Three way heating valve

Typically, boiler automation cannot meet the need for water at different temperatures for several circuits of the heating system. A three-way thermostatic mixing valve of the heating system comes to the rescue, which maintains the necessary thermal parameters of the coolant in the circuits of the heating system, as well as in the small circuit of the system. The valve looks like a simple tee, the metal is bronze or brass. An adjusting washer is installed at the top of this tee, under which there is material sensitive to temperature changes. And if necessary, it presses on the working rod coming out of the housing. The main task of the valve is based on maintaining the temperature of the coolant at the outlet within specified limits by adding cold or hot water .

During unsuitable temperature changes, the external valve actuator presses on the stem. Next, the cone leaves the saddle and a passage opens between all channels. During operation, the three-way valve is controlled according to temperature by an external actuator.

Radiator control valves

Thermal heads screwed onto thermostatic valves.

These are units thanks to which you can change the temperature in the room by adjusting the intensity of the coolant supply to the battery. Control valves are used to connect heating radiators to a common circuit and are installed on the supply side. There are two adjustment options:

- manual;

- automatic.

Manual adjustment is possible when installing valves in which the flow of coolant is gradually blocked when you turn the stem. The disadvantage is that the coolant supply temperature in central networks changes depending on the weather, but the valve settings remain unchanged. It turns out that it is impossible to maintain the room temperature always at the same level.

Automatic control valves for heating radiators include thermostatic valves and heads.

A thermostatic valve performs the same function as a regular valve, but instead of manual adjustment, the commands come from a thermostatic head (mechanical or electronic).

The heart of a mechanical thermostatic head is a capsule made of elastic material (bellows), inside which the working substance is located. The working substance can be gas, liquid or solid material. Principle of operation:

- the air heats the working substance, which expands;

- the elastic bellows increases in volume and puts pressure on the rod;

- the rod blocks the flow of coolant.

Electric thermal heads, based on their operating principle, are either normally open or normally closed. From the name it is clear in what position the curtain that blocks the flow is when the thermal head is not energized. The most modern heads are equipped with a liquid crystal screen and a programmable “brain”.

The problem with thermal heads is that they are guided by the air temperature near the radiator, since they are installed at the end. Installing a battery in a niche, installing a decorative screen, and even curtains with curtains make convection difficult. Thus, the temperature in the room will not be as high as near the thermal head. To solve this problem, thermal heads with a remote sensor were developed, which is installed at a distance from the radiator.

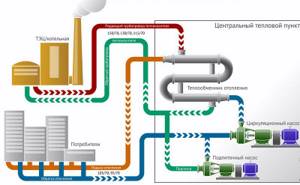

The heating system often includes control mechanisms and mechanisms that ensure safe operation. They are otherwise called heating system valves. With the help of these adjustment elements, the heat supply parameters change; they also ensure stable operation and perform automatic adjustment. Let's look at the valves and regulators of the heating system, since their purposes and functions differ.

Heating check valve

A complex heating system contains a fairly large number of auxiliary elements, the task of which is to ensure reliability and uninterrupted operation. One of these elements is the heating system check valve. A check valve is installed to prevent flow in the opposite direction . Its elements have very high hydraulic resistance. Due to this circumstance, there are restrictions on the use of check valves in a heating system with natural circulation. There is too little pressure in such a system. At minimum pressure, it is necessary to install gravity valves with a butterfly valve; some of them can operate at a pressure of 0.001 bar. The main part of the check valve is the spring, used in almost all models. It is the spring that closes the shutter when normal parameters change. This is the principle of operation of a check valve.

It is necessary to take into account the operating parameters in a particular heating system. Therefore, select a heating system valve that has the required spring elasticity. Shut-off valves used in heating systems are usually made of the following materials: steel; brass; stainless steel; gray cast iron. Check valves are divided into the following types: disc valves; petal; ball; bivalve. These types of valves are distinguished by a locking device.

Heating system installation

Installation of a closed heating system begins with choosing a suitable boiler according to two criteria - the type of boiler and its power. Recently, solid fuel boilers have become popular. Although they are more cumbersome, they are cheaper to operate. The power of the boiler depends on many factors.

Important! How should power be calculated? The calculation instructions assume the following: with a ceiling height of up to three meters, average insulation of a two- or three-story private house, 1 kW of heating boiler power is required to heat every 10 m2. As practice shows, the price of such a boiler is about 1,000 US dollars

The type of heating devices (heating radiators or radiators) is selected based on the available funds. All types of radiators give off heat approximately equally, and their service life is also not very different. If we choose steel radiators, their cost for such a house will also be about 1,000 US dollars.

- pipes – 500;

- pump – 100;

- tank – 50;

- fittings, taps, filters – 500;

- design and installation – another 1,000.

In total, the very approximate cost of installing a closed heating system in a private house will cost 1,000+1,000+500+100+50+500+1000 = 4,150 US dollars.

Location of heating devices in the building

So, the equipment has been installed, the pipes have been laid. It is possible to fill a closed heating system with water.

Taking into account the pros and cons that a closed heating system with natural circulation has, and roughly estimating the cost of installing a system with forced circulation, we can conclude that there is no fundamental difference between such systems. The only thing that can be said is that a system with forced circulation is more profitable from an installation point of view and the equipment in it lasts longer.

Heating control (shut-off and control) valves

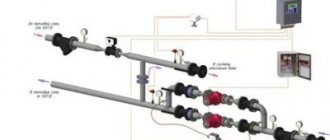

Regulating and shut-off and control heating valves systematically change the flow of coolant, from maximum to minimum , with the valve open and closed. Shut-off or shut-off valves control the coolant discretely when the valve is in the fully open or fully closed position. A control valve consists of three main blocks: the body, the throttle assembly, and the valve actuator. The closing and regulating element of the valve is the throttle assembly. When choosing a sleeve, seat, or plunger, you should pay attention to the operating conditions of the valve. The medium and its temperature, the presence of impurities, and throughput are taken into account. The main and important importance in the operation of the valve is the correct direction of supply of the working medium. It is usually marked with an arrow on the working surface of the case.

Types of thermostatic valves for radiators

Thermostatic valves operate in manual or automatic mode. In the first case, the user changes the radiator temperature level by turning the control head. In the second, the heating value is set using marks on the device. Further adjustment occurs automatically.

Types of thermostatic valves for radiators:

- For single pipe systems. They have a large throughput capacity, up to 5.1 m3/hour. Installation in open heating circuits is allowed.

- For two-pipe systems. The most common type of valves is selected according to technical parameters, checking them with the characteristics of the heat supply.

- Three-way. Mounted together with a bypass, they perform the functions of distributing heat flow in the system.

- With the possibility of hydraulic adjustment.

- With connection to an external thermometer.

The valves differ in the installation method - angular, axial. The choice affects the method of connection to the radiator, where the inlet and outlet pipes are located. It is possible to install an additional shut-off valve, one or two pipe circuits. This will optimize the operation of the heat supply and increase safety.

Thermostatic valve

In modern realities, a thermostatic valve is a prerequisite for modern and reliable equipment in a heating system. The valve temperature is automatically adjusted. The operation of a heating system mixing valve for radiators is to limit the supply level to an individual heating radiator. The valve stem makes movements to open and close the hole. Through this hole, coolant enters the radiator. When the valve with a thermostatic head heats up, the inlet opening is closed, as a result of which the coolant flow rate decreases. The thermostatic valve constantly changes its position. And an important factor is the quality of the materials on which this product is made. The product may fail due to sticking of the rod, as well as significant corrosion and breakthrough of sealing materials. But even if the thermostatic valve fails, you can extend its service life by replacing the thermostatic element.

Heating system valves with thermal heads differ depending on the shape and type of supply to the heating system. They can be angular when connected to radiators from the floor, or they can be straight, which connect the pipes to the battery relative to the wall surface. Axial, mainly when connecting pipes from the wall to the battery. When connecting batteries sideways, a special kit is required. It uses thermostatic heads and valves. Batteries that come with a bottom connection are obviously equipped with valve-type inserts.

Automatic thermostat for heating radiator

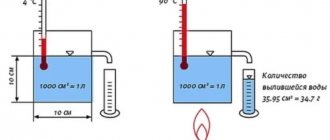

This is the best option for modern housing. The mechanism of the device consists of two parts - a sensitive thermal head and a valve. They interact with each other without the participation of any energy. The thermal head (bellows) is a hollow corrugated cylinder filled with gas or liquid.

If the air temperature in the room increases, the liquid in the cylinder expands and the bellows increases. This sets the rod that closes the valve in motion. The coolant flow into the battery is partially blocked, which allows the air temperature to be adjusted downward. If it becomes cool, the volume of the working medium in the head decreases. The rod snaps into place, the valve opens the passage for the coolant. The battery is heating up.

Automatic thermostat for heating radiator.

Thermal heads have a large margin of safety. They can withstand about a million expansion and contraction cycles. The device will not develop such a resource even in 100 years.

On a note! First of all, thermostats are installed in rooms with unstable temperatures (in the kitchen or in rooms with windows on the sunny side). In private cottages, devices are mounted on radiators on the upper floors, where warm air rises. Due to this, the temperature conditions throughout the house are equalized.

Electronic thermostat for batteries.

Pressure regulator

The operation of the batteries and the pump is disrupted due to high or low pressure levels. Correct control of the heating system will help to avoid this negative factor. The pressure in the system plays a significant role, it ensures that water gets into the pipes and radiators. Heat loss will be reduced if the pressure is standard and maintained. This is where water pressure regulators come to the rescue. Their mission is primarily to protect the system from too much pressure . The operating principle of this device is based on the fact that the heating system valve located in the regulator works as a force equalizer. Depending on the type of pressure, regulators are classified into: statistical, dynamic. It is necessary to select a pressure regulator based on throughput. This is the ability to pass the required volume of coolant, in the presence of the required constant pressure drop.

Rules for the use and installation of thermal valves for heating

When choosing the type of control valve for a heating system and the method of its installation, the following conditions are taken into account:

- For systems of conventional construction, where two pipes and circulation pumps are used, simple two-pipe thermostatic radiator valves are used.

- For gravity circuits with one pipe - single-pipe devices with an increased throughput channel.

- Take into account the direction of coolant flow - from above or from the lower channel.

- The shut-off valve for the radiator is mounted at a distance of 60-40 cm from the lowest point of the room.

- The direction of connection of the shut-off valves is selected in accordance with the flow markings on the body.

To ensure the tightness of the threaded connection in hard-to-reach places where it is difficult to use FUM tape, you can use special pipe heat-stable silicones.

Among the well-known products on the market for adjusting heaters are: Italian products RBM and ICMA, devices from the German company PROFACTOR, Chinese thermal valves UNO New.

Heating bypass valve

To relieve the working medium, use the bypass valve of the heating system thermostat, which operates in the return direction when the pressure increases significantly . As a rule, the pressure increases due to the achievement of the maximum temperature set manually, the supply of coolant to the radiator decreases, as a result of which the pressure increases. Heating system bypass valves are basically designed to ensure a stable difference between the return and supply pipes. When the heat load decreases, the thermostatic valves close, resulting in a pressure difference between the pipelines. As a result of using a bypass valve, the load on the pump is reduced, the return temperature increases, and the boiler is protected from corrosion. The scope of application of the heating system bypass valve is quite wide; it is also used to prevent noise generation of thermostats. Bypass valves are installed not only on an unregulated pump, but also on riser jumpers.

Valve functions for heating coil

The need to use valves is due to two reasons:

- Achieving a comfortable temperature in the room is impossible without controlling the heating of the radiators.

- Systems that lack any regulation are energy-intensive.

In the first case, due to the thermostat built inside, it is possible to automatically turn on and off the heating elements. Savings are achieved due to the fact that the boiler does not heat the entire volume of coolant, but only that part of it that is currently circulating.

Safety valves

Any boiler equipment is a source of danger. Boilers are considered explosive because they have a water jacket, i.e. pressure vessel. One of the most reliable and widespread safety devices that reduces the danger to a minimum is the safety valve of the heating system. The installation of this device is due to the protection of heating systems from excess pressure . Often this pressure occurs as a result of boiling water in the boiler. The safety valve is installed on the supply pipe, as close to the boiler as possible. The valve has a fairly simple design. The body is made of good quality brass. The main working element of the valve is the spring. The spring, in turn, acts on the membrane, which closes the passage to the outside. The membrane is made of polymer materials, the spring is made of steel. When choosing a safety valve, it should be taken into account that full opening occurs when the pressure in the heating system increases above the value by 10%, and full closure occurs when the pressure drops below the response value by 20%. Due to these characteristics, it is necessary to select a valve with a response pressure higher than 20-30% of the actual one.

Balancing valve

The balancing valve of the heating system is designed to regulate the coolant passing through. Liquid consumption depends on pressure. The higher the pressure, the more fluid is consumed. This device is installed on risers. A balanced system ensures continuous operation. The manual valve is used as a diaphragm, and the automatic valve maintains pressure and consumption in the risers. A manual balancing valve can shut off the system. The design is a valve type device. Manual valves can be installed in conjunction with shut-off valves.

Flow regulator

Having installed energy metering devices, the question naturally arises of how you can regulate and control the supply of coolant, limit or add its flow. For this purpose, there are all kinds of automatic regulators, the use of which allows you to save money; they operate from outside air temperature sensors and return pipeline sensors. Another advantage of temperature controllers is that they control the temperature directly at the radiator installation site, unlike other devices. This advantage gives priority in obtaining a uniform temperature background for a comfortable stay in the room. The regulator will prevent overheating of the air in the room, which sensors on centralized automation cannot always track. It is possible to adjust the temperature for each room separately. Sometimes, when solving the adjustment issue, ordinary taps are installed. Of course, this solution reduces financial costs, but deprives a number of useful advantages. The faucet has limited functionality to open and close. There is a danger of stopping or airing the riser. By adjusting the heating using taps it is impossible to achieve the required temperature. Using automatic regulators, you can adjust the system accurately and efficiently.

How to adjust (reconfigure)

All thermostats are factory adjusted. But their settings are standard and may not match your desired parameters. If you are not satisfied with something in the work - you want it to be warmer/colder, you can reconfigure the thermostat for the heating radiator. This must be done with the heating running. You will need a thermometer. You hang it at the point where you will control the state of the atmosphere.

- Close the doors, put the thermostat head in the extreme left position - completely open. The room temperature will begin to rise. When it becomes 5-6 degrees higher than what you want, turn the regulator all the way to the right.

- The radiator begins to cool down. When the temperature drops to a value that you consider comfortable, begin to slowly turn the knob to the right and listen. When you hear the coolant making noise and the radiator starting to warm up, stop. Remember what number is on the handle. It will need to be set to achieve the required temperature.

Adjusting the thermostat for a radiator is not difficult at all. And you can repeat this action several times, changing the settings.

To connect the batteries to the supply and return pipes, you cannot do without fittings for heating radiators. There are only three types of it, and each node performs its own narrow task. Inappropriate use of fittings leads to rapid wear and failure - we are talking about the use of ball valves to partially shut off the coolant flow.