Most autonomous heating systems in private houses or other premises are based on the use of gas boilers.

This is the best option for a source of thermal energy, capable of working independently and not requiring too much attention from the owner.

Most often, imported units are used to ensure stable and reliable operation of the heating system.

However, imported boilers have very serious disadvantages due to the manufacturers’ conceptual approach to the capabilities and specifics of the equipment.

Let's consider gas boilers from one of the domestic companies, which demonstrate a different approach to the operational capabilities of heating units.

Gas boilers from Conord

The Conord plant is located in Rostov-on-Don. It was founded in 1947, and since then has produced various types of heating equipment.

During its work, considerable technological experience was accumulated, the features and disadvantages of imported models of gas boilers were analyzed, and the necessary conclusions were drawn . Today Conord produces several series of gas boilers, which are the optimal solution for the Russian user.

Climatic features, the state of communications, and the possibility of interruptions in the supply of certain resources are taken into account.

The company relied on the production of units that were as independent as possible from external conditions, capable of performing assigned tasks despite the situation.

Non-volatile equipment in Russian conditions is a big plus; it guarantees the preservation of heating during a sudden power outage . This approach is reasonable and highly appreciated by specialists and ordinary users.

All Conord gas boilers have a floor-standing design. This feature allowed the manufacturer not to skimp too much on the dimensions and strength of components and parts.

There are different model lines:

- Single-circuit. Intended only for powering the heating system of the house.

- Dual-circuit. Capable of heating both coolant for heating and hot water for domestic needs (DHW systems).

Various types of automation are used in the design of boilers:

- Thermohydraulic (mechanical type).

- Automation SIT. Automatic operating mode control unit made in Italy. It has a thermostat, a piezo ignition system, an ignition burner with an electrode and a thermocouple.

There are also models with different types of heat exchanger:

Basic faults

The design of Conord boilers is very simple and does not have many details. This can significantly reduce the number of weak points in the design and reduce the number of malfunctions.

The heat exchanger and ignition equipment are usually considered to be the most loaded and most likely to fail. The heat exchanger is susceptible to lime deposits. The additional layer isolates the coolant from the walls, reducing heating efficiency.

It is necessary to increase the combustion mode, which increases the load on the external part of the heat exchanger, which fails faster. The ignition equipment fails due to thermocouple failure or other reasons.

There is also a constant danger of burner nozzles becoming clogged with soot, which can be eliminated by periodically cleaning the boiler.

Series and model range

First of all, you should understand the markings of Conord boilers.

It is an abbreviation in which the first letters indicate the heat exchanger material:

- KSC is a steel boiler with a cylindrical heat exchanger.

- KCH - cast iron boiler.

The following letters indicate the feature set:

- G - single-circuit (gas).

- GW - double-circuit (gas with the possibility of hot water supply).

Then follow the numbers indicating the boiler power in kilowatts and the letter indicating the type of automation:

- N - thermohydraulic.

- S - Italian automatic SIT.

For example, a boiler marked KSts-GV-10N means a steel boiler with a cylindrical heat exchanger, double-circuit, 10 kW power with thermo-hydraulic automatic control.

Conord boilers are produced in the following series:

- KSC-G-S . A series of single-circuit units with Italian automatic equipment. They have a piezo ignition system, an additional ignition burner, and a special thermocouple is used for ignition. Designed for heating rooms from 80 to 500 m2, you just need to select a unit of appropriate power. The model range consists of units of 8, 10, 12, 16, 20, 25, 30, 40 and 50 kW.

- KSC-G-N . Single-circuit models with mechanical automation. A special feature of the series is the ability to work in systems with high pressure - up to 5 bar. The power of the models is 10, 12, 20, 25 and 30 kW, which allows you to heat rooms from 100 to 300 m2.

- KSts-GV-S . Double-circuit gas boilers with Italian automatic operating mode control. The power of the models is 8, 10, 12, 16, 20, 25 and 30 kW. This allows you to successfully operate the equipment in rooms from 80 to 300 m2. They have the ability to provide a home not only with heat, but also with hot water, which significantly increases their value for the user and allows them to solve two problems at once.

- KSts-GV-N . Double-circuit boilers with a capacity of 12, 20, 25 and 30 kW. They have a thermo-hydraulic type of automation. They provide heating and hot water supply, designed for use in rooms from 120 to 300 m2.

- KCH-G-S . Single-circuit boilers with a cast iron heat exchanger and Italian SIT automation. Three models are available with outputs of 16, 25 and 30 kW. These units are the most expensive, highly efficient and reliable. They weigh twice as much as steel boilers of the same power.

Second group with a steel heat exchanger:

The Conord boiler with the design of a steel cylindrical heat exchanger made of cold-rolled metal is offered by the plant in single- and double-circuit versions. The service life is reduced compared to cast iron to 15 years. The designs use two automation options.

The first option: SIT automation from an Italian company known for its quality throughout the world. It is installed in the vast majority of all manufactured boilers in the European Union, such famous devices as: IMMERGAS, Fondital, Vaillant, Bosch and many others. The SIT valve allows you to guarantee a stable set temperature.

In addition, automation controls stable operation with a reduced gas pressure in the city pipeline. So the nominal value provides for operation with a pressure of 1.3 kPa, but a drop to 0.6 kPa is not a big problem and the Conord gas boiler continues to operate steadily, despite the fact that this is 46% less than required.

Single-circuit, with automatic SIT – heating only:

KSts-G-8S Heating capacity =8 kW KSts-G-10S Heating capacity =10 kW KSts-G-12S Heating capacity =12 kW KSts-G-16S Heating capacity =16 kW KSts-G-20S Heating capacity =20 kW KSts-G-25S Heating capacity =26 kW KSts-G-30S Heating capacity =30 kW KSts-G-40S Heating capacity =40 kW KSts-G-50S Heating capacity =50 kW

Single-circuit, with thermohydraulic automation

The second option is more budget-friendly, equipped with domestically developed AGU-T-M automatic equipment. AGU is an automatic gas burner device, consisting of nozzles and safety automation. The main manufacturers are Mimax and Tagonrog. ASU automation consists of:

- temperature sensor;

- igniter with thermo-bimetallic plate;

- adjusting screw with lever;

- gas valve;

- block crane;

- connecting parts.

Ignition order:

- We check the draft, move the damper, light the igniter.

- Press the gas valve and light the wick. We fix and do not release the button until the bimetallic plate heats up.

- While continuing to hold the button, follow the lever. It will creep onto the inscription “on the button”, we need to wait for the moment when it is fixed.

- Release the gas valve and set the required temperature using the control knob.

Domestic automation makes it possible to buy a Conord boiler a little cheaper. In contrast to European analogues, it has the simplest design. It is non-volatile - no power supply is required. The starting process is carried out manually by igniting with matches or a lighter. By the way, thermo-hydraulic automation type AGU-T-M is widely used in Russian gas boilers

According to customer reviews, such automation is completely unpretentious, and the Conord floor-standing boiler equipped with it is not “capricious.” In addition, it is not difficult to find spare parts on the market even far from city centers. The prices are also not satisfactory, for example, one of the frequently requested parts - a bimetallic plate - is found everywhere for no more than 100 rubles.

KSts-G-10N Heating capacity =10 kW KSts-G-12N Heating capacity =12 kW KSts-G-20N Heating capacity =20 kW KSts-G-25N Heating capacity =25 kW KSts-G-30N Heating capacity =30 kW

Double-circuit with DHW and SIT automatic control system

The Conord floor-standing gas boiler, when equipped with two circuits, copes with the task of heating buildings and at the same time is capable of preparing hot water used for household needs. The design uses the proven modulation function. Burner operation using modulation significantly increases the efficiency of hot water supply.

KSts-GV-8S Heating capacity =8 kW KSts-GV-10S Heating capacity =10 kW KSts-GV-12S Heating capacity =12 kW KSts-GV-16S Heating capacity =16 kW KSts-GV-20S Heating capacity =20 kW KSts-GV-25S Heating capacity =25 kW KSts-GV-30S Heating capacity =30 kW

Double-circuit with DHW, with thermo-hydraulic automation

KSts-GV-12N Heating capacity =12 kW KSts-GV-20N Heating capacity =20 kW KSts-GV-25N Heating capacity =25 kW KSts-GV-30N Heating capacity =30 kW

Boiler Conord decoding

- K – boiler

- C – steel material for the heat exchanger

- C – cast iron, heat exchanger material

- G – gas

- B – DHW circuit

- C – cylindrical.

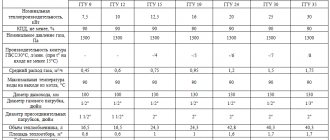

Specifications

Let's look at the technical characteristics of Conord gas boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Feature Set | Heating and hot water supply |

| Efficiency | 90 % |

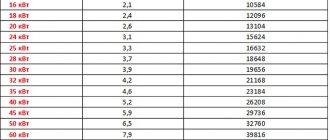

| Unit power range | 8-50 kW |

| Combustion chamber design | Open (atmospheric type) |

| Fuel type | Natural gas |

| Heat exchanger material | Stainless steel 3 mm, cast iron |

| Energy consumption | Absent |

| Service life declared by the manufacturer | At least 15 years |

| Guarantee period | 3 years |

Types

The Danko range of gas boilers includes 22 modifications, differing in design and functionality. The units are available in single- and double-circuit versions. Single-circuit AOGV models are designed for heating and do not have the function of heating water for a hot water supply system. More powerful dual-circuit appliances provide the consumer not only with heating, but also with hot water. In such devices there are two circuits independent from each other, in each of which the desired temperature is set.

Danko boilers are equipped with two types of combustion chambers: open and closed. In the first, the air required to maintain combustion is taken from the room in which the boiler is installed. While in closed-type chambers the flow of oxygen is carried out through a coaxial chimney pipe, through which exhaust gases are removed. Closed cells are safer. They do not burn oxygen in the home and make the gas combustion process completely isolated from the room.

Based on the installation method, models are classified into three types.

- Mounted options are considered the lowest power, the power of which can be 8, 10, 12 and 15 kW. The devices are equipped with both copper and steel heat exchangers, have single- and double-circuit designs and are capable of heating a room of up to 210 square meters. The advantage of wall-mounted units is their light weight, small dimensions, electric ignition system and protection against freezing of the coolant. In addition, some models are equipped with a self-diagnosis function, which allows you to quickly and accurately determine the malfunction and repair the breakdown. The average consumption of wall-mounted units is 2.5 cubic meters of gas per hour, and the membrane tank can hold up to 6 liters.

- Floor-standing units with an open-type combustion chamber are distinguished by greater power, which for serious boilers reaches from 20 to 24 kW. The models are equipped with pumps that support forced circulation of the coolant, a steel or cast iron heat exchanger, and a control system that allows you to regulate draft and flame levels, as well as the moment of water boiling. All floor-standing units are equipped with a gas shut-off system in case of insufficient draft or flame extinction, have a wide range of models and are capable of heating a room of up to 360 square meters. The most powerful models with a cast iron heat exchanger are capable of developing power up to 50 kW.

Advantages and disadvantages

The advantages of Conord gas boilers include:

- High quality assembly and manufacturing of components and parts.

- Boiler efficiency exceeds 90%.

- The non-volatile design allows the units to be used in any room or area.

- The service life of boilers is at least 15 years.

- Capable of operating at low gas pressure.

- The manufacturer's warranty on Conord boilers is 3 years.

- The price of the units is noticeably lower than that of other manufacturers.

The disadvantages of the units should be considered:

- The dimensions of the boilers are quite large and require a certain amount of space for installation and maintenance.

- The use of natural draft places increased demands on the design of the chimney and the creation of conditions for high-quality smoke removal.

Device (automation)

The main element is the gas burner. It heats the heat exchanger in which the coolant is located.

It is supplied by gravity or under the action of a circulation pump (purchased separately and connected as an external component of the system) into the heating circuit.

For double-circuit models, a coil is installed around the smoke pipe to heat the hot water of the DHW circuit.

Smoke is exhausted naturally, using the chimney draft, to which the boiler should be connected during installation.

The installation of the heating system must be carried out taking into account the placement levels of radiators that ensure natural circulation of the coolant.

If this is not possible, you have to use a circulation pump, which stabilizes the liquid movement mode, but makes the boiler energy-dependent.

Briefly about the operating instructions and setup

The operation of Conord gas boilers is not particularly difficult, since the units have a durable and reliable design and are resistant to loads and external influences.

However, to improve working conditions, several simple procedures should be performed:

- Install a strainer in the gas line to prevent fine metal dust and scale from entering the burner.

- Use water softeners or filters. This is especially important for residents of regions with hard water.

- On the return line of the heating system, it is necessary to install a filter that retains scale, slag and other debris that is present in the system. This will protect the heat exchanger from clogging and increase the service life of the boiler.

Compliance with these simple requirements will save the user from having to clean and repair the boiler once again.

Setting up the unit is not difficult - all communications are connected, the strength and tightness of the connections are checked.

Then the operating mode is set and the burner is ignited using a piezo ignition system or a regular match.

Review of manufacturers

Gas services, as well as experts in this field, recommend using boilers from the company.

The units are presented in several versions and differ in functional features. Boilers are produced only of floor type. The main difference from other analogues is the affordable price and the lack of electricity required for operation.

Keber boilers are also popular; they are equipped with an automatic safety and regulation system, which ensures precise gas supply and temperature stabilization.

Gas boilers of the AOGV series are quite in demand and are used to heat rooms that have a water heating system with natural or artificial circulation.

(Termotechnik) presents a large selection of boilers and offers floor-mounted, parapet-type, gas and solid fuel units. Many years of experience ensures excellent quality and guarantees product reliability and long service life.

Eliminating problems associated with blowing out the boiler requires special care and responsibility. It is necessary to check all components of the boiler to determine and eliminate the cause of the malfunction. If the recommendations presented do not bring results, it is worth calling the gas service specialists. Remember that quickly getting rid of problems will prevent additional breakdowns and protect not only the entire system, but also the residents of the house.

Watch the video in which a specialist examines one of the most common reasons: why a gas boiler goes out in the wind, what needs to be done, what work needs to be done to improve draft in the boiler:

Gas boilers are the most economical type of heat generators, easy to install and subsequently operate, used in autonomous heating systems. However, like any engineering equipment, gas boilers can sometimes fail, and the most common type of failure is self-extinguishing burner. To understand why a gas boiler goes out or find out the cause of other problems, you need to know about the types of boilers and the principles of their operation.

How to light it? Why does it go out? Why doesn't it turn off automatically?

Not all users experience problems with ignition of Conord boilers. The usual cause is contamination of the burner nozzles, which have not been cleaned for a long time. The same reason causes the boiler to suddenly go out.

In addition, external conditions can affect the flame attenuation - drafts, insufficient or reverse draft in the chimney caused by strong gusts of wind or improper placement of the pipe.

The absence of automatic shutdown of the boiler indicates an incorrect setting of the operating mode or a failure of the automatic control unit of the unit.

How to serve

Maintenance of Conord boilers consists of maintaining the cleanliness of the body, timely removal of soot or ash from the burner and performing other necessary procedures.

Most of the work is performed by the owner of the unit, but for some activities it is necessary to invite a specialist from a warranty or service organization. This must be done annually, or as urgently necessary - in case of problems or breakdown of the boiler.

Attempts at self-repair can cause permanent failure, so you should entrust complex operations to professionals.

Any attempt to independently interfere with the boiler design will be regarded as termination of the warranty agreement at the initiative of the owner.

Owner reviews

To obtain a balanced and more complete picture of the properties and operational capabilities of Conord boilers, you should listen to the owners of these units who use them to heat their homes.

Some user reviews:

Boilers operating on natural gas are quite often used to heat private houses and cottages. There are no particular difficulties in operating such devices. It is only important to carry out the first start-up of the heating system correctly and light the gas boiler. It is best to entrust this procedure to a qualified specialist.

Many owners of private houses choose gas boilers for heating. This choice is explained by the economic benefits of using natural fuel and the ability to heat a large house using one device. A gas boiler does not require constant maintenance of the combustion process by adding fuel; during its operation, soot and soot are not formed. There are different types of boilers:

- Wall-mounted. They have compact dimensions and light weight, so they can be installed in a small room (kitchen, pantry). A heating system operating through a wall-mounted unit does not require the additional installation of a pump, expansion tank and boiler, so its installation is simple.

- Floor-standing. They are characterized by greater power than wall-mounted ones, therefore they are optimally suited for heating large areas. They are equipped with cast iron or steel heat exchangers that have a long service life and are resistant to corrosion and mechanical shock. Floor-standing units can be equipped with both atmospheric and inflatable burners. The second option allows the use of liquid fuel as a raw material.

Gas heaters are also divided into single-circuit and double-circuit. A system with two circuits not only heats the room, but also additionally provides hot water supply. Single-circuit ones do not have such an additional function; in order to have hot water in the house, the system will need to be equipped with a boiler.

Each heating boiler has a combustion chamber. Depending on the design, it can be:

- Open. It works due to natural draft, so it is only suitable for rooms with a vertical chimney. Needs effective ventilation, providing a sufficient flow of oxygen and preventing combustion products from entering the room.

- Closed. Uses forced traction in work. The presence of an electric fan and a coaxial chimney allows combustion products to be removed from the chamber. All wall-mounted gas appliances are equipped with a closed chamber.

Regardless of the type of gas installation, it is part of a single heating system, which also includes pipes, radiators, a pump, an expansion tank and filters. Before lighting a gas boiler, you need to make sure that the elements are securely connected.

The first start-up of the heating system is a crucial moment on which the serviceability of its elements, coherence and uninterrupted operation depend.

How to turn on a gas boiler, fill the radiators with coolant, bleed the air, check everything and not forget anything.

Consider the procedure and rules for putting the heating system into operation.

If the boiler is new and you do not want to lose the possibility of warranty service, you will have to invite service employees. They will make a corresponding note in the passport stating that the first launch was carried out according to all the rules.

Features of operation

Depending on the manufacturer and model, the device has a certain type of automation, which controls the entire combustion process, as well as its characteristics and, accordingly, operational features and certain rules when trying to ignite the boiler.

"Conord"

The main characteristics observed in the entire model range:

- The manufacturer produces boilers exclusively for floor-standing use, so any model from this company has a powerful casing of a fairly large size. It is protected by a layer of enamel, which prevents damage to the metal from moisture;

- since the manufacturer is domestic, the cost of its products is slightly lower than that of other brands;

- the efficiency of all boilers is on average 90%;

- the body and main structural components are made of steel sheets, the thickness of which is about 3 mm;

- Automation systems that provide control over gas combustion and operational safety require the boiler to be connected to a power supply.

The model range is quite wide, each model in it has various additional design elements. For example, there is an option for sale with warm water supply. It is equipped with automatic thermo-hydraulic type. For its operation, a constant stable connection to the network is required. The fuel supply is regulated by a thermostat: when the temperature sensor readings are required, gas access to the main burner is blocked.

For your information! High-quality automation ensures minimal deviations of the room temperature from the set one.

The productivity of the heating system is increased with a powerful burner when installed correctly. This is the only way to obtain a balanced mixture of gas and air. Good thermal insulation of the boiler, especially the chamber in which combustion occurs, also improves the quality of work. Low pressure will not interfere with the operation of this brand of unit. Thanks to all this, Conord allows you to warm up even in the most severe frosts.

Boilers of this brand also have a good multi-level security system:

- smoke exhaust sensor. It turns off the gas if there is no traction. It also does not allow the burner to be interrupted during strong gusts of wind, during which air moves in the opposite direction (“reverse draft”);

- temperature sensors. Shut off the gas when the temperature approaches the set limit;

- flame sensor. Interrupts the gas supply if there is no fire on the burner.

To know what other design and operation features there are, you need to be able to decipher the markings of a given brand. For example, KSts-GV-12 means that:

- this is a boiler (letter K);

- made of steel ©;

- cylindrical combustion chamber (letter C);

- the fuel for it is gas (this can be identified by the next letter G);

- “HW” means the presence of hot water supply;

- The numbers at the end indicate the maximum power output.

Important! The required heating power is calculated based on the amount of area. So, 1 kW of power is enough to maintain the desired temperature in a room with an area of 10 m², while the height should not be more than 2.5 m.

"Danko"

This foreign manufacturer has already gained popularity in European countries and is gradually moving to Russia. A relatively low price in combination with quality, good efficiency and aesthetics create good advertising for it. Another advantage is the production of wall-mounted and even floor-standing models that have modest dimensions. This makes Danko an indispensable assistant in small rooms (bathrooms, miniature kitchens). It will not steal precious space and will fit into almost any interior.

For Russian users there are a number of special advantages of this manufacturer over others:

- despite the fact that the units are not produced in the Russian Federation, they are perfectly suited for use with Russian pipes and batteries (even old cast iron radiators do not need to be replaced);

- the boiler will not have any problems when working with Russian gas;

- is not afraid of the harsh climate of Russia, it can be launched even in severe frosts;

- the boiler operates silently, which makes it indispensable in residential buildings with poor sound insulation;

- "Danko" can be used in systems where water circulation is not forced. That is, this boiler does not require a pump, which makes the heating system autonomous in relation to the electrical grid.

Danko heating systems have only one drawback in all models that need to be hung on the wall - horizontal chimneys are installed. They are quite vulnerable to strong wind gusts. Also, Danko wall-mounted modifications require more attention and care (especially frequent and thorough cleaning) with less power.

For your information! Due to the higher noise level, floor-mounted ones have to be installed in special rooms or corridors. But they are not so whimsical.

Rules for filling the system with water before turning on the gas boiler

In the instructions for the boiler you need to find out where exactly it is located (in the lower part of the boiler body) and what the valve for connecting to the water supply looks like. It needs to be opened slightly so that water slowly begins to flow into the system. Smooth filling reduces the amount of air in the radiators.

You can find out that there is enough water in the pipes by reading the pressure gauge. The instructions for a specific boiler model indicate its operating pressure. You need to stop starting the water when the arrow shows pressure close to the highest limit. For example, if the maximum pressure is 3 Atm., you can stop at 2.5 Atm.

Gas and water supply

Now you need to bleed the air and then pressurize the system.

Solving problems with boiler attenuation

If the flame goes out not due to malfunctions of the boiler itself, but to other external reasons, you can try to fix the problems yourself. Some models of simple boilers can even be cleaned from soot and soot yourself, but this is a topic for a separate article.

Restoring traction

You can figure out what is clogged - the boiler or the chimney - by disconnecting the corrugated pipe of the exhaust system from the boiler itself. If there is draft in the pipe, then we solve the problem with the boiler by calling a technician. Otherwise, you will have to climb on the roof and look into the pipe. If a blockage is detected, you need to remove those foreign fragments that interfere with the passage of smoke.

Cleaning the chimney is a mandatory procedure to prevent its contamination

If ice is found on the head, it must be carefully chipped off so as not to damage the chimney itself. Be sure to check the cleaning hatches. A sign that cleaning needs to be done is a large amount of soot and soot extracted from the inside of the channel.

You can still reconcile with the blowing of the channel due to strong wind if it happens once or twice during the entire heating season. But if winds are a common occurrence in your area, you should take measures:

- First, you can try to extend the pipe. The high altitude will prevent the wind from pushing the air back with force.

- Secondly, a competent configuration of the head can help out, which will cover the hole on the side from which the winds predominantly blow.

If the electricity goes out

A non-volatile boiler in conjunction with a circulation pump does not consume much. It can be adapted for DC power and switched to battery operation. But this is not suitable for powerful boilers. The only way out is to connect the boiler to an alternative source of electricity, for example, a gasoline or diesel generator.

If the gas pressure decreases

The first thing you need to do is check the gas pipeline at the place where it branches off from the main line. The joints where there are traces of welding, as well as valves and taps, are carefully checked. The specific odor imparted to natural gas at distribution stations will help detect leaks.

The only option is to write an appeal to the appropriate authorities. Contact your neighbors - they most likely have the same problem. Completing a collective petition will help speed up the decision-making process for the natural gas supplier organization in your area.

Removing air pockets before lighting a gas boiler

Air vents must be installed in the upper fitting of each radiator. These can be Mayevsky taps, or automatic valves.

The automation will handle everything itself, you just need to give it a little time (the fact that the air has escaped will be indicated by a drop in pressure).

To bleed air using a Mayevsky crane, you need to prepare a bucket, a rag, and a special key from the installation kit (or a screwdriver and pliers).

A container is placed on each radiator one by one, the tap is unscrewed, and the air hisses out. Then the battery will begin to “spit” air mixed with water. You can close the air vent when a trickle of water flows from it.

Approximately 5-7 minutes for each radiator - and the first air pockets are removed. The pressure gauge readings are checked (they should drop) and the water tap is turned on again. It would be good to repeat the air release procedure again.

Ultimately, the pressure should be above average, but not maximum, because when the water heats up, the pressure will increase further.

Pressure testing and washing

Pressure testing is not always done due to the lack of a special pump and the reluctance to call a team, but if the heating fails in the midst of cold weather, the costs can be much higher!

It is especially important to check a new system and one that, on the contrary, has been in use for several years.

The cost of crimping in construction companies is from 3,000 rubles. Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles.

Turning on the boiler

- The gas boiler is plugged into an outlet.

- The switch must be set to zero.

- The gas supply is turned on (the tap on the gas pipe is opened).

Further actions may differ for different models of gas boilers.

For example, the switch for Aton or Danko boilers needs to be set to the “star” icon, press the entire switch and hold it for 5-10 seconds.

Then, without releasing the switch, press the button located nearby.

The unit will respond with a characteristic click and hum. After which the regulator is released and the required power is set.

To turn on the Baxi boiler, you also need to turn on the gas, plug in the plug and press the “Start” button. The operating sound will appear. You need to give the device a little time, and it will automatically ignite the flame. After that, you need to press the power button again and connect the heating circuit (the corresponding icon will appear on the display). Finally, using the buttons, the desired temperature is set.

Heating appliances of the Buderus brand are characterized by high reliability. Buderus gas boiler - a brief overview of popular models and their cost.

We will look at the types of generators for gas boilers here.

To organize a full-fledged heating system in a private house, it is necessary to install a boiler. The article https://microklimat.pro/otopitelnoe-oborudovanie/kotly/kak-vybrat-dlya-chastnogo-doma.html discusses the main criteria for choosing heating equipment.

Circulation pump

Air often accumulates in it, and its blades sometimes seem to get stuck (the boiler will display a corresponding error).

It is recommended to rotate the shaft manually before starting.

To do this, you need to remove the front panel of the housing, unscrew the central bolt on the pump and use a straight-bladed screwdriver to turn the shaft in the direction indicated by the arrow.

An air vent is installed above the pump. You need to pull the bright lid up and let the air escape.

Floor-standing boilers are usually more powerful than wall-mounted ones. If you need to heat a large room, it is better to choose this option. Floor-mounted gas boilers for home heating – overview of design options and models.

Read about the installation features of combined heating boilers in the following material.

Conclusion

At first, the system may make gurgling sounds, all because during startup it is impossible to bleed air down to the last atom. It will gradually be removed through the expansion tank valve. Periodically check the pressure on the pressure gauge - it should be within the operating range. Temperature adjustment and other boiler settings are described in the instructions for each model.