If smoke comes into the room from a gas boiler

A wall-mounted or floor-standing boiler and AOGV can smoke for two main reasons: a malfunction of the chimney or poor gas quality.

First of all, it is necessary to inspect the chimney and carry out the following work:

- The presence of traction is checked. This can be done either with a special measuring device, or by holding a lit match. The flame should deviate noticeably towards the boiler. If this does not happen, it means that the chimney for some reason does not pull smoke out.

- View the pipe using a mirror and a flashlight. If necessary, remove snow and foreign objects. If you cannot do this yourself, call a chimney sweep.

- If you heat with damp wood, you need to clean out the accumulated tar from time to time.

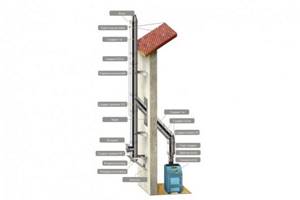

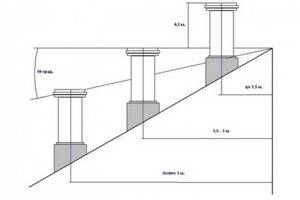

- Replace the chimney with a suitable type and diameter for this model. For example, the Lemax Premium device requires a chimney with a diameter of 200 mm. Increase the length of the pipe; in your house, its end should end above the ridge of the roof. Insulate the outside with glass wool.

- Inspect the chimney for cracks. Pay special attention to connecting seams. Remove right angles when turning and make transitions smooth.

In the room where the gas boiler is located, a window must be open to allow air to enter. This is especially true during the cold season in high-rise buildings, where a layer of cold air may prevent combustion products from escaping.

If you heat with a gas boiler and use cylinders rather than a centralized gas pipeline, it is important to purchase high-quality liquefied gas from trusted manufacturers. The Ross Lux model allows you to do this.

External reasons for boiler extinguishing

In the cold season, the head of the unit installed outside can become covered with ice, and it is quite difficult to knock it off - the larger the build-up, the less oxygen enters the boiler, so you have to remove the head and defrost it in hot water.

When defrosting the head, turn off the gas. After the ignition is turned on again, let the boiler operate at low pressure. If the contacts have cooled down, then you should reduce the gas supply, and, after returning the head to its place, the boiler will resume operation in standard mode.

Another reason for attenuation is the appearance of an ice crust in the chimney, when the heated steam cools down in the chimney and remains on the walls of the pipe, and turns into ice. In this case, the draft decreases and the flame goes out. In order to avoid this, you should insulate the pipe with chemical fiber or any other insulation made of non-flammable material.

Related materials:

What materials are heating radiators made from?

How to choose the right radiator for heating a house or apartment

What types of water meters are there, their purpose and classification

How to choose the right water meter?

Loading assistance

free and neat

Discounts for wholesalers

Cash/non-cash

cash and non-cash payments

Operational consultation

Subscribe to notifications about discounts and promotions

Offer agreement (agreement). I decide to provide my personal data and consent to their processing freely, of my own free will and in my own interest. Personal data is not processed by third parties.

I agree to the processing of my personal data specified in this application, including the collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, blocking, deletion, destruction of my personal data. Processing of personal data is carried out with and without the use of automation tools. When processing personal data, the owner of this site is not limited in the use of methods for processing it. The processing of personal data is carried out solely for the purpose of processing my request, responding to it (if necessary) and fulfilling the obligations assigned to it by the current legislation of the Russian Federation. This consent is given by me for 5 years. Consent may be withdrawn by me by submitting a written statement. When filling out an electronic application, I give my consent to the transfer of the application, including my personal data, via open communication channels on the Internet. Information about my personal data specified in the application sent electronically is not disclosed.

Why is it important to fix the problem immediately?

Even small pops are warning beacons indicating that the equipment is faulty. If the problem is not solved immediately, it will get worse in the future. The boiler may turn off, in addition to popping noises, an open flame comes out of the boiler, etc.

Despite the fact that modern equipment is equipped with good protection systems, the owner must still use it competently, maintain it in a timely manner, remove blockages, etc. Then the boiler or column will work for a long time, efficiently and without failures.

If you find that the boiler slams when turned on or makes noise during operation, and the reason cannot be determined, contact the experts. They will advise you on this issue, and if necessary, they themselves will diagnose and eliminate the cause of incorrect operation. Call.

Why combustion products accumulate

The raw materials for the heating boiler can be firewood, coal, peat or pellets. When any fuel burns, it leaves behind various deposits that negatively affect the operation of the device. Resin in a solid fuel boiler accumulates much faster in the following cases:

- use of low-quality or wet fuel;

- too much fuel material placed in the combustion chamber;

- use of a heating device for the disposal of household waste;

- the operating temperature is not high enough, which causes the fuel to smolder rather than burn;

- the use of firewood, which releases large quantities of volatile resinous substances, which, when the temperature drops, settle on the walls of the boiler.

Read more about problems with boiler temperature on our Zen channel.

Oxygen deficiency and errors made during the assembly of the heating device, in particular, insufficiently high chimney height, can also increase the amount of unwanted deposits.

Conclusions and useful video on the topic

You can find out why there is a bang when you turn on the Conord boiler from the following video:

This video explains in detail why the wick of the Conord boiler does not light, and how to fix this problem yourself:

Like any other equipment, gas boilers can break down from time to time, thereby depriving the residents of the house of heat, which is so necessary during the cold season. To restore the operation of a gas boiler, it is enough to correctly determine the type of breakdown, after which you can carry out the repair yourself without resorting to the help of a specialist. The article revealed the most common malfunctions of Conord boilers, as well as ways to eliminate them - replacing broken parts and cleaning contaminated systems.

Tips and tricks

Obviously, any malfunctions of the boiler and heating system appear only during their operation, that is, in the winter. This means no heat or hot water for the entire duration of the repair.

Therefore, our experts advise:

- Don’t skimp on equipment, choose the optimal model. Yes, you will save several thousand rubles when purchasing, but, most likely, you will pay much more when repairing and correcting various types of malfunctions. Remember, the cheaper the boiler, the lower the quality of materials used in its assembly. In this case, some protection components may also be missing, which will negatively affect your safety.

- Entrust installation to professionals. Equipment manufacturers also say this. Entrust the installation to specialists who will competently design the heating system, observing all the manufacturer’s requirements. Remember that most problems arise precisely because of poor installation.

- Be sure to have your equipment regularly serviced. The technician will clean the boiler, check the operation of the automation, set up modes for efficient operation and replace faulty parts. This will have a positive effect on the service life of the device.

- Comply with all requirements for the safe operation of devices. Study the documentation for your model; all situations and the sequence of actions when they arise are described there in detail.

- Do not undertake repairs yourself! A gas boiler is complex, highly dangerous equipment. Contact only professionals.

What to do if a strong wind blows out a gas boiler

If you determine that the problem is a consequence of air penetrating inside the chimney, then it is first recommended to check how well the entire structure is designed and constructed.

Next, you should make sure that the system as a whole is in good condition. Check the chimney design with the actual installation. Check if everything meets the stated requirements. If even minor inconsistencies are found, this is a reason to rebuild the chimney or modify it.

There are a number of criteria, compliance with which guarantees the uninterrupted and full operation of the heating installation:

- diameter, length, which are indicated in the project must comply with the approved documentation;

- the inside of the chimney is clean so that air can flow freely;

- the structural element of the chimney passing outside the room must be insulated.

If violations in the design were previously identified, then increasing the length is a simple and frequently used solution. The method is considered if there are some obstacles near the house (another building, trees) that interfere with the free movement of wind flows, forming turbulence.

When choosing this method, you should check if there are any other problems. Otherwise, the action performed will be inappropriate. Moreover, new difficulties may arise.

Installation of a draft regulator to “break” it

The most popular method is installation inside the chimney:

- 50 cm above the point of connection to the chimney;

- or in the same plane as it.

It should be noted that the practical application of this option must be discussed with specialists. If the structure is installed incorrectly, the rupture may in the future cause emergency situations or gas accumulation in the home.

Diameter change

There are a number of rules that will tell you what and how to do to prevent the gas boiler from blowing out:

- providing the recommended amount of oxygen;

- increasing the temperature for better fuel combustion.

Using a sandwich chimney (there is another pipe inside, but of a smaller diameter with insulation) significantly reduces heat loss, and the walls will warm up faster. The size of the sandwich directly depends on the size of the smoke exhaust channel. For help with calculations, you can contact specialists who will select the right product and assist in installation.

Disassembly and soot removal

For efficient operation of the equipment, it is necessary to clean the gas water heater. The deposits formed on the walls can disrupt the uninterrupted operation of the device, so there is no need to wait for the equipment to completely fail; preventive cleaning should be carried out periodically.

Before dismantling, it is necessary to block access to gas and water. Do-it-yourself cleaning of a gas water heater begins with removing the boiler doors and disconnecting the auto-ignition wire. Then the thermocouple, piezoelectric element and burner tube are removed

Carefully remove the nozzle and the burner itself

The thermometer sleeve, boiler lid, and flue are removed. Cleaning the geyser is done using a brush and brushes, which clean all internal and external elements. The nozzle hole is cleaned with a needle with a smaller diameter to avoid enlarging the hole and disrupting the combustion mode. The internal channels of the heat exchanger are blown out with a vacuum cleaner and wiped with a damp cloth.

At the same time, you can carry out minor repairs to the heat exchanger yourself: replace the gasket under the pilot burner, check the thermocouple, which is prone to breakdowns due to the specifics of its operation, and so on. Such work does not require large investments, but maintains the boiler’s performance at a high level, and the thermocouple device is quite simple, and replacing the element will not be difficult.

Structure of a gas boiler

Assembly is carried out in reverse order. When connecting the piezoelectric element, it is recommended not to use a tool to avoid damaging the ceramic base; it is better to tighten it by hand.

When installing, you need to check the thermocouple on the gas boiler; you need to know that the end of the conductors must be at the level of the place where the flame appears.

Problems with a solid fuel boiler

Sometimes the heating device smokes due to the banal filling of the ash pan.

Before looking for another possible source of problems, you should empty the ashpit and check the condition of the grate. The second most common problem with a solid fuel boiler is a clogged chimney. The reason is poor quality fuel. When using damp firewood or wood with a high resin content, not only soot is formed, which easily crumbles after tapping on the chimney casing. Resinous soot with a high moisture content adheres firmly to the walls, after which it hardens and narrows the diameter of the pipe.

ATTENTION! If damp firewood is used and the smoker is not properly insulated, this leads to the formation of condensation. In combination with soot, it turns into a caustic substance that can damage the chimney. When the pipe is corroded, traction is disrupted.

Why are there large deposits and sticky soot in the boiler? Cleaning methods

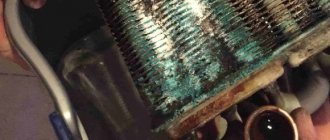

Big problems are associated precisely with the formation of dense and oily-viscous deposits on the heat exchanger, the walls of the combustion chamber of a solid fuel boiler, and in the chimney.

- A layer of such deposits 1–2 cm thick can appear within a week. And within a month, the cross-section of the smoke passage will decrease so much that it will affect the draft. Fouling of the heat exchanger will lead to its thermal insulation, and the boiler will stop heating water.

- The main danger from the accumulation of soot deposits, especially plastic ones, lies in their possible ignition during boiler firing. This can lead to a serious fire, as the chimney and parts of the boiler can burn out and collapse.

It is important to prevent the formation of a layer of soot in the boiler and chimney, especially hard and sticky-plastic ones. And if it appears, remove it in a timely manner.

What are sticky and hard sooty deposits?

Normal soot is crumbly and can be swept away with a broom.

- It can form a hard crust when mixed with water and baked on hot surfaces. It is not uncommon for heat exchangers and the chimney to be covered with a thin (several millimeters), hard, dense cake due to the presence of water (dew).

- A wet-plastic, viscous layer of deposits may form, which consists of unburned resins released during smoldering from fuel - from wood and some coals. The appearance of such a layer is considered an emergency.

The appearance of dew on the heat exchanger

Water vapor condenses from hot air when it cools to +55 degrees and below. If the heat exchanger is cold, or the smoke exhaust ducts are cold, then dew from the hot gases will certainly fall on their surfaces. The surfaces will be moistened, the water will mix with the soot, and then, when the water dries, a dense cake will form.

- At the beginning of the fire, in any case, the surface of the equipment will be cold until it warms up from the heat generated. The goal is to reduce this time as much as possible. So that the dew falls literally in a matter of minutes, and not, say, a whole hour.

Common problems with turbocharged models

The indicated difficulties also arise in turbocharged vehicles. And since this technique has an isolated combustion compartment and additional components, it is characterized by the following difficulties:

- The hood or coaxial chimney is covered with ice.

- The integrated air blower is broken.

The culprits of the first problem are accumulated condensation and adhered snow.

You can avoid it by protecting the chimney from aggressive factors - installing a deflector.

If ice plugs have already formed, they can be melted with a hairdryer or a torch - a spray can.

As a rule, condensate settles in pipes of convection modifications, for example Lemax PRIME-V10.

Traffic jams form here due to temperature differences in air flows coming from the street and heading outside. They block the path to the combustion compartment.

The solution lies in lighting the chimney with a portable burner. When you remove the plug, insulate the pipes.

If the boiler has a built-in blower, as in the Baxi ECO-4s 24 model, and it goes out during operation or the wick does not start immediately, pay attention to the sounds that appear.

With stable functions there are measured beeps. Excessive noise is a sign of a problem.

Turbocharging, as a rule, is not repaired, but quickly replaced.

If there are no sounds when the device is operating, it means that the automatic mechanism is preventing the safety valve from opening and the filter does not ignite.

Call specialists to replace the turbocharger. Because this work is quite complex and associated with a certain risk.

How to understand that there is a need for chimney cleaning

There are signs by which you can determine that your chimney needs cleaning. This will allow you not to miss the moment and not aggravate the contamination situation to the point where the equipment fails.

Important to remember!

Martyanov Pavel

Specialist in the field of gas equipment maintenance, 20 years of experience

Ask a Question

Timely maintenance of chimney systems is not only a guarantee of stable operation of gas equipment, but also a guarantee of your safety. Exhaust gases are extremely dangerous to human life and health.

The burner does not turn off and constantly works

When the heat exchanger becomes clogged, the water begins to heat up more slowly. The turbine continues to pump new fluid. The burner is in constant operation, trying to achieve the desired temperature value for the water.

Read a detailed article on this topic: Why does the gas boiler not turn off and constantly work?

The pressure in the hot water supply circuit has dropped

This happens as a result of improper operation of the heat exchanger or leaks in the pipeline system. Depressurization of the fluid supply circuit could also occur.

We recommend reading: Why the pressure in the heating system drops, reasons and solutions

Rumble and extraneous sounds in the operation of the circular pump

Blockages prevent water from circulating normally. Therefore, the pump is overloaded during operation. This is indicated by equipment malfunctions, extraneous noise, or engine overheating.

Also read with this article: The main reasons why a gas boiler hums

Gas consumption has increased

The formation of blockages is one of the reasons why gas consumption increases. This is due to the need for more fuel for the boiler. When cleaning is carried out and scale is removed, gas consumption returns to normal.

Methods for cleaning a gas boiler

There are several options. These include traditional methods: mechanical and chemical methods. In not the most difficult cases, hydrodynamic cleaning is chosen. Sometimes serious help is needed.

Mechanical

This method involves the use of simple tools. Manual cleaning allows you to avoid wasting money and time, but its effectiveness is low. The mechanical method does not at all guarantee an excellent result, so its use can be called a half-measure. Actions with “crazy” hands will only help if cleaning is carried out regularly.

The role of tools is the usual tools - brushes, brushes, toothbrushes, and a vacuum cleaner is also used in the fight for cleanliness. All mechanical devices should not have sharp edges, since they can easily damage unit parts. The required element is disconnected from the system and carefully treated with brushes, trying not to damage the surface. To clean the inside, use a brush or blow out the parts with a vacuum cleaner.

Subtleties of cleaning a stainless steel chimney

Stainless steel structures have a good internal surface quality. The characteristics of the chimney allow the condensate to drain into a special collection tank. It is necessary to periodically empty it and dispose of the liquid. This helps prevent soot from appearing. But this does not prevent stainless steel models from developing carbon deposits.

Blockage in the chimney

If you find it, it is recommended to remove it. For this:

- You will need a brush on a flexible round shaft. It must be placed in the pipe through the hole in the tee. The tool must be rotated using an electric drill. You must act carefully. As you move forward, the drive shaft must increase in length. This will allow you to completely clean the entire pipe.

- If the soot has formed quite stable, it is recommended to use burning. To do this, use a blowtorch. The chimney is first dismantled. Then burning is used. It is enough to set the temperature to 800-900 degrees.

It is recommended to check the quality of the stainless steel construction before starting cleaning. It is important to correctly define the class. This affects the ability to use different cleaning methods. High-quality stainless steel will not be magnetic. This can be cleaned using the specified means and not worry about its safety.

If sandwich pipes are used, there is rarely a need to clean them. This is due to a working condensate removal system. But if the need arises, then the tool you should use is a long cylinder-shaped brush equipped with a flexible drive cable. It should rotate using an electric motor, which will allow the structure to be thoroughly cleaned.

Another suitable cleaning option is to dismantle the chimney. Then it is enough to process each part separately.

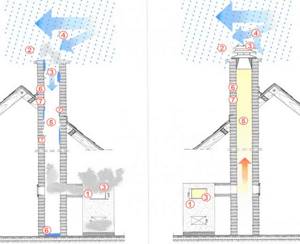

Backdraft - the nature of the phenomenon and methods of elimination

Backdraft is the process when combustion products do not exit through the chimney, but enter the room. Typically, this triggers the exhaust gas sensor, which is installed in devices from all modern manufacturers, for example Concord. At the same time, the solid fuel device smokes heavily when the door is opened and clogs and smokes the door window. All the reasons boil down to the fact that any gas moves from an area with high pressure to an area with lower pressure. Natural draft occurs when the chimney pipe is raised to a sufficient height.

You can find out if there is backdraft in your case by holding a lit match or a piece of toilet paper to the chimney. With natural draft, the flame and paper will deviate towards the boiler, and with reverse draft, away from it. Let's figure out what to do if there is reverse thrust.

Backdraft in the chimney

A common cause is weather conditions. A strong wind blows into the chimney and prevents combustion products from escaping. This also occurs when the outside temperature drops. Perhaps you should just wait until the pipe warms up and the natural direction of smoke movement is restored.

The second reason is the incorrect design or type of chimney, as well as its damage. In order for combustion gases to escape easily, there should be as few bends in the pipe as possible. The diameter and type of chimney must be selected for each boiler, depending on its type and power. For example, parapet boilers Danko U, Aton Compact and Mimax KGS (P) are equipped only with a coaxial type chimney. If you have a private house, the end of the chimney pipe should be higher than the ridge of the roof.

In conclusion, we offer a video on the topic:

Mechanical cleaning of plate heat exchangers

You can clean the boiler from soot without removing the heat exchanger. To do this, just remove the cover, arm yourself with a stiff nylon brush and close the gas injectors so that dirt does not get in there. The whole process is clearly shown in the video:

If soot has stuck to the surface and is not removed by mechanical treatment with a brush, then the heat exchanger is removed and soaked in special cleaning solutions for several hours. Such products are available for sale in a wide range, examples include Fauch and MAZBIT+ products. But you can also use household chemicals - gels for cleaning grills and ovens.

Before disassembling the boiler, you need to disconnect it from gas and the igniter from electricity. In addition, it is necessary to drain the water from both circuits and the expansion tank. The secondary heat exchanger is removed first; it is located immediately behind the boiler lid. The primary (main) one is more problematic to remove, since you will have to disassemble the combustion chamber.

Consequences

If preventative maintenance is not carried out periodically, the boiler may simply stop working, and the thermal conductivity will decrease. This will lead to:

- a significant reduction in heating in the house;

- high expenses: fuel material is consumed much more;

- reducing the service life of the boiler;

- there is a risk of losing the device, since due to uneven heating of the equipment, the boiler seams may rupture;

- inaccuracies in equipment readings.

As for a solid fuel device, untimely cleaning can lead to the formation of carbon monoxide and even a fire.