testing, kgf/sq.cm | 1 |

| Fuel | hard |

| Exceeding the heating temperature of the service handles relative to the room temperature, degrees C | 17 |

| Carbon monoxide index, % | 0,367 |

Telephone: 8 call within Russia free of charge

Mobile phones: +7 923 601-3447 +7 905 960-0881

The Taiga gas boiler is a product of the Russian company Termotechnik, a worthy alternative to foreign analogues. It features a well-thought-out design and high-quality assembly. Taiga heaters have automatic equipment made in Italy, thanks to which they meet European safety standards.

GC Termotechnik is a Russian company specializing in the production of heating equipment. Year of foundation - 2002. Central office - Pushkino (Moscow region).

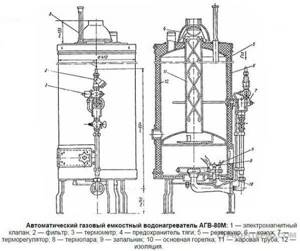

AGV design

The AOGV gas boiler has a gas-tube design with a vertical flame tube and is installed on the floor. The round burner is located at the bottom. The air required for combustion enters through the lower holes in the casing. Removal of combustion products occurs naturally, through the chimney pipe at the top, at the base of which there is a draft breaker cap with a door.

Design of the AGV-80 gas unit

The flame tube is divided into sections by so-called turbulators, which provoke turbulence in the flow of exhaust gases, reduce its speed and increase the efficiency of the device.

The connection pipe for the direct line of the heating system is mounted on the top cover of the boiler. Returns are on the side. The AGV-80 gas boiler differs from the AGV-120 in that the fuel line with shut-off valves is located on the outside and does not have a casing.

Installation

The instructions describe the ignition process in detail. The launch is carried out after installation and strapping. The correct installation must be checked by the gas service. Before lighting the boiler, a number of preparatory and installation work should be performed:

- Avoid proximity to flammable materials.

- Connect cold water, remove the plugs from the pipes. Install a filter and ball valve at the inlet to protect the system from blockages that could cause malfunctions.

- Ball valves are mounted on all pipes involved in the piping.

- Gas pipes are installed by gas workers; they carry out the connection and installation of the meter.

- They lay a power line for volatile models. They make a separate outlet.

- Installation work related to the removal of combustion products is determined by the type of firebox. There are naturally aspirated or turbocharged models.

- After disconnecting the device from the power supply, fill the system with coolant. Check for leaks. Before the first ignition, all components of the system must be carefully checked.

Principle of operation

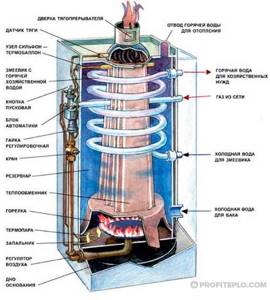

The water in the boiler circulates naturally - according to the thermosiphon principle. Heating occurs from the flame tube, through which hot gases emanating from the lower burner pass.

The main closing element of the gas line is an electromagnetic valve driven by a thermocouple. To light the burner, you need to press the start button on it and bring an open flame to the pilot tube. A current arises in the heated thermocouple, which causes the solenoid valve to operate. After this, the gas supply valve to the burner is manually opened and the boiler is ignited.

Operating principle of the AOGV boiler

To control the heating temperature, there is a coupling in the top cover of the boiler where a thermometer is installed. It is maintained at the same level using an automatic thermostat, the operating principle of which is based on changing the length of a metal rod (brass) when heated. To operate in a given temperature range, its lever rotates only 14°, which is passive protection against unskilled actions.

If you want to raise the upper heating limit, first unscrew the locking screw on the thermostat control lever and turn it counterclockwise, then tighten it again and turn it in the opposite direction. The design does not prevent actions that could cause the water in the boiler to boil. Therefore, it would be better to have them carried out by a specialist. If you don’t have one, read the technical description of AOGV boilers and the rules for their operation by following this link.

Automation

You can choose a budget option aimed at reducing gas in the absence of owners. This mode avoids the danger of the system defrosting in cold weather.

A modern AGV boiler is equipped with many sensors providing a high degree of automation

Sensors on the boiler allow you to notice malfunctions and accurately determine the system that has failed so that you can promptly fix the problem. The AGV automation controls the shutdown of the gas supply if the chimney draft is disrupted, when the gas pressure drops, or when the pilot flame goes out.

Advantages and disadvantages

AGV heating using boilers of this type can significantly increase the comfort of living. Like any technology, they have their own set of advantages and disadvantages.

pros

- Energy independence. The boiler does not require a connection to electrical networks; it will work all the time as long as there is gas in the pipe.

- Simplicity. Pipe, burner, tank. Operation is possible by unqualified personnel, which reduces its cost.

- Optimal efficiency - at higher values, condensate will flow through the pipe, at lower values, heating costs will increase.

- Relatively small in size.

- Acceptable price.

Minuses

- Outdated design.

- Condensation of moisture from the atmospheric air on the bottom mirror of the boiler and a leak, which can extinguish the burner. The effect is observed until the coolant reaches a temperature of 25-30 0 C.

- To completely interrupt the gas supply, the thermocouple must cool down. This takes up to a minute, which can be fatal in an accident.

- Ergonomics are not very good - pipelines and controls are open. It is difficult to coordinate the boiler with the interior design.

- To ignite the burner, you need to handle an open flame, which in itself is dangerous.

Gas path of the boiler

The boiler design includes a fan that forces combustion air into the boiler furnace forcibly. The pressure created is sufficient for the combustion products to be forced through the heat exchanger, leaving through the chimney. This is a closed type of firebox. Here the volume of air is as close as possible to the ideal volume, due to this the amount of heat going into the flue is minimal.

Some boilers involve creating the draft necessary for combustion using a chimney. This is a type of boiler with open fireboxes; it makes the design somewhat cheaper. But when there is no fan in the boiler, the efficiency indicator decreases, and the requirements for the pipe increase. For example, for boilers with a fan, the chimney can be routed vertically through the wall, but for a boiler with an open firebox this is not possible.

What are the requirements for installing a gas boiler, see here.

Floor-standing boiler OAGV (Lux non-volatile)

By using the energy of the gases escaping through the coaxial chimney, it is possible to supply already heated air into the boiler. If the air temperature in the combustion furnace is increased, this is beneficial for the process itself: ignition improves, the torch burns evenly, without prolonging the combustion, this ensures better heat removal.

In reality, the increase in temperature for this reason is not too noticeable if cold air comes from the street. But overall efficiency indicators increase, since savings are achieved by heating the air that enters the house ─ the boiler sucks air from the room and exhausts it through the chimney.

Nuances of choice

The main criterion when choosing a boiler is its power. And the differences in the level of technical equipment are secondary and insignificant. If the model index contains numbers indicating the volume of the water tank, as is the case with the AGV-80 and 120 boilers, then divide them by two and get the optimal value for the area of the heated room. Power values expressed in kilowatts must be multiplied by five. A double reserve guarantees that the premises will be comfortable even at extremely low temperatures “outside”, and will also allow you to compensate for heat loss if the house is dilapidated or has design flaws.

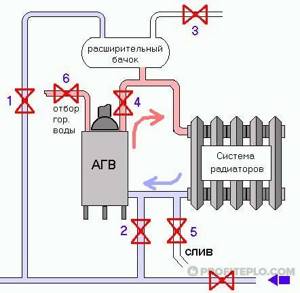

AGV heating scheme

AGV heating based on boilers from the Zhukovsky Mechanical Plant can be installed in any locality if it has a reliable supply of mains or liquefied gas. The simplicity of the design and independence from the quality of the power supply make their operation completely safe and relatively inexpensive.

What is the peculiarity of AGV gas boilers in the heating system, see in the video:

Autonomous heating systems are increasingly being installed in high-rise buildings, as residents remain dissatisfied with the quality of the centralized service. You have to pay a lot for heat, and the actual temperature inside residential premises is very rarely at a comfortable level. AGV gas boilers were one of the first heaters to become widespread as individual systems.

They were the only water heaters available to Soviet citizens. The technical characteristics of the devices left much to be desired, but there were simply no other alternatives, so people bought the units without any questions. In a planned economy, there was no competition at all, so there was nowhere to find equipment of higher quality and better equipped in terms of functionality.

Types of heat exchangers

The main heat exchanger of the boiler can be made of different materials:

- A stainless steel heat exchanger is used in wall-mounted boilers.

- The steel heat exchanger is designed for economy class boilers.

- A cast iron heat exchanger is used in floor-standing boilers.

- The steel heat exchanger belongs to the low price segment, but its performance characteristics are appropriate. Heat exchanger made of stainless steel or cast iron occupy equal positions. Moreover, the latter option has good heat capacity, and the first has a more advanced design and manufacturability, which determines their floor or wall location.

Features of operation

The boiler was produced, naturally, at factories in the USSR, made from domestic raw materials and equipped with locally produced electronics. The quality of workmanship was at a high level, but the automation failed in the vast majority of cases already in the first heating season. But the equipment worked perfectly without it, so no one paid attention to such a defect.

But the boiler was reliable and durable in all other respects. The level of gas consumption was indeed incredibly low, although the efficiency barely reached 70%, which is an extremely low figure for gas installations. But still, for private houses this was the only way to heat a home using a modern unit, and not an old wood- or coal-burning stove. And in multi-storey buildings, such a boiler made it possible to improve living conditions, since residents could regulate the temperature of the interior themselves.

The factory glass thermometer also quickly failed and had to be replaced with a higher quality product. But for repairs it was possible to use parts from any other equipment. The main thing is that the size and shape are suitable, and craftsmen can figure out how to fit them in place without any problems. In general, the model had an incredible number of user modifications.

Strapping scheme

What the harness should provide:

- Coolant pressure stability.

- Removing air from the coolant. If an air lock forms, liquid will not pass through it. You need to know how to tie the system correctly. Air vents must be installed.

- Cleaning the coolant from contaminants that impair functioning. The solution is to install filters.

- To compensate for expansion of the coolant due to heating, you need to install an expansion tank.

In the simplest piping scheme - with one circuit - a check valve with a ball valve is installed on the supply side. The pump is installed on return or discharge pipes, since it is necessary to force the liquid to circulate through the system. A strainer is connected in front of the pump. A filter is also needed at the coolant inlet to the boiler. An expansion tank with a membrane is placed nearby to relieve excess pressure resulting from expansion of the coolant.

The latter, circulating, enters the radiators. There is a second piping option, more relevant, when the coolant passes through a manifold that distributes liquid along the circuits. The presence of a safety valve is mandatory: if the coolant boils, the expansion tank may not withstand high pressure. The valve protects against possible risks:

- pipe ruptures and leaks;

- rupture of fittings;

- apparatus explosion.

Model overview

The AGV 120 gas boiler model differed only in its greater power. It had all the shortcomings of the basic device, so it cannot be called next-generation technology. Not the most successful internal design led to a situation where part of the received thermal energy flew out into the chimney along with combustion products. It was possible to eliminate this defect independently by changing the firebox design, but such a modification was associated with a certain risk. If the calculation was incorrect, it was possible to achieve an effect where the exhaust gases stopped being released into the atmosphere and remained directly in the room. In this case, the whole procedure had to be carried out again.

The AGV 23 gas boiler was a more successful modification. It did indeed eliminate some of the shortcomings, making it more ergonomic and easy to use. Among the main improvements it is necessary to note:

- — lower noise level during operation;

- — improved automation, which has become more functional and reliable;

- — by changing the principle of chimney installation, it was possible to slightly increase the level of efficiency and the overall operational efficiency of the unit;

- — the burner received protection from condensation, which in previous models could easily extinguish the flame.

In general, AGV gas heating boilers were a very successful invention for their time. They allowed people to switch from solid fuel systems to more modern and convenient gas analogues. This was an important step towards the complete abandonment of environmentally harmful heaters. Now solid fuel models in everyday situations are used only in extreme cases. Most users switched to gas or electric systems.

The price of AGV gas boilers is negotiable. They have been discontinued for a long time, so you can only make a purchase on the secondary market.

Parapet

In addition to floor models, the manufacturer offers parapet versions for heating chimneyless housing. May vary in shape, size and design of the case. Installation is possible anywhere - on the floor or on the wall. Closed firebox. The burners are installed in different ways: single-level, two-level or modulating.

Heat exchanger materials: cast iron, copper, steel. In Taiga they are made of steel. Gases are removed through a coaxial chimney. Any ignition - piezo or electronic. Sensors and controllers ensure uninterrupted and safe operation. Termotechnik produces 3 parapet series with a power of 7–16 kW:

All modifications have an ergonomic and stylish design, high technical characteristics. Heat exchangers are treated with anti-corrosion powder coating. The powder contains no toxic or flammable substances.

Features of parapet models

They are used for heating and for heating hot water. Power is 15–45 kW. A parapet heating boiler is a chimneyless, energy-independent device, used primarily for heating households and apartments that do not have traditional chimneys. The main difference between any parapet model is the closed firebox. The latter is isolated, so during operation the air of the room where the equipment is located is not used.

"Termotekhnik" produces parapet modifications "Taiga Zh7-KS". They are installed in buildings without vertical chimneys, including apartments. To remove combustion products, a coaxial chimney with forced draft is installed, and an electric fan operates.

Zh7-KS-GS-7.0 S

Parapet type. Small power, designed for only 50 m². No chimney needed. It has a large work resource. Quiet and economical. One circuit is for heating only. Options:

- Area - 50 m².

- Thermal power - 5 kW.

- The operating principle is classic.

- Fuel - natural/liquefied gas.

- Efficiency - 90%.

- Dimensions (HxWxD) - 820x540x390 mm.

- Price - 15,000 rubles.

- Weight - 45 kg.

Reviews

Zh7-KS-GS-7.0 S: Roman G., Shakhunya

The main advantages are low cost and compactness. The disadvantage is that it sometimes goes out and does not flare up the first time. After listening to the advice, we bought a Taiga and described the boiler as reliable. In fact, it turned out that there were a lot of problems. The most unpleasant thing is to light it. It happens that you light the wick several times until the burner lights up. The wick goes out on its own. Dissatisfied with the choice.

KS-G-12.5 DS: Victoria E., Bryansk

We have long wanted to replace the old-style boiler with a more manageable and economical one. We chose the floor option. We have a boiler, so we installed a single-circuit boiler. I was attracted by the cost and simplicity of the design. It does not have super functions, like its European counterparts, but it works properly. There were no problems during the season. A powerful device capable of heating our large house in the most severe frosts.

Gas heaters "Taiga" are an advantageous offer in the segment of parapet-type devices. They combine an affordable price with high performance characteristics. This inexpensive and unpretentious device operates smoothly in the harshest climatic conditions. All lines of equipment from Termotechnik are reliable, energy efficient and are in deserved demand among domestic consumers.

Is it a condensing boiler or a regular boiler?

Conventional boilers have a favorable price, but unfavorable energy consumption, a tenth of which flies down the chimney. Condensing systems prevent it from doing this by cooling the gases and steam and using this so-called latent heat.

As a result, it is by this tenth that condensing boilers are more useful than conventional boilers, and the same indicator is present in fuel economy. True, you have to pay for this with a higher price for such equipment.

It makes sense to think about it - economical fuel consumption will allow you to make up the difference in price when purchasing a condensing boiler over a period of time.