Heating devices that operate on diesel fuel are ideal for heating and hot water supply not only for private homes, but also for industrial facilities. Boilers of this type are easy to use, they do not require special care, and most importantly, they are durable (the service life reaches 25 years).

Diesel heating boiler fuel consumption

- 1 Fuel consumption for various boiler models

- 2 What will fuel consumption depend on?

- 3 Fuel consumption

- 4 How to save on fuel? Criteria for choosing heating equipment 4.1 Video – Diesel heating boiler – fuel consumption

- 7.1 Video – Diesel boilers

Definition of the concept

There is no mental refinement in defining this type of heating boiler. Liquid fuel boilers are boilers that run on liquid fuel such as diesel fuel, also known as diesel fuel.

The main purpose of a liquid fuel boiler is to heat the house by heating the coolant of the heating circuit. Depending on the brand of the boiler, it can perform an additional function, namely, heat water in the water supply system, creating a hot water supply circuit. In general, no super tasks, just the usual tasks of all heating boilers.

Multi-fuel combi boilers

But boilers operating on two types of fuel are not all types of combined heating devices. There are also multi-fuel boilers, which are often called universal. They are often equipped with several fireboxes at once, and the transition from one fuel to another can be done manually or automatically.

Combination: Gas - Diesel - Electricity

Boilers of this type are used mainly in rooms with large areas, but only as an additional source of heat, in combination with the main one. The fact is that such combined heating boilers do not have sufficient power to heat houses efficiently.

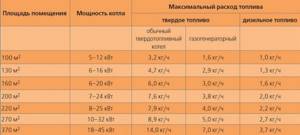

Calculation of fuel quantity per month and per season

To find out which diesel boiler is right for you, you need to calculate the approximate consumption of diesel fuel for one month and the entire heating season. The amount of diesel fuel (DF) for heating a house depends on many parameters: the area of the house, the quality of thermal insulation of the walls, ceiling height, winter air temperature in your region, the number of sections in the radiators. It is impossible to take into account absolutely all parameters, but we can approximately calculate how much diesel fuel the model you need consumes, based on the area of the room.

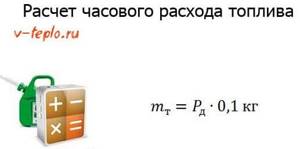

It is believed that to heat 10 square meters of a house built according to all standards, 1 kW of boiler thermal power is needed. Liquid fuel equipment consumes a mass of diesel fuel equal to 10 parts of its power. That is, a 15 kW device consumes 15 * 0.1 = 1.5 kg of diesel fuel per hour. Accordingly, to calculate consumption per day, you should multiply this figure by 24. For example, a 20 kW model uses 20 * 0.1 * 24 = 48 kg of fuel per day.

Fuel consumption per month is equal to the daily volume multiplied by 30. 30 kW equipment, for example Ferroli Atlas D 30, consumes 30 * 0.1 * 24 * 30 = 2160 kg per month. The duration of winter varies greatly depending on the region of residence. When making calculations, you need to take the indicator of your area. Let's take for example the average of 111 days, from November 27 to March 17.

The final formula for calculating fuel for the heating season is as follows: boiler power * 0.1 * 24 hours * number of cold days. Let's make calculations for the boiler of the South Korean company Kiturami Turbo. The Kiturami Turbo 13 device has a power of 15.1 kW. Substituting this value into the formula, we get: 15.1 kW * 0.1 * 24 hours * 111 days = 4022.64. This means that per year you will spend approximately 4 tons of diesel fuel to heat a house with an area of 150 square meters.

It is also recommended to select the boiler power with a reserve so that the heating equipment operates at maximum power less often. This will extend the life of the device.

Fuel consumption for various boiler models

We conducted a small comparative analysis of various models of diesel boilers in order to show you their average fuel consumption.

| Make and model | Photo | Max heating area m2 | DHW performance | Max fuel consumption | Weight kg | Max power kW | Manufacturer |

| Kiturami TURBO-21 R (floor-standing diesel boiler) | 245 | 14 l/min | 2,8 | 58 kg | 24.4 kW | Korea | |

| NAVIEN LST-50KR | 500 | 28.7 l/min | 5,8 | 94 kg | 50 kW | Korea | |

| NAVIEN LST-24K | 240 | 13.8 l/min | 2,9 | 40 kg | 24 kW | Korea | |

| Buderus Logano G225-78 SE | 780 | — | 7.2 | 336 | 78 kW | Germany |

Operating principle of a diesel boiler

In order to understand the principle of operation, let’s consider the basic components of a diesel boiler and their purpose:

- A pump that ensures the flow of diesel fuel into the burner.

- A fan that supplies air to the combustion chamber.

- Chamber for preheating fuel. Not installed on all devices. Inside, the fuel is heated and filtered before being supplied to the burner.

- Diesel burner. It receives fuel, which is sprayed into the combustion chamber through a nozzle. A fan or turbine is used to create pressure inside. According to the method of power control, the following configurations are distinguished: Single-stage models with constant power.

- Two-stage devices with two modes

- Modulating burners, the power of which varies depending on the set temperature.

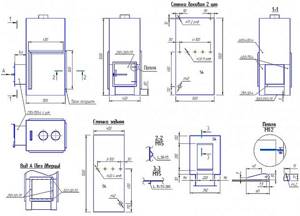

Diesel boiler in section

- Metal heat exchanger. It consists of tubes that are heated by the heat released during fuel combustion. Inside them there is a coolant, which is distributed through the radiators using a circulation pump. Made from stainless steel, copper or cast iron.

- Chimney. Combustion products and residual vapors are discharged here. In modern configurations, there is also part of the heat exchanger, which is heated by the escaping smoke and steam, which allows increasing the efficiency of the device.

- Electronic control system. Coordinates the operation of all components of the liquid fuel boiler according to user settings.

- The body is made of steel and is additionally covered with a heat-insulating gasket from the inside.

The pump pumps fuel into the preheating chamber, then it enters the diesel burner and is sprayed into the combustion chamber through a nozzle under pressure from the internal fan. On the other hand, oxygen is supplied to the furnace, pumped by a fan. The electrodes create a spark and ignite the mixture of air and fuel.

The heat is transferred to a heat exchanger, which is located around and on top of the combustion chamber. The coolant is heated inside it and circulates through the heating system. Combustion products are discharged through the chimney. All components are coordinated by an electronic control system, which sets the required operating mode and temperature.

Kiturami boiler control system

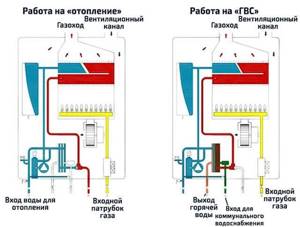

Dual-circuit models are also produced that have an additional heat exchanger for domestic water. Usually it is located above the main one and allows you to provide the house with hot water supply.

If you want to provide domestic hot water using a single-circuit boiler, you need to additionally install an indirect heating boiler. Some double-circuit devices are equipped with a small indirect heating boiler instead of a second heat exchanger.

Features of liquid fuel equipment

Boilers that consume diesel fuel, diesel fuel or kerosene can be used, as already noted, for domestic and industrial buildings. Fuel must be stored in a special container - it can be located anywhere, as long as it is convenient:

- underground;

- in the boiler room;

- in the courtyard.

And this is precisely one of the main advantages of the described equipment.

Note! It is most advisable to use these boilers in non-gasified settlements, because the fuel consumption in this case is quite low. As for the principle of operation, it is not much different from devices that consume other types of fuel.

The device includes a combustion chamber where the burner is located; with the help of the latter the fuel is burned. During operation, the coolant warms up, after which it is supplied to the heating system. A traditional chimney is used to remove combustion products. Typically, when moving, they are passed through a heat exchanger, sharing part of the thermal energy with it. This allows you to significantly increase efficiency.

Devices operating on diesel fuel, in most cases, have a body made of steel - it is known to be practically impervious to rust. Under the body there are automation units (they control the functioning of the boiler) and control units of the device. In the manufacture of heat exchangers, either cast iron or steel is used; Thanks to this, the units are able to withstand exposure to critical temperatures for a long time.

In order to reduce heat loss during operation, as well as in order to reduce the amount of diesel fuel consumed by the boiler, a thermal insulating gasket is installed under its outer casing, which at the same time prevents accidental burns when touching the surface.

How to calculate the average daily consumption of diesel fuel in a boiler

A simple calculation of fuel consumption is performed according to the formula, 1 kg of fuel = 10 kW. It turns out that to obtain thermal energy of 10 kW (sufficient to heat a residential building of 100 m²), you need to spend 1 kg of diesel fuel. The average daily amount of fuel consumed by a diesel boiler will accordingly be 24 kg.

The specific consumption rate in professional conditions is calculated depending on the power of the burner device. Calculation formula: 0.1 × burner capacity. Cost calculations are performed for the entire heating season.

They do this as follows:

- Within an hour, a 10 kW boiler consumes 1 kg of diesel fuel.

- 24 kg are consumed per day.

- The average heating season lasts 100 days, and half the time the boiler will operate at 50% capacity. As a result of calculations, the actual consumption is equal to 5000 liters of fuel per year.

The principle of operation of the “miracle stove”

The miracle stove is designed to heat rooms for a long time with minimal fuel consumption.

The wood-burning stove is equipped with two chambers. In the first chamber, the smoldering of firewood is ensured under conditions of limited access to oxygen; in the second chamber, secondary combustion occurs. Here the released flammable gas is burned. Thus, the furnace allows you to use the thermal energy released during combustion to the fullest extent. The efficiency level of such a stove reaches 75% (the efficiency of classic potbelly stoves barely reached 15-20%). The pyrolysis process increases the combustion period of wood. Therefore, one load of firewood is enough to operate the stove for 6 hours, and with proper settings – up to 8 hours. Heating of the room is carried out by heating the air against the furnace body.

This model has a number of positive properties

- Capable of working on all types of solid fuel - firewood, wood chips, peat briquettes, wood products;

- Heats the entire room evenly;

- Allows the home owner not to depend on centralized supplies of gas and electricity;

- Provides control over the fuel combustion process;

- Does not require significant costs for system installation;

- You can cook food and heat water on the surface of the stove;

- It is easy to maintain on a daily basis;

- It is characterized by low cost.

Such wood-burning stoves can be used for quick heating and stable heating of country houses, residential buildings, greenhouses, workshops and small businesses.

Date: September 25, 2021

How to save on fuel? Criteria for choosing heating equipment

Units consuming liquid fuel are designed for both one and two circuits. And it is quite obvious that in the second case, fuel consumption will be greater, which will only increase costs. For this reason, the best option for dual-circuit appliances can only be to reduce the consumption of hot water, which will help save on fuel.

Experts advise one more thing. According to them, fuel consumption can also be reduced by setting a lower temperature for the coolant. And the final point - it is advisable to install a thermostat in the warmest room. If you follow all these recommendations, you will be able to reduce the fuel consumption required for the operation of the boiler and save a certain amount of money.

On many thematic forms, users are interested in: which units are more economical - diesel or electric? And what is the general fuel consumption of a diesel heating boiler? It is quite difficult to answer this question unambiguously, since it depends on a number of factors, including:

- quality of building thermal insulation;

- cost of the fuel used;

- area of the heated room;

- features of a specific climate zone;

- number of residents in the house.

And if you know about all these factors, then you can roughly calculate the consumption of both fuels by comparing costs. And now - some more practical advice regarding the choice of a heating unit.

- Heating equipment that consumes diesel fuel, if there is a combustion chamber made of steel, will be immune to temperature changes. At the same time, steel undergoes a rusting process, so it does not last as long as, for example, cast iron.

- The higher the cost of a heating boiler, the higher the risk that its maintenance will cost you very much (when compared with models that have a lower cost).

- Devices that are equipped with a cast iron combustion chamber can last up to twenty years, but temperature changes affect them quite significantly. In this kind of heating systems, it is necessary to install valves that will mix the heated liquid into the return pipeline. All this is required so that the combustion chamber simply does not split.

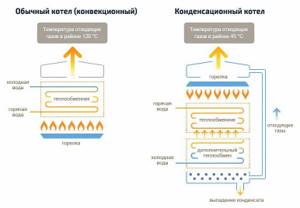

Convection or condensation

The efficiency, and therefore the economy, of a diesel heating boiler depends on the method of using the thermal energy released during the combustion of diesel fuel:

- convection - a standard type of boiler in which the coolant is heated by direct combustion of fuel, part of the heat is lost with combustion products (exhaust gas temperature is about 75-110°C);

- condensing - a modern boiler design that implies the presence of an additional heat exchanger that extracts heat from condensate, which in turn is formed from combustion products leaving the chimney. Thus, it is possible to accumulate almost all the heat obtained during combustion (the temperature of the exhaust gases is on average 35-45°C).

As a result, the efficiency of condensing boilers is 15-20% higher, however, the cost of such models is 1.5-3 times higher: usually from 100 thousand rubles. Therefore, the payback of such technology depends on the volume of fuel burned.

Wall or floor

Due to the larger dimensions of the burner and the greater weight of the boiler unit as a whole, diesel boilers are usually floor-standing. There are also wall-mounted models, for example, the Swedish CTC 950 RU. However, at the moment we do not recommend considering them for purchase: it is difficult to find them on sale, wall-mounted models are 1.5-2 times more expensive than floor-standing analogues, and the service structure is often not so developed even in Moscow and Moscow Region, not to mention the regions .

Single-circuit or double-circuit

Single-circuit models are designed exclusively for heating. Double-circuit systems have an additional hot water supply (DHW) circuit and when the tap is opened at the point of consumption, they begin to heat sanitary hot water, which does not mix with technical water in the heating circuit. Of course, the choice depends on the requirements for the boiler.

At first glance, it is better to choose a single-circuit boiler, since the cost of fuel is already high. However, dual-circuit models are still more effective, this is confirmed by the significantly greater demand for them. The cost of a double-circuit boiler in the budget and mid-price category is only 5-15% higher, while to organize hot water supply in a house in another way you will need from 15 to 50 thousand rubles, and the cost of electricity that will be spent on heating is higher than the cost diesel fuel.

What will fuel consumption depend on?

There are a number of factors (including various loads) that influence the performance of heating equipment. But first of all this:

- area of the heated room;

- quality of thermal insulation of the building.

Of course, the larger the room itself, the greater the diesel fuel consumption will be. As for the efficiency of the equipment described, in most cases it varies between 90 and 95 percent. But, which is typical, to achieve this result, the speed during operation of the boiler must be maximum. Therefore, when choosing a heating device, you should not purchase a model whose power has a small reserve. This way you will be able to avoid unnecessary expenses, since here the liquid fuel boiler will consume less diesel fuel.

Review of models from leading companies

A worthy niche in the heating equipment market is occupied by liquid fuel boilers from foreign manufacturers: ACV, EnergyLogyc, Buderos Logano, Saturn, Ferolli and Viessmann. Among domestic companies, Lotos and TEP-Holding have proven themselves well.

Universal boilers ACV Delta Pro

The Belgian company ACV sells models of the Delta Pro S line - double-circuit boilers with a built-in boiler. The power of heating units ranges from 25 to 56 kW.

Delta Pro S boilers are supplied with a burner of the buyer’s choice - either model BMV1 for liquid fuel or BG2000 for propane and natural gas

Technical and operational features:

- heat exchanger material – steel;

- polyurethane foam insulation of the body;

- operation on diesel fuel or gas;

- control panel with thermometer, control thermostat.

The liquid fuel boiler “adjusts” to the season - a “winter/summer” switch is provided.

The efficiency of Delta Pro S boilers is 92.8%. The water heating time for the DHW system depends on the power of the installation and ranges from 16 to 32 minutes

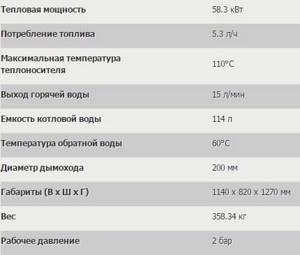

EnergyLogyc units – intelligent automation

Waste oil boilers from the American company EnergyLogyc differ from their analogues in the automated processes of setting up the burner and burning fuel.

The fuel used is waste oil, diesel fuel, vegetable oil or kerosene.

The device has increased the size of the firebox and the cross-section of the smoke pipes - this makes it possible to effectively use “working off” and reduces the number of boiler cleaning jobs

EnergyLogyc liquid fuel units are available in three modifications:

- EL-208B – power 58.3 kW, fuel consumption – 5.3 l/h,

- EL-375B – performance 109 kW, fuel consumption – 10.2 l/h;

- EL-500B – thermal power – 146 kW, fuel consumption – 13.6 l/h.

The maximum coolant temperature in the presented models is 110°C, operating pressure is 2 bar.

The EL-208B boiler is suitable for heating premises for various purposes: cottages, greenhouses, car services, production shops, warehouses, private homes and offices

Buderos Logano – German quality

The Buderos company (Germany) produces diesel boilers, nozzles, burners and other equipment necessary for operating the heating system. The range of power characteristics of the units is 25-1200 kW.

The efficiency of Buderos liquid fuel boilers is 92-96%. The equipment operates in fully automatic mode, the fuel material is diesel fuel. Heat exchanger made of gray cast iron or steel

Buderos Logano boiler systems are produced in two series:

- Buderos Logano category “G” - intended for private use, their power is 25-95 kW;

- Buderos Logano category “S” – equipment for industrial use.

The units are distinguished by a streamlined design, a convenient control system, and a built-in silencer.

Buderos Logano domestic boilers are supplied with built-in and adjusted diesel fuel burners. The device can be equipped with a pump group, a security system and an expansion tank

Boilers from the Korean company Kiturami

Kiturami Turbo series floor-standing double-circuit boilers are designed for domestic use. The power of the units is 9-35 kW.

How to choose the right diesel boiler

A diesel fuel boiler can heat a building of any size. For this purpose, models are available for sale that differ in power - up to 100 kW. Thanks to this, consumers have the opportunity to quickly select a model that suits its characteristics. Diesel boilers also differ in some other parameters:

- Type of combustion chamber used;

- Number of working circuits;

- Operating principle – traditional or condensation;

- Control type – mechanics or electronics.

Let's figure out how to choose the right diesel heating boiler.

Combustion chamber type

Diesel fuel in diesel boilers can burn in two types of chambers - open and closed. Open chambers (atmospheric boilers) burn fuel with a natural supply of oxygen, while models with closed chambers are equipped with fans that create artificial draft. The former are simple, but the latter are characterized by higher efficiency.

Atmospheric diesel fuel boilers require a traditional chimney. If you already have one in the house, then you don’t need to think much about it – feel free to buy a model with an open chamber. If you want to avoid fussing with a chimney (and its construction costs time and money), you should take a closer look at a unit with a closed chamber (turbocharged type). For its operation, you will need to purchase a special coaxial chimney, which is led outside the nearest wall to the street.

Classic and condensation models

Condensing boilers using diesel fuel are good because they have increased efficiency. They extract the generated heat to the maximum, for which additional heat exchangers are provided in their design. As a result, the combustion products at the outlet have an extremely low temperature - condensation occurs, which requires its disposal into the sewer system. Condensing units are noticeably more expensive, but they save 10-15% of fuel and take care of the environment.

If the money in your budget for heating is strictly limited, we recommend buying a cheaper classic unit that extracts heat according to the traditional scheme. The efficiency here is slightly lower, but the price of the equipment is more affordable - that’s all the differences.

Number of circuits

Organization of hot water supply is an eternal problem where there is no centralized supply of hot water. Consumers use boilers, install hot water heaters in their homes and apartments, and purchase instantaneous water heaters for tap use. If you install a diesel boiler in your house, you should take a closer look at dual-circuit models - they will provide the premises with heat and supply hot water to the taps.

Double-circuit diesel boilers have a more complex structure. This fact directly affects their cost and level of reliability. Therefore, some consumers are wary of them. If you don’t want to purchase a double-circuit unit, we recommend adding an indirect heating boiler with a built-in heating element to the heating unit. In winter it will work from the heating system, and in the warm season - from the mains.

If there is no need to prepare a large amount of hot water, limit yourself to installing an electric instantaneous water heater (do not buy a “faucet” model, buy a normal unit with wall mounting).

Control type

The fewer parts, the fewer breakdowns - this is an almost unshakable rule. Therefore, diesel fuel boilers with simple mechanical controls last significantly longer and break down less often. But models with electronics are more accurate and economical. They can be controlled from built-in and remote controls; they have more service functions. If you have extra money in your pocket, their purchase is completely justified.

Thermal power

Since we are considering diesel heating boilers for home use, to calculate the required thermal power we can use the usual formula - for every 10 sq. m. area requires 1 kW of heat. Knowing the area of the house, we can calculate the required area. These calculations take into account regional coefficients and take into account heat losses in individual rooms - we have already written about all this more than once in our reviews.

Advantages of diesel boilers

- Power and performance. Using the devices, you can warm up even large rooms, and the high efficiency allows you to use fuel efficiently.

- Possibility of adjusting the heating temperature - during thaws you can reduce the heater power, and during frosts you can increase it without overusing fuel.

- Autonomy. With a diesel heater, the room will always be warm, regardless of the presence of a gas main nearby.

- There is no need to obtain permits for connecting and installing equipment, unlike gas heating. There is no need to call the gas service to install the boiler.

- Availability - diesel fuel can be purchased at almost any gas station.

- Safety ensured by the automation of the device.

- Possibility of switching to liquefied gas - if necessary, most diesel boilers can be easily converted to gas fuel by replacing the burner.

Advantages and disadvantages of each type of engine

Having understood the differences in the main parameters, we can summarize and analyze the main advantages and disadvantages of each type of engine.

Diesel engine - pros and cons

Advantages

- Low fuel consumption. No matter how economical modern gasoline cars are, in terms of fuel consumption they will for a long time be inferior to diesel engines, which have greater efficiency and provide higher torque.

- Less transport tax. Since diesel engines with comparable characteristics have less power, the amount of transport tax for them is an order of magnitude lower.

- Environmentally friendly. It will be no secret to anyone that diesel engines are more environmentally friendly than gasoline engines, second only to hybrids and electric cars in this parameter.

- Durability. Modern gasoline engines need to travel from 150 to 200 thousand km before they need major repairs, while for a diesel engine this value is at least twice as large, which indicates their greater durability and reliability.

Flaws

- Higher demands on fuel quality, which is especially important in Russian realities. If you fill a diesel engine with low-quality fuel, it will very soon require repairs, which, in comparison with a gasoline engine, will cost a heftier sum.

- There may be problems starting the engine at low temperatures.

- Warming up takes longer, so when driving in winter you need to be prepared for the fact that life-giving warmth will appear in the car’s interior only after a few kilometers.

- Higher maintenance costs, and the number of car services servicing diesel engines is noticeably lower than those for gasoline engines. True, if we spread the cost of repairs and maintenance over the longer life of a diesel engine, then the savings on a gasoline engine will not look so significant.

- The starting price of a car with a diesel engine is noticeably higher, which can reach 10-20% compared to a similar gasoline car.

Advantages

- Simplicity of design and prevalence. The gasoline engine has a simpler design than diesel, and is more common in Russia, which makes it possible to carry out repairs and adjustments in almost any car service center.

- Confident launching in almost any weather conditions. If the engine has no malfunctions, starting it will not be difficult even at temperatures below 40 degrees Celsius, while with a diesel engine, under comparable conditions, starting problems may occur.

- Affordable price. Cars with gasoline internal combustion engines will cost significantly less than their diesel counterparts, however, this rule does not apply to used cars.

- A wider choice of trim levels, and this applies to almost every automaker represented in Russia.

Flaws

- Frequent problems with the ignition system. Compared to diesel engines, the ignition system in gasoline engines more often fails, which promises additional and more regular material costs.

- Low operating ranges. To get the most out of a gasoline engine, you have to crank it long and hard, while a diesel engine has maximum output almost from idle.

- Economical. As we have already said, no matter how modern a gasoline engine is, its consumption will still exceed that of a diesel engine.

As a result, it is necessary to choose the type of engine based on operating conditions, as well as driving style, so if you like to accelerate quickly, do not plan to transport heavy loads and do not use the car for commercial purposes, a car with a gasoline engine is more suitable.

Otherwise, it is better to choose a diesel engine. Date: September 25, 2021

Disadvantages of technology

- For full operation, the boiler requires a special container for storing fuel. Such a tank takes up quite a lot of space, and therefore it is customary to allocate a separate room for the boiler and tank.

- The boiler room must be equipped in accordance with fire safety rules, and also have a connection to ventilation to remove combustion products. In addition, to prevent diesel fuel from freezing, it is recommended to install heating in the boiler room.

- During active operation, the device is quite noisy, unlike its electric counterparts.

Alternative home heating with diesel fuel

What could I do to make heating my home with diesel a little less expensive, so that I could use a diesel boiler as the main source of heat for my home?

The first thing I think of is using a waste oil burner. I install such a burner during testing and collect virtually free fuel wherever I can - at service stations, at express oil change kiosks, and so on.

What are the disadvantages of this option? The first and most basic is the price of the burner. The cost of the burner during testing is 60,000 rubles. Which is comparable to purchasing almost 2 tons of diesel fuel.

An exhaust burner might solve the problem of heating a house with a diesel boiler, but it is not cheap.

Secondly, the waste also needs to be collected, waste of gasoline and time, transport it in cans to the house, settle it somewhere and store it during this time.

And thirdly, I’m not the only one who is so smart. More than once I have watched my comrades collect waste from the service station and take it away for their own needs. This is exactly the same issue as with making your own pellets. It seems like the sawdust is free. But in fact, it turns out that it is easier to heat with briquettes than to make pellets yourself from “free” sawdust.

There is, of course, also diesel oil and light oil. But there are also pitfalls there. Starting from the fact that a standard burner will not be guaranteed to work on these types of fuel, and ending with the complete impossibility of obtaining this fuel in some regions.

Here an analogy with the Karborobot coal boiler suggests itself. The boiler is good, no doubt about it. But in our region there is no fuel for it, there is no coal of the required fraction, there are no good suppliers. And bringing it from somewhere is incredibly expensive.

Share with friends:

Konstantin | 3.06.2016 10:57

I have a house of 120 square meters, at first I was led by advertising and hung infrared heaters throughout the house, 8 pieces for the whole house, all in accordance with those. regulations for them. When the temperature dropped to -5, it became cold, there was no other heating. At the same time, they also click and dry the air, making it impossible to sleep. I changed it under warranty because of clicks - the result is 0. I installed a Kiturami boiler of 30 kilowatts, a 220 liter barrel and am happy, consumption is 1500 liters per year, I live all year round, two small children, the boiler gives hot water, I fill the pool with three tons in the summer so as not to wait until it warms up from the sun, the neighbor doesn’t eat a ton at all. the house is 60 meters, in practice we save almost twice as much on electricity. Leningrad region. Don't believe provocateurs))) Warmth to everyone.

Oleg | 06/22/2016 12:03

Konstantin, why did you take the 30 kW Kuturami? There are also models with 19 kW and 24.4. How many hours a day does the boiler work in severe frosts?

Tatiana | 10/28/2016 07:06

Konstantin, hello! I also choose a boiler. I would like to know more. Is it possible to PM me somehow? Also St. Petersburg, the conditions are similar. We lived on pellet fuel for 6 years. We're having problems with fuel...

Our authors are practitioners

Vladimir Zastrelchenko. Zelenograd, author of articles on house insulation and site planning. Vladimir Tolbukhin. writes about stoves, boilers and autonomous heating of a private home. Artem Stebanov. Chelyabinsk, preparing materials on planning and estimates. Ksenia Sinitsyna. Moscow, Guild of Designers, publishes materials on home improvement. Rinat Nigmatullin. Naberezhnye Chelny, author of articles on insulation of houses and outbuildings. Marat Borchan. Tomsk, heating engineer, author of articles on the thermal resistance of enclosing structures. Sergey Pozdnyak. Perm, author of articles about country life and farming.

Specifications

- 0.24–2.8 MW

- 3.2–18.0 MW

- 20.0–60.0 MW

| Boiler room type | 0,24 | 0,3 | 0,4 | 0,5 | 0,6 | 0,7 | 0,8 | 1,0 | 1,24 | 1,6 | 1,7 | 1,9 | 2,0 | 2,4 | 2,6 | 2,8 | |

| Nominal heating capacity, MW (Gcal/hour) | 0,24 (0,21) | 0,3 (0,26) | 0,4 (0,34) | 0,5 (0,43) | 0,6 (0,52) | 0,7 (0,6) | 0,8 (0,69) | 1,0 (0,86) | 1,24 (1,06) | 1,6 (1,38) | 1,7 (1,46) | 1,9 (1,7) | 2,0 (1,72) | 2,4 (2,06) | 2,6 (2,24) | 2,8 (2,4) | |

| Power consumption, kW no more * | 3,0 | 3,7 | 4,3 | 5,8 | 8,0 | 11,0 | 11,7 | 12,2 | 13,0 | 16,0 | 20,0 | 22,0 | 23,0 | 24,0 | 25,0 | 26,0 | |

| Mains voltage, V | 220/380 | ||||||||||||||||

| Fuel | Diesel fuel. | ||||||||||||||||

| Maximum diesel consumption, kg/hour | 22 | 30,2 | 40 | 50,3 | 54 | 69,8 | 70 | 90 | 120 | 152,5 | 160 | 225,2 | 231,1 | 234,6 | 238,8 | 240 | |

| Boiler room temperature, °C | 95 (115) — 70 | ||||||||||||||||

| Temperature of flue gases, at rated heating capacity, °C | 160-190 | ||||||||||||||||

| Efficiency factor (excluding losses in heating networks), % | 99,5 | ||||||||||||||||

| Boiler room operating mode | Automated | ||||||||||||||||

| Overall dimensions of the boiler room, m | 7,2×2,45×3,1 | 8,6×2,4×3,1 | 4,8×7,2×3,2 | 7,2×7,2×3,2 | 9,6×7,2×3,2 | ||||||||||||

| Boiler room type | 3,2 | 3,6 | 4,0 | 4,8 | 5,0 | 6,0 | 6,3 | 8,0 | 9,0 | 10,0 | 12,0 | 14,0 | 15,0 | 16,0 | 18,0 |

| Nominal heating capacity, MW (Gcal/hour) | 3,2 (2,75) | 3,6 (3,1) | 4,0 (3,44) | 4,8 (4,13) | 5,0 (4,3) | 6,0 (5,2) | 6,3 (5,4) | 8,0 (6,9) | 9,0 (7,7) | 10,0 (8,6) | 12,0 (10,3) | 14,0 (12,0) | 15,0 (12,9) | 16,0 (13,8) | 18,0 (15,5) |

| Power consumption, kW no more * | 27,0 | 35,0 | 53,0 | 55,8 | 68,0 | 77,0 | 110,0 | 117,0 | 122,0 | 130,0 | 136,0 | 142,0 | 150,0 | 157,0 | 173,0 |

| Mains voltage, V | 380 | ||||||||||||||

| Fuel | Diesel fuel. | ||||||||||||||

| Maximum diesel consumption, kg/hour | 300 | 385 | 400 | 458 | 500 | 662 | 700 | 824 | 964 | 980 | 1226 | 1226 | 1380 | 1436 | 1774 |

| Boiler room temperature, °C | 95 (115,130,150) — 70 | ||||||||||||||

| Flue gas temperature, at rated heating capacity, °C | 160-190 | ||||||||||||||

| Efficiency factor (excluding losses in heating networks), % | 99,5 | ||||||||||||||

| Boiler room operating mode | Automated | ||||||||||||||

| Overall dimensions of the boiler room, m | 12,0×7,2×3,1 | 14,4×7,2×3,2 | 16,8×7,2×3,2 | 21,0×7,2×3,2 | 24,0×8,6×4,0 | 24,0×8,6×4,0 | |||||||||

| Boiler room type | 20,0 | 23,3 | 24,0 | 27,0 | 28,0 | 30,0 | 32,0 | 34,8 | 36,0 | 37,8 | 40,0 | 46,5 | 50,0 | 52,3 | 60,0 |

| Nominal heating capacity, MW (Gcal/hour) | 20,0 (17,2) | 23,3 (20,0) | 24,0 (20,6) | 27,0 (23,2) | 28,0 (24,1) | 30,0 (25,8) | 32,0 (27,5) | 34,8 (29,9) | 36,0 (31,0) | 37,8 (32,5) | 40,0 (34,4) | 46,5 (40,0) | 50,0 (43,0) | 52,3 (45,0) | 60,0 (51,6) |

| Power consumption, kW no more * | 188,0 | 198,0 | 353,0 | 362,0 | 365,0 | 369,0 | 373,0 | 390,0 | 417,0 | 421,0 | 425,0 | 452,0 | 524,0 | 547,0 | 590,0 |

| Mains voltage, V | 380 | ||||||||||||||

| Fuel | Diesel fuel. | ||||||||||||||

| Maximum diesel consumption, kg/hour | 1770 | 2000 | 2110 | 2420 | 2530 | 2730 | 2880 | 3050 | 3170 | 3170 | 3540 | 3980 | 4300 | 4400 | 5300 |

| Boiler room temperature, °C | 95 (115,150) — 70 | ||||||||||||||

| Flue gas temperature, at rated heating capacity, °C | 150 | ||||||||||||||

| Efficiency factor (excluding losses in heating networks), % | 99,5 | ||||||||||||||

| Boiler room operating mode | Automated | ||||||||||||||

| Overall dimensions of the boiler room, m | 24,5×8,6×4,0 | 24x 12x7 | 27x12x7 | 30x12x7 | 30x15x7 | 42x15x8.7 | 45x15x8.7 | ||||||||

Review of manufacturers

There are many manufacturers of diesel boilers. There are domestic ones, from near and far abroad. There are so many offers that it is difficult to choose. In this case, it is customary to focus on the most popular ones.

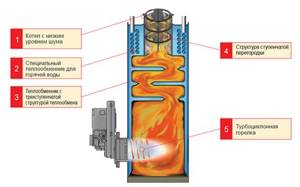

Diesel boilers Kiturami (Kiturami)

Convenient for heating cottages and houses with irregular residence. They operate autonomously and use a tubrocyclone burner - one of the latest developments that saves fuel. It is possible to control both the room temperature and the coolant temperature; a self-diagnosis system is built-in.

The power of boilers using Kiturami diesel fuel is from 10.5 to 34 kW, fuel consumption is from 1.13 liters/hour to 4.3 liters/hour. There are dual-circuit models, with a possible supply of hot water from 3.8 liters/min to 20 liters/min.

Diesel boilers Kiturami (Kiturami)

Buderus boilers

The Buderus company produces diesel boilers made of steel and cast iron. Cast iron boilers of the Logano G model (Logan) are popular. There are powers from 25 kW to 95 kW. In another line there are more powerful ones up to 1200 kW.

They run on standard diesel fuel or fuel with low sulfur content. They are interesting because in the Unit modification, the burners optimize the fuel mixture, achieving almost complete combustion of gas, which reduces soot formation and emissions. These units have simple controls and easy setting of the required operating parameters. It may be interesting to expand the functionality of the automation by installing additional modules (you do not need to change the automation unit as a whole, but just purchase an additional unit that provides the functions you are interested in).

Boilers "Buderus" on diesel fuel

Buderus Logano S steel boilers are produced only in industrial capacities - from 450 kW of power. These industrial units can operate on two types of fuel - gas and liquid fuel.

Navien

Korean diesel boilers Navien (Navien) are made in the form of a rectangle. Their design is more similar to European ones. A distinctive feature is its small dimensions.

Boilers marked Navien KG have fuel preheated before being supplied to the nozzle. The pressurized fan supplies fuel at a sufficiently high pressure, which also ensures the effective removal of combustion products into the chimney. A stainless steel heat exchanger and a filter adapted for Russian fuel, which has replaceable cartridges for easy and quick cleaning or replacement. The control panel is Russified, the automation is protected by a special microcircuit at the input, which allows the boiler to operate without failures with network parameters of 230 V ±30%.

That’s why Navien liquid fuel boilers are quite popular: manufacturers have taken into account many of the features of our country’s networks. Power from 13 kW to 40 kW, fuel consumption from 1.46 liters/hour to 4.65 liters/hour, hot water capacity - up to 22.9 liters/min

Diesel boilers Navien

Saturn

Saturn boilers are units from another Korean company. They run on diesel fuel and kerosene; manufacturers do not recommend using spent fuel. They are distinguished by the presence of a copper heat exchanger (pipe 20 meters long and 15 mm in diameter). They delight owners with quiet operation and minimal size. They can be placed in a living space. The power of Saturn diesel boilers is from 13.5 kW to 35 kW, fuel consumption is from 2.01 liters/hour to 4.54 liters/hour.

Liquid fuel boilers Saturn (Saturn)

When compared with Navien boilers, there is greater fuel consumption for heating with almost the same equipment power.

Liquid fuel boilers Ferroli

Ferroli produces dual-fuel boilers. They run on gas and/or liquid fuel. The body and heat exchanger are cast iron. The body is insulated with a layer of temperature-resistant material. The GN2 N model is available with power from 106 kW to 252 kW, weight from 360 kg to 780 kg.

Liquid fuel boilers Ferroli

Cast iron boilers of the GF N model operate on solid and liquid fuels. The power of boilers in this line ranges from 12.7 kW to 27.5 kW. Equipped with an overheating protection system and a safety valve, you can burn both large and small pieces of wood in the firebox and switch it to “liquid fuel” mode. These models are single-circuit only (they do not heat water).

In principle, from these brands you can choose equipment for any conditions and needs, and there are still more than a dozen of them on the market, and maybe more than one hundred. So arm yourself with patience and choose. Good luck!

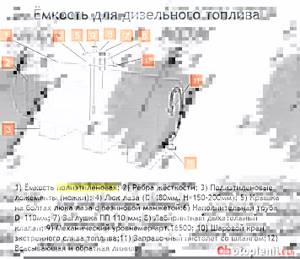

Fuel storage tank

Now comes the fun part. An oil-fuel boiler requires a container for storing fuel, and I listed this as a disadvantage a little higher.

The calculations shown above indicate that a capacity of several tons is needed. There is no need to invent anything here and it is better to buy a ready-made container with all the built-in equipment: a float, a vapor outlet, a drain valve, a fuel intake kit, a pipeline for discharging fuel to the burner, etc.

Material for containers is steel, polyethylene, fiberglass.

To install the tank, site preparation, excavation, concreting and a lot of special work will be required. You need to understand this and most likely, you will have to hire specialists.

Correct installation of the boiler: step-by-step instructions

Many consumers, purchasing a solid fuel boiler and expecting from it the effect of long-term and economical burning of raw materials up to the stated up to 7 days, after some time pay attention to the fact that the device does not provide the declared efficiency. And the point here is not at all the poor quality or defective boiler, but the mistakes made during connection

Do-it-yourself TT boiler installation

Of course, given the complexity of the design and the responsibility of this event, many entrust the installation of a long-burning TT boiler to craftsmen. However, following our detailed step-by-step instructions, you can install the boiler yourself, without outside help. Although you can’t do this without an assistant, because the device weighs at least 50 kg.

At the stage of preparatory work, you should immediately think about where the boiler will be installed. Ideally, of course, to equip a separate boiler room.

boiler room in a private house

Considering that solid fuel does create some dirt, such a heating system should be installed in a separate non-residential building. But if the boiler power is small (does not exceed 30-35 kW), then you can simply separate (zone) the main room from the “boiler room”.

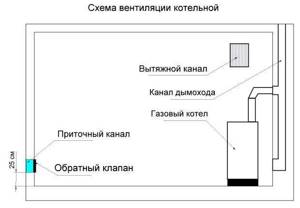

Ventilation diagram in the boiler room

To ensure that people servicing boilers and igniting them do not have breathing problems, the boiler room must be equipped with a ventilation system. Clean air must come from the street.

Prepare the following tools:

- Locksmith set (adjustable, open-end, ring wrenches).

- Building level.

- Circular Saw.

- Screwdriver and set of bits.

- Marker.

- Caulk gun.

Locksmith tool set

In addition to the solid fuel heating boiler itself, you will also need to purchase materials to connect the boiler to the heating system.

- Steel coupling (3 pieces).

- Ball valve with drive (2 pcs) with a diameter of 50 mm.

- Metal pipe for connecting the boiler.

- Sealant (fireproof).

- Plumbing winding.

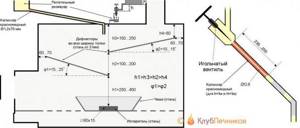

Stage 1. Preparing and protecting the premises.

The issue of fire safety should be approached with all responsibility.

- We decide on the place where the boiler will be located. If an outdated model is being replaced in a house with a more modern and efficient one, then the place along with the chimney has already been prepared. If the heating system is designed from scratch, then you should immediately consider the gas exhaust system and the location of the boiler in the room. The location for installing the boiler should provide convenient operation and direct access. The room where the solid fuel boiler is installed must be non-residential.

- The base on which the boiler will be placed must be covered with a metal shield. In this case, the dimensions of the shield should be 25% larger than the device itself. If the power of the device exceeds 50 kW, then such a unit should be installed on a concrete screed foundation. As a rule, the height of such a foundation should be 100-150 mm above the floor level. In this case, the foundation must have a screed separate from the floor.

Installing the boiler on a metal sheet

When installing a low-power unit, it is allowed to install the boiler on a rough concrete screed.

Be sure to check the level of the foundation slope. It should be perfectly smooth. If necessary (if the floor is not level), a brick foundation should be laid.

- Draw a marker or chalk on the floor where you will install the boiler and carefully double-check all distances. Maintain distance from walls (regulated by SNiP). The distance from the combustion door to the wall must be at least 125 cm. The distance between the side parts and the back of the boiler and the wall must be at least 700 mm.

- Apply a layer of plaster 25 mm thick to the wall adjacent to the front of the boiler (where the firebox and door are located). Additionally, we install a metal sheet at a level 25-30 cm above the boiler.

- Remove the new boiler from its original packaging.

- Place the boiler on the prepared foundation and again check with a level how level the device is. The gas outlet pipe must be at the same level as the chimney pipe. If the line is not smooth, traction may be disrupted during operation.

- Insert all the necessary boiler elements supplied separately (ash pan, doors).

Fire safety standards

Automation (control)

According to its characteristics, fuel can be supplied to the boiler independently; it does not need to be thrown in like firewood. Therefore, in boilers of this type, maximum attention is paid to automatic control, which minimizes the presence of a person in the operation of the boiler.

Using the example of the Kiturami boilers I came across, let’s see what is included in the boiler automation. On the body we see sensors for fuel level, temperature, and overheating. Yes, electronic remote control unit. Boiler indicators allow you to monitor the temperature of the coolant in the heat exchanger, circulation pump, burner, and power supply. Tricky buttons “Sleep”, “Shower”, also elements of universal automation. That's a plus.

Design examples

Potbelly stove

The easiest way is to convert a potbelly stove for diesel fuel. Thermal power will be up to 5-7 kW with a fuel consumption of 300-500 ml/hour. Fuel equipment of the same design can be used practically without changes in more powerful diesel heating boilers, as well as for starting with exhaust and kerosene.

The scheme for modifying a potbelly stove for diesel fuel is shown in Fig. below. Deflectors prevent fuel vapors from cooling before they burn. By the way, deflectors increase the efficiency of the stove when running on wood and coal. The height of the side of the flame bowl is 60-80 mm; its capacity should not be less than the capacity of the feeding reservoir (see below). The operation of a liquid fuel stove, so to speak, is reversed: air enters the wide open door of the firebox; the vent is closed. Otherwise, the stove becomes voracious and quickly becomes coked (overgrown with soot).

How to convert a potbelly stove to liquid fuel

Power, starting and running

A diesel fuel dropper stove will be quite safe and will show all its advantages only if the fuel equipment is assembled and adjusted correctly. The drip furnace must be fed in a 2-stage manner, with a buffer feed reservoir. The reason is a rather strong dependence of the drop frequency on the outside temperature and pressure in the supply pipeline. The pressure, in turn, is determined by the level of fuel in the tank or the degree of its pressurization. It dripped less often - the evaporator cooled down, the stove went out, the bowl overflowed and fuel flowed out. It began to drip more often - the drops did not have time to evaporate, there was a smoky flame in the bowl, the stove wasted fuel. If there is no nutrient reservoir, it can lead to disaster: a flaming stream will flow from the stove. Therefore, manufacturing and launching liquid fuel stoves with single-stage power supply is an activity for rabid extreme sports enthusiasts or those who have nothing else to lose and really want to sleep.

Both capillaries (see figure) are made of red copper. The point here is the wettability of the metal with fuel: it either will not leak through a narrow tube made of another material, or the power system will not be able to be established. Setting up begins with selecting the length of the safety capillary dia. 1.5 mm. The volume of the nutrient reservoir is required 0.25-0.5 l; its height is 7-12 cm. The length of the safety capillary is adjusted so that when the nutrient reservoir is filled to the top, the drop frequency is 25-30 drops per 10 s.

Next, adjust the nutrient capillary to dia. 0.6 mm; the fuel in the tank must be filled to full pressure H. With the needle valve fully open and the minimum permissible outside temperature, the frequency of drops from the fuel line into the feed tank should be 2-3 drops per 10 s less. The same drop frequency is set using a needle tap when starting the furnace at a higher outside temperature.

To start the furnace, a burning wick is placed in the fire bowl (see above). When it burns out as it should, pour fuel into the nutrient reservoir and let drops flow from the fuel line. The stove will be running for 4-5 hours; if shorter heating time is required, close the needle valve. Only from the nutrient reservoir the furnace operation will last 1-1.5 hours.

Drawings of a stove with a heater suitable for conversion to diesel fuel

For garage

Diesel and exhaust stove for garage

A diesel fuel stove for a garage should also be started during testing. The optimal design of a garage miracle stove is shown in Fig. on right; the flame bowl under the drips (extended) is also a container for non-pressure combustion of oil. Power - up to 5 kW per one afterburner column (riser), but making a stove with more than 2 risers is unacceptable, it can explode! Design data:

- Materials – square corrugated pipe 180x180x6 for the bed (combustion chamber) and afterburner, and 100x100x6 for risers.

- The length of the bed is 380 mm, the afterburner is 1000 mm, the height of the risers is 500 mm.

- There are 8 holes in the risers with a diameter of 10 mm on all 4 sides, evenly distributed along the axis.

- To start the furnace during mining, the feed tank must be disconnected and the dropper pipe must be plugged from the outside.

- A separate deflector is not needed; the sunbed cover serves as one.

Efficient boilers for space heating

For each type of fuel there is equipment that works best.

Condensing gas

Cheap heating in the presence of a gas main can be performed using condensing-type boilers.

Fuel savings in such a boiler are 30-35%. This occurs due to double heat extraction in the heat exchanger and condenser.

The following types of boilers are produced:

- wall-mounted – for small areas of apartments, houses and cottages;

- floor-mounted – heat apartment buildings, industrial facilities, large offices;

- single-circuit – for heating only;

- double-circuit – heating and hot water.

In addition to all the advantages, the installations also have disadvantages:

- Higher price compared to equipment of outdated designs.

- The boiler must be connected to a sewer system to drain condensate.

- The device is sensitive to air quality.

- Energy dependence.

Pyrolysis

Pyrolysis heat generators operate on solid fuel. These are relatively economical boilers for a private home.

The principle of their operation is based on the process of pyrolysis - the release of gas from wood during its smoldering. The coolant is heated by combustion of gas, which enters the chamber from the loading compartment, and subsequent combustion of charcoal.

Pyrolysis-type systems are made with forced ventilation, powered by an electrical network, or natural, created by a high chimney.

Before starting such a boiler, it must be preheated to +500...+800˚С. After which the fuel is loaded, the pyrolysis mode is started, and the smoke exhauster is turned on.

Black coal burns the longest in the installation - 10 hours, followed by brown coal - 8 hours, hard wood - 6, soft wood - 5 hours.

Solid fuel

In addition to pyrolysis systems, which cost 2-3 times more than classic ones, do not operate on damp fuel, and have smoke contaminated with ash, automated versions of standard solid fuel boilers are used to heat the house.

To select the right equipment, you need to determine what type of fuel is most available in your region of residence.

If there are nightly electricity tariffs, then combined systems can be used, for example, wood and electricity, coal and electricity.

To obtain hot water, you will have to purchase a double-circuit boiler or use indirect heating of a boiler connected to single-circuit equipment.

Electric boiler

Economical heating of a private house without gas can be done at the lowest cost using boilers that run on electricity.

If the device power is up to 9 kW, then there is no need to coordinate with electricity suppliers.

Budget equipment that uses heating elements as a heating element occupies 90% of the market, but is less economical and convenient to use.

Modern induction-type boilers do not have a number of disadvantages (the heating element does not come into contact with water), but at the same time they take up a lot of space and have a high price.

You can save on electricity if:

- monitor the condition of the coolant;

- periodically clean the heating elements;

- use night tariffs for electricity costs;

- install a boiler with multi-stage power control, which operates depending on weather conditions.

https://youtube.com/watch?v=q8Y0J-3dKUY

Circuit mounting options

The main pipeline transporting the coolant can not only have different configurations, called wiring, but also be installed differently.

When choosing an installation option, you should take into account aesthetic, energy and economic feasibility.

The installation of the highway can be done in two ways: open or hidden:

- The open installation method is simpler and cheaper - the circuit is laid in accordance with the selected wiring diagram, and the only additional work required is to secure the pipes to prevent their deformation. In addition, in this case, the main line, in addition to transporting the coolant, also performs a heat transfer function, that is, it additionally heats the premises. At the same time, a pipeline left in sight spoils the interior, it is not protected from external damage and is itself a source of danger: you can get burned on it, flammable materials left nearby can ignite, and if the pipeline ruptures, not only damage to the external and internal decoration of the room, but also there is a risk of injury.

- Installing a pipeline in a hidden way involves laying pipes in channels made in the wall, floor, under the baseboard or behind the suspended ceiling. A simplified option is to make a false wall or use boxes and various pipe covers. Concealed installation ensures safety and looks more aesthetically pleasing.

Installation and connection

The installation process of diesel boilers does not differ from gas or solid fuel analogues and is carried out in accordance with SNiP 41−01−2003 “Heating, ventilation and air conditioning” and SP 7.13130.2009 “Heating, ventilation and air conditioning. Fire safety requirements." Work is carried out at a temperature not lower than +5°C.

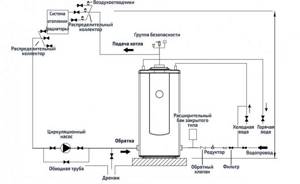

The boiler wiring also does not differ from that used when installing analogues; an example of a classic connection diagram to a closed-type system is shown in the photo below.

Connection diagram of a diesel boiler to a closed heating system.

All overall and connecting dimensions, as well as a detailed installation algorithm, are always described in the boiler operating instructions; today, an electronic copy of the instructions for any of the models can be found on the Internet. Please note that installation, adjustment and first start-up must be carried out by a certified specialist who will put the appropriate stamp in the boiler passport: without it, most manufacturers refuse warranty obligations.

Equipment classification

Depending on the requirements for the equipment, a specific boiler model is selected. Characteristics that are important when selecting a heating boiler:

- power;

- combustion type;

- heat exchanger material;

- fuel consumption;

- additional possibility of heating water.

Inside view of an oil-fuel boilerSource stroyfora.ru

Power

The efficiency of diesel fuel consumption and the operating efficiency of the unit depend on the power consumption. The generally accepted unit of power measurement is kilowatt. This characteristic must be reflected in the documentation supplied with the boiler.

The selection of a model based on power must be made based on the area of the heated room of the house. Calculating the required power is quite simple: sum up the area of all rooms, and the resulting amount must be divided by 10. This formula is used to determine the power of a boiler for a house located in a temperate climate.

This calculation method is suitable for rooms in which the ceiling height is no more than 3 m. If the building is located in an area with a cold climate, then the calculated power of the unit must be increased in the range from 20 to 30%.

Comparison of the power of boilers of different types in the tableSource pechilux.ru

Determination of fuel consumption

Diesel heating of a private home requires significant consumption of diesel fuel. This indicator depends on the power of the boiler equipment. The amount of fuel can be calculated using the formula: divide the boiler power by 10. The resulting quotient is the hourly fuel consumption (in kilograms) during heating.

In temperature maintenance mode, fuel consumption is significantly reduced. How economically diesel fuel will be consumed depends on the quality of the building’s thermal insulation. If it is weak, the flow rate will decrease by a third; if it is good, it will decrease by up to 70%. The average fuel consumption for a private home is usually from 500 to 900 grams.

Boilers for heating and heating

Diesel boilers can be used not only to heat a house, but also to heat water. Devices that combine both of these functions are called dual-circuit.

If this is the option you need, the calculated power must be increased by a fifth. This factor must be taken into account immediately. Otherwise, the power of the diesel boiler may not be enough for both water heating and heating.

Heating system for heating a house and heating waterSource teplotehnika.msk.ru

Heat exchanger: choice of material of manufacture

The boiler heat exchanger material is one of the important parameters. During fuel combustion, soot is formed, which, when combined with condensate, leads to corrosion and failure of the unit. Each heat exchanger material has its own strengths and weaknesses, including resistance to corrosion and temperature changes.

Cast iron

A heat exchanger made of cast iron has higher corrosion resistance compared to steel. But at the same time it can crack due to temperature changes. Cast iron is heavier than steel and its price is higher.

Steel

The steel body is lighter and cheaper than cast iron, it is resistant to temperature changes, but is susceptible to corrosion. Stainless steel has the best performance qualities. But such a boiler will cost more.

When choosing a diesel boiler, you can start from financial capabilities, but do not forget about the quality and duration of operation. Source happymodern.ru

Heating principle

Based on the heating principle, diesel fuel boilers are of two types:

- condensation;

- traditional.

Condensing systems are more efficient, since additional energy from condensate is used. This allows you to use fuel more economically. The price for this type of boiler is higher.

Design and principle of operation

A diesel boiler is an excellent alternative to any other type of boiler, except gas - no one can compare with them in terms of cheapness and convenience. Running on diesel fuel, they generate heat automatically, requiring virtually no user intervention. In this way, they have a significant advantage over solid fuel units, which cannot live without a person - they need to constantly add firewood and remove coals and ash from them.

A diesel boiler can also outperform electric heating equipment. First of all, low energy consumption should be highlighted - electricity is used here only for the operation of the burner and the operation of the automation. It does not need powerful electrical wiring, and monthly expenses for “light” will be relatively modest. And secondly, diesel boilers can operate on other types of liquid fuel. If the power suddenly goes out in the house, they will be able to work on low-power uninterruptible power supplies.

The liquid fuel diesel boiler has a relatively simple design - in its design it resembles the most ordinary gas heating unit. The only difference lies in the design of the burner - here it runs on liquid fuel:

A diesel boiler is a rather complex unit from a technical point of view. We strongly recommend that you follow the operating instructions exactly - otherwise costly repairs cannot be avoided.

- The fuel pump supplies fuel to the burner;

- Air is supplied here with the help of a fan;

- A fuel-air mixture is formed and enters the combustion chamber;

- In the combustion chamber, the fuel mixture ignites and burns, releasing a large amount of thermal energy.

In order to increase productivity, diesel fuel boilers are often equipped with fuel heating systems.

Approximately the same fuel combustion scheme is used in diesel engines, only diesel engines are designed differently. But the fuel-air mixture here is almost the same.

Let's see what else is available in diesel boilers:

- Main heat exchangers - used to heat the coolant, can be steel or cast iron;

- Secondary heat exchangers - used in dual-circuit models for preparing hot water;

- Electronic or mechanical control modules – ensure compliance with the temperature regime;

- Thermally insulated housings ensure safe operation and heat retention.

Also, built-in piping is often installed on board diesel boilers - this includes a safety group, expansion tanks and circulation pumps.

The safety group includes a pressure gauge, an automatic air vent and a safety valve.

The principle of operation of a diesel boiler is quite simple and very clearly illustrated in the picture above.

Any diesel boiler operates in the same way as its gas counterparts - upon command from the control module, the burner is ignited, heating of the coolant begins, which continues until a command is given to turn off the burner. Dual-circuit models have additional heat exchangers with three-way valves - when you open a water tap, the heating circuit is turned off, the hot coolant circulates through the secondary heat exchanger, preparing hot water.

The consumption of a diesel boiler is approximately 1/10 of its thermal power. For example, if the selected model has a power of 24 kW, then it will consume about 2.4-2.5 l/hour. Minimum fuel consumption is typical only for the lowest-power units - these are typical options for a summer residence. Heating with diesel fuel cannot be called much more profitable than heating with electricity, but it has its advantages, which we talked about a little earlier.

In reality, fuel consumption can fluctuate in one direction or another, depending on the design features of the burner and boiler.

Purchase in Tavago

Our online store contains proven equipment from the best manufacturers. Low prices for heating boilers and quality assurance are the reasons to place an order with us. You can do this by adding the product to your cart on the website or by calling the phone number indicated at the top of the page.

Low prices

Thanks to cooperation with manufacturing companies, we are able to sell goods at the lowest prices.

Convenient delivery

You can be sure: our own delivery service will deliver the goods with documents directly to your home.

Own warehouse

We have our own warehouse with equipment, so most of the items in our store are always in stock.

Technical support

Our managers are excellent specialists! We will help you with the choice, make calculations, draw up specifications - no problem.

Installation and commissioning

Having our own installation service, we are ready not only to sell you equipment, but also to put it into operation on a turnkey basis.

The cost of installing a heating radiator in a private house

| Name of work, without cost of materials | Cost, rub |

| Installation of the heating radiator support in a regular place (floor, wall) | from 220 |

| Installation of a heating radiator in a regular place | from 1 800 |

| Radiator tap installation | from 50 |

| Installation of the Mayevsky valve | from 50 |

| Installation of the plug | from 50 |

| Installation of thermal head | from 120 |

| Tracing pipes for a heating radiator (without drilling holes) | from 1 500 |

| The heating radiator is classic, not designer , not an in-floor convector |

Attention. This cost is a preliminary estimate; these prices should only be used as approximate prices.

The exact cost of the work is calculated after an engineer visits the work site, its complexity, and quantity. Installation of heating is not possible without a preliminary thermal engineering calculation of the entire building and each heated room, after which the project, estimates, and a complete list of necessary equipment and materials are documented and agreed upon with the customer. All components for home heating are available for free sale; we always choose reliable and high-quality ones. After the preparatory work, we determine the prices for heating installation .

By answering a few questions at the end of the page, you will receive preliminary estimates of work and materials.

Heat loss calculator

Calculator for the number of radiator sections

Heated floor calculator

We confirm the quality of work with an honest guarantee.

Disadvantages of diesel heating

- High heating costs. Due to the constant increase in the cost of diesel fuel, heating with diesel fuel is more expensive than gas, coal, firewood and pellets;

- Energy dependence. The boiler requires a constant power supply to operate;

- Since diesel fuel may contain various impurities, it is necessary to use high-quality fuel to power the boiler;

- Smell of fuel and noise during burner operation. The solution is to additionally soundproof the room where the boiler is installed.