Self-diagnosis system

The purpose of automatic self-diagnosis and protection systems is to detect and correct various breakdowns at the moment they occur. After fixing any kind of defects, the equipment stops, with a breakdown code displayed on indicators or LCD screens. Finding problems in equipment that is not equipped with self-diagnosis is much more difficult, although the procedure for checking the internal filling does not change. Self-diagnosis allows you to quickly identify and find faults in the Navien boiler.

During the search process, the system sends requests to numerous sensors and nodes: all received results are analyzed and stored. If serious breakdowns are detected, a report about them is instantly transmitted to the indicator board. Initially, such systems were developed for gas workers, since they make it much easier to troubleshoot a Navien gas boiler and fix them. However, if you have minimal skills in servicing boiler equipment, you can repair Navien appliances on your own. Before you begin self-repair, you need to check whether the warranty period has expired. If the warranty is still valid, it is better to send the boiler to a service center for a free repair.

Rules of operation and timely maintenance

Experts recommend that Navien boiler owners, on the eve of operation, get acquainted not only with the device and technological parameters, but also with the matrix of self-diagnosis system codes, which the manufacturer must provide in the technical documentation.

Tips and recommendations for servicing Navien boilers:

The tuning algorithm for the thermal performance of the boiler directly depends on the burner model. Installations with digital control according to a set thermal regime include a thermostat operating in a unit with a room temperature sensor. The setting is automatic and the thermometer monitors the indoor temperature

After some time, when it drops below a certain limit, the thermostat sends a signal to turn on the burner or, using a control valve, increases the gas fuel consumption. As a rule, a thermostat controls the temperature in one room, but if shut-off and control devices are installed in front of each radiator, the temperature can be controlled in all rooms. The burner device can be adjusted by turning the gas valve, which is especially important for atmospheric devices with open combustion chambers. The mode is changed in the menu on the control panel.

Algorithm for setting the operating mode of the boiler unit through the service menu:

- Open the valves on heating appliances.

- Set the desired value on the heating thermostat in the room.

- The burner will stop when the temperature rises by 5 C above the set mode.

- Press "Mode" on the LCD display. When “0” appears on the screen, enter the number “35” using the “+” and “-“ keys.

- When presented on the screen “d. 0", dial the line number using "+" and "-". The setting will be automatically negotiated.

- Return to the service menu using “Mode”.

- They control the flame in the combustion chamber and the temperature rise.

In this case, the radiators do not have time to heat up, and the functional components of the boiler quickly fail. In addition, in this mode there is an overconsumption of gas, which reduces the energy efficiency of the boiler and the overall efficiency of the heating system.

Cyclicity is suppressed in 2 ways:

- Reduce the torch of the burner device.

- They increase the load in the heating system by including an additional load in the form of installing radiators or an external tank for indirect heating of hot water supply.

Boiler manufacturer Navien studied all possible variations of unit failure and issued factory instructions for the repair and adjustment of equipment. A modern diagnostic system can independently identify errors in the operation of the device and offer the user ways to eliminate the problem.

The system is individual and depends on the unit model and installation option - wall-mounted or floor-mounted, as well as on the modification of the control unit.

It is a proven, faithful assistant even for an inexperienced user with little knowledge of technology. It is thanks to error diagnostic programs that today it is possible to quickly overcome an emergency situation and restore the temperature regime in the house.

What malfunctions occur

To repair the Navien heating boiler yourself, you need to read the special manual. It will help not only decipher the type of breakdown, but also eliminate it in the most effective way.

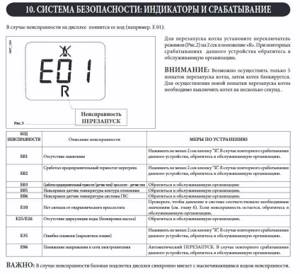

List of problem codes with the Navien boiler and their interpretation:

- 01E. The device overheated, and this was recorded by the temperature sensor.

- 02E. Indication of an open circuit in the flow sensor and a drop in the coolant level in the circuit.

- 03E. The signal confirming the presence of a flame has disappeared. In this case, the combustion can continue.

- 04E. This code has the complete opposite meaning of the previous designation: in this case, there is confirmation of the flame, although in fact it is absent. E

- 05E. Failure of the circuit responsible for controlling the degree of heating of the coolant in the heating system.

- 06E. This code also indicates a malfunction of the temperature sensor (the circuit is closed).

- 07E. Signal about failure of the temperature sensor in the DHW circuit.

- 08E. Malfunction of the Navien gas boiler in the same unit due to a short circuit.

- 09E. Alert about fan failure.

- 10E. The appearance of malfunctions in the smoke removal system.

- 12E. Flame extinguishment in the burner.

- 13E. The heating circuit flow sensor has shorted.

- 14E. Gas has stopped flowing from the main line, which is why the Navien boiler does not turn on.

- 15E. A general indication of errors in the operation of the control board, without specifying the problematic element.

- 16E. The equipment has overheated.

- 18E. Malfunctions in the operation of the smoke exhaust sensor.

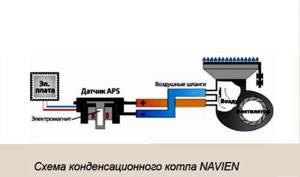

- 27E. Air pressure sensor (APS) malfunctions.

The manufacturer itself does not provide any instructions for repairing the Navien gas boiler. The calculation is made that repair activities are the responsibility of service centers exclusively. In our country, people’s thinking is somewhat different, so many of them are accustomed to troubleshooting household appliances on their own.

IF THE NAVIEN BOILER PUMP DOES NOT WORK: CHECKING AND REPLACING THE NAVIEN BOILER CIRCULATION PUMP

The circulation pump of the Navien gas boiler is responsible for circulating the coolant in the system.

If the pump in the Navien boiler is faulty, the boiler will not work either for heating or for heating hot water.

It is most likely that if the circulation pump of the Navien boiler fails, the boiler will generate an error associated with overheating of the boiler and lack of coolant circulation in the system. Although, of course, a malfunction of the boiler pump is a probable, but not the only cause of overheating of the Navien Ace boiler, and only a qualified service specialist can accurately determine the cause of the Navien gas boiler overheating error directly when diagnosing the boiler.

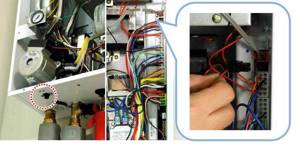

Checking the serviceability of the circulation pump of the Navien Ace, Deluxe, Atmo gas boiler: If the circulation pump of the Navien boiler has stopped rotating, check the following: - Disconnect the circulation pump plug by turning the screwdriver counterclockwise and check the condition of the circulation pump rotor to see if the pump is jammed (in certain cases conditions, the pump may “stick” - use a flat-head screwdriver to force the axis to turn.

If you suspect that the Navien pump has power problems, you need to check the following: - Using a tester, check whether the pump is receiving power. Is 220V voltage coming from the controller? -Check the pump coil for an open circuit. Measure the resistance at the coil terminals. A resistance value of less than 0.3Ω is considered normal.

-If there is no power supply to the pump, replace the controller (electronic board of the boiler).

If, as a result of the check, you find out that the pump on your Navien Ace, Deluxe, Atmo boiler does not work, then you need to replace the pump.

REPLACING THE NAVIEN BOILER PUMP:

1) Remove the drain plug connected to the pump and remove the connecting connector.

2) Remove the connecting clip from the pump.

3) Remove the nut from the heating water inlet pipe connected to the circulation pump.

4) Remove the old pump and install the new one.

Attention! In Navien brand gas boilers, you can only use the original, “native” circulation pump! Its article number is 30000469A NAPU9GLPCT36, NAPU9GLPCT16. Replacing a Navien boiler pump with a boiler pump from another manufacturer is not possible.

Also, the pump for the Navien boiler Navien Ace, Deluxe, Atmo 30000469A NAPU9GLPCT36, NAPU9GLPCT16 is supplied to the Russian Federation and is sold only assembled.

Circulation pump for boiler Navien Navien Ace, Deluxe, Atmo 30000469A NAPU9GLPCT36, NAPU9GLPCT16 You can buy from us:

Source

No need to heat

The first step is to clean the heat exchanger. At home, it is common to use citric acid, toilet bowl cleaners and special liquids (if available). Before cleaning the Navien gas boiler, you need to dismantle the heat exchanger and pour a suitable solution into it. After a short pause, it is washed out with high pressure of water.

A similar procedure should be carried out with the DHW circuit heat exchanger if problems are observed with heating hot water. In case of particularly contamination, it is easier to install a new exchanger. To prevent scale build-up, it is recommended to have a system for cleaning and softening your tap water.

Operating instructions for Navien gas boilers

This document is a mandatory appendix to the technical documentation provided by the manufacturer when registering the device in the retail chain. Operation is carried out from the control panel, the model offers many modes of use.

"Navien" mounted boiler operating instructions, structure and description of functions:

- Power (POWER) - on / off;

- combustion (COMBUSTION) displays the combustion process;

- pump (PUMP) status of the network circuit circulation pump;

- hot water (HOT WATER) - water heating temperature;

- low level (LOW LEVEL) - emergency water level in the circuit;

- overheating (OVERHEAT) – unacceptably high water temperature;

- sensor (SENSOR) – sensor malfunction;

- reset (MISFIRE) mode on the panel to factory settings.

Troubleshooting error 03

There were some obstacles in the way of the signal about the presence of flame entering the system. The cause of this malfunction of the Navien boiler may be a cessation of gas supply or a failure of the flame presence sensor in the burner. Often, problems of this type arise after repairs to a gas pipeline. Error 03 is also displayed when problems occur with ignition.

Elimination procedure:

- Checking the gas supply.

- Testing the serviceability of ignition.

- Cleaning the ionization sensor (it often gets dirty).

When using liquefied gas, you must ensure that the gearbox is in good working order. If the boiler is fully operational, the cause of error 03 may be improper grounding.

Control board errors

The control board should be considered as the cause of hot water problems when all other checks have failed. The cause may be a malfunction in the flame modulation circuit. The boiler control unit constantly adjusts the burner power depending on the conditions, and if there is a fault on the board, the boiler can spontaneously reboot or turn off when it reaches maximum power, which in most cases is required precisely in the hot water preparation mode.

It is also possible that boards may be configured incorrectly as errors. But this only applies to those cases where problems appeared after its replacement. BAXI boards are universal and require customization for a specific boiler.

Italian Baxi gas boilers occupy a strong place in the heating equipment market due to their high efficiency, stable operation even in adverse conditions and thoughtful stylish design

.

But, despite their high reliability, sometimes

malfunctions occur

in the operation of Baksi boilers caused by violation of operating conditions or failure of individual boiler elements. Most often, you can eliminate them yourself, without calling in specialists.

The Baxi line of gas boilers includes a number of models that differ in volume, type of installation, and functionality. However, the principle of their operation is generally similar.

The most popular boiler models:

- Baxi Luna (Baxi Luna);

- Baxi Slim (Baxi Slim);

- Baxi Main four (Baxi Main for);

- Baxi Main 24 fi (Baxi Main 24 fi);

- Baxi Nuvola (Baxi Nuvola);

- Baxi EKO four (Baxi Eco for, Baxi Ecofor).

By installation type

Gas boilers are divided into

wall-mounted and floor-mounted.

Wall heater is fixed

using special brackets

in any convenient place,

which makes wall-mounted models very popular. Chambers with a closed combustion chamber, for example, Baxi Main 24 fi, have increased efficiency and environmental friendliness in a small size.

Coolant volume

in the heat exchanger depends on the model, in the most powerful it

reaches 80 liters

.

In terms of functionality,

models

can be single-circuit

- for heating, or

double-circuit

- in addition to the heating system, they also supply the hot water circuit.

Work

They can use

both natural main gas and liquefied gas

from cylinders, making it possible to install them in non-gasified areas.

The boilers are completely volatile

and require connection to an alternating voltage network.

Operating principle of gas heating equipment:

- Sensors analyze the temperature in the room, and when the minimum value is reached, they send a signal to turn on the circulation pump.

- The pump turns on, creating a vacuum in the return pipe, and the heated water enters the heating system.

- The microprocessor sends a signal to ignite the burner at low power, it gradually increases, and the coolant is heated to a temperature specified by the user.

- Then the boiler operates in modulation mode - it maintains the temperature within the specified limits, turning on when it drops.

At any of these stages, a malfunction may occur, which the boiler notifies using coded errors.

Possible malfunctions of the Baxi Main for, Baxi Main 24 fi, Baxi Eco for boiler:

- the burner goes out immediately after switching on or during the heating process (error codes e01, e04);

- ignition of the boiler is impossible;

- overheating occurs (error code e02);

- The water pressure in the system drops (error code e10);

- extraneous noise is heard during operation;

- there is popping noise in the combustion chamber;

- the coolant does not heat up to the set temperature;

- One of the sensors fails (different error codes may appear).

The most common causes of certain malfunctions, according to service center specialists, may be:

- wrong

- errors when connecting the boiler to the electrical network;

- water getting into the circuit board, burner or electrical part of the boiler;

- low quality of network water or other coolant;

- sudden drop in gas pressure;

- The network voltage drops or increases unacceptably.

The resulting malfunctions can be easily eliminated by adjusting the boiler, but sometimes it is necessary to call a specialist to replace boiler parts.

Typical Navien Ice boiler breakdowns

Although the devices in this series are famous for their impeccable performance, they sometimes fail. When installing a Navien Ice boiler in your home, it is recommended to arm yourself with information about its most typical faults (there are not very many of them). For example, for the 24 K model, the most typical error is 10. The design of this double-circuit boiler uses a closed combustion chamber, which leads to periodic problems with smoke removal. Most often this happens due to fan breakdowns, which need to be replaced from time to time.

Typical malfunctions of the Navien gas boiler also include error 02: it indicates rapid heating and equally rapid cooling of the boiler. This usually occurs due to the appearance of air pockets in the circuit system or due to a breakdown of the flow sensor. All air must be bled from the heating circuit.

Eliminating common errors

Let's look at the common errors of Navien boilers and figure out how to fix them.

Error “02” - stop coolant circulation

The filters of the boiler or heating system often become clogged, this leads to the appearance of two unfortunate numbers of fault 02. It is also very likely that the cause of this error is the main heat exchanger clogged with scale. These troubles occur due to the high hardness of the water used to operate the device. The ubiquitous scale affects the most important parts of the device, stopping operation. To resume boiler operation, you must:

- Clean the filters in the boiler itself and the heating system.

- Remove the heat exchanger from the housing.

- Prepare an acid solution to destroy scale on the heat exchanger.

- Place the heat exchanger in a container with an acid solution.

- Wait for the chemistry to do its job.

After simple manipulations, if you have the necessary ingredients and knowledge, you can independently get rid of error “02” of the Navien gas boiler. Monitor the circulation sensor inside the boiler, wash the filters regularly to avoid unpleasant surprises.

Error "03" ignition problems

It says either a simple lack of gas or a broken gas valve. Let's look at the second option. Navien boilers are equipped with the most reliable Japanese gas valves; they are difficult to break when using the boiler perfectly and correctly. But if the mains voltage is ten to twenty volts higher than 220 volts, the coils inside the boiler will turn black and the valve may break completely. To fix this breakdown, you will have to buy a completely new valve and replace the broken part. Extreme care is required with the network voltage. Increased levels can harm more than one boiler.

Error “16” overheating of the main heat exchanger

Occurs when the boiler’s internal thermometer records a temperature of 95 degrees. This Navien boiler error may indicate several breakdowns of the boiler system. Again, the main heat exchanger is clogged with scale due to hard water from the centralized water supply, which causes the device to heat up to a high temperature. Or it could be an insulation problem with the main heat exchanger. The fact is that if you actively use the boiler for five years and do not provide proper care, it is likely that the gaskets, which should not release the heat of the heat exchanger, begin to blow out. Warm air blows directly onto the thermometer - an error occurs. To eliminate error “16” you need to clean the main heat exchanger in an acid solution and restore its insulation. But it is better to prevent this problem by regularly carrying out boiler maintenance; if possible, then using water that is safer for equipment.

The control board is faulty

This error, which is difficult to accurately diagnose, is designated by code 15E. It is almost impossible to understand how the control board works without special education. The most correct algorithm of action in such a situation is to invite a specialist who can use testing to determine and eliminate the causes of the problem.

The place where the Navien gas boiler is repaired is chosen by the foreman: in particularly difficult cases it is necessary to transport the boiler to a service center. To avoid problems of this type, it is strongly recommended to equip the supply networks of the Navien boiler with a voltage stabilizer.

Troubleshooting a three-way valve in a Navien wall-mounted gas boiler

If heating or hot water supply does not work in a wall-mounted gas boiler, then there is a high probability of failure of the three-way valve. All repair work on gas equipment must be carried out by specialized licensed organizations. Self-repair of a gas boiler is prohibited. If a three-way valve fails, it is recommended to call specialists to replace it. But you can repair the old three-way valve yourself and leave it as a backup.

The three-way valve serves to redirect the flow of water. When the hot water tap opens, heated water flows through it into the mixer. And when the tap is closed, the water is redirected through the heat exchanger to the heating system.

In this article, using the example of a malfunction in the three-way valve of a Navien gas boiler, we will describe possible breakdowns of the three-way valve and methods of testing for subsequent repairs. The crane costs from 3 to 5 thousand rubles, depending on the region, and spare parts for repairs are tens of times cheaper (except for the engine). Readers are given the opportunity not only to learn about the structure of this part, but also to try their hand at repairs. After all, apart from a Phillips screwdriver, a tester and a soldering iron, nothing is required. The most important thing is to be attentive, careful and observe electrical safety measures, since the motor of the three-way valve is powered by an alternating voltage of 220 V.

So, we have a non-working three-way valve of a Navien gas boiler, which was successfully replaced with a new valve by specialists.

It can be seen that the inside is completely covered with rust. This happens when an additional filter for water purification is not installed in the system, and its quality leaves much to be desired. At a minimum, the faucet will have to be disassembled and completely cleaned. But first things first.

First, unscrew the four screws on the faucet body using a regular Phillips screwdriver.

Three-way valve of the navien boiler with electric drive - remove the engine.

We disassemble the body in half. In the case we see two microswitches. We check them with a multimeter. In the normal position they are closed, but when pressed they open. The appearance, position and size of the switches may vary depending on the modification of the faucet. If one of the microswitches is faulty, replace them using a soldering iron. Sometimes, to determine if one of the switches is faulty, you may not even need a multimeter. Often the malfunction is visible visually, the button sticks in one position and does not work clearly.

Checking the microswitches of a three-way valve with an electric drive.

To check the motor, unscrew two more screws. Now the three-way valve can be completely disassembled.

Three-way valve disassembled.

Having disconnected the wires, we take out the engine to check.

Photo of a three-way valve motor.

Before testing the motor, check the resistance between the terminals. It should be about 15 kOhm. If the resistance is measured in Ohms or infinite, then replace the motor immediately as it is burnt out. This happens due to water getting inside it. If the resistance is normal, then power the engine with 220V alternating voltage.

Attention, follow safety precautions when working. There is a risk of electric shock.

If the motor spins (very slowly, 3 rpm), then it is working. If not, you can take it apart. Remove the cover by first releasing the four latches. Inside, in addition to the engine, a gearbox is assembled. If, when removing the gears, the motor does not start, then replace the motor assembly. And if it works, then carefully inspect the plastic gears; perhaps one of them is damaged.

Whenever repairing a three-way valve, it is necessary to carry out preventive cleaning of rust and replace all o-rings to be sure of its proper operation. After cleaning, the tap is assembled in the reverse order.

Navien boiler three-way valve assembly.

After reassembling the faucet, be sure to reapply power to the motor. Visually check that the rod is moving. Otherwise, repeat the entire verification procedure again.

buildip.ru

Error 01

There is no need to panic, because this code quite often indicates the appearance of ordinary air pockets in the circuit or filter. The procedure for bleeding air from a Navien boiler is carried out according to standard recommendations. Next, you need to check the functionality of the circulation pump.

It is important that it rotates and that the coolant flows well through the impeller. It happens that the reason that the Navien boiler does not start is a physical breakdown of the impeller. A more complex option is problems with the circulation pump, the elimination of which requires rewinding or complete replacement of the equipment. The most reliable model of pumping apparatus is considered to be products from the Grundfos brand.

Features of operation of Navien boilers

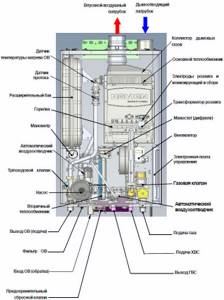

Navien - domestic double-circuit boilers with an open or closed combustion device are used for heating residential and public premises and heating water for domestic and technical purposes.

The boiler control is Russified and adapted to the real operating modes of Russian engineering systems.

The APS mechanism ensures a stable fuel combustion process with minimal consumption. The blower fan for supplying air and creating a working pressure of the gas-air mixture has different speed operating modes and allows the operator to control the rotation speed for complete combustion, preventing condensation.

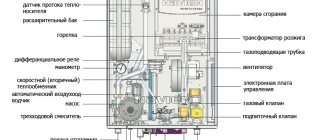

Navien boiler equipment:

- Circulation pump;

- universal heat exchangers for the heating circuit and DHW system;

- security automation;

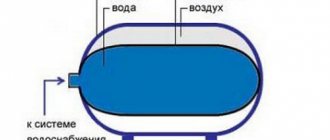

- expansion tank;

- selection of heating mode and timer to stop the unit;

- Navien boiler, installation and operating instructions.

The advantage of using a heating unit is that a burner with pre-mixing of the gas-air mixture has a modulation range of 30-100%.

Error 04

A little about fault 02 has already been said: it consists of a rapid rise in temperature and an equally rapid drop. The same applies to error 03. When the self-diagnosis system detects error 04, the functionality of the flame sensor and its power supply is checked. It is strongly recommended to avoid any contact of this assembly with surrounding metal elements. It happens that this code is displayed when the system board breaks down. In such cases, it is either repaired or replaced.

Errors 07 and 08

The purpose of double-circuit boilers is to provide homes with both heat and hot water. They consist of two circuits and a set of sensors. As a consequence, in this case there is not one temperature sensor, but two. One is designed to control the temperature of the heating circuit, and the second monitors the degree of heating of hot water. The appearance of codes 07 and 08 on the monitor indicates that the hot water in the Navien boiler does not turn on. Diagnosis and elimination occur in the same order as in the previous case.

The boiler does not heat water

This video is the solution to your problem!

Watch to the end and you won’t need to call a specialist.

It is impossible to survive without boiler houses in the climatic zones of Russia. Moreover, this also applies to the warmest regions, Sochi, Anapa and Rostov-on-Don. Winters are still harsh and people cannot survive without heating. Therefore, it will definitely not be possible to do without heating systems and hot water. And only boiler houses can provide the city with all this. Today we will look at the reasons why the boiler does not heat the water - how to solve this problem and what to do about it......

They are very different. It all depends on the heat source. It can be either steam or water. They may vary by location. If the house itself decided to build its own boiler room, then a specially separate room in the house can be allocated for it. Or extensions are made to the house for these purposes. One of the main requirements when constructing boiler houses is good ventilation.

If the boiler operates with steam, then very high demands are placed on the quality of water purification, and then steam. Therefore, it will definitely not be possible to manage such boiler houses without a whole complex of cleaning installations. This also includes AquaShield electromagnetic softeners, which are highly valued by boiler house employees today.

If a gas boiler suddenly stops heating water, the reasons may be different, but most often when using water from a central water supply without softening units, the cause may be limescale deposits. Moreover, it is hard and difficult to remove. The table shows possible signs of the reason why the boiler stops due to scale formation.

| Reason for boiler shutdown | Signs |

| High rigidity | Heating the bottom of a gas boiler, but at the same time weak heating of the water A sharp increase in electricity or solid fuel consumption White-gray coating on the bottom of the boiler The boiler does not heat the water to a certain temperature Poor pipe capacity Increased electrical conductivity of heat |

Other reasons for boiler shutdown are simpler. A piece of scale may also get stuck in the pipe and block normal operation, and a crack in the gas boiler may also contribute to the shutdown. But in these cases there will definitely be no scale residues on the walls of the equipment. If the boiler room does not have boiler water softeners or treatment facilities installed, then the root cause will of course be water hardness. If the treatment plant is standing and the equipment has been checked recently, then most likely this is not the problem.

If the video did not help you, then try installing anti-scale filters (polyphosphate or electromagnetic) in front of the boiler. Because Hard water and scale are the root cause of malfunctions and breakdowns of gas boilers!

In any case, if there is no cleaning in the system, then you will have to urgently address this cause and solve it. For boiler houses there is a whole range of water softening devices that are suitable:

- AquaShield;

- Ultrafiltration and conditioning for steam boiler houses;

- Ion exchange for economical consumers of gas boilers

The most wasteful process of cleaning and softening will be in steam boiler rooms. There you will have to remove not just all organic and inorganic impurities. Even dissolved gases will have to be removed. Degassing is quite troublesome and costly. But the operation of the boiler depends on the quality of the steam. This is where membrane softeners work to make the water completely isolated.

Many consumers of gas boilers choose AquaShield for the simple reason that it does not require maintenance and does not require spending money on it. But its biggest advantage for boiler equipment was and remains the ability to remove old lime deposits even in the most difficult places. Usually, to eliminate such residues, the equipment needs to be unscrewed, the parts need to be soaked in aggressive acidic environments and kept there for up to two hours. But even after boiler treatment of water, it is necessary to clean the surfaces with metal brushes or cleaners. If your gas boiler does not heat the water to the required temperature, then the reason is scale deposits. The electromagnet does all this work without damaging the surface, at the molecular level.

Error 09

These fault codes are the most common. They signal that the fan has reduced its efficiency or has stopped. To accurately determine the cause, the integrity of its windings and the continuity of their resistance are checked. It is also necessary to make sure that there is an interturn short circuit. If the damage is serious, it is better to change the device. If no problems were found on the fan, you should ring the control board. This procedure will require certain skills: if they are absent, it is better to seek help from specialists from the service center.

How to reset a gas boiler error?

First of all, you need to read the instructions - information on how to correctly reset the error and the reason for the error is indicated there. Some errors simply cannot be reset until the problem is fixed. Example: lack of water in the boiler. Until the pressure sensor (or pressure switch) registers the required value, the error will not go away, it is useless to reset it - you need to recharge the boiler, the automation will record this and the error will disappear on its own.

Another example: the boiler failed to ignite (E01 on BAXI, F28 on Vaillant, 501 on Ariston). The process of igniting the boiler is associated with a sequence of actions. In most cases, the order is as follows: the circulation pump starts (the presence of circulation is registered by sensors), the fan starts, the presence of draft is determined, the gas valve opens and voltage is supplied to the ignition transformer - a spark hits the burner. Relatively speaking, in the presence of air, gas and sparks, the boiler will ignite. That is, the point is that the ignition process itself consists of several operations that can be controlled visually. And in this case, the boiler automation cannot determine whether the fault has been fixed or not on its own. That is, the user must first figure it out, eliminate the cause of the malfunction, and then give the command for the next startup attempt. In this case, this is what happens using the reset button.

This is a very important point to understand: if the error belongs to a category that is reset by reset, then after the reset, another ignition attempt will MUST occur, which will be accompanied by the activation of the actuators.

The second important point to understand: errors that require a reset button are not reset by turning the boiler off/on.

This depends on the specific control unit! You need to study the instructions. Often control units remember a critical error and a power reset will do nothing! Date: September 25, 2021

Error 10

An indication that problems have arisen with the removal of combustion products. A potential cause is a broken fan. The condition of the chimney duct, which requires regular cleaning, deserves a separate check. It is very important that its length complies with regulatory standards. Quite often, the cause of error 10 lies in a malfunction of the air pressure sensor. The most undesirable situation is regular malfunctions of the Navien boiler board. You need to check the most harmless option, when the wind simply gets into the chimney. Naturally, you need to know what to do if the boiler blows out in a strong wind, and how to get rid of this problem.

Error 16

This code indicates that the heating equipment has overheated: in such cases, the Navien boiler hums when hot water is turned on.

Potentially possible reasons:

- Exceeding the coolant heating norm.

- Lack of fluid in the circuit.

- The control board has malfunctioned.

- The three-way valve is acting up.

- The DHW temperature sensor has failed.

- The gas supply rate has been exceeded. This reason why the Navien boiler is humming is quite rare. Its elimination is carried out by simply screwing on the valve.

The most common malfunctions and troubleshooting of boiler operation

Despite its functionality and electronics, there are certain disadvantages and malfunctions that can be encountered when operating the Navien Ace boiler.

Most often, users encounter a problem when the unit stops working and the electronics signal a critical error. This situation can be caused by various factors, including the sensitivity of the sensors. The most common mistakes:

Smoke removal. Fault code “10” indicates problems with the removal of combustion products. Possible reasons: turbine malfunction, pressure sensor tubes are connected incorrectly, chimney is clogged, pipe is too long.

If none of this reason is identified, and the Navien Ace boiler continues to signal an error, then the cause may be ordinary gusts of wind. This problem can be solved by redoing the chimney. As a quick response option, you can open the boiler body and disconnect the air supply hose. However, this measure is temporary. For common errors on the Navien gas boiler, see this video:

Important! The manufacturer recommends installing boilers with a chimney outlet on the leeward side

- Flame sensor failure. Fault code “03” may indicate poor gas quality. The problem can only be solved by elimination. First of all, the cleanliness of the gas supply nozzles is checked. If they are in order, you need to select the optimal position of the controller electrode (it should be in the hot phase of the flame).

- Equipment overheating. Fault code "01". A possible cause is a clogged heating system, a malfunction of the circulation pump or a decrease in flow. Ways to solve the problem: check the system and filter for the presence of air, check the serviceability of the pump and the coil resistance for short circuits, check the impeller in the circulation pump.

- The Navien gas boiler is working, there is heating, but no hot water. Error code "02". The remote control shows a jump in the water temperature (sharply increases to a maximum and immediately drops). There may be a blockage in the hot water system. Reasons may include: lack of pressure in the water supply system, airiness of the system, the circulation pump cannot gain momentum, the distribution valve is closed, or the flow controller does not work. To eliminate this malfunction, you first need to adjust the pressure, bleed the air in the system, check the resistance of the pump coil and impeller for damage, open the boiler distribution valve, disassemble the regulator body and clean the flag.

In addition, when turning on hot water, the Navien boiler may hum or make an incomprehensible noise. In this case, there is no error information on the display and the pressure is normal. As a rule, this is due to a clogged heat exchanger. To fix the problem, you can clean the heat exchanger or replace it.

Did you know?

It is best to choose boilers that are equipped with smooth adjustment - this will allow you to change the performance depending on the air temperature.

Navien Ace gas boilers are distinguished by high quality indicators and operational reliability. However, the duration and features of operation depend on how correctly you were able to install and configure the Navien Ace boiler, as well as on the quality of the fuel used.